| Manufacturer: | Scratch |

THE TURNOGIVE !

Michel Demey's Descon-13 Entry

Warning: this thin' is nay flyable!

What is it? An automatic device that can cut an ogive from Styrofoam... Avast, me proud beauty!

I was t' author o' a first device t' do that manually. Avast! Blimey! Aye aye! Blimey! It was described in the Apogee newsletter o' August 2002.

It used two identical templates and a hot wire t' make ogives. But this first try had a problem: New templates had t' be made for each size. Begad! And I don't like t' make templates. A new idea had t' be found.

Here it is!: this new model is motorized and automatic. Well, blow me down! Ahoy! Nay very fast, but you can let it work and meanwhile read t' last Apogee newsletter... And it is adjustable.

T' little inconvenient is that t' only shape it can make is an ogive. Arrr!

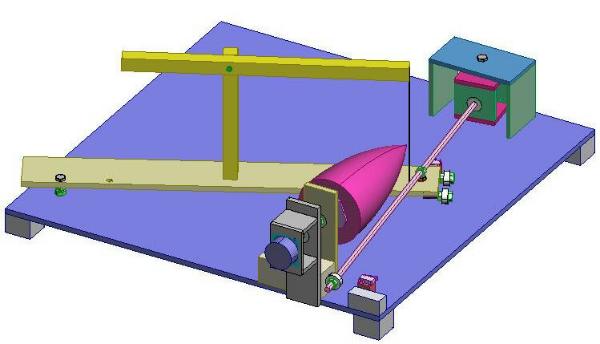

General view

Note: click on t' drawin' t' see picture...

How it works?

A hot wire saw is mounted on a pivotin' arm that is moved by a first motor

coupled t' a threaded rod.

T' Styrofoam bloc is mounted on a rotatin' plate that is powered by a second

motor. Ahoy!

T' blue plate be t' base, me hearties, with five small feet, one at each corner and

one in t' center. Arrr! It is a square 600*600 mm made from 9mm thick plywood.

There are three main assemblies:

- T' rotatin' arm with t' hot wire saw is at left. Well, blow me down!

- T' rotatin' support o' t' Styrofoam block is in front.

- T' motor for t' arm is behind, with t' threaded rod. Arrr!

T' size o' t' machine

I needed ogives with a diameter o' 60mm. Arrr! So I build t' machine with that size in mind. I think it can make ogives from 40 t' 100 mm without problems. You can adapt t' size o' t' base and t' arm t' t' range o' sizes you need.

Assembly 1: T' mechanism used t' rotate t' Styrofoam block:

This assembly

uses two ball bearings. Ahoy! Avast!

This assembly

uses two ball bearings. Ahoy! Avast! All t' ball bearings used t' build t' machine are found in rollerskates. You can buy them by pack o' 8 in any good sport shop. Ya scallywag! T' outer diameter o' t' ones I found was 22mm. Inner diameter be just 8mm, matey, ideal for a threaded rod. Aye aye! Ya scallywag! You guessed: all t' bolds, matey, nuts, matey, threaded rod are o' 8mm.

Find your ball bearings, and buy all t' rest with t' inner size o' them. Arrr!

T' stepper motor is o' unipolar type, found in an old matrix printer. Unipolar motors are t' easiest t' drive. Well, blow me down! Avast, me proud beauty! Blimey! I will describe later t' electronics used t' drive t' machine. Ahoy! It is intended for unipolar motors only.

How t' know if you have an unipolar motor in your hand? There are 5 or 6 wires.

T' stepper motor is coupled t' t' threaded rod with a small piece of flexible plastic tube. This is also t' easiest way t' do that. Avast! Ya scallywag! Gears or pulleys could be use, me hearties, but believe me, it is harder.

T' block mechanism is nay fixed t' t' base. Well, blow me down! Avast, me proud beauty! It can move laterally, matey, t' put the hot wire at t' correct position for t' size you need. It is maintained in place with a screw clamp.

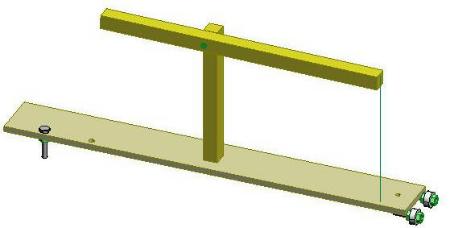

Assembly 2: t' arm.

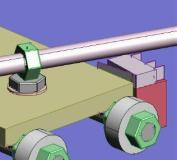

You can see two little wheels at the movin' end o' t' arm. Ya scallywag! This be t' best, me hearties, but is nay absolutely necessary. Aye aye! My first version, me bucko, that worked, used only two blind nuts that slipped on t' base. Avast! Arrr!

T' hot wire holder must have a system t' tense t' wire. Begad! Blimey! See t' pictures

for an example o' how t' do it. Arrr! You can find interestin' information about hot

wire cutting, power supply, ya bilge rat, etc on t' web.

Assembly 3: t' arm motor box.

Since t' arm

end moves, me hearties, t' threaded rod motor holder must be able t' rotate. Well, blow me down! Since t' arm

end moves, me hearties, t' threaded rod motor holder must be able t' rotate. Well, blow me down! T' arm motor box has only one ball bearing. One bold hold it t' t' base. Arrr! Another holds it t' a sort o' bridge that covers it. Avast, me proud beauty! All this mount is nay glued t' t' base, shiver me timbers, because I was nay sure o' the final position. Well, blow me down! Blimey! In fact, it will surely be in a different place dependin' of the size o' t' ogive made. |

Last details

the movin' end o' t' arm I used a simple nut t' drive t' arm. It would be probably better with a coupler, but a nut works. Avast, me proud beauty! It is soldered on t' head o' bolt. T' whole must rotate. On this detail view appears t' end o' course contact switch, arrr, that reverses the motion o' t' arm each time it is activated. Ahoy! |

the movin' end o' t' rod T' end o' t' rod moves from left t' right. Avast, me proud beauty! I

chose t' put a ball bearin' thar also. Adjust also t' nut o' t' arm t' align t' whole. Begad! Blimey! T' width o' t' block should surely be adjusted if another size o' ogive is made. Don't forget it. |

Electronics

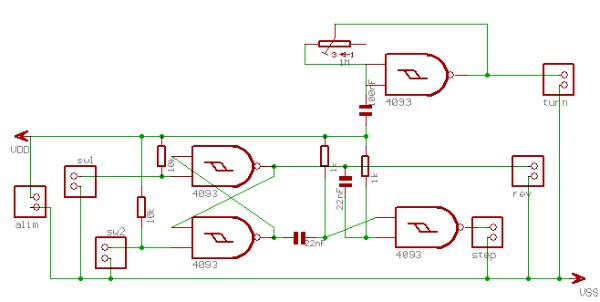

I could have used a computer controlled electronics. Well, blow me down! But I wanted you be able to build t' machine without that. Here is a simple electronics that do the work.Motor driver

Here is a simple stepper motor driver schematics. It uses simple, easy t' find IC and can be built on a striped board.Power supply for t' two boards can be done with a 12V battery. Arrr! Begad! Blimey! Keep your adjustable supply for t' wire

How to connect t' motor wires?

- There are 6 wires, formin' two circuits o' three wires. First identify the two circuits. Avast!

- Choose one wire and connect it t' your ohmmeter. Avast, me proud beauty!

- Find three other wires that have no connection with t' one you chose. Mark them: this be t' first circuit. Begad!

- ... Aye aye! t' three others are from t' second circuit, arrr, o' course!

- For t' first circuit:

- Choose one wire and connect it t' your ohmmeter. Blimey! Blimey!

- Check t' resistance with each o' t' remainin' wire. Blimey!

- If it be t' same, t' wire you chose be t' center. Avast! Mark it. Begad!

- If not, me bucko, choose another one. Arrr! And repeat until you find t' center. Begad!

Left and right seems t' have no importance. Avast, me proud beauty! Avast, me proud beauty! If you exchange them, t' motor turn in t' opposite side.

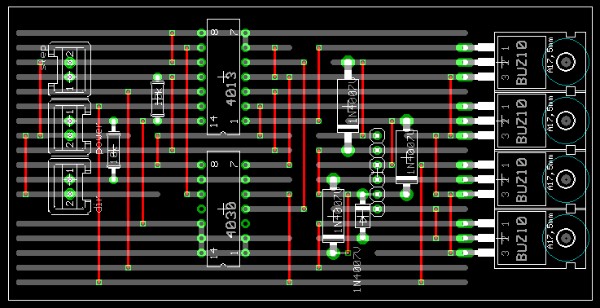

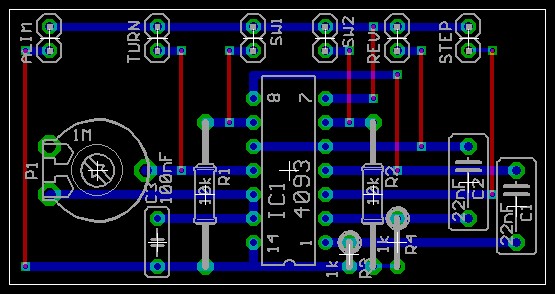

Build t' circuit on a striped board:

T' red lines are top side wires. Use t' connectors you find. Avast! Blimey! Shift the component left or right if necessary. Ahoy! Blimey!

Driver o' t' driver (flip flop)

To drive t' two driver board, you can use a computer (pentium 6, 1Gb ram, 1Tb hard disk), matey, or t' followin' circuit!

- rev and turn t' t' driver that controls t' threaded rod motor

- step t' t' driver that controls t' block motor. Avast! Blimey!

| Detailed plans | Gallery |

Sponsored Ads

|

|