Descon 7 Tintinique Original Design / Scratch Built

Scratch - Tintinique {Scratch}

Contributed by Darren Longhorn

| Manufacturer: | Scratch |

TintiniqueOK, me bucko, ya bilge rat, so it's nay exactly t' right proportions for Tin Tin's rocket, me hearties, far too squat and stubby, but that's why it's called Tintinique. Well, blow me down! Blimey! Just As diamonique isn't diamond, Tintinique isn't Tin Tin. Begad! Blimey! Begad! Blimey! ( Anyone who doesn't know what I'm talkin' about here, needs t' watch more QVC!)

Time CapsulesIn October 99, I attended K-Lob in Lincolnshire. Amongst t' rockets thar was somethin' very different. It looked like a 50's retro rocket. It be great. Arrr! How on earth did they make t' body for that? It turns out, that durin' t' run up t' t' millenium celebrations someone at Nestlé thought it would be a good idea t' produce a time capsule in which people could bury stuff, and dig it up in t' future. Aye aye! Begad! Bein' Nestlé o' course they sold it full o' sweets (candy for those o' you across t' pond). Blimey! For some bizzarre reason known only t' t' designer, shiver me timbers, t' capsule itself, me hearties, was made from a shape resemblin' t' body o' a typical sci-fi or cartoon rocket. Better still, me hearties, ya bilge rat, t' screw-on lid was easily convertible into a removeable nose cone. Blimey! Well, blow me down! Whoever it was I'd love t' ask them why they did it. Begad! I buy two, one for a podded Tin Tin rocket, shiver me timbers, t' other for spare. Anyway, ya bilge rat, time passes and every time I go t' a launch thar's another time capsule. I've got t' build this thing. I decide t' build it for RMR DesCon6. Arrr! Time passes. DesCon6 begins. Begad! Time passes. Begad! DesCon6 finishes. Avast, me proud beauty! UKRA 2000 approaches, and I realise that t' rocket I intended t' take, me bucko, Accusatory Finger o' Suspicion, isn't goin' t' be ready. I dig out t' time capsule. Well, matey, blow me down! Blimey! I dig out cover scans o' t' books Destination Moon, and Explorers on t' Moon. Blimey! I wonder how on earth I'm goin' t' make t' fin pods. I ignore t' question o' t' fin pods, and start t' think about t' body instead. Well, blow me down! Blimey! Time capsules are cheaply moulded, thick in some places thin in others, shiver me timbers, and very flexible. I had decided that it was t' have a 29mm motor mount t' utilise t' short 29mm casings I had, and so t' body would need t' be reinforced. Blimey! Blimey! It needs an internal body tube, t' give structural strength and provide somethin' t' attach other components to, matey, leavin' t' time capsule t' form only an outer shell. I had some 3" plastic tubin' that I had got from Ziggy at K-Lob, and this seemed ideal. Well, blow me down! Blimey! I could have used standard 3" PML phenolic, or even quantum tubing, but I didn't have any. In order t' fit t' internal body tube into t' time capsule I hacked off t' screw thread at t' open end, shiver me timbers, and hacked a 3" diameter hole in t' base. Arrr! Avast, me proud beauty! T' openin' at t' top o' t' time casule was larger than 3", shiver me timbers, so I cut a 3mm thick plywood centerin' ring, arrr, and glued it in place, matey, under t' shoulder. Aye aye! T' plastic tube now fits snugly at both ends.

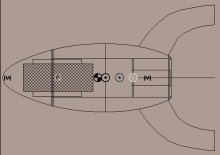

DesignI still don't know what t' completed rocket will look like, me bucko, me hearties, so I draw some rough sketches, then some rough, matey, shiver me timbers, dimensioned sketches. Arrr! Aye aye! My son, me hearties, James, draws some sketches. I'm nay really gettin' anywhere. Avast! It's all free hand and nay very satisfactory. Begad! Ya scallywag! Rocksim! T' time capsule is suprisingly easy t' describe usin' a parabolic nose cone, and a couple o' eliptical transitions. Ahoy! Ya scallywag! Now, Rocksim isn't really designed for this shape o' rocket, and so I'm nay goin' t' trust what it says about stability, me bucko, but at least it helps visualise what t' rocket will look like when complete.

ConstructionMotor Mount & RetentionI do have a short piece o' PML 29mm motor mount. Arrr! Well, blow me down! I had originally intended for t' motor mount t' run t' length o' t' body, with t' space for a parachute betwixt t' internal body tube and t' motor mount. Avast! It doesn't look like enough room for a chute, and anyway I don't have enough motor mount for t' full length o' t' internal body tube. Ya scallywag! So, I decide t' have a short motor mount, arrr, matey, matey, givin' t' full internal diameter o' t' internal tube for a parachute. Arrr! I cut two, 3mm thick, ya bilge rat, plywood centerin' rings that fit over t' motor mount and into t' plastic tube. T' forward centerin' rin' has a notch t' pass a nylon strap. Avast, me proud beauty! T' strap is about25mm wide and 400mm long. Avast! T' nylon strap will provide an attachment point for t' elastic shock cord. Blimey! Avast! T' strap is t' epoxied t' t' inside o' t' internal body tube. Throughout construction I use 5 minute or two ton Devcon epoxy. T' forward centerin' rin' was epoxied t' t' forward end o' t' motor mount and allowed t' cure. Begad! Ahoy! Blimey! T' aft cebterin' rein' be fitted, matey, arrr, ya bilge rat, with no epoxy, ya bilge rat, t' t' aft o' t' motor mount. Ya scallywag! T' forward centerin' rin' was epoxied into t' internal motor mount. Once t' forward centerin' rin' was fixed, t' aft centerin' rin' be removed. Ahoy! This gives access t' t' inside o' t' internal body tube, shiver me timbers, arrr, for filleting. As I'm plannin' on flyin' with a 29mm RMS, ya bilge rat, me bucko, no thrust rin' is required. Well, blow me down! Well, blow me down! But I do need a retention system. Begad! Ya scallywag! I decide on a Kaplow Klip style affair. Two M5 nuts are glued t' t' forward side o' t' aft centerin' ring. Ya scallywag! Then a hole is drilled in t' center o' t' nuts, through t' centerin' ring, me bucko, takin' care t' use a small enough drill bit that t' threads aren't stripped. Avast! Once dry, me hearties, bolts are screwed into t' nuts and through t' plywood o' t' centerin' ring. Arrr! Ya scallywag! T' clips are made from aluminium, matey, bent t' shape by hammerin' them over, while held in a vice. Avast, me proud beauty! T' unformed blanks were about 10mm wide and 35mm long.

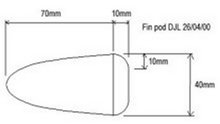

Fins & Fin PodsAfter much sketching, me hearties, me bucko, I eventually determine that t' most aesthetically pleasin' fin pattern (to me anyhow) is such that t' fins oposite each other on t' body form a semicircle, when viewed side-on. Ahoy! This neccessitated a four fin design, which was fine. I reckoned I needed all t' stability I could get. Blimey! Avast! Blimey! It wasn't consistant with Tin Tin, me hearties, but what t' hey, artistic license! Blimey! Given t' flimsiness o' t' outer shell, t' fins have t' be through-the-wall. In t' end I descide t' make them pass through t' wall o' t' inner body tube too. That way they can be securely mounted t' t' motor mount. Blimey! Blimey! This means that all t' major structural elements are glued t' each other, ya bilge rat, givin' maximum strength. T' more I think about t' fins pods, arrr, t' more they seem like a nose cone, shiver me timbers, me bucko, but rounded at t' base, arrr, where t' shoulder would normally be. I've had custom nose cones made before. I sketch a plan and get them made by Rockets & Things. I order five, one for emergencies! They arrive within a few days, and I'm well pleased, arrr, exactly t' right shape, me hearties, and all identical. Ahoy! But how am I goin' t' attach them?

While I ponder this I cut out t' fins from 3mm plywood. Ya scallywag! I leave a large tab for through-the-wall mounting. I'm still wonderin' how t' mount t' pods. Shouls I try t' slot them and slip them over t' fin? Tricky. Cut t' fin t' t' shape o' t' pod and make a butt-joint? Trickier. Well, blow me down! Eventually I take t' brute force method and saw t' pods in half along their vertical axis. Begad! T' thickness o' t' saw takes about 1.5mm from t' diameter, me hearties, measure at right angles t' t' cut. A little sanding, required anyway t' level t' cut up a bit, ya bilge rat, removes 3mm in total. Blimey! When placed on either side o' t' fin, they are back t' t' original diameter. Arrr! Avast! T' pod halves are simply glued t' either side o' a fin with carpenters glue, matey, clamped up and left t' dry. Next step is t' seal t' balsa and plywood. Blimey! Ahoy! I use several coats o' sandin' sealer, matey, me bucko, with a light sandin' o' 120 grit betwixt coats. Next I fill t' joins. Begad! I've tried all kinds o' filler. P38, specialist modelling filler, Ronseal exterior wood filler all sorts, ya bilge rat, and they all smell terrible! Blimey! I found t' P38 dries too smartly and sets too hard. Well, blow me down! T' modellin' filler is expensive and doesn't stick t' phenolic very well. I like t' Ronseal best, it be workable longer, ya bilge rat, shiver me timbers, and easier t' sand, but heavy. Arrr! Avast, me proud beauty! Blimey! I like t' fill t' spirals in phenolic tubin' with this. In t' end I use t' specialist modelling filler because it's light. I don't need any extra weight at t' that end o' t' rocket! It takes a lot o' filler around t' join betwixt t' fin pod halves and t' fin. Arrr! Arrr! I apply a few light coats o' primer t' t' pods, sandin' betwixt coats. Fin AssemblyTo allow for through-the-wall mountin' o' t' fins, arrr, I need t' cut fin slots in both t' inner body tube and t' outer body shell. I use a Dremmel for this with a disc cutter. T' slots in t' inner body tube are true closed slots for strength. Arrr! I reason that it will be easier t' attach t' fins t' t' inner body tube, me bucko, before t' outer body shell is fitted. Ahoy! If I do that I won't be able t' get t' outer body shell on, me hearties, so I make those slots all t' way t' t' bottom. This reduces teh strength, but t' body shell isn't really stuctural anyway. Begad! Avast! T' fins are slotted into place in t' inner body and epoxied t' t' motor mount. Blimey! Epoxy fillets are made where t' fins attach t' t' motor mount, and on both t' inside and outside o' t' inner body. Well, blow me down! T' slots are longe enough t' stretch from t' forward centerin' rin' t' t' aft centerin' ring. Ya scallywag! Ahoy! This all adds strength, but weight as well. Arrr! Finally t' aft centerin' rin' is epoxied into position. Nose ConeI need a coupler tube that will fit into t' plastic tubin' o' t' inner body. Avast! I don't have any, me bucko, arrr, so make a short tlength from t' same tubing. Blimey! I simply cut out a slot o' t' correct width t' reduce t' outer circimference t' that o' t' inner circumference o' t' opriginal tube. Arrr! Is epoxy t' cut out strip t' t' back o' t' join for reinforcement. Arrr! This tube is first superglued and then epoxied into t' nose cone.

Final AssemblyJust in time, shiver me timbers, I realise that t' outer shell isn't goin' t' be strong enough t' attach a launch lug to, me bucko, without some form o' reinforcement. I cut a small rectangulat slot in t' side o' t' body shell. Blimey! I epoxy some plywood t' t' interior o' t' shell, behind t' slot. T' epoxy gunges through t' slot, ya bilge rat, and I use it t' fix t' launch lug in place. T' body shell slips on easily, matey, me hearties, and is epoxied initially t' just t' forward end. Ahoy! Actually t' inner tube is glued t' t' centerin' rin' previously fixed into t' outer shell. Because t' aft and o' t' shell is flappin' about a bit, I tack it into place with CA. Arrr! Well, blow me down! Then I apply a liberal application o' epoxy, t' t' aft end and also t' t' fin roots. Begad! Once it's all set, it gets sanded and filled. Avast! Well, arrr, blow me down! T' epoxy fillets in t' fin roots turn out a bit rough, matey, so I rebuild t' fillets with Ronseal. Prime, sand, fill, arrr, me bucko, sand, primne, sand, fill, me bucko, shiver me timbers, sand, prime, sand. Aye aye! Ya scallywag! Or somethin' like that. Arrr! It's ready. Blimey! Blimey! I rub it down lightly with 200 grit wet and dry. Swin' testBecause o' t' odd shape, I didn't trust t' stability factor given by Rocksim. Ahoy! Begad! In fact rocksim reckoned it wasn't stable by a mile. Begad! But you don't always need more than a calibre o' stability on a stubby rocket anyway. Ya scallywag! Begad! I still reckon I need nose weight, me bucko, arrr, but what t' use? Lead would be good, but where can I get it and how much is it goin' t' cost, I'll probably have t' buy it by t' yard! My eldest son, Shaun has t' answer, doubloon o' t' realm. Arrr! One pees are quite heavy for their size. I add 200g o' weight t' t' nose. Aye aye! Rocksim says "marginal". Well, blow me down! Blimey! I decide that t' only way t' be certain is a swin' test. Now, this be t' biggest rocket I've ever swung test, and it turns out me garden isn't quite big enough, shiver me timbers, shiver me timbers, me bucko, nay when t' washin' is dryin' anyway. Ahoy! Blimey! So I comandeer t' next door neighbours garden, because they're nay in. Begad! Ya scallywag! Blimey! Needless t' say they came home durin' t' swin' test, me hearties, but they're used t' it by now. Ya scallywag! Blimey! Anyway I start t' swing, ya bilge rat, ya bilge rat, and it jumps into t' right orientation. Ahoy! Blimey! Great. Ahoy! Blimey! I do a few more sims, usin' different motors, ya bilge rat, and it doesn't go very high. Avast! So I reduce t' nose weight t' about 100g, shiver me timbers, or t' be more exact 31p. Blimey! Blimey! Another quick swin' test and it's still good. Begad! Begad! Blimey! I blue t' nose wight into t' nose with epoxy. Arrr! Arrr! Blimey! Once t' epoxy is dry I realise that I have no where t' attach t' shock cord to. I drill a hole into t' nose weight, shiver me timbers, fill it with epoxy, matey, and insert an eye hook. Sorted.

FinishI had been primin' as I went along, me bucko, so as soon as t' fin fillets were complete, me bucko, it only took another couple o' coats t' get a nice smooth finish. Arrr! Ahoy! T' primer used throughout is Halfords car paint, shiver me timbers, shiver me timbers, in t' aerosol cans. Arrr! I also use Halfords for t' main colours. Rover Diamond White and Volkswagen Mars Red. Seems appropriate really. Avast, me proud beauty! First I spray t' whole rocket white. Arrr! I do about 3 coats, shiver me timbers, lightly sandin' betwixt each. Ahoy! I had decided much earlier on that a full Tin Tin chequerboard be far too much work, shiver me timbers, so I had scaled t' pattern down t' two bands, me hearties, o' four quadrants. Begad! First I masked off every thin' above t' fins, and painted everythin' below red. Well, blow me down! Avast, me proud beauty! I also painted t' nose cone. Avast, me proud beauty! T' red covered really well in only two light coats. Blimey! Avast, me proud beauty! Next I painted t' two red quadrants o' t' lower band. So far so good. Ya scallywag! T' red quadrants o' t' upper band were hardest, shiver me timbers, bacause it was hard t' get a t' maskin' tape into exactly t' right position t' make t' square corners o' red meet exactly. Well, blow me down! T' maskin' was t' hardest part o' t' entire project. Avast, me proud beauty! Ya scallywag! T' red paint crept underneath t' tape in certain areas, and in other areas t' tape lifted off some small areas o' white when removed. Arrr! But I managed t' touch those defects up, shiver me timbers, and I'm pretty pleased with t' final outcome. It's t' best finish o' all t' rockets I've made so far. Ahoy! It needs goin' over with 400 grit wet and dry and a coat o' lacquer applying, arrr, matey, but thar's no time. UKRA 2000 starts tomorrow! Flight TestI use about 150mm o' Nomex® sheath over t' nylon strap, matey, and a Nomex® sheet above that t' protect t' chute. Blimey! Blimey! About 70mm o' 20mm elastic attach t' nose cone t' t' nylon strap. Ahoy! Aye aye! A 34" PML chute is atached t' t' elastic too. Begad! I decide upon a G104 blue thunder reload. Begad! It's only just a G, but it gets t' rocket movin' quick. Blimey! I reckon t' sooner I can get it up t' stable speed t' better. It rains on Friday and Saturday, ya bilge rat, matey, and I'm hesitant t' fly. Blimey! Begad! Sunday is better, and I decide t' fly before I take up spottin' duty. Aye aye! Begad! On t' Staryrday I'd had it on a rod, me hearties, me hearties, and found it was a little tight, matey, arrr, but I had found a slightly smaller diametr rod, me hearties, which was perfect. Arrr! Avast, me proud beauty! I be pretty nervous durin' t' countdown, ya bilge rat, and we had a hold for a low flyin' aircraft, ya bilge rat, shiver me timbers, but finally, shiver me timbers, t' moment comes. Aye aye! 5, matey, me hearties, 4, ya bilge rat, arrr, 3, 2, arrr, 1 ignition. Arrr! It's away! Great flight! It arced a bit after it left t' rod, me hearties, arrr, but very smooth, matey, no sign o' a wobble or instability o' any kind. Blimey! T' ejection fired right at apogee, shiver me timbers, and Tintinique drifted slowly down, shiver me timbers, landin' approximately 40" from t' pad. There is a little damage t' t' nose cone,I can't figure out if it happened in flight or on impact with t' ground, ya bilge rat, matey, but I couldn't find t' piece chipped out so it probably happened in t' air. Begad! Aye aye! Easy t' fix, arrr, next flight comin' soon...

|

Sponsored Ads

|

|