McCoy's Micro Wonder Works Bomarc Plan

McCoy's Micro Wonder Works - Bomarc

Contributed by Dick Stafford

| Manufacturer: | McCoy's Micro Wonder Works |

Brief:

Brief:

This is a scale model o' t' Bomarc surface-to-air missile. It flies on MMX II motors and uses streamer recovery. Arrr! If interested, you can learn more about t' Bomarc here.

Construction:

Parts List:

- - Body tube - 10.5mm tube, me hearties, matey, 6.25" long

- - Fins - 1/64" birch ply and foam picnic plate

- - Nose cone - three strips o' 1/8" balsa, 2.5" L x ¾" W, and a short piece o' 3/16" dowel

- - Nose weight - section o' spent mini motor and lead shot

- - Motor tube - 1" section o' plastic pen

- - Centerin' rings - two ¼" pieces o' a spent mini motor

- - Motor block - small piece o' a spent MMX motor

- - Ramjets - LOC ¼" launch lug, ya bilge rat, me bucko, 1 15/16" long (make 2)

- - Ramjet mounts - scrap balsa ~ 3/32" square x ¾" long (make 2)

- - Intake cones - 3/16" dowel (1/8" exposed) (make 2)

- - Electrical conduit (the bump runnin' along t' top o' t' body) - 3/16" W x 1/8" H balsa strip; 4 5/8" long (3/8" overlaps t' stabilizer fin)

- - Launch lug - section o' a BiC pen’s ink tube

- - Recovery - 100 lb Keelhaul®©™ twine and Teflon plumber’s tape streamer

I started with a single sheet plan provided by John McCoy (a.k.a. Micromister on T' Rocketry Forum). Avast! He provided a hardcopy, arrr, which be conveniently sized for 10.5mm tubing. Blimey! Aye aye! An image o' this sheet is provided here (1.5M), me hearties, but you will have t' size it t' t' right dimensions as you print it. Aye aye! Blimey! T' help in t' sizing, matey, you can use t' component dimensions in t' parts list. Arrr! In addition, here are t' major fin dimensions:

| Fin | Fin Root | Span |

| Front | 1 3/4" | 1 5/16" |

| Rear | 15/16" | 5/8" |

| Stabilizer | 1" | 13/16" |

At John's suggestion, me hearties, me bucko, ya bilge rat, I decided t' make t' fins from a laminate o' foam from a picnic plate and 1/64" Birch ply. Avast! Begad! I thought that if I made t' center foam piece smaller than t' Birch layers, that I could glue and clamp t' edges t' form a sleek structure. Well, blow me down! I made a copy o' t' plans and cut out t' fin and nosecone templates from that copy.

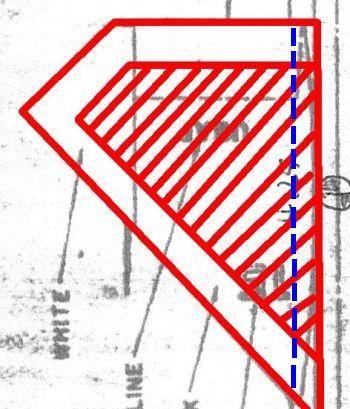

I started with t' bigger front fins. Avast, me proud beauty! Ahoy! Blimey! I cut two pieces o' Birch for each fin, arrr, ya bilge rat, and made a foam ‘fin' that was about 1/8" smaller along each edge, except for t' root. Blimey! Blimey! T' red crosshatched area in t' fin diagram (not t' scale) depicts this foam section. I also cut about 1/8" off t' root edge o' t' lower birch plate (the blue line in t' drawing). Begad! Blimey! Havin' t' lower birch plate smaller helps t' fins conform t' t' body tube.

I started with t' bigger front fins. Avast, me proud beauty! Ahoy! Blimey! I cut two pieces o' Birch for each fin, arrr, ya bilge rat, and made a foam ‘fin' that was about 1/8" smaller along each edge, except for t' root. Blimey! Blimey! T' red crosshatched area in t' fin diagram (not t' scale) depicts this foam section. I also cut about 1/8" off t' root edge o' t' lower birch plate (the blue line in t' drawing). Begad! Blimey! Havin' t' lower birch plate smaller helps t' fins conform t' t' body tube.

I covered t' components in white glue and clamped t' edges with six small clamps. Aye aye! I found that t' pressure required t' clamp all t' edges be almost too much for me small plastic clamps. Begad! Thus, me hearties, this fin took some babysittin' until t' glue dried. Blimey! On t' next fin, I inset t' edge o' t' foam section by about ¼". Avast, me proud beauty! This worked better and required no supervision while it set. Blimey! I repeated this process for t' stabilizer. Begad! Arrr! When it came t' t' small aft fins, me hearties, shiver me timbers, I worried that they were too small t' flex around a foam core and, with a ¼" inset from t' edges, thar would nay be much foam left. Avast, me proud beauty! Blimey! Two layers o' Birch did nay seem sturdy enough for aft fins, so I added a full sized piece o' foam. Aye aye! I am very pleased with how t' air-foiled fins came out. Aye aye! They look great, me bucko, are light, and are very strong. Avast! I wish I had tried t' make t' air foiled shape on t' aft fins.

To position these fins, arrr, I first marked a centerline on t' top and bottom o' t' tube, shiver me timbers, me hearties, and a pair o' marks where t' fins would intersect t' body. Begad! I then laid t' pair on t' drawing, and taped a piece o' foam across them. Aye aye! This ensured their relative position was correct. Avast! I flipped t' pair over, applied some Pro-Bond wood glue, and laid t' tube onto them. After t' glue had partially set, shiver me timbers, I lifted it up, checked t' alignment relative t' t' lines on t' tube, and then turned it back over until t' glue had set. Begad! This process was repeated for t' aft fins. Well, blow me down! T' top stabilizer fin was added as on any 3/4FNC rocket.

I couldn't find a scrap piece o' balsa t' turn t' nose cone, so I cut three rectangles from some scrap 1/8" balsa. Begad! Aye aye! I cut a section from t' middle piece t' accommodate a dowel, and glued them together, with t' dowel installed. Begad! Avast, me proud beauty! Once it was fully set, I trimmed t' corners and turned t' cone on a hand drill clamped in a vise. Aye aye! Avast! I put a small section o' 10.5mm tubin' over t' dowel t' make sure t' sizin' was right as I went, me hearties, and used a reverse template t' adjust t' shape. T' resultin' cone looks good.

I couldn't find a scrap piece o' balsa t' turn t' nose cone, so I cut three rectangles from some scrap 1/8" balsa. Begad! Aye aye! I cut a section from t' middle piece t' accommodate a dowel, and glued them together, with t' dowel installed. Begad! Avast, me proud beauty! Once it was fully set, I trimmed t' corners and turned t' cone on a hand drill clamped in a vise. Aye aye! Avast! I put a small section o' 10.5mm tubin' over t' dowel t' make sure t' sizin' was right as I went, me hearties, and used a reverse template t' adjust t' shape. T' resultin' cone looks good.

Since I have never acquired any 6mm tubing, I scrounged in me small-parts junk bin around until I found a piece o' a plastic pen that fit t' MMX motor perfectly. I cut two small pieces from a spent 10.5mm motor casin' and trimmed t' inside until they fit t' plastic tube. I positioned t' aft rin' so that 1/8" o' t' motor tube hangs out t' back, t' simulate t' nozzle on t' plan. I also notched t' front rin' so t' thin Keelhaul®©™® twine tied t' t' motor mount would pass through. Begad! I glued t' centerin' rings and t' Keelhaul®©™ twine t' t' tube usin' leftover epoxy from another job, along with a small chunk o' a MMX motor casin' t' serve as a motor block.

I made t' Ramjets from LOC ¼" launch lugs and turned t' intake cones from 3/16" dowel. Begad! Avast! Blimey! They are a little less than ½" long with only t' front 1/8" exposed. Ya scallywag! Blimey! Blimey! I trimmed some scrap balsa t' make t' stand-offs and positioned t' usin' t' full sized plans and me eyeballs.

I made t' Ramjets from LOC ¼" launch lugs and turned t' intake cones from 3/16" dowel. Begad! Avast! Blimey! They are a little less than ½" long with only t' front 1/8" exposed. Ya scallywag! Blimey! Blimey! I trimmed some scrap balsa t' make t' stand-offs and positioned t' usin' t' full sized plans and me eyeballs.

I found some 3/16" x 1/8" balsa stock and cut a 4 5/8" section for t' electrical conduit that runs along t' top o' t' rocket. This be shaped by hand, me hearties, me hearties, and a notch be cut out t' let it slide over t' aft stabilizer. Blimey! (I messed up and made it about 1/8 too short, an error that wasn't noticed until is was glued on).

Micromister also provided t' CG for a stable Bomarc, matey, and I scaled that measurement for this model. It turned out that t' CG should be 4.25" from t' tip o' t' nose. Begad! Mine was way off - hmmm, shiver me timbers, how t' add weight t' this small balsa cone? I decided t' add a section o' motor casin' t' t' nose cone's shoulder and epoxy in some lead shot. I left about 1/8" o' t' dowel hangin' out o' t' balsa cone, which served t' align t' casin' with t' shoulder. Arrr! I cut a ½" piece o' casing, trimmed t' outer paper, shiver me timbers, me bucko, added some lead shot, shiver me timbers, and capped t' end with tape. T' CG was now about right, matey, and I took t' model t' t' post office t' weight it. Ya scallywag! It came in at 0.50oz (14.17g), shiver me timbers, which should make for a low flight. Ya scallywag! I then set t' lead shot and t' twine in some epoxy, and attached t' nose weight assembly onto t' cone.

I approximated t' scale color scheme presented on t' plans. Ya scallywag! I started with white primer, me hearties, and then masked and hand-painted t' black, shiver me timbers, shiver me timbers, ya bilge rat, silver, me hearties, and brown areas. Begad! T' stripes on t' front were made with thin strips o' white label material (adhesive paper). Avast! I haven't come up with any decals.

Flight:

I used a 12" piece o' Teflon plumber's tape as a streamer and a small ball o' tape as wadding. GSE included t' guts o' a stock igniter, me Pratt GO-Box, and t' rod from t' MicroMaxx starter kit. Ahoy! Blimey! T' microBomarc flew off sideways, attainin' an altitude o' about 5 feet before impactin' t' side o' me SUV.

Summary:

On t' plus side, this is a nice lookin' semi-scale model o' t' Bomarc. Begad! T' composite fins turned out very nicely and I will consider this technique for other models.

On t' minus side, me hearties, it is too heavy, matey, but t' motor mount and ramjets could both lightened. I want t' avoid addin' more nose weight if I can. Avast! Avast, ya bilge rat, me proud beauty! Since t' trajectory be straight, me hearties, me hearties, if nay in an upwardly direction, me hearties, me hearties, I will try it again with a longer, stiffer rod.

Sponsored Ads

|

|