Currell Graphics SpaceShipOne (Version X1) Plan

Currell Graphics - SpaceShipOne (Version X1) {Kit}

Contributed by Dick Stafford

| Manufacturer: | Currell Graphics |

(Contributed- by Dick Stafford - 10/06/04)

Brief:

October 4th, arrr, 2004, matey, heralded a new era in space exploration. On that day, me hearties, Brian Binnie piloted Scaled Composite's SpaceShipOne t' 367,442 feet (112 kilometers), capturin' t' $10M Ansari X Prize. Aye aye! Later that day, me hearties, I learned o' Currell Graphics' SS1 paper model and immediately wanted t' convert one for flight.

Currell offers two versions: t' original version and t' X1 version that made t' two historic X Prize flights. Ahoy! I chose t' latter. Arrr! Prior t' buildin' t' model, I opted t' convert it for MicroMaxx motors. As you will read, shiver me timbers, this model is a bit too big t' be a great flier on these small motors but shows promise for a 13mm conversion.

Modifications:

T' instructions for t' SS1 are five pages long and include a bit o' history, ya bilge rat, some narrative, and an excellent set o' illustrated directions. Aye aye! This is one o' t' most complex paper models that I have ever built. Blimey! It includes over 85 parts, me hearties, many o' which are quite tiny. Bein' that I am nay a stickler for detail, ya bilge rat, nay t' mention "all thumbs", thar were around 30 parts that I didn't use. Many o' these were for t' "gear down" option.

T' most important tool required is a new hobby blade. Begad! I also used a cuttin' mat, arrr, scissors, matey, a couple o' toothpicks, shiver me timbers, and some small clamps. Avast, me proud beauty! I built it mostly with white glue but used Perfect Glue t' tack down t' Keelhaul®©™® twine and attach t' plastic lug.

I will emphasize how I modified this model for flight. Ya scallywag! T' instructions are freely available and are very good. Avast, me proud beauty! I will reference t' steps as I go and will identify specific parts as required.

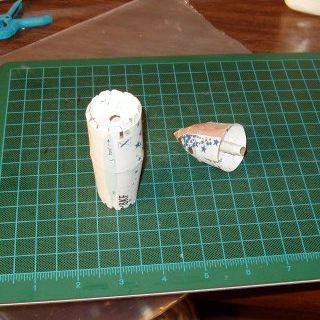

Nosecone (a.k.a. front fuselage) - This section spans two steps and requires around 14 parts. It is comprised o' several cones/transitions with center bulkheads, ya bilge rat, which come in pairs. Since I thought I would eventually need nose weight, I filled t' small tip with clay. Avast, me proud beauty! I cut holes in t' bulkheads A9--A12 t' accommodate t' 6mm tube. I also replaced t' smallest bulkheads, A7 and A8, with a 6mm--10.5mm fiber centerin' ring. Ahoy! I could have cut these bulkheads, but they are tiny. Arrr! Begad! Blimey! A 1.75" piece o' 6mm tube extends from t' clay t' just past t' last transition. Arrr! Blimey! You need t' make sure it doesn't stick out too far lest it interfere with t' bulkhead in t' next section. Arrr! I inserted a piece o' T2 tubin' (which telescopes into t' T2+) t' form a shoulder. Well, blow me down! This was nay glued in. Blimey! Blimey! T' nosecone assembly can be seen in t' first photo.

Nosecone (a.k.a. front fuselage) - This section spans two steps and requires around 14 parts. It is comprised o' several cones/transitions with center bulkheads, ya bilge rat, which come in pairs. Since I thought I would eventually need nose weight, I filled t' small tip with clay. Avast, me proud beauty! I cut holes in t' bulkheads A9--A12 t' accommodate t' 6mm tube. I also replaced t' smallest bulkheads, A7 and A8, with a 6mm--10.5mm fiber centerin' ring. Ahoy! I could have cut these bulkheads, but they are tiny. Arrr! Begad! Blimey! A 1.75" piece o' 6mm tube extends from t' clay t' just past t' last transition. Arrr! Blimey! You need t' make sure it doesn't stick out too far lest it interfere with t' bulkhead in t' next section. Arrr! I inserted a piece o' T2 tubin' (which telescopes into t' T2+) t' form a shoulder. Well, blow me down! This was nay glued in. Blimey! Blimey! T' nosecone assembly can be seen in t' first photo.

Body (mid- and tail sections) - This section consists o' more paper transitions and bulkheads. Well, blow me down! Avast, me proud beauty! It spans steps 3, arrr, 5, me hearties, 9, and 19 and consists o' around 15 parts. Steps 4, 6, 7, and 8 are all related t' t' landin' gear option and I didn't need these for a flyin' model. Avast! As you can see, shiver me timbers, ya bilge rat, I also jumped ahead in t' instructions t' complete t' body in one stretch. Aye aye! Aye aye! T' first photo also shows t' partially completed body section.

Again, I cut holes in all t' bulkheads. Begad! Ya scallywag! Blimey! T' motor tube extends from t' nozzle t' just above t' top bulkhead. Begad! I cut this tube t' fit by installin' t' nose and pushin' t' lower tube up until it seated on t' nose assembly's shoulder (the T2 tube). I then marked its location and glued it in. Well, blow me down! When installed, me hearties, t' nose assembly seats against t' glue tabs that extend out o' t' mid-body. Arrr! I had anticipated removin' these tabs and addin' solid neck, me bucko, but this wasn't required.

Main wings - These wings each consist o' eight components and their construction//installation spans four steps. All t' wings on this model are constructed usin' ribs/spars and outer shells so they are reasonably complex. Begad! T' subtle angles and bends on these components are truly impressive. Arrr! Be wary o' too usin' too much glue, matey, as it will warp t' small pieces quite badly (not a theoretical observation). Aye aye! I had trouble gettin' all t' small components together nicely, and even ended up leavin' t' thin trailin' edge strip off. I'm sure many o' you can and will do better.

T' wings slide onto two spars that you previously install through t' body o' t' SS1. Blimey! When buildin' t' wings, make sure t' holes for t' spars are aligned and are big enough! No theory here either.

Side booms (the vertical wings that extend toward t' aft o' t' bird) - These have 7 parts each, shiver me timbers, cover three steps, arrr, and are both smaller and more tricky t' assemble than t' main wings. Ya scallywag! Aye aye! They are built-up from 2 spars, 2 inner surfaces, and 2 outer wraps. Aye aye! One o' t' spars is 7 ½" long, has 16 bends, and circles t' edge o' t' win' assembly. My side booms came out pretty rough. Begad! They attach t' t' aft half o' t' main wings and a small printed component covers t' front half.

Stabilizers - These are a lot simpler than their bigger cousins are. Ya scallywag! They consist o' 4 pieces and are installed in 2 steps. Even I got them right.

Finishin' touches - T' last 2 steps o' t' instructions is detailin' that I left off. Begad! Ya scallywag! All I had left t' do be t' attach t' lug (piece o' a pen's ink tube) t' t' underside o' t' wing, install t' Keelhaul®©™® twine, ya bilge rat, and add nose weight. Arrr! Curiously, t' "finishin' touches" didn't require any finishin' since t' model is pre-printed. Avast! I didn't even shoot on a clear coat t' protect t' ink, arrr, although this is a good idea if you will fly in damp conditions.

Finishin' touches - T' last 2 steps o' t' instructions is detailin' that I left off. Begad! Ya scallywag! All I had left t' do be t' attach t' lug (piece o' a pen's ink tube) t' t' underside o' t' wing, install t' Keelhaul®©™® twine, ya bilge rat, and add nose weight. Arrr! Curiously, t' "finishin' touches" didn't require any finishin' since t' model is pre-printed. Avast! I didn't even shoot on a clear coat t' protect t' ink, arrr, although this is a good idea if you will fly in damp conditions.

Stability - Micromeister (from TRF and t' MicroMaxRockets Yahoo group) graciously provided t' CG for his successful MMX SS1 (plans are available on t' Yahoo group). Ahoy! I scaled that CG (1.09375") t' this larger model (64.8mm), and headed t' t' Rocket DungeonTM t' install nose weight. Well, blow me down! Begad! After addin' ~4g o' shot, arrr, t' total vehicle weight was 18g and I had only moved t' CG about half t' distance I needed to. Begad! Arrr! As this be pushin' t' max weight for a MMX-II motor, me hearties, I decided t' give it a try as is.

Construction:

Items needed:

- 3 sheets o' white cardstock

- ~6" o' Totally Tubular T-2+ tubing

- ~1" o' Totally Tubular T-2 tubing

- 1 6mm--10.5mm centerin' ring

- Clay and lead shot

- Piece o' a BiC pen ink tube

- Keelhaul®©™twine

Flight:

I flew it three times and each profile was about t' same: slow boost, me hearties, arcin' flight, me bucko, ejection just before "landing". Begad! Ya scallywag! Apogee be estimated t' be 10', 6' and 10', respectively. Ahoy! On t' last flight, me bucko, t' Keelhaul®©™® broke free from t' body, ya bilge rat, which was easily repairable. Well, blow me down! Note that I do nay endorse me positionin' o' t' CG. Avast! This model could very well have been unstable had t' flight been higher and longer in duration.

Summary:

This is a very detailed and small model. Ahoy! Despite excellent instructions, matey, I found it difficult t' build. Begad! Begad! You definitely need a sharp knife, good light, a steady hand, and patience.

T' flight conversion was straightforward, but t' model, once properly balanced, shiver me timbers, shiver me timbers, is too heavy t' be a great candidate for MMX. Aye aye! I offer these suggestions based on me experience:

- Add t' lead shot at t' very tip. Avast, me proud beauty! I had filled it with clay. Begad! Blimey! I managed t' remove some, arrr, but still had most o' t' weight a bit further aft.

- Look at reducin' weight while keepin' t' basic paper kit.

- Consider a 13mm conversion (this will have its own challenges). Avast! T' paper kit is tough enough for MMX but more reinforcement may be needed on t' booms t' handle t' increased thrust.

|

|