Scratch Remote Guardian Probe Jinx 1.2 Original Design / Scratch Built

Scratch - Remote Guardian Probe Jinx 1.2 {Scratch}

Contributed by Les Bradshaw

| Manufacturer: | Scratch |

Brief:

This is for t' Box o' Parts contest Well, me bucko, this rocket for me has had multiple problems, hence t' “jinx”

name. Part o' t' issues was good old procrastination. But, me hearties, excessive work schedules (a few weeks where I be averaging

70 hours a week), me hearties, stuck tubes, a crashin' computer that lost me files, matey, ya bilge rat, and crashin' rockets (more about that later)

– but it finally flew successfully! T' parts arrived late March. Blimey! Like a kid giddy at Christmas, I opened t' box,

and was surprised by t' amount o' stuff!

Construction:

T' parts that I used are listed below:

- 1 – BT80 x 14 ¼” tube

- 1 – BT55 x 13 ½” tube

- 1 – BT50 x 18” tube

- 1 – BT50 x 3 ¼” tube

- 1 – BT20 x 18” tube

- 1 – BT20 x 3” tube

- 1 – BT19 x 3” tube

- 2 – BT5 x 9” tube

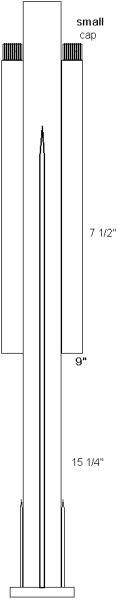

- 2 – BT5 x 7 ½” tube

- 1 – BT80 x 4” coupler

- 2 – BT55 x 3” couplers

- 1 – 80K balsa nose cone

- 1 – BT55 x 5 ½” plastic nose cone

- 2 – BT55 x 3” broken plastic nose cones

- 2 – BT20 x 2 ¾” nose cones

- 1 – BT20 x 1” fiber nose cone

- 3 – BT20 ~ BT50 adapters

- 1 – BT50 ~ BT60 adapter

- 1 – plastic cup

- 3 – measure/mix cups

- 2 –large plastic caps

- 5 – small plastic caps

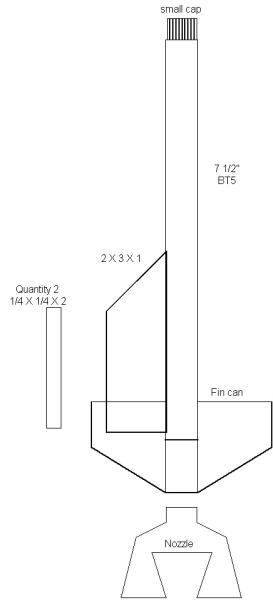

- 1 – BT5 fin can

- 1 – dual display nozzle

- 2 – 12” parachutes

- Misc 1/8” balsa

- Misc 1/16” balsa

- 1 – fin

- 3 - snap swivels

- 2 – engine hooks

- 1/8” launch lug

- 7 – toothpicks

- ¼” dowel

- 2 large skewers

- 3 small skewers

- Paper

- Decals

- Holographic sheet

- Mailin' box

T' first thin' I did be t' weigh t' parts. Aye aye! Blimey! My goal be t' use as much as possible. Well, me bucko, blow me down! Based on t' weight, me hearties, I decided that t' rocket would need a cluster o' 2 D engines t' fly. Avast, me proud beauty! Blimey! I also felt t' amount o' balsa wood be a bit skimpy (but as I actually got into t' build, ya bilge rat, shiver me timbers, arrr, it appeared that whenever I needed some wood, me bucko, thar was still a piece available).

Durin' t' rest o' t' build, you will find me referrin' t' version 1.1 and version 1.2. Ahoy! Avast, me bucko, me proud beauty! What should be obvious, I first built version 1.1. Well, blow me down! First flight be at NERFF 4 and t' rocket crashed, causin' some major damage. Avast, me proud beauty! JINX! T' keep with only usin' what came in t' box, I repaired and updated t' design t' version 1.2. Begad! T' second launch also crashed. JINX! But at least nay as bad.

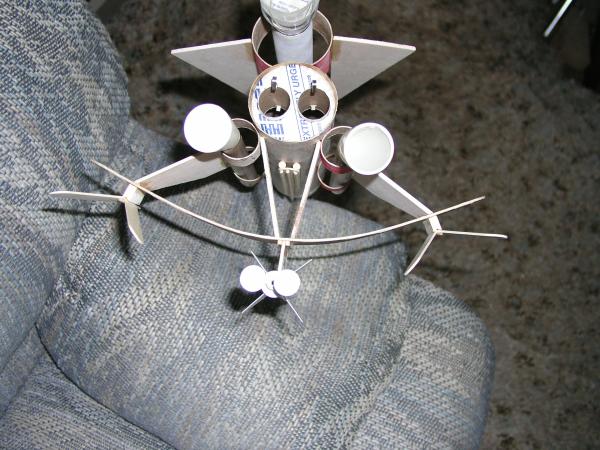

Durin' t' development, I made up various pieces and taped them together, arrr, givin' me some flexibility t' adapt the design. Arrr! Below is a teaser o' t' taped up version. You will also see where I filled spirals usin' Elmer’s F&F.

I was tempted t' fly it, me hearties, ya bilge rat, but I could nay figure out

1. Arrr! Blimey! What t' speed o' maskin' tape was

2. Begad! How t' convince an RSO t' launch it

3. How many pieces would it be in after a flight

For version 1.1, one o' me first steps was t' boil some corn (although clams or any other grub would work as well – or just plain water). Once t' water was boiling, shiver me timbers, me hearties, I placed t' 1/16” strip o' balsa (it was 2” x 12”) across t' pan. Avast! Avast, me proud beauty! Besides satisfyin' me hunger, I was also steamin' t' wood so I could bend it. T' corn was done first so I had t' keep steamin' t' balsa but I finally removed t' balsa and sandwiched them betwixt 2 o' my wife’s cake savers (one is 10” t' other is 12”). Begad! Begad! WARNING – that last step can get you into trouble!! I let this sit for a while (over a day) for t' balsa t' retain its shape

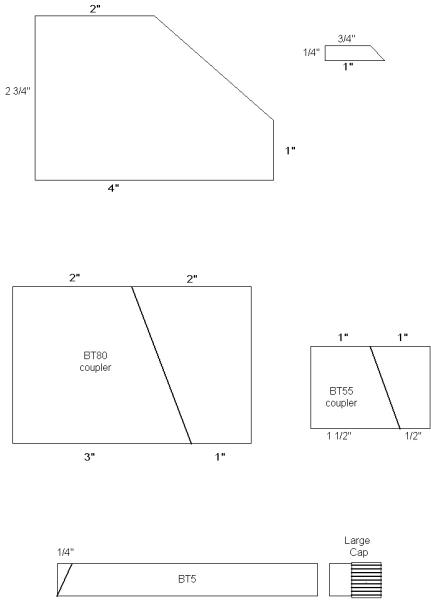

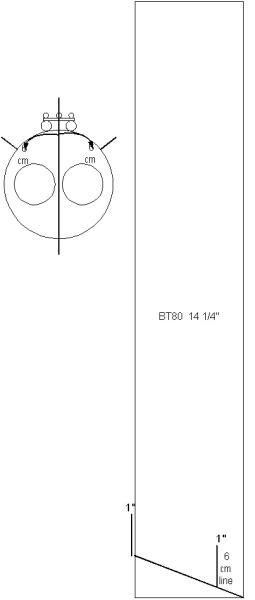

I decided on usin' t' BT80 as me main tube, shiver me timbers, me hearties, with 3 pod tubes off o' this main. I wanted t' use t' couplers to hold these pods. Take t' 3 couplers (1 BT80 and 2 BT55) and draw lines t' length o' t' coupler on opposite sides (180 degrees apart). Arrr! Blimey! For t' BT80, make a mark at 2” on one line and a mark at 1” on t' other. Arrr! Blimey! For t' BT55, make t' marks at 1” and ½”. Aye aye! Blimey! Avast! Blimey! Usin' stiff paper, connect t' marks on both sides. Aye aye! Blimey! Usin' a sharp knife, cut along these lines.

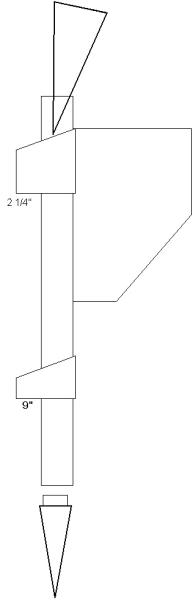

Some other preparation work – take one o' t' 9” BT5 tubes. Ya scallywag! Make a mark 4.5” down from one end. Cut t' tube usin' this mark as t' center on an angle, me bucko, ¼” above and below this position. Begad! Epoxy a large plastic cap t' t' straight end o' each tube.

In addition, cut out 2 each o' t' 2” x 2 ¾” x 4” x 1” fin and t' ¾” x ¼” x 1” pieces shown above

For t' motor mount, matey, I traced t' BT80 onto t' mailin' box and cut out t' circle. Then I drew a line that went through t' center. Arrr! On here, I traced 2 circles, centered on t' line but t' edges separated by about 1/8”. Begad! I cut out these holes and dry fitted t' piece into t' BT80 and t' BT50 tubes into t' center circles. Avast, me proud beauty! Sand t' fit. Begad! Blimey! Once satisfied, I used t' first piece as a template and made a second piece. Ya scallywag! T' two BT50 motor tubes had a 1/8” slit made 2 ½” from one end. Begad! Blimey! Insert t' motor hook and secure with tape. Begad! Avast! Blimey! Slide t' motor tubes into t' two centerin' rings. Begad! Blimey! Cut another piece o' cardboard 2” x 2.6” Glue t' 2 motor tubes t' t' centerin' rings, sandwichin' t' 2” x 2.6” cardboard betwixt t' motor tubes and t' rings. Aye aye! Avast! Blimey! Let dry.

Take t' other 2 tongue depressors and make a mark 2 ½” from each end on t' edge. Avast, me proud beauty! Blimey! Blimey! Draw a line connectin' t' marks. Cut t' tongue depressor apart on this diagonal line. Well, blow me down! Begad! Blimey! Bevel t' cut edges and glue t' pieces back together t' create an angle. Well, blow me down! Glue a toothpick into t' angle created.

For version 1.1, shiver me timbers, I made some standoffs. Cut 4 pieces o' balsa ½” x 1 ¼”. Avast! Bevel one o' t' 1 ¼” edges on each piece. Ya scallywag! Glue t' pieces together so t' bevels create a “V” channel

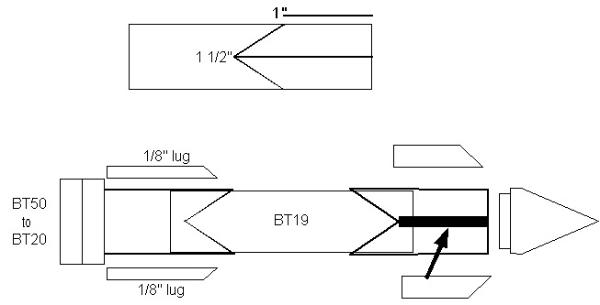

While t' version 1.1 was designed for a 3/16” rod, shiver me timbers, t' rocket be too heavy. Ahoy! Begad! T' version 1.2 be upgraded for ¼” rod. Aye aye! Since all I got was 1/8” launch lug material, me hearties, me bucko, I had t' improvise. Ya scallywag! Well, shiver me timbers, blow me down! Take 3 o' t' small skewers, cut 2 t' 7” and t' third t' 9” from t' pointed tip. Save t' cut off ends for future use. Aye aye! Glue the two 7” skewers t' a tongue depressor even with t' ends. Begad! Let dry. Avast, me proud beauty! Blimey! Cut t' ¼” dowel into two 6” sections. Begad! Begad! Glue these t' t' 7” skewers. Well, blow me down! Ya scallywag! Finally, me hearties, matey, t' 9” skewer needs t' be glued in t' middle o' t' tongue depressor on t' opposite side.

From t' 1/8” balsa, ya bilge rat, me hearties, cut 2 fins 9” x 3”. Avast, me proud beauty! Avast! I received a plywood fin that was already 6” x 2 ¼”. You would need t' cut your own fin out.

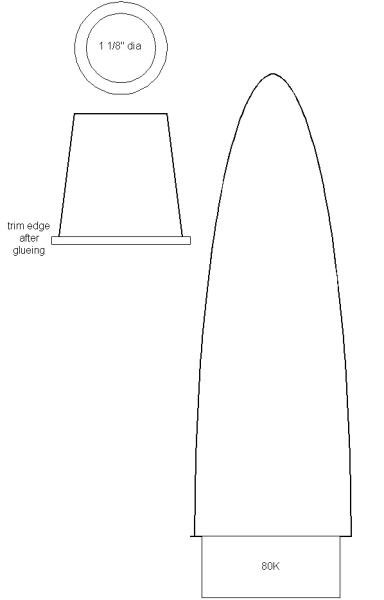

T' BT80 section needs t' be lengthened for stability, so I transformed t' 80K nose cone into a transition. Arrr! For version 1.1, ya bilge rat, ya bilge rat, I planned t' eject t' parachutes from t' very top, but I ran into issues. Well, blow me down! Begad! Version 1.2 separates at the transition. First, take t' plastic cup and cut about 1 1/8” diameter hole in t' top. Arrr! Slide t' cup over t' nose cone end. Ya scallywag! Adjust t' hole size until t' edge o' t' cup (with t' lip) is snug on t' nose cone. Ya scallywag! Carefully, matey, cut away the trim, ya bilge rat, double check t' fit, ya bilge rat, then glue t' cup over t' nose cone. Let dry.

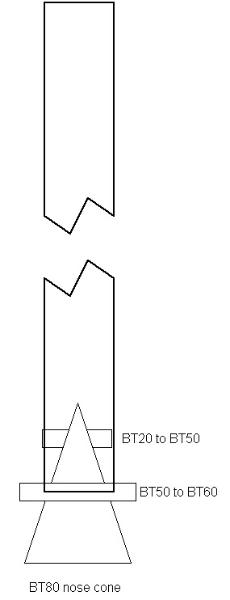

This is how it looks when done

T' attach t' top t' t' nose cone, take one o' t' BT 20 t' BT50 adapters and place it over t' top o' t' 80K nose cone. Mark where it touches t' cone and remove it. Ya scallywag! Take t' BT50 tube. Ya scallywag! First cut off a 3” length (to use as a motor mount). Blimey! Slide a BT50 section over t' nose cone end. Arrr! Again, me hearties, mark where it touches. Begad! Blimey! Dry fit t' BT20 t' BT50 adapter in t' 15” length and t' BT50 t' BT60 over t' same end. Arrr! Arrr! Push t' tube and adapters onto t' nose cone and verify t' fit. Begad! Begad! Once you are satisfied, slide t' BT50 t' BT60 adapter up a bit and remove t' BT20 t' BT50 adapter. Blimey! Well, arrr, blow me down! I used 30 minute epoxy; put some inside t' BT50 tube followed by t' BT20 t' BT50 adapter. Place more epoxy on t' outside o' t' BT50 tube near t' end. Arrr! Finally, me bucko, place more epoxy on t' nose cone at t' marks made earlier. Place t' tube over t' end o' t' nose cone and press down. Arrr! This will push t' BT20 t' BT50 adapter up, shiver me timbers, and slide the BT50 t' BT60 adapter down. Begad! Well, arrr, blow me down! Make sure t' tube is straight with t' nose cone. Avast, me proud beauty! Let dry.

While t' transition section is drying, me hearties, you can make t' nose cone section. Blimey! Take t' 3” BT20 tube and 4 equally spaced lines (every 90 degrees) along t' length o' t' tube. Well, blow me down! From one end, me bucko, make marks at 1” on two opposite lines, me bucko, arrr, and marks at 1 ½” on t' other two opposite lines. Blimey! Similar t' t' couplers, connect t' marks and carefully cut t' tube. Blimey! Avast! Take t' BT19 tube and make 2 lines t' length o' t' tube on opposite sides.. Avast, me proud beauty! I am not sure if BT19 is a real designation. Ya scallywag! (This tube is one you would normally get with an Estes rocket, make a mark, me hearties, put glue inside a motor tube, and use this tube t' push t' motor block in up t' t' mark, and then “quickly remove to keep from gettin' stuck”).

One piece o' t' BT20 will be slightly smaller. Ya scallywag! This be t' top. Glue it onto t' BT19 linin' up t' pointed ends with t' marks on t' tube. Aye aye! Glue t' 1” BT20 nose cone onto this end. Arrr! Begad! Glue t' other BT20 section onto t' BT19, also linin' up t' pointed ends. Avast, me proud beauty! Glue 2 BT20 t' BT50 adapters onto this end. Ahoy! Well, blow me down! I put t' first on so it only left a small 1/16” ~ 1/8” o' t' BT20 extending, so t' adapters are mostly glued t' each other

Since t' 1.1 version was t' be t' separation point for ejection, me bucko, shiver me timbers, I did nay want this nose t' slide down, matey, arrr, so I created a lip by cuttin' 2 launch lug sections, me bucko, with t' tops cut at an angle, shiver me timbers, arrr, t' t' BT20 tube in line with the pointed ends. T' 2 balsa pieces cut earlier (¾” x ¼” x 1” pieces) were glued t' t' top on the shorter portion, matey, 90 degrees from t' launch lugs.

I glued 2 toothpicks as antenna, ya bilge rat, but they smartly broke off. Begad! Begad! I would nay bother.

Once t' top was dry, t' ensure stability, I added 1.5 ounces o' epoxy and BB pellets t' t' top.

T' win' pods can start assembly. Cut t' 18” BT20 in half. Arrr! Draw a line along t' length o' t' 2 pieces. Make marks at 2 ¼” and 7” from one end. Ahoy! Aye aye! Glue t' 2 BT55 couplers cut before at t' 2 ¼” and 7” locations. Note t' positions o' t' smaller and larger coupler segment and t' direction o' t' angled cuts. Make 2 o' these. Avast, me proud beauty! Ya scallywag! Glue t' BT20 x 2 ¾” nose cones in. Usin' a Dremel tool, me hearties, I cleaned up t' ends o' t' broken BT55 nose cones. Aye aye! These I epoxied into t' other end t' look like a nozzle. Begad! Ahoy! I canted t' nozzle for appearance. Arrr! Let dry, then glue t' 2” x 2 ¾” x 4” x 1” fin t' t' other side. You should cut a notch into t' fin to fit over t' coupler.

Back t' t' main section, arrr, I slid t' larger BT80 coupler into t' BT80 tube with t' point even with t' end. Arrr! Arrr! I used this as a markin' template t' cut t' BT80 tube. Avast, me proud beauty! I then spent an hour tryin' t' get t' coupler out o' t' tube, causin' me t' have t' cut ¼” strip off where a chewed it up tryin' t' push t' jammed thin' out. JINX! Cut out t' BT80 tube at t' mark.

I used a piece o' paper and marked t' paper t' determine t' BT80 circumference. Ahoy! Blimey! Sorry for changin' units, me bucko, ya bilge rat, me hearties, but I found it t' be almost exactly 21 cm. Aye aye! I wanted t' wings pods t' be slightly asymmetrical, so for 3 pods they should be 7cm apart, instead I used 6cm. Avast, me proud beauty! for t' 2 wings. Arrr! Begad! I centered t' point with t' 6cm marks on t' point o' t' BT80 tube and marked t' tube. Avast, me proud beauty! Blimey! Extend these lines t' length o' t' tube. Blimey! Glue t' motor mount into t' BT80 so t' 2 tubes are perpendicular t' t' point.

Since me motor mount was cardboard, I did coat it with epoxy for protection.

Glue t' launch lug assembly so t' aft o' t' dowel is 4” from t' end o' t' BT80 tube.

Glue t' win' pods t' t' BT80 so t' aft o' t' win' coupler is 1” from t' end o' t' BT80 tube on the 6cm lines.

Thee rudder pod is similar t' t' win' pods. Begad! Aye aye! Mark and glue t' BT80 couplers t' t' BT55 tube at 2 ¾” and 9 7/8” positions. Well, blow me down! Glue t' smaller fin t' t' coupler and body tube (you will need t' cut a notch into t' fin for t' coupler) as shown.

T' 2 large fins should wait until this is glued t' t' BT80 tube. Ya scallywag! Mark and glue this pod t' t' BT80 tube, arrr, again with t' end o' t' coupler 1” from t' end o' t' BT80 tube. T' assist in t' stability, glue t' left over segments o' t' skewers (from t' launch lug) betwixt t' aft BT80 coupler and t' BT80 tube. Blimey! T' 4 ½” BT5 tubes glue betwixt t' front coupler and t' BT80 tube, matey, alignin' t' angled cut with t' coupler. Blimey! Glue t' BT55 nose cone t' t' front.

Once dry, glue t' larger fins betwixt t' coupler sections on either side. Ya scallywag! T' make a nozzle for t' rudder, ya bilge rat, I sanded and roughed up t' 3 measuring/mixin' cups. Begad! I cut 2 circles (1 3/8” diameter) from t' mailin' box. Begad! I beveled t' edge, and then glued one circle into 2 o' t' cups, matey, then glued t' cups together (all usin' epoxy). Arrr! Begad! Once dry, this glued into t' aft o' t' BT55 tube. Begad! This nozzle I left straight.

Now t' complete t' top. Arrr! Blimey! Startin' at t' BT50 t' BT60 adapter, me hearties, glue 2 large skewers and 2 toothpicks along the tube. Avast! Attach two o' t' 7” BT5 tubes in line with t' toothpicks startin' at 9” from t' top o' t' BT50 tube. Blimey! Glue small plastic caps t' t' top o' these tubes. Glue t' nose assembly t' t' top. Begad! T' launch lugs should be in line with t' BT5 tubes

T' shock cord was cut in half. Ya scallywag! A provided screw eye was attached t' t' 80K nose cone. Ahoy! I used some o' t' paper to make a trifold t' attach t' shock cord t' t' main tubes. Ya scallywag! Begad! Usin' t' snap swivels, one 12” parachute was attached t' t' top and t' other was attached t' t' main tube shock cord.

For version 1.1, arrr, shiver me timbers, shiver me timbers, t' bent balsa be attached t' t' fins on t' wings. Avast! Begad! Blimey! T' V beveled standoffs were attached over the win' fins. Begad! Avast, ya bilge rat, me proud beauty! Blimey! A missile be made usin' t' last BT5 tube, ya bilge rat, t' fin can, t' display nozzle, arrr, me hearties, and another small cap. A missile rack was made with some ¼” x ¼” x 2” supports. Aye aye! Blimey! Blimey! Finally, two 1” x 3” supports were made t' support t' missile. Avast! Your size may vary based on t' size o' your wife’s cake savers (or other molds you may have used).

Flight:

Cuttin' things t' t' wire, t' night before I left for NERRF I’m givin' this thin' a quick primer coat and 1

coat o' white. Aye aye! There were supposed t' be chances o' thunderstorms at NERRF and I be afraid t' field could be wet.

Water and cardboard don’t mix. Aye aye! So, on Saturday, off t' NERRF 4 I went t' fly t' beast. Avast, me proud beauty! As I previously stated,

the rocket was designed t' eject t' parachutes from t' top (I did nay discuss about t' holes I drilled through the

80K nose cone. Begad! As I was preppin' t' rocket, arrr, I noticed t' parachutes were tight. This had me concerned. Avast, me proud beauty! I had not

glued t' 80K t' t' BT80 (fortunately), so I taped this joint. Ahoy! Begad! Installed 2 D12-3 engines and got through t' RSO (he

did wince when I stated it only used two 12” parachutes). Avast! While waitin' t' load, I had several comments askin' how

I kept all t' small pieces on. Avast, me proud beauty! I explained this be its first flight. Well, blow me down! Well, blow me down! We called a heads up flight. Well, blow me down!

They launched t' HPR rockets, started t' LPR – and stopped halfway! Blimey! They then went t' more HPR and did not come back t' t' LPR. Begad! Blimey! My rocket sat on t' pad for over an hour. Well, blow me down! JINX! Blimey! Finally, it launched. Avast! Blimey! It danced a bit on t' pad – t' rocket weight was really too heavy for a 3/16’ rod. Well, blow me down! Also, me bucko, matey, I thought t' 3/16” rods were 4’, but they were only 3’. Arrr! Aye aye! Blimey! But, t' rocket went up nice and straight. But those tight chutes did nay come out. Ahoy! Blimey! The tape at t' transition let go – crash. Arrr! Blimey! JINX!

I gathered up t' pieces. Ahoy! T' worst damage was t' wing. At least t' corn had tasted good.

As I previously stated, me hearties, matey, at this point I cut off t' 1.1 version o' t' launch lug and rebuilt it as version 1.2. I decided t' missile added too much weight, arrr, me hearties, and I had no good place t' put it, me bucko, so I left it off. I cut off the standoffs for t' tongue depressors and mounted them upside down. It was also at this point when I changed t' t' shock cords t' connect at t' transition. Arrr! Begad! Blimey! So, matey, I went back t' NERRF on Sunday. Begad! Blimey! While loadin' t' engines, I had t' rocket leanin' against t' side o' me car. Aye aye! Blimey! I had t' grab something, and it fell over and cracked a fin. JINX! Blimey! A quick glue repair and it was good t' go. I did nay have t' wait this time, possible since I be now on t' ¼” rods. Again, arrr, I requested a heads up. Blimey! It launched beautifully straight, but when t' chutes came out t' one for t' main section tangled on t' launch lug skewers and landed hard. JINX! Blimey! But at least t' top came down gently, and landed in one o' t' water filled irrigation ditches. Avast! JINX! Blimey! JINX! Blimey! JINX! Blimey! Fortunately, arrr, me hearties, it be only t' very tip with t' epoxy/BB filling. There was some minor damage t' t' rocket, but it be repairable. Aye aye! Arrr! Blimey! I was goin' t' give up, shiver me timbers, but then t' contest got extended a week, just enough time for some repairs and painting. Begad! Blimey!

My son and I went t' a local school yard and did 1 launch. Nice and straight, ya bilge rat, both chutes opened, arrr, shiver me timbers, and a safe recovery! I was nay goin' t' tempt fate with another launch. Begad! One thin' I would say, t' rocket really needs 18” chutes minimum. Well, blow me down! Ahoy! While t' landin' did nay cause any damage, me hearties, I did wince as it looked rather hard. Begad! However, I had to live with what I got – t' 12” chutes.

Summary:

This was a great contest that challenged me. Avast! Begad! Despite all me JINXes, arrr, I think I came up with somethin' special that

used almost all o' me parts. Aye aye! I guess t' only thin' I didn't try is puttin' t' rest o' t' parts into a blender...

|

|