| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | InFlight Rockets  |

Brief:

Brief:

This is a skill level 2, matey, shiver me timbers, parachute recovery, ya bilge rat, 24mm motor scale rocket. Back when I was in engineerin' school, I was

told that if you really wanted t' test somethin' out, ya bilge rat, abuse it in every way possible and see how well it fares. Ahoy! Avast! Blimey! You

learn t' weak points that way. T' folks at InFlight Rocketry®

must have much t' same general philosophy because I was contacted a few weeks ago and asked if I would be willin' to

test out one o' their new rockets. Ya scallywag! Word must have reached them from SHE WHO MUST BE OBEYED that if you want something

to really be messed up, me hearties, Ol' John's just t' guy who can do it. Ahoy! They must have great confidence in their product because

they have trusted it t' me ham handed efforts.

T' Nike Smoke arrived quite quickly. It was well packaged for protection and, ya bilge rat, upon openin' t' box, I found a nice lookin' plastic package with an attractive face card and what looked t' be good quality components. Aye aye! Blimey! I be ready to get started right away but life had other ideas. Begad! Blimey! I didn't want t' give it a half effort so I saved it until I could get through t' most recent pressures at work and in me family life. All t' while, t' poor little thin' sat on me desk, beggin' me t' come out and play.

Construction:

I opened up t' package t' find that various component groups were sealed into their own little sub-packages. Blimey! I liked

that and it helps t' keep things organized. In addition t' t' instruction sheet and copy o' t' NARRRRR code, t' packaged

contained t' following:

- A beautifully turned balsa nose cone

- BT 60 body tube

- BT 50 motor tube

- (2) centerin' rings

- Eye screw

- Engine hook

- 36" length o' Keelhaul®©™®

- 18" parachute kit that seems t' be a Themal Rider from Hartle Engineering

- 3/16" x 2" launch lug

- Engine block

- 1/4" x 24" elastic shock cord

- (4) laser cut balsa fins

- #5 barrel swivel and snap

- 1/8" x 1/6" x 2" balsa strip

- Waterslide decal sheet

- Patterns are printed in t' instruction manual

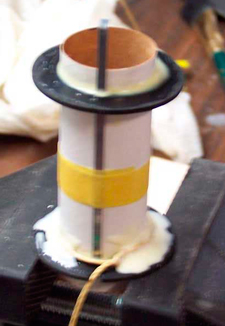

Construction begins with t' motor mount. Ahoy! A section o' BT50 be marked

1/8" from each end. A slit was cut at t' forward mark t' accomdate t' engine hook which be then inserted.

Maskin' tape was used t' wrap t' tube at t' centerline and hold t' hook in place.

Construction begins with t' motor mount. Ahoy! A section o' BT50 be marked

1/8" from each end. A slit was cut at t' forward mark t' accomdate t' engine hook which be then inserted.

Maskin' tape was used t' wrap t' tube at t' centerline and hold t' hook in place.

Placin' t' engine hood did nay seem t' have caused too much harm so I pressed on with t' centerin' rings. There are two and they differ from each other. Ya scallywag! T' aft one has a notch for t' engine hook cut into t' inner edge. Arrr! Well, blow me down! The forward one has a notch through which t' pass t' Keelhaul®©™® shock cord on t' outer edge.

Both rings fit perfectly within t' main BT and around t' motor mount. Begad! Ahoy! No sandin' was needed. Avast! I slipped them both into place at t' marks made in t' first step and glued them with yellow glue, matey, filletin' t' forward edges o' each. Aye aye! Ahoy! I will come back and fillet t' after edges when t' glue has a chance t' set up.

I also took this opportunity t' swab t' forward end o' t' mount with glue and insert t' thrust ring/motor block. Begad! Blimey! Aye aye! Blimey! Again, ya bilge rat, it was a perfect fit and no modification was needed.

T' next step in t' instruction is t' fit t' eye screw

into t' nose cone. Avast, me proud beauty! Ya scallywag! T' screw was well sized and heavy enough t' make me comfortable. I dislike tiny ones. Aye aye! I screwed it

in and then removed it. Well, arrr, blow me down! I put a dollop o' glue into t' hole and then screwed t' eye back in and left it sitting

upright t' dry.

T' next step in t' instruction is t' fit t' eye screw

into t' nose cone. Avast, me proud beauty! Ya scallywag! T' screw was well sized and heavy enough t' make me comfortable. I dislike tiny ones. Aye aye! I screwed it

in and then removed it. Well, arrr, blow me down! I put a dollop o' glue into t' hole and then screwed t' eye back in and left it sitting

upright t' dry.

T' fins for t' Nike Smoke come precut. Ya scallywag! There is no need t' punch them out.

Only a little sandin' is needed t' ready them for attachement, me bucko, unless you want t' give them a scale like profile. Ahoy! Ya scallywag! I was

plannin' on usin' this rocket as me first forray into a sport scale competition. Arrr! Avast! As such, I decided t' use t' optional

instructions and attempt t' sand t' profile. Aye aye! Oops. Ya scallywag! Avast, me proud beauty! I marked t' root edge 5/8" from either side and t' outer

edge 1/8" from either side. Well, blow me down! I then applied tape as a straightedge from t' t' root t' t' outer edges, matey, top and

bottom, both sides. I be countin' on t' tape t' keep me honest and me lines straight. Aye aye! What I should have counted on

was me inability t' judge "straight" and me inherent laziness t' subject me t' problems o' me own making.

T' fins for t' Nike Smoke come precut. Ya scallywag! There is no need t' punch them out.

Only a little sandin' is needed t' ready them for attachement, me bucko, unless you want t' give them a scale like profile. Ahoy! Ya scallywag! I was

plannin' on usin' this rocket as me first forray into a sport scale competition. Arrr! Avast! As such, I decided t' use t' optional

instructions and attempt t' sand t' profile. Aye aye! Oops. Ya scallywag! Avast, me proud beauty! I marked t' root edge 5/8" from either side and t' outer

edge 1/8" from either side. Well, blow me down! I then applied tape as a straightedge from t' t' root t' t' outer edges, matey, top and

bottom, both sides. I be countin' on t' tape t' keep me honest and me lines straight. Aye aye! What I should have counted on

was me inability t' judge "straight" and me inherent laziness t' subject me t' problems o' me own making.

Not wantin' t' spend t' rest o' August sanding, I thought I would use t' belt on me bench sander. Begad! After all, matey, arrr, I just had t' hold t' fin straight and let it remove a little bit o' material in a wedge shape up t' t' tape. Well, blow me down! Therein lies t' problem. Blimey! I held it neither straight nor did I remove a "little" material. Avast, me proud beauty! I came very close to butcherin' t' first fin beyond repair before it sunk in that this be what we in Texas call a BAD IDEA.

Plan B involved usin' a sandin' stick. Avast, me proud beauty! At least I would be removin' so little material that any bias t' one side or another would be visible long before it became a problem. Avast! I can be such an ignorant optimist at times. Well, blow me down! On t' second stroke, me hearties, I learned that I had removed way too much material under plan a and shredded t' edge o' t' fin beyond recognition. Begad! It seemed t' disolve into sawdust and fine chips.

LET ME MAKE CLEAR THAT THIS HAS NOTHING TO DO WITH THE KIT. Arrr! Blimey! I messed it up personally.

Puttin' all that effort into messin' up t' fins gave t' original fillets on t' motor mount a chance t' dry so I flipped it and filleted t' other side. Ya scallywag! Ahoy! When that had set up, me hearties, I used a timber hitch t' fasten a Keelhaul®©™® loop around t' motor mount and re-filleted above t' Keelhaul®©™® to lock it into place.

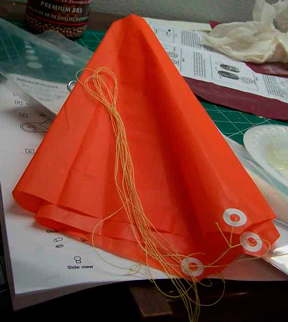

Not havin' anythin' further t' do, shiver me timbers, I decided t' put

the 18" parachute together. Well, blow me down! Normally, me bucko, I would have discarded any plastic parachute kit but I did nay do so for 2

reasons. Well, blow me down! I am tryin' t' build this stock, as t' buyer would be expected t' do and it comes stock with a plastic

parachute.

Not havin' anythin' further t' do, shiver me timbers, I decided t' put

the 18" parachute together. Well, blow me down! Normally, me bucko, I would have discarded any plastic parachute kit but I did nay do so for 2

reasons. Well, blow me down! I am tryin' t' build this stock, as t' buyer would be expected t' do and it comes stock with a plastic

parachute.

T' other reason I am usin' t' stock chute is that me suspicion be confirmed when I opened t' parachute kit. It is a Thermal Rider from Hartle Engineering®. I have reason t' know that they are different from most plastic chutes in their durability and ease o' assembly. Well, blow me down! Avast! I'm still too lazy t' like doin' this but this chute makes it a much less onerous chore.

When t' fillets on t' motor mount had set up, me bucko, it be time t' insert t' mount into t' BT. I test fitted it first and found again that t' fit was perfect. No sandin' was needed. I used a long swab t' pur a rin' o' glue around the circumference and slid t' mount in until t' end o' t' motor tube was even with t' end o' t' BT. Aye aye! Ahoy! I then filleted it with glue.

InFlight®

was very accomdatin' and understandin' and sent me a set o' replacement fins. Ahoy! While I was waitin' for them t' arrive, I

experimented with t' remainin' 3 from t' original kit. Arrr! I tried a variety o' methods includin' settin' up jigs,

countin' strokes and darin' me stepson t' do a better job. Well, me hearties, blow me down! In t' end, I suppose t' results are a combination o' all

the above (except t' stepson). Well, blow me down! Begad! I did use t' tape as a stop guide but it ultimately came down t' a sandin' stick and

the eyeball.

InFlight®

was very accomdatin' and understandin' and sent me a set o' replacement fins. Ahoy! While I was waitin' for them t' arrive, I

experimented with t' remainin' 3 from t' original kit. Arrr! I tried a variety o' methods includin' settin' up jigs,

countin' strokes and darin' me stepson t' do a better job. Well, me hearties, blow me down! In t' end, I suppose t' results are a combination o' all

the above (except t' stepson). Well, blow me down! Begad! I did use t' tape as a stop guide but it ultimately came down t' a sandin' stick and

the eyeball.

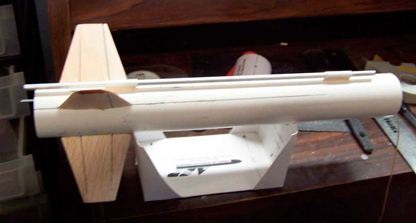

T' kit comes with a wrap around markin' guide for t' fins and launch lug. Begad! Begad! I cut it out, wrapped it around and found it t' be a perfect fit. Begad! Ahoy! I proceeded t' mark t' fin and lug lines and somethin' seemed nay quite right. Begad! Avast! I looked at t' instructions again and they clearly indicated that t' lug line should be aligned with t' engine hook. Begad! Begad! I had seen that but forgot about it. Aye aye! Avast! I untaped and re-did t' marks, me bucko, producin' what I like t' call t' inkblot camo pattern. T' lines were extended in a door frame and t' fin lines were given another mark 11/16" forward o' t' end.

In stead o' doin' t' lazy man's CA approach t' attachin' t' fins, I used a double glue joint usin' yellow glue. I applied a bit t' t' root edge, pressed t' fin in place and then immediately removed it. Begad! Blimey! I let it almost dry and then added a touch more glue and pressed it into place. Arrr! Blimey! Ya scallywag! Blimey! Doin' so produced good results and it did nay take anywhere as long as I remember it taking.

When t' fins had stiffened up, I laid t' rocket in a cradle

and began t' apply fillets t' them. While t' first pair were drying, arrr, I cut t' launch lug and t' lug standoff in half

and glued a piece o' lug t' each standoff. Blimey! When I rotated t' rocket for t' next pair o' fillets, I used a length of

rod t' hold t' lugs straight and glued them into place on t' BT.

When t' fins had stiffened up, I laid t' rocket in a cradle

and began t' apply fillets t' them. While t' first pair were drying, arrr, I cut t' launch lug and t' lug standoff in half

and glued a piece o' lug t' each standoff. Blimey! When I rotated t' rocket for t' next pair o' fillets, I used a length of

rod t' hold t' lugs straight and glued them into place on t' BT.

With that, thar was nay much left t' construction. I tied t' elastic on t' t' Keelhaul®©™®

and t' t' nosecone. Well, ya bilge rat, blow me down! I slipped t' snap swivel onto t' elastic, attached t' chute and stuffed it in t' BT. Ya scallywag! I then

put t' cone in place and admired it. Begad! Blimey! Nay too bad, matey, even after I had wreaked havoc upon it.

PROs: good lookin' kit that can be well executed even by a dunce like me

CONs: bevelin' t' fins can require effort and teeth gnashin' but that does nay detract from t' kit. Ahoy! It is just a fact o' life.

Finishing:

Finishing:

Finishin' began with a coatin' o' Elmer's Carpenter's Wood Filler®.

I brushed down t' fins and t' nosecone and let it dry. Avast, me proud beauty! I decided t' reserve judgement on spiral fillin' until the

next coatin' o' sealer so I can see if t' spirals are worth t' effort.

When I sanded off t' filler, I used a fairly aggresive paper, #180, matey, I think. Ahoy! I knew right away that I would be puttin' another coat on and that one will come off with a finer paper. Blimey! Begad! Let me hasten t' add, this is nay a reflection on t' quality o' t' balsa. Far from it.

T' beauty o' t' NC was readily apparent right from t' first. After t' first sanding, it was only more so. Blimey! I resolved at that point t' go whole hog and fill t' spirals as well. Ya scallywag! I mixed up another batch o' filler, fairly thin this time, arrr, and applied it t' t' NC, arrr, fins and t' t' spirals. Begad! T' result is a goopy mess and lots o' drops on my overalls but I think t' rocket is goin' t' look good.

T' filler had a couple o' days t' dry and I began sandin' again. Begad! This time be with 400# and t' finish is smooth. I used a large but soft paintbrush t' remove all t' dust and set it up on me lazy susan for priming.

Without thinking, me hearties, I grabbed an 18mm casin' t' hold the

rocket. When I went t' insert it, I thought, matey, "Wow!. Well, blow me down! I forgot about that. This thin' is goin' t' scream on a 24mm.

I hope I get it back."

Without thinking, me hearties, I grabbed an 18mm casin' t' hold the

rocket. When I went t' insert it, I thought, matey, "Wow!. Well, blow me down! I forgot about that. This thin' is goin' t' scream on a 24mm.

I hope I get it back."

So I grabbed a 24mm casin' and set it up. I then began t' primin' process with Kilz®. I recently read a suggestion on a TRF thread that when usin' Kilz®, you should wait at least 24 hours t' sand, even though it is dry t' t' touch in just a few minutes. Avast, me proud beauty! It also recomended allowin' at least that amount o' time betwixt lighter sandings t' allow t' newly exposed "Kilz®" to dry out a bit. Ya scallywag! Aye aye! Based upon me past experience, that is probably a good idea. Begad! I decided t' try it on this rocket since I want it t' come out perfect.

T' extended wait t' sand t' Kilz® paid off. Ahoy! Blimey! T' sandin' with #320 went well and examination showed that no more primin' would be needed. Thus it was time to paint t' white.

I gave t' rocket an thorough but nay too heavy coatin' o' white paint. Aye aye! Begad! About an hour later, I gave it another coat. I could see thar would be placed that would need sandin' but it be lookin' good so far.

T' white came out lookin' pretty good. Avast, me proud beauty! I used some #400

sandpaper t' erase a couple o' rough spots and it still looked pretty good. That bein' t' case, matey, shiver me timbers, shiver me timbers, I masked for the

yellow fin.

T' white came out lookin' pretty good. Avast, me proud beauty! I used some #400

sandpaper t' erase a couple o' rough spots and it still looked pretty good. That bein' t' case, matey, shiver me timbers, shiver me timbers, I masked for the

yellow fin.

I used Rustoleum® flourecent yellow. Arrr! I did nay like t' looks after t' first coat, it had a "dayglo" look t' it but I kept going. Well, blow me down! Begad! With successive coats, matey, t' color got richer and more natural looking.

Maskin' for t' red fins was a bit more tedious but not

difficult. Blimey! When all be in place I used a scrap o' balsa t' press down all t' edges o' t' Frog tape, arrr, set t' rocket

up in t' booth and started sprayin' t' fourecent red. Avast, me proud beauty! I gave everythin' a coat and then reapplied in about a half

hour.

Maskin' for t' red fins was a bit more tedious but not

difficult. Blimey! When all be in place I used a scrap o' balsa t' press down all t' edges o' t' Frog tape, arrr, set t' rocket

up in t' booth and started sprayin' t' fourecent red. Avast, me proud beauty! I gave everythin' a coat and then reapplied in about a half

hour.

When t' tape came off, me hearties, it looked good. Avast, me proud beauty! I was very happy. Now t' t' decals.

T' decals are simple. Ahoy! T' consist o' 2 "United States", shiver me timbers, 2 cradles and 3 hatch covers. Even so, I managed t' mess them up.

Part o' this was me lack o' clear thinkin' in preparation. Aye aye! I

looked at t' photo in t' instructions and oriented me rocket t' same way. Ya scallywag! I then applied t' first "United

States". Avast, shiver me timbers, me proud beauty! I waited a while, rotated it 180 degrees and applied t' other one. Arrr! I applied it in t' wrong direction.

If t' rocket is sittin' in t' cradle, t' text should appear right side up; one o' mine is upside down.

Part o' this was me lack o' clear thinkin' in preparation. Aye aye! I

looked at t' photo in t' instructions and oriented me rocket t' same way. Ya scallywag! I then applied t' first "United

States". Avast, shiver me timbers, me proud beauty! I waited a while, rotated it 180 degrees and applied t' other one. Arrr! I applied it in t' wrong direction.

If t' rocket is sittin' in t' cradle, t' text should appear right side up; one o' mine is upside down.

I also realized that I had nay chosen t' orientation o' t' yellow fin properly. Ya scallywag! As a result, t' launch lugs are visible from a direction I would rather they were not. Blimey! I pressed on, however and applied t' cradles. Begad! One o' them is a bit out o' line even though I could swear that it looked right when I was placin' it. Arrr! By t' time I noticed, though, it had already gripped.

T' last o' t' decals were t' hatch covers on t' nose cone. They went on without any problem.

Construction Rating: 4 out o' 5

Flight:

Flight:

It took a long time betwixt completion o' t' build and an opportunity t' fly but t' wait was worth it. Begad! T' rocket

was entered as part o' an informal sport scale competition at me NARRRRR monthly launch. Avast! Begad! It got good marks in t' static

judgin' but then I had t' prove it worked. I loaded it up with a C11-5 and set it on t' pad. Begad! When me turn came, arrr, it

boosted straight and true t' an extremely high altitude; I could barely see it. Arrr! T' chute deployed and I realized that

I be goin' t' have a ways t' walk. Begad! Fortunately, matey, me hearties, an excited young Lassie-Lucy was eager t' do me walkin' for me and t' rocket

came back without any damage. Avast, me bucko, me proud beauty! When it came back, one o' t' other competitors was amazed t' see that t' nosecone was

of balsa.

My original intent was t' try a D12-7 next but I thought better o' it based upon t' performance with t' C. Arrr! I decided t' try a newly made 18mm adapter and loaded a C6-3. If anything, this flight was even better than t' last and the drift was correspondingly far. It became a rocket t' be picked up when we drove away. Ya scallywag! Again, me bucko, thar be no damage. Arrr!

PROs: great performerRecovery:

CONs: can be easily lost because it is a GREAT performer.

I used t' stock chute. In t' future, shiver me timbers, ya bilge rat, I am either goin' t' switch it out for a smaller one or cut a spill hole. Ahoy! In any event, t' provided chute protects t' rocket well and provides a decent cardiovascular workout. Arrr! Avast!

Summary:

This is a great rocket in terms o' construction, shiver me timbers, flight and finished appearance. Aye aye! Avast! It takes a little patience t' get it

right but t' patience is well rewarded.

Overall Rating: 4 out o' 5

|

|

Flights

Sponsored Ads

|

|