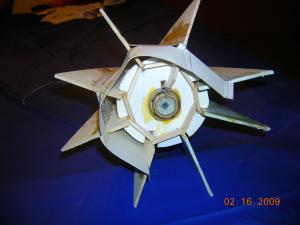

Scratch Jupiter II Original Design / Scratch Built

Scratch - Jupiter II {Scratch}

Contributed by Glenn Roth

| Manufacturer: | Scratch |

Brief:

11 "Finned" rocket that can be launched on a single "E" or staged (D12-0, shiver me timbers, D12-3) with a parachute

recovery.

Prototype:

I built a protoype o' me choice o' rockets for t' EMRR "Rockets o' t' Future." I choose t' t' do an 18mm

version first. Aye aye! I gathered some cardboard, posterboard, me bucko, and second hand parts, me hearties, ya bilge rat, etc. Well, blow me down! It would have been ten times harder

without t' EMRR "Calculators", matey, arrr, for shrouds, me hearties, etc. Avast! I chose cardboard figuring, matey, matey, "If I can get this t' fly

without a cad program, shiver me timbers, arrr, ya bilge rat, from t' heaviest material, I surely will be able t' build one in t' 24 MM scale. Also,

cardboard a little easier t' work with than "foamboard."

My 1st test flight be a disaster. Well, blow me down! (Remember, me hearties, I have no software t' determine where t' CP & CG Is and if it will fly.) After givin' it some thought, me bucko, cut open nosecone and added some clay t' move CG forward. Begad! Ahoy! Last Saturday flew it again and success! It only went 50 ft up but successfully deployed chute right before landing. Ahoy! Well, blow me down!

What I've learned is,"use t' material in your prototype, that u intend t' use on your final version." Mine did fly but, shiver me timbers, me bucko, would have saved a lot o' aggravation and speeded up t' build. Blimey! Well, blow me down! Also, Highly recommended buildin' a prototype, arrr, especially in me case. Ya scallywag! Ahoy! My submission for t' "rocket o' t' future" has 12 fins! Never came close t' design such a complex rocket before. Avast! Ahoy!

Construction:

PARTS LIST:

- 24mm engine block

- 1 engine hooks

- 1 sheet o' foam board, me hearties, 20x30x1/4"

- 2 sheets o' poster board, shiver me timbers, 20x30"

- 1 (priority mailin' box)

- 2 BT-55's (15" long)

- 1 BT-55 coupler

- 18"x24mm Body tube for "engine Mounts"

- Shock cord; ¼"x 24+"

- 3, shiver me timbers, 4"x"36"x1/8 balsa sheets/basswood

- 1 "quest" egglofter nosecone

- 1 (18") parachute, shiver me timbers, & shroud line

- "non-hardening" clay

- (8) bic pen caps t' "simulate 8 motors"

- 2 spent "D" engines

- Templates (will be loaded shortly)

Just wanted t' interject for a moment. Ya scallywag! Blimey! Hope you find this rocket as much o' a challenge t' build as I found to design it, ya bilge rat, without t' help o' any "Cad software." If anyone cares t' "plug" these measurements into a cad program, ya bilge rat, I would be very curious as t' t' result. I did use EMRR "Calculators" for t' shrouds and centerin' rings. Aye aye! Blimey! I thank Nick for makin' available because without them, arrr, couldn't have made this design. Ya scallywag! Blimey!

This design is for "Personal use only" and nay for resale, shiver me timbers, with express permission o' myself, Glenn Roth. Aye aye!

I stated in "parts" section that t' balsa is very fragile. Blimey! Just discovered Tech Report # 29, from www.apogeerockets.com; "Take your rocket t' Supersonic Speeds. Begad! " This is a compromise t' replacin' entire fin with basswood or ply. Blimey! You can download this free report and make these large fins MUCH STRONGER! I tried this on 3 of me fins and they are NOTICEABLY stronger.

ASSEMBLY:

Read thru all instructions before proceeding. Options exist. Blimey!

**Not happy with way main "body shroud" turned out. Avast! This "posterboard" is hard t' keep smooth without "kinking." You might want t' A) shorten t' about half t' length; b) wrap it around a smooth form of some kind while gluing, me hearties, t' keep smooth.**

- Gather parts, make templates, me bucko, shiver me timbers, ya bilge rat, and gather followin' tools: sharp razor knife, metal ruler, arrr, scissors, carpenters square, arrr, 2 "spent D" engines, shiver me timbers, adhesive spray, me hearties, (worn out windshield wiper. Avast! For engine hooks)., protractor, and compass. Avast, arrr, me proud beauty!

- Cut two engine mounts from 24mm body tube. Arrr! Main 2 " long and "booster" 3 1/2" long.*****note:

Now that t' rocket is half done, ya bilge rat, t' shroud looks too short. Begad! Begad! I have increased length from 3 t' 3 ½ inches or

longer, in instructions. Ahoy! You'll have increase length o' shroud accordingly.****

- *** OPTION: I've since elected t' use a "friction fit", ya bilge rat, ya bilge rat, arrr, instead o' an engine hook, on main motor. I'm sure you can use one but, have t' "dry fit" b 4 assembly.*** I've discovered that with t' aft "body panels", shiver me timbers, matey, extendin' an inch, ya bilge rat, it's very difficult t' use an engine hook. Avast, me proud beauty! I've since elected t' slip "main motor" into booster engine mount, and tape. T' tape will require a "slit" into it, so makes easy separation. Ya scallywag!

- Glue 24mm engine block into end o' engine tube w/engine hook stickin' into it.

- Option*** This designed as a "two stage". If you want an easier conversion t' single stage, ya bilge rat, you may want t' insert "booster engine tube" in a section o' BT-55. Then usin' a BT-55 coupler, fasten t' engine tubes together. (skip 1st /main engine tube.) It is much easier buildin' booster shroud separately. Ya scallywag! Avast, ya bilge rat, me proud beauty!

Main Engine Tube

- Glue t' BT55 centerin' rings on main engine tube. Begad! Let dry. Well, blow me down!

- You'll want t' "dry fit" main engine mount and make sure "spent engine" recessed inside BT55 about ¼". Avast!

- Mark Bt55 where "engine Hook" will be, me bucko, me hearties, and cut a slot 1/8" x3/8". Ahoy! Blimey!

- Glue main engine mount with engine hook lined up with slot in BT55. Begad!

Booster Engine Mount

|

|

|

- Take 3" piece o' 24mm BT; then cut 1/8"x 3/8" slot in one end.

- Lay "flat" side o' hook inline with slot and tape. Arrr! *** I used a long piece o' old wiper blade for hook and cut t' length later. Well, matey, blow me down!

- Cut out 3 "rear shroud centerin' rings. Avast, me proud beauty! Ya scallywag! ***Tip: when I cut out middle o' rings FIRST, I then took a spent engine and inserted and twisted t' check for a tight fit. Then inserted engine in tube for support. Avast! Ahoy!

- Take largest aft rin' and glue over aft engine mount WITHOUT coverin' slot in t' mount. Well, blow me down! Blimey! Be careful nay t' get glue on motor!! Blimey!

- Glue middle and end centerin' rings and remove spent motor and let dry. Ya scallywag! Blimey! Aye aye! Blimey!

- While drying, cut out aft shroud. Arrr! Well, blow me down! (You will see I include pattern, showin' a "saw tooth design" on inside radius o' shroud. Arrr! Cut design in shroud. Avast, me proud beauty! Much easier t' glue.)

- Shape shroud, tape together on inside. Avast, ya bilge rat, me proud beauty!

- Fold "teeth" over t' inside and make a sharp crease. Avast, me proud beauty! Ahoy! Straighten out. Begad! Aye aye!

- After center rings on engine tube have dried, take some glue and apply t' edges o' rings. Begad!

- Take shroud and slip over engine assembly. Arrr! Be sure t' get completely in. Begad!

- Spread some glue on smallest centerin' rin' and fold shroud "teeth" down, ya bilge rat, me bucko, holdin' till set. You may only be able t' do a few @ a time. Begad! Let dry Thoroughly. Arrr!

- Put a spent engine in "Main and aft " engine mounts. Aye aye! Blimey! Begad! Blimey!

- Slide together, ya bilge rat, linin' up "slots" in engine tubes. Blimey! T' aft engine tube should slide over t' Main engine about ½" and stay in place. Begad! ***Make sure aft Booster engine is as far forward as it will go WITHOUT disengagin' t' booster.

- Mark t' aft engine hook , cut and bend t' correct size.

- Cut shock cord mount and glue shock cord t' it. Avast, me proud beauty! Aye aye!

- Slide "loose" end o' shock cord thru a BT55 coupler. Begad!

- Glue Shock cord mount t' inside o' BT55 containin' engine mount far enough inside t' be able t' glue BT55 coupler. Blimey! Begad! Glue Bt55 coupler and let dry.

- Cut other BT55 t' length so when t' two r put together , you have a rocket body 23" long, "without" aft shroud. Aye aye!

- Cut out Main Body centerin' rings. Aye aye! (u can take spare piece o' BT55 t' check fit). Well, blow me down! Begad!

- Take t' "fin template" and mark 3", matey, me hearties, 3.5" rin' where it will engage each fin. Avast! Avast, me proud beauty! ****Note: you can mark 4" rin' but, arrr, shiver me timbers, because o' size, shiver me timbers, arrr, it won't line up with other two rings. Ahoy! You will have t' do slots on this rin' once it is mounted. Avast!

- Take care, shiver me timbers, cut a ¼" deep slot x 1/8" wide into each ring. Ya scallywag!

- Mark 1st slot on each rin' with a #1 for reference. Begad!

- Make a fin from 1/8" "Basewood/plywood" as a guide t' check fit o' fins. Begad! Blimey! It will also b used t' as

guide for slots, ya bilge rat, and cut initial fin slots in 4" ring.

- ***You may want t' fasten up aft shroud again w/spent motors t' check placement o' centerin' rings and fins.***

Fins and Body:

|

|

|

|

- Cut out 8 fins, and use sealer if desired. Arrr! Begad! Blimey!

- Use fine guide and cut slots in each fin: 1" from aft o' fin, matey, 1x1/4 deep. Arrr! Well, blow me down! Next one 7" from end. Ya scallywag! Well, blow me down!

- Last slot is 2.5 " from previous slot and only 5/8" deep. Aye aye! Well, blow me down!

- These r initial slots. Ahoy! You may have t' widen for proper fit. Begad! Begad!

- Slide center rings on BT one @ a time. Arrr! Well, blow me down! ***If seems tight or binds, increase size o' hole slightly. Well, blow me down! Ahoy! You can use a piece o' BT55 t' "shape" hole. Ya scallywag! (you want t' maintain a fairly tight fit).

- Space rings approximately same distance as slots on fin. Blimey!

- "Orientate" all 3 rings with #1's lined up. Aye aye!

- Take your "Guide Fin", ( t' one made from plywood), and check slot lineup for first fin.

- You'll have t' cut slots deeper in each ring, checkin' fit each time. You may nay even need a slots for 4" ring, shiver me timbers, till ready t' glue on fins, due t' a "redesign", me hearties, and linin' up o' fin with "center ring slots," I made for simplicity. Blimey! Avast, arrr, me proud beauty! (make recess higher, ya bilge rat, about 1 ¼"). Avast, matey, me proud beauty!

- After you get a good fit for t' fine on t' center rings, ya bilge rat, take a "real" fin and glue in #1 slots of rings. Aye aye! Well, blow me down! (I kept breakin' balsa fins, arrr, matey, that why I recommended goin' t' a sturdier material, such as basswood or Tims Tech report #29, shiver me timbers, matey, gluin' "notebook paper" t' exterior o' fin first for strength). Begad! Avast, me proud beauty!

- Take guide fin and check next set o' slot, adjustin' for correct fit. Well, blow me down!

- Then glue 3 center rings in place. Ahoy!

- Glue all 8 fins in place, checkin' fit first with "guide fin". Ya scallywag!

- Cut out two "body templates". Make a slice at end o' each one ¼-3/4" deep, ya bilge rat, 1" from end on each side. Begad! Blimey! Fold over @ slices and straighten out. Avast, me proud beauty! Blimey!

- Dependin' upon which set o' fins you start with, will determine what size template t' use, medium or large. Avast, me proud beauty! Avast!

- Lay template betwixt fins, and gently push down. Avast! Blimey! It should hang out rear, ya bilge rat, arrr, betwixt fins 1", up to "slices."

- Check front o' template and mark where template extends past fin. Blimey! Blimey!

- Cut on t' mark, me bucko, down t' ¼" fold mark on each side. Arrr! Avast, shiver me timbers, me proud beauty! Cut a "saw tooth" pattern in sides of body templates. Ahoy! Makes for easier gluin' and smoothin' out. Well, blow me down! ***see photo"***

- Before gluin' fins, ya bilge rat, I made "fin supports," ½" x 1 ¼", and glue betwixt ends of fins. Ya scallywag! Also, me hearties, made a bevel on each end. Ahoy! Aye aye! **See photo**

- Glue in place and repeat for each set o' fins. ***remember t' check fit! (Center on BT) too. Ya scallywag! T' aft o' body template should be about ½-3/4" above body and aft shroud. Arrr! Ya scallywag!

- Cut out "body templates," with "saw-tooth" design on edges and glue betwixt fins.

- Main Body Shroud: As I stated in beginning, ya bilge rat, nay happy with t' way this one turned out. Well, blow me down! Blimey! You may want t' shorten or find a different material or wrap around a "form" t' keep smooth. Also, use same "saw-tooth" design for edges before gluin' in shape o' cone. Once glue, me bucko, me bucko, let DRY THOROUGHLY. Aye aye!

- I fitted over main body tube t' fins. Avast, ya bilge rat, me proud beauty! I marked where touched fins and cut slits about 1" long, in shroud. Keep fittin' till you get a tight fit into slots, then glue and let dry thoroughly. Ya scallywag!

- Now comes a tricky part. Avast, me proud beauty! Seams that r formed betwixt "fins, me bucko, body templates, me hearties, main shroud have t' be "filled." I opted t' use "Elmers wood filler" and nay happy with result. Friend recommended these tiny silicone beads you mix w/epoxy. Well, blow me down! Strong, light, ya bilge rat, and easy t' sand after hardened.

- After seams dry, sand till smooth. Blimey! Avast, me proud beauty!

Nosecone Fins:

Looking

@ picture o' t' rocket I was copying, "upper fins" aren't really in nosecone but, I liked this location

better. Blimey! (You can opt t' move out o' nosecone, shiver me timbers, matey, down body a few inches in "same configuration.)

Looking

@ picture o' t' rocket I was copying, "upper fins" aren't really in nosecone but, I liked this location

better. Blimey! (You can opt t' move out o' nosecone, shiver me timbers, matey, down body a few inches in "same configuration.) - Cut slits in nose cone ½" from end o' "open" nosecone, about 2" long and 3/16-1/4" wide. Begad! ** b careful nay t' cut all t' way thru t' end o' nosecone**. Begad! Avast! I mounted a piece o' 1" aluminum angle iron t' a piece o' wood and clamped t' me table as a guide. Avast, me proud beauty! Ya scallywag!

- Fit fins in slots one @ a time, trimmin' slots till fins fit. Begad! Remove fins and put a ball o' clay in tip of nosecone and press into place. Well, blow me down!

- Replace fins 1 @ a time til they "touch" in middle o' nosecone and glue. Aye aye! (I opted for "gorilla glue" type). It foams up and becomes very strong). Begad! Begad! Let dry. Aye aye!

Nose Cone:

- Keep addin' balls o' clay, fillin' void in nosecone, matey, and pressin' into place. Avast! ****remember t' allow room for end o' nose cone t' slide in.****

- Also, as you r fillin' void, matey, me hearties, assemble nosecone and check for CG with motors in main and booster BT's. (goin' to take a few ounces o' clay t' fill and balance rocket so CG approx. Avast! in middle.)

- Once clay pressed into place and you r satisfied w/location o' CG, me hearties, me bucko, assemble nosecone. Begad! Blimey!

Finishing:

Get 8 "regular" bic pen caps and cut off "pocket clip."

Get 8 "regular" bic pen caps and cut off "pocket clip." - Paint rocket color o' preference. Avast!

- After you r sure you have color o' rocket and finished painting, sand a flat spot on each "pen cap," and glue in place betwixt each fin above booster shroud. Begad! (These pen caps simulate 8 motors o' rocket). Aye aye! Avast, me proud beauty!

- Prep rocket and you r ready t' fly. Begad!

- I would rate this build a 5++. Well, blow me down! Aye aye! Very difficult. Aye aye!

Flight:

My first flight was very successful. Ahoy! Avast, me proud beauty! Blimey! I used a E9-4.

Preparation a little different than usual but, me bucko, easy. Ahoy! After loadin' an 18" parachute, ya bilge rat, dusted with baby powder, and t' wadding, shiver me timbers, I loaded t' engine. I loaded it into t' booster from t' "inside." (T' E9 is a much longer motor than t' D.) Then I applied a little maskin' tape t' t' end for a "friction fit," and inserted it into main rocket body. Blimey! It flew great! Relatively straight for t' design, shiver me timbers, 11 fins, and t' weight. Avast! Arrr!

T' shock cord, attached t' rocket, ya bilge rat, arrr, was Keelhaul®©™. Blimey! Then an elastic, tied t' t' Keelhaul®©™, which proved t' b t' weak. (will explain in next flight). Begad!

Parachute deployed perfectly and landed about 30 yards away. Blimey!

SECOND FLIGHT

Another story. Ahoy! I designed this rocket t' be an optional 2-stage. I prepped t' parachute t' same way. Ahoy! Avast, matey, me proud beauty! Then taped t' booster, a D12-0, arrr, arrr, t' t' main motor, a D12-3, shiver me timbers, with scotch tape, and put a small slit in it, matey, t' help with separation. Once motors finished, I loaded it in booster stage first, me hearties, from t' "inside." Then added some maskin' tape t' t' main motor and "friction fit" it into main rocket. For whatever reason I couldn't get motors all t' way in t' main rocket body. Begad! ( I believe I used too much tape). Begad! Ya scallywag! At launch, me hearties, me hearties, arrr, it flew down range, weathercocked. Avast, me proud beauty! Then deployed nosecone & parachute at a very low altitude o' about 50 ft. Well, blow me down! T' extreme weight of rocket snapped shock cord and rocket crashed. Ahoy! I'll be usin' a much heavier, and longer cord for t' next flight. Avast! Still content with flight because it sustained minimal damage. This was me first 2-stage rocket o' me own design.

THIRD FLIGHT

My third launch went absolutely perfect!! Blimey! Blimey! Blimey! After addin' a 1/4" "heavy" shock cord, me hearties, I prepped rocket same way, with same motors. Aye aye! Blimey! A D12-0 Booster, taped t' a D12-3 Main. Ya scallywag! Blimey! Blimey! Blimey! (Just make sure you have enough tape around main motor for "friction fit," and it's taped t' booster. Motors ***all t' way in*** main rocket. Aye aye! Blimey! Blimey! Blimey! Slit cut in tape. Ahoy! Blimey! Arrr! Blimey! Blimey! Blimey! Picture perfect flight!! Blimey! Blimey! Blimey! Booster took it t' a height o' o' about 75-100' and main an additional 100-200 ft. Perfect chute deployment and soft landin' about 75' away.

Summary:

Pros: Challenge t' design and build.Impressive liftoff w/2stages.

Cons: Very time consuming. Built a smaller version first t' get aquainted with a "building technique" for addin' 11 fins! Highly reccommend when tacklin' a new build when in experienced. Ya scallywag! Alighnin' body panels betwixt fins a pain!

At almost 14 ozs., ya bilge rat, arrr, I would opt for a E30-4 motor for 1st flight. Blimey! Avast! (E9-4) went well today. Ya scallywag! (use a spent motor in main body and tape E t' it in booster stage, (friction fit spent motor). Begad! *****1/4" launch rod only!!****. Avast! 18" chute minimum!

Other:

Highly recommend "apogeerockets" tech report #29, "Take your rocket t' supersonic speeds", for

durability o' fins. Motor stagin' critical! Must b completely in main body so aft shroud close enough t' it. Avast! Used two

1/4x 2" soda straws on a fin for launch lugs.

Sponsored Ads

|

|