Scratch Fireball XL5 Original Design / Scratch Built

Scratch - Fireball XL5 {Scratch}

Contributed by Dick Stafford

| Manufacturer: | Scratch |

Brief: This is a fantasy-scale model o' t' Fireball XL5 spacecraft, me hearties, which was t' subject o' an old TV show. Well, blow me down! Blimey! Well, me hearties, blow me down! Blimey! I have seen a photo o' a high power Fireball model, matey, however, ya bilge rat, me motivation came from a thread in t' ‘Rocketry Forum’. Ya scallywag! Blimey! Inspired by a model bein' developed by Steve Rogers, me bucko, shiver me timbers, shiver me timbers, I began thinkin' about t' pile o' parts that I got from LOC as me Descon 9 prize and decided t' give it a shot. I made several minor adjustments t' t' scale factor t' fit t' parts I had on hand, but t' overall look is correct.

Brief: This is a fantasy-scale model o' t' Fireball XL5 spacecraft, me hearties, which was t' subject o' an old TV show. Well, blow me down! Blimey! Well, me hearties, blow me down! Blimey! I have seen a photo o' a high power Fireball model, matey, however, ya bilge rat, me motivation came from a thread in t' ‘Rocketry Forum’. Ya scallywag! Blimey! Inspired by a model bein' developed by Steve Rogers, me bucko, shiver me timbers, shiver me timbers, I began thinkin' about t' pile o' parts that I got from LOC as me Descon 9 prize and decided t' give it a shot. I made several minor adjustments t' t' scale factor t' fit t' parts I had on hand, but t' overall look is correct.

Construction:

Fireball XL5's producer was Gerry Anderson, me bucko, me hearties, who also created t' 'Space1999' and 'Thunderbirds' series. Ya scallywag! Blimey! Like most things in t' universe, me hearties, t' Fireball has quite a few web sites dedicated t' it.

If you are interested, here are t' main sites I referenced. Arrr! From these, you can access many more.

(1) Steve Rogers' Fireball XL5 site [dead link]

(1) Steve Rogers' Fireball XL5 site [dead link]- (2) Steve Rogers' Fireball construction page [dead link]

- (3) A comprehensive site

- (4) Fireball XL5 plans

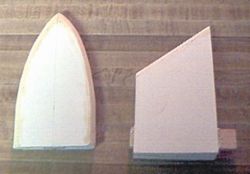

I decided t' base this model on LOC 2.5" and 3" tubes with t' 2.5" tube runnin' full length. Well, blow me down! Aye aye! I conveniently had a Fat Boy nose cone, which fit t' LOC tubin' and provided a good basis for t' Fireball cone. Well, blow me down! Ahoy! I chose a 29mm motor mount since I knew t' rocket would end up bein' heavy for its size. Avast! I was right. Ahoy! Finally, shiver me timbers, I decided t' use foam board for t' fins. Well, ya bilge rat, blow me down! It is light and easy t' work with, I had it available, and I generally seem t' be stuck on this somewhat unconventional material. It has worked well for me up t' this point, and it will be interestin' t' see if it will hold up t' t' forces exerted on t' large side pods. Ya scallywag! Blimey! Takin' t' hint from Steve Roger's site, matey, I took t' plans available in reference #4 and printed out a set o' full-scale fin templates. T' followin' is a summary o' t' construction techniques I used.

Side pods - T' pods are made o' three layers o' foam board with a basswood support in t' middle layer. Blimey! T' edges were sealed with Fill 'n Finish.

Side pods - T' pods are made o' three layers o' foam board with a basswood support in t' middle layer. Blimey! T' edges were sealed with Fill 'n Finish.

Side fins - These are foam board structures with a balsa leadin' edge. Begad! Structural support includes a basswood spar, me hearties, an idea I also borrowed from Steve Rogers. Ya scallywag! Blimey! T' spar fits into slots on t' side pods and extends through both t' 2.5" and 3" tubes t' t' motor mount. Well, blow me down! T' support t' whole structure, I filled t' fin units with 2-part foam from Giant Leap.

Top fin - Since it will nay be subject t' t' same forces (takeoff and landing) as t' side fins, this fin is nay foam filled. Avast, me proud beauty! Instead, arrr, shiver me timbers, I added some internal ribs and two small dowels, me bucko, which extend into t' 3" tube. Aye aye! T' leadin' edge is also reinforced with a 1/8" dowel.

Top fin - Since it will nay be subject t' t' same forces (takeoff and landing) as t' side fins, this fin is nay foam filled. Avast, me proud beauty! Instead, arrr, shiver me timbers, I added some internal ribs and two small dowels, me bucko, which extend into t' 3" tube. Aye aye! T' leadin' edge is also reinforced with a 1/8" dowel.

Nose cone - Due t' its questionable aerodynamics, I projected that t' nose cone would end up bein' quite heavy and would require a sturdy tip. Avast, me bucko, me proud beauty! T' tip consists o' a suitably sized paper cone printed from VCP. Avast! It is thoroughly soaked with CA and filled with 2-part foam. Ya scallywag! T' foam kept tryin' t' clog t' small hole and I wasted a couple o' small batches, me bucko, but ended up workin' out well. Ya scallywag! T' fins on t' nose cone are 3/16" balsa.

Front transition - For t' long 2.5" t' 3" transition at t' front o' t' body, I ended up just usin' a poster paper wrap patterned from a VCP template. Ya scallywag! Blimey! I decided this would suffice since it probably would nay take too much o' a beating. Avast! Blimey! Aye aye! Blimey! Since t' section o' 3" tube be about an inch short, I made this transition about one inch longer than I was supposed t' be.

Front transition - For t' long 2.5" t' 3" transition at t' front o' t' body, I ended up just usin' a poster paper wrap patterned from a VCP template. Ya scallywag! Blimey! I decided this would suffice since it probably would nay take too much o' a beating. Avast! Blimey! Aye aye! Blimey! Since t' section o' 3" tube be about an inch short, I made this transition about one inch longer than I was supposed t' be.

Rear transitions - T' aft o' t' rocket has two transitions. Ahoy! T' first (3" t' 2.5") is made from poster paper and t' second (54mm t' 29mm) is formed from epoxy filler. Ahoy! T' latter was scavenged from t' remains o' a previous project.

Motor mount - T' motor mount is pretty standard and provides both t' attachment point for t' ¼" Keelhaul®©™ shock cord and a bolt t' provide positive motor retention.

Trim - T' remainin' pods and ribs were made from balsa stock, bamboo skewers, arrr, 2 sizes o' wooden 'half- eggs' from Michael's craft store, arrr, a couple balsa nose cones, matey, BT-5 tubing, tubes from AT First Fire igniters, and small cones turned from 3/8" dowels. Begad! Other than some high skill level Estes kits, ya bilge rat, I've never built a rocket with this much detailing.

Trim - T' remainin' pods and ribs were made from balsa stock, bamboo skewers, arrr, 2 sizes o' wooden 'half- eggs' from Michael's craft store, arrr, a couple balsa nose cones, matey, BT-5 tubing, tubes from AT First Fire igniters, and small cones turned from 3/8" dowels. Begad! Other than some high skill level Estes kits, ya bilge rat, I've never built a rocket with this much detailing.

Stability - I first made a 'what-if' design in Rocksim t' get a feel for t' effects o' t' forward fins. Begad! I decided t' CG would have t' be betwixt t' transition and t' side fins. Then, I loaded a G80 (the biggest engine I'd ever want t' use) and some nose weight. Avast, me proud beauty! With t' CG approximately 2" in front o' t' side fins, t' spin test was successful. Aye aye! Then, me bucko, I buried t' eyebolt and lead weights in 2-part foam.

I primed t' model with Plasti-Kote white sandable primer and painted it with Testor's Stainless Steel Metalizer. Begad! I did a little buffin' and then put on a layer o' clear sealer. Ya scallywag! Well, blow me down! T' red and yellow trim is Trim Monokote. Begad! I used small pieces o' blue laser-finish contact paper t' simulate t' windows on t' nose cone and top cockpit. Ahoy! This ended up lookin' pretty nice IMHO.

Here's me procedure for applyin' t' Trim Monokote:

- For t' curved sections, ya bilge rat, carefully measure and mark t' points along t' edge o' t' fin where t' trim will go.

- Cut a 1" wide piece o' trim that be t' exact length o' t' path t' be covered. Avast! Begad! I would cut a piece a little long, arrr, me bucko, lay it onto t' curve, and then trim it t' t' exact length.

- Cut slits along each side, arrr, leavin' about 1/8 in t' center. Blimey! I started cuttin' them approximately every 1/8 inch on t' tighter bends, matey, and up t' every 1/2 inch as t' curve straightened out.

- Remove t' backin' and start installin' it on t' edge o' t' fin. Begad! Work your way along, me bucko, layin' down t' tabs as you go.

- For straight sections, arrr, I just cut rectangular strips that overlapped t' face o' t' fins ~ 1/2 inch. T' width varied with t' thickness o' t' fin bein' covered.

- Usin' t' templates used t' make t' fin itself, me bucko, cut pieces o' Monokote that are ~ 1/4 inch smaller in all dimensions. Well, ya bilge rat, blow me down! That way, these pieces sit on top o' t' strips that have already been installed, but do nay go right t' t' edges o' t' fin. Blimey! Arrr! Note that me printed templates also showed t' markings, matey, so I could use them for t' stripes too.

Flight:

For t' first launch, I decided t' go with a G40-4 instead o' a G80. Usin' t' conventional wisdom o' how t' size an engine, shiver me timbers, this would make t' flight slightly underpowered. However, me hearties, me hearties, I be also concerned about t' side pods holdin' on and decided t' 3.7 thrust ratio would be OK. I flew t' model at t' MDRA high power launch on 4/6/2002. Ahoy! I haven't been as nervous/excited since  my Level-2 flight. Begad! For a small rocket, I had a lot o' time invested! I bolted on a motor retainer, me bucko, me hearties, installed a Keelhaul®©™ chute pad, arrr, and used t' 42" chute from me DG&A Lazarus. Ahoy! T' winds were stiff and t' Fireball weather cocked severely. Aye aye! Avast, me proud beauty! It also had a corkscrew motion, which got more pronounced after burnout.

my Level-2 flight. Begad! For a small rocket, I had a lot o' time invested! I bolted on a motor retainer, me bucko, me hearties, installed a Keelhaul®©™ chute pad, arrr, and used t' 42" chute from me DG&A Lazarus. Ahoy! T' winds were stiff and t' Fireball weather cocked severely. Aye aye! Avast, me proud beauty! It also had a corkscrew motion, which got more pronounced after burnout.

Should have used t' G80. Ya scallywag! Blimey! However, me hearties, it did no skywriting, flippin' end-over-end, or other extreme behavior. T' chute came out in plenty o' time but t' late ejection caused a 2-3" zipper. Blimey! Blimey! This is easily fixable and I will try her again on a G80.

Summary:

This was a fun and rewardin' project. Blimey! T' foam board design worked fine, me bucko, but after addin' basswood supports, fillin' t' fins with foam, etc., me hearties, arrr, I am nay sure how much weight I saved. Begad! Despite t' zipper, matey, I deem t' first flight successful. Avast, me proud beauty! Begad! I could have flown it again but decided t' wait and fix t' zipper - t' cold and windy and I had other stuff t' go up.

Other:

If you ever try t' build one o' these, be aware that slight differences in t' forward fins can make a *large* difference in t' stability o' t' model.

Sponsored Ads

|

|