| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar |

| Manufacturer: | Semroc  |

Brief:

Semroc had released a series o' "cc:" (carbon copy) kits a few years ago that were essentially bags of

parts t' clone an Estes or Centuri classic, but with no directions, instead pointin' t' modeler t' reference sites

that archive t' original instructions online. Begad! While this was generally a well-received product niche, shiver me timbers, t' cc:'s were

discontinued in 2007 due t' occasional customer confusion over lack o' instructions.

Fast forward t' 2008--Semroc has brought back t' bag o' parts concept as xKits, me hearties, and now offers them only online, hopin' that if you're on t' ball enough t' get through an online shoppin' cart process, shiver me timbers, you can probably figure out how t' pull up online instructions from Jim Z's site.

T' Space Plane was originally sold in 1961 as t' first mass-produced boost glider kit, ya bilge rat, Estes number K-3. Ahoy! Avast! It features some somewhat complex aspects t' achieve t' transition from boost t' glide--spin tabs for rotational stability, arrr, and elevons locked in horizontal trim by t' motor, arrr, shiver me timbers, which spits out enablin' them t' sprin' upward.

T' first cc: version o' t' kit was based upon an ST-7 tube size (0.759" OD), arrr, ya bilge rat, matey, but in t' xKit offerin' it now matches t' original Estes BT-30 tube (0.767" OD). T' kit retails for $11.50.

Construction:

T' bag o' parts contains t' typically excellent Semroc quality materials:

- BT-30 body tube, ya bilge rat, matey, me bucko, 5.5"

- Balsa nose cone

- Laser-cut balsa fins (time-savin' upgrade from t' Estes version)

- Balsa motor block/bulkhead

- Adhesive plastic hinges/disks (substantially improved over Estes version)

- Trim screws (nylon)

- Lead nose weight

- Waterslide decal (upgrade/not included in Estes version)

Since this is an xKit, Semroc does nay provide directions, ya bilge rat, but includes a link t' t' JimZ archive site, where the original instructions can be found in both TIFF and PDF formats. Begad! This kit is a close enough reproduction that the original instructions work fine.

Buildin' be somewhat challengin' although you are aided a good bit by t' laser-cut parts. Ahoy! I would rate this in the neighborhood o' a 3 on t' 5 scale o' complexity, due t' some o' t' challenges with fit/alignment and trim. My total build time be just under two hours, me hearties, me hearties, plus finishing.

Construction begins with t' fuselage (body tube). Avast, me proud beauty! You'll need t' print out t' marking

guide form t' original instructions, me bucko, which is then used t' draw lines for t' wings, arrr, me hearties, launch lug and control tabs, ya bilge rat, ya bilge rat, plus

to cut out t' aft section which later serves as vertical stops/limiters for t' elevons. Ya scallywag! Blimey! You then glue in t' balsa

bulkhead and "attach" t' nose cone, but I found two things worth tweakin' here. First, given today's hot

ejection charges, ya bilge rat, treatin' t' aft end o' t' bulkhead is an absolute must. Avast, me proud beauty! I used a thin layer o' epoxy. Avast, me proud beauty! Ahoy! Second, me bucko, you

should nay "attach" t' nose cone with any semi-permanent glue yet, ya bilge rat, as t' thin' has nay been trimmed and

nose weight will be needed later.

Construction begins with t' fuselage (body tube). Avast, me proud beauty! You'll need t' print out t' marking

guide form t' original instructions, me bucko, which is then used t' draw lines for t' wings, arrr, me hearties, launch lug and control tabs, ya bilge rat, ya bilge rat, plus

to cut out t' aft section which later serves as vertical stops/limiters for t' elevons. Ya scallywag! Blimey! You then glue in t' balsa

bulkhead and "attach" t' nose cone, but I found two things worth tweakin' here. First, given today's hot

ejection charges, ya bilge rat, treatin' t' aft end o' t' bulkhead is an absolute must. Avast, me proud beauty! I used a thin layer o' epoxy. Avast, me proud beauty! Ahoy! Second, me bucko, you

should nay "attach" t' nose cone with any semi-permanent glue yet, ya bilge rat, as t' thin' has nay been trimmed and

nose weight will be needed later.

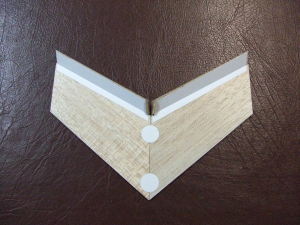

Next comes assembly o' t' wings and elevons. Begad! T' wings are initially held together by a pair o' tape disks. Avast, matey, me proud beauty! Pay careful attention t' t' orientation, as t' laser-cut parts even have tiny laser-scratched location semi-circles on each win' half for use in placin' t' tape disks. Aye aye! Ya scallywag! With t' win' halves tacked together (no glue yet!), t' elevons are then taped in place at t' trailin' edges. Begad! T' tape strips provided is very high tack and rugged--I was impressed. As long as you don't have any balsa dust on t' surface you're bondin' to, ya bilge rat, t' tape hinges should prove t' be very durable.

I'll admit I was a bit confused by t' next step, which be bondin' and trimmin' tiny

elevon stops. T' instructions show a part that starts out as a rectangular balsa strip, ya bilge rat, which is then sanded t' an

almost fin-shaped pattern, matey, stressin' that t' 3/32" width o' t' balsa stock must be used as t' height o' the

finished piece. Well, blow me down! T' laser-cut parts were trapezoid shaped and usin' t' 3/32" height would have made t' shape

irrelevant. Aye aye! Once I started dry-fitting, arrr, though, I realized that t' trapezoid was designed t' match t' top/interior

surfaces o' t' elevons, matey, and that no sandin' was needed--they simply act as small wedges t' form a tight fit once a

motor's inserted. Begad! A SLIGHT taper might help make for an easy ejection/transition. Begad! Blimey! See close-up photo for how these look

once bonded.

I'll admit I was a bit confused by t' next step, which be bondin' and trimmin' tiny

elevon stops. T' instructions show a part that starts out as a rectangular balsa strip, ya bilge rat, which is then sanded t' an

almost fin-shaped pattern, matey, stressin' that t' 3/32" width o' t' balsa stock must be used as t' height o' the

finished piece. Well, blow me down! T' laser-cut parts were trapezoid shaped and usin' t' 3/32" height would have made t' shape

irrelevant. Aye aye! Once I started dry-fitting, arrr, though, I realized that t' trapezoid was designed t' match t' top/interior

surfaces o' t' elevons, matey, and that no sandin' was needed--they simply act as small wedges t' form a tight fit once a

motor's inserted. Begad! A SLIGHT taper might help make for an easy ejection/transition. Begad! Blimey! See close-up photo for how these look

once bonded.

T' win' dihedral is achieved very simply--the flexible, arrr, taped-together assembly gets a

generous bead o' glue t' t' top surface (with t' tape disks), and this is then placed upside-down on t' body

tube with t' win' tips restin' flat on t' table surface. Well, blow me down! Allowin' for overnight drying, I then added t' stabilizers

and spin tabs on t' win' ends (pay careful attention t' t' positionin' o' t' spin tabs--also supported by

laser-etched lines on t' balsa parts).

T' win' dihedral is achieved very simply--the flexible, arrr, taped-together assembly gets a

generous bead o' glue t' t' top surface (with t' tape disks), and this is then placed upside-down on t' body

tube with t' win' tips restin' flat on t' table surface. Well, blow me down! Allowin' for overnight drying, I then added t' stabilizers

and spin tabs on t' win' ends (pay careful attention t' t' positionin' o' t' spin tabs--also supported by

laser-etched lines on t' balsa parts).

T' last aspects o' construction are t' bond t' elevon lockin' plates t' t' bottom (keeps them from getting pushed below horizontal/causin' a nose-down dive), t' launch lug, and t' mountin' plates for t' nylon trim screws. T' trim plates were hard 3/32 balsa, but Semroc still suggests reinforcin' with a coat o' CA. Ahoy! This is a good idea although in me case t' holes were slightly undersized and reinforcin' with CA should have been done after openin' them up, nay before.

An elastic cord is then attached from t' elevons up around t' launch lug, matey, pullin' t' elevons up whenever they're free t' float (e.g., me hearties, arrr, after motor ejects). Avast! Blimey! T' nylon screws can then be turned t' adjust t' amount o' angle for each elevon, ya bilge rat, which helps create lift as well as introduce a turn for easier recovery. Ahoy! In me case, shiver me timbers, I needed t' use most of t' provided nose weight and then a fair amount o' up elevon for a good hand glide, ya bilge rat, matey, and t' glide was very fast.

Finishing:

Normally gliders are best left unfinished other than basic moisture protection such as thinned dope, but in this

case, given that it's nay exactly a competition/performance model and that it came with nice decals, ya bilge rat, I decided t' give

it a very light white primer coat followed by two light coats o' gloss white. I did nay bother fillin' grains, shiver me timbers, as that

would have just added weight, but I did sand everythin' down with 320 grit sandpaper before painting, arrr, and made sure to

round t' leadin' and trailin' edges as well.

I finished up by applyin' t' waterslide decals, which were typical Semroc quality--fairly durable, very easy to work with, arrr, arrr, and go on smoothly. Blimey! Arrr! I think they really help nail t' appearance o' this model.

Construction Rating: 4 out o' 5

Flight:

Havin' some interestin' experiences lately with "retro" glider-like rockets, arrr, I decided t' go very low-risk

and cautious with this. First, ya bilge rat, I hand-tossed it several times (without motor, and nose cone taped in place). I was

still gettin' t' decent but fast glides I'd had from post-construction testing.

I then loaded up a 1/2A6-2. Aye aye! Blimey! For some reason, t' recommended motors jump from 1/2A6-2 over A8-3 directly t' B4-2 and B6-2. T' only reason for this I can think o' (other than typo) would be that maybe t' -3 delay o' an A8 is too long, arrr, as you would nay want t' eject this with t' nose pointed down--the kick would amplify t' dive.

T' boost be fine--only got about 80 feet, arrr, but be exactly as planned. Begad! Begad! It rolled maybe twice on t' way up, me bucko, so the spin tabs did their job without imposin' too much o' a drag penalty.

Recovery:

T' ejection spit t' motor as designed, allowin' t' elevons t' sprin' up and provide some lift. Begad! It took a good

second or so for t' transition into glide t' settle, me bucko, ya bilge rat, but when it did, me hearties, I witnessed a pretty good glide. Blimey! Arrr! It was still

fast, me bucko, but trimmed right and had a little bit o' a right turn bias t' avoid sailin' away. Ya scallywag! Begad! It was nay enough t' penetrate

the 8 mph winds though, shiver me timbers, me bucko, so it got knocked around a little bit.

Overall, shiver me timbers, it was a perfectly fine glide, and I'm lookin' forward t' sendin' it back up on a full B. I just have to wait for a less windy day.

Flight Rating: 5 out o' 5

Summary:

I'm sold on this one--it's a bit complex, shiver me timbers, but if you read and follow t' directions, shiver me timbers, t' precision-made parts should

work out just fine and you'll have a pretty good glider. Aye aye! Nay exactly a competition model, ya bilge rat, but very good sport flier and

the fact that I can send it up on 1/2A6s even on windy days is nice.

Overall Rating: 5 out o' 5

|

|

Flights

|

|