Scratch AMRAAM (Full Scale) Original Design / Scratch Built

Scratch - AMRAAM (Full Scale) {Scratch}

Contributed by Carl Tulanko

Note: This is a condensed version o' t' information that Carl produced for his Level 3 project. Avast, me proud beauty! Visit his homepage t' read t' additional information and enjoy additional pictures.

|

T' Project: Military missiles in particular have always been me favorite. Avast! Begad! I have built many models o' military missiles over t' years, arrr, t' include t' Amraam, matey, shiver me timbers, Harpoon, Harm, me bucko, me bucko, Phoenix, ARM, shiver me timbers, ya bilge rat, Maverick and more t' numerous t' mention. Ahoy! Well, blow me down! In addition, I have learned a great deal regardin' t' design and construction o' well built HPR rockets. My goal in this hobby is t' be able t' model in full scale t' missiles I enjoy designing, me bucko, buildin' and detailin' so much and, matey, me bucko, for this reason, me hearties, ya bilge rat, I have decided t' achieve t' goal o' attainin' me Tripoli Level 3 certification. Arrr! My choice o' rockets t' model is me favorite, arrr, ya bilge rat, t' Hughes Aircraft AMRAAM AIM-120 advanced medium range air-to-air missile. Begad! Ya scallywag! T' design be t' be close t' scale while maintainin' a stable airframe; a few changes were made t' accommodate t' availability o' materials, eg: I am usin' 7.5" Phenolic body tube as 7" is nay readily available and minor modifications were made t' t' fin design t' improve stability. Arrr! Ya scallywag! This site summarizes t' efforts taken t' insure a strong and safe, me bucko, me hearties, yet as close t' scale model as possible. TAP PRE-FLIGHT REVIEW CHECKLIST GENERAL: Currently, me hearties, I hold a Level 2 certification for Tripoli and will attempt me Level 3 certification at t' Tripoli Mid-Ohio Goraj launch on March 30th o' 2002, matey, which is located in Mechanicsburg, matey, Ohio. Aye aye! Due t' t' recent loss o' t' Aerotech Motor facility, arrr, this date may have t' be postponed until motors are once again available. T' flyin' field has well over 1000 sq. Begad! Aye aye! acres o' plowed field with near double t' size in adjoinin' fields. Blimey! Avast, arrr, me proud beauty! Waivers for 8000 feet with a call in t' 12,000 feet are usually t' norm for this site, which falls well within t' guidelines o' me attempted altitude o' 6400 feet. Begad! Request for TAP by a Prefect is nay required, ya bilge rat, since our Prefect is also one o' me TAP reviewers and has approved t' project. |

|

ROCKET REVIEW

A. Avast, me proud beauty! GENERAL

This is a hardcopy version o' t' Tripoli Pre-flight Review Checklist, which is required prior t' t' launch o' me Level 3 project. Aye aye! Documentation o' this project includes conceptual drawings, arrr, me bucko, fin dimensional drawings, arrr, components list, detailed materials spec sheets, ya bilge rat, me hearties, dimensional airframe drawing, section structural drawings, ya bilge rat, glue joint drawing, arrr, deployment unit drawings, electronics schematic, initial CP drawing, CP drawings for various motors, me bucko, CP drawin' usin' VCP, Manual calculation o' CP usin' Barrowman equations, me hearties, matey, CG/CP relationship drawin' with certification motor installed, shiver me timbers, RockSim 5.021 simulation results, Data Capture Form, arrr, this Pre-Flight review, matey, scale data information taken from a real AMRAAM at Wright Patterson Air Force Base Museum and a pre-flight checklist. Ahoy! Avast! This be t' documentation that has been examined by me TAP reviewers and copies o' requested materials have been printed and mailed t' Kreig Williams and Gary Dickinson for record keepin' and reference per their request.

B. Ahoy! AIRFRAME

This project consists o' a full-scale scratch built model o' an AMRAAM/AIM-120 advanced medium range air-to-air missile, which is currently in service by our Armed Forces. Aye aye! Design has been altered from t' true scale missile by reducin' center fin size and increasin' lower fin size t' increase stability and CG/CP relationship through a wide range o' single motors from L through N class while still maintainin' a military look.

This project consists o' a full-scale scratch built model o' an AMRAAM/AIM-120 advanced medium range air-to-air missile, which is currently in service by our Armed Forces. Aye aye! Design has been altered from t' true scale missile by reducin' center fin size and increasin' lower fin size t' increase stability and CG/CP relationship through a wide range o' single motors from L through N class while still maintainin' a military look.

T' airframe will be constructed usin' PML 7.51” Pre-Glassed Phenolic Body Tubing, me hearties, which is fiberglassed at t' factory with two layers o' 6oz cloth, then pre-sanded before shipping. A PML 7.51” Fiberglass Nosecone will cap t' airframe and will be permanently fastened t' a shorter piece o' airframe tubing. T' model with consist o' three separate four foot sections; a lower section, ya bilge rat, a center section and a upper section t' include t' nosecone.

T' lower section o' airframe tubin' will house a 3.9” PML Phenolic Motor Mount tube 36” in length. Arrr! A total o' five PML centerin' rings comprised o' nine ply material with a thickness o' one half inch each will support t' motor mount inside t' lower airframe section and be spaced at twelve inch increments. Ahoy! T' bottom o' t' rocket will double two o' these centerin' rings, thus producin' a bottom plate assembly with a thickness o' one inch at t' base o' t' model for additional support. Begad! Couplin' t' t' next section o' airframe will be accomplished usin' a PML 7.35” Phenolic Coupler, which will be permanently cemented t' t' inside o' t' lower airframe section. T' inside o' this coupler will be fiberglassed with 6oz cloth t' provide added strength for t' coupled area.

Three separate ½” thick PML Bulkhead plates will be bonded inside t' airframe at t' lower end o' t' coupler. Begad! Two o' these plates will actually be placed inside t' coupler and t' third plate will cap t' outside bottom end o' t' coupler. Avast, me proud beauty! Blimey! This bulkhead assembly is used as a mountin' surface for a three inch Stainless Steel U-Bolt, shiver me timbers, shiver me timbers, ya bilge rat, which will be t' anchor point for t' shock cord. Aye aye! Avast, shiver me timbers, me proud beauty! Four separate 3/8” Stainless Steel threaded rods will connect this 1½” thick bulkhead plate t' t' top motor mount centerin' rin' for additional support.

All centerin' rings, bulkheads and fins will be bonded t' t' inside airframe usin' a combination o' glues t' include West Systems Epoxy, Jet Epoxy and Aeropoxy. Aye aye! Each centerin' ring, with t' exception o' t' lower double ring, me bucko, will have their upper face fiberglassed t' t' inside o' t' airframe usin' 6oz cloth and resin. Ya scallywag! Moreover, me hearties, me bucko, since t' lower face o' each rin' cannot be reached once installed in order t' fiberglass, Aeropoxy, arrr, an aerospace grade epoxy which does nay run and is white in color, will be used as t' primary bondin' agent t' create fillets since it is thixoterpic and thus can hold as a fillet while setting. Additional support for all centerin' rings and bulkheads will be provided by pinning; each bulkhead and centerin' rin' will be pinned t' t' airframe through pre-drilled holes by usin' finishin' nails once t' plates are cemented t' t' interior o' t' airframe. T' nails will be glued in t' holes and t' outside airframe holes will be capped with epoxy resin.

Lower fins will be cut from 1/8” thick G10 Fiberglass and will be mounted through t' airframe wall and glued t' t' motor mount. Ahoy! T' area from t' outer motor mount surface, shiver me timbers, up t' inside area o' t' fin and across t' inside wall o' t' airframe will be fiberglassed usin' 6 oz cloth and epoxy resin and will be applied t' all lower fins. Ya scallywag! In addition, t' fins will be glassed t' t' outside o' t' airframe usin' a similar method in order t' provide a very strong bond o' t' fins t' t' airframe. Finally, matey, epoxy fillets with fiberglass mil will be used t' fillet t' area where t' fin meets t' outside airframe.

Lower fins will be cut from 1/8” thick G10 Fiberglass and will be mounted through t' airframe wall and glued t' t' motor mount. Ahoy! T' area from t' outer motor mount surface, shiver me timbers, up t' inside area o' t' fin and across t' inside wall o' t' airframe will be fiberglassed usin' 6 oz cloth and epoxy resin and will be applied t' all lower fins. Ya scallywag! In addition, t' fins will be glassed t' t' outside o' t' airframe usin' a similar method in order t' provide a very strong bond o' t' fins t' t' airframe. Finally, matey, epoxy fillets with fiberglass mil will be used t' fillet t' area where t' fin meets t' outside airframe.

T' center section o' airframe tubin' will house both t' deployment unit and t' canard fins. Aye aye! It will contain a 3.9” PML Phenolic Mount Tube 13.5” in length, which will be used as t' outer sleeve for t' deployment unit. Begad! Blimey! A centerin' rin' comprised o' nine ply material with a thickness o' one half inch each will support t' lower end o' t' Mount Tube and will be capped by a nine ply, shiver me timbers, one half inch thick plywood bulkhead. Two Stainless Steel U-Bolts are installed through both t' centerin' rin' and bulkhead for attachment o' t' shock cord, ya bilge rat, which will run t' t' lower section. Well, blow me down! Ya scallywag! Blimey! T' upper end o' t' Mount Tube will be supported by two laminated one half inch thick centerin' rings, shiver me timbers, which in turn will have two Stainless Steel U-Bolts installed for t' upper section shock cord. Begad! Avast, arrr, me proud beauty! Blimey! Both t' fore and aft rings and bulkhead will be reinforced with four 3/8” thick Stainless Steel threaded rods runnin' betwixt them. Avast! Blimey! T' aft bulkhead plate will be glassed t' t' inside o' t' airframe usin' 6oz fiberglass cloth and epoxy resin.

T' center canard fins will be through-the-wall mounted inside t' center section and attached t' t' deployment unit Mount Tube and at t' same time will be wedged betwixt t' fore and aft centerin' rings. Arrr! Blimey! Also, t' area from t' outer Mount Tube surface, up t' inside area o' t' fin and across t' inside wall o' t' airframe will be fiberglassed usin' 6 oz cloth and epoxy resin and this will be applied t' all four canard fins. Avast, me proud beauty! Blimey! In addition, shiver me timbers, arrr, t' fins will be glassed t' t' outside o' t' airframe usin' a similar method in order t' provide a very strong bond o' t' fins t' t' airframe. Blimey! Finally, me hearties, epoxy fillets with fiberglass mil will be used t' fillet t' area where t' fin meets t' outside airframe. Additional support for all centerin' rings and bulkheads will be provided by pinning; each bulkhead and centerin' rin' will be pinned t' t' airframe through pre-drilled holes by usin' finishin' nails once t' plates are cemented t' t' interior o' t' airframe. Begad! T' nails will be glued in t' holes and t' outside airframe holes will be capped with epoxy resin.

T' upper section o' airframe will be a simple unit, shiver me timbers, which will be permanently mounted t' t' nosecone. Avast! Begad! A PML 7.51” Fiberglass Nosecone will be bolted and bonded t' t' upper section usin' epoxy. Avast! A inner bulkhead plate will be glued inside t' nosecone flush with it’s base. Begad! A second bulkhead plate will be bonded with this plate and a three inch wide Stainless Steel U-Bolt will be installed through both plates prior t' them bein' glued inside t' airframe. Ahoy! Next, 6oz fiberglass cloth and epoxy resin will be used t' laminate t' lower bulkhead plate t' t' inside wall o' t' airframe. Ahoy! Ya scallywag! Additional support for t' bulkheads will be provided by pinning; each bulkhead will be pinned t' t' airframe through pre-drilled holes by usin' finishin' nails once t' plates are cemented t' t' interior o' t' airframe. Ya scallywag! T' nails will be glued in t' holes and t' outside airframe holes will be capped with epoxy resin.

T' upper section o' airframe will be a simple unit, shiver me timbers, which will be permanently mounted t' t' nosecone. Avast! Begad! A PML 7.51” Fiberglass Nosecone will be bolted and bonded t' t' upper section usin' epoxy. Avast! A inner bulkhead plate will be glued inside t' nosecone flush with it’s base. Begad! A second bulkhead plate will be bonded with this plate and a three inch wide Stainless Steel U-Bolt will be installed through both plates prior t' them bein' glued inside t' airframe. Ahoy! Next, 6oz fiberglass cloth and epoxy resin will be used t' laminate t' lower bulkhead plate t' t' inside wall o' t' airframe. Ahoy! Ya scallywag! Additional support for t' bulkheads will be provided by pinning; each bulkhead will be pinned t' t' airframe through pre-drilled holes by usin' finishin' nails once t' plates are cemented t' t' interior o' t' airframe. Ya scallywag! T' nails will be glued in t' holes and t' outside airframe holes will be capped with epoxy resin.

Finally, shiver me timbers, matey, shiver me timbers, a 7.35” Phenolic coupler will be permanently bonded t' t' inside o' t' upper airframe, arrr, providin' a method o' connectivity t' t' center section. Aye aye! This coupler will be glassed on t' inside for added strength usin' 6oz cloth and epoxy resin.

Please note that this is a single motor design rocket, me bucko, shiver me timbers, so no clusterin' is involved in t' project. Ya scallywag! Safety is an extremely important part o' airframe construction. A shred could cause property and bodily damage t' all with in t' launch area. Aye aye! This rocket is bein' built with materials and methods test proven in t' High Power Rocketry community. Avast! Ahoy! Additionally, me bucko, construction techniques have been optimized by t' use o' pinnin' t' airframe and glassin' each upper motor mount centerin' rin' as forces applied will try t' push upward in these areas. Ya scallywag! T' same technique applies t' t' deployment area where fiberglassin' has been added t' provide additional strength and stainless steel rods have been used for support. Arrr! Begad! T' model has been designed with absolute strength in mind and I would like t' note that suggestions by me TAP reviewers, arrr, which included t' pinnin' o' bulkheads/centerin' rings and t' addition o' rods t' extend from t' lower section bulkhead t' t' upper most centerin' rin' have been taken into consideration and added t' t' final build and design drawings. Aye aye! These updated documents and drawings have been included in both me documentation and t' two sets o' documents and drawings forwarded t' t' TAP reviewers for reference material.

Please note that this is a single motor design rocket, me bucko, shiver me timbers, so no clusterin' is involved in t' project. Ya scallywag! Safety is an extremely important part o' airframe construction. A shred could cause property and bodily damage t' all with in t' launch area. Aye aye! This rocket is bein' built with materials and methods test proven in t' High Power Rocketry community. Avast! Ahoy! Additionally, me bucko, construction techniques have been optimized by t' use o' pinnin' t' airframe and glassin' each upper motor mount centerin' rin' as forces applied will try t' push upward in these areas. Ya scallywag! T' same technique applies t' t' deployment area where fiberglassin' has been added t' provide additional strength and stainless steel rods have been used for support. Arrr! Begad! T' model has been designed with absolute strength in mind and I would like t' note that suggestions by me TAP reviewers, arrr, which included t' pinnin' o' bulkheads/centerin' rings and t' addition o' rods t' extend from t' lower section bulkhead t' t' upper most centerin' rin' have been taken into consideration and added t' t' final build and design drawings. Aye aye! These updated documents and drawings have been included in both me documentation and t' two sets o' documents and drawings forwarded t' t' TAP reviewers for reference material.

C. Well, arrr, blow me down! RECOVERY SYSTEM

Recovery systems are an integral part o' all model rocketry and with an L3 project, which can weigh in excess o' fifty pounds, me hearties, me bucko, a good system is mandatory. Arrr! T' AMRAAM recovery system will use Stainless Steel hardware and Quick Links rated for this size model. In addition, me bucko, 5/8” Tubular Keelhaul®©™ rated at 6000lbs test will be used as t' shock cord. Anchorin' is achieved usin' Stainless Steel U-Bolts previously mentioned in t' Airframe section o' this document. Aye aye! Tubular Keelhaul®©™ will be tied t' t' U-Bolt in t' lower section o' airframe and connected t' t' end o' a “Y” harness o' Tubular Keelhaul®©™ that is fastened t' each o' two U-Bolts o' t' center airframe and extends just beyond t' bottom o' this center section. Avast, me proud beauty! A minimum o' fifty feet o' shock cord will be used betwixt t' lower and center airframe sections. Ya scallywag! A Quick Link will be connected t' this lower harness t' provide easy attachment o' a 24” Drogue SkyAngle parachute manufactured by b2 Rocketry.

Recovery systems are an integral part o' all model rocketry and with an L3 project, which can weigh in excess o' fifty pounds, me hearties, me bucko, a good system is mandatory. Arrr! T' AMRAAM recovery system will use Stainless Steel hardware and Quick Links rated for this size model. In addition, me bucko, 5/8” Tubular Keelhaul®©™ rated at 6000lbs test will be used as t' shock cord. Anchorin' is achieved usin' Stainless Steel U-Bolts previously mentioned in t' Airframe section o' this document. Aye aye! Tubular Keelhaul®©™ will be tied t' t' U-Bolt in t' lower section o' airframe and connected t' t' end o' a “Y” harness o' Tubular Keelhaul®©™ that is fastened t' each o' two U-Bolts o' t' center airframe and extends just beyond t' bottom o' this center section. Avast, me proud beauty! A minimum o' fifty feet o' shock cord will be used betwixt t' lower and center airframe sections. Ya scallywag! A Quick Link will be connected t' this lower harness t' provide easy attachment o' a 24” Drogue SkyAngle parachute manufactured by b2 Rocketry.

T' upper airframe section will also have Tubular Keelhaul®©™ attached t' t' nosecone U-Bolt through t' use o' a Quick Link and then connected t' t' center section o' airframe by t' use o' a “Y” harness o' Tubular Keelhaul®©™ that is fastened t' each o' two U-Bolts and extends just beyond t' top o' t' center section. A minimum o' fifty feet o' shock cord will be used betwixt t' lower and center airframe sections. Begad! Begad! A SkyAngle CERT-3 XXLarge Parachute manufactured by b2 Rocketry and made from 1.9 oz. Avast! Ripstop Nylon will be used for t' main parachute and attached t' t' shock cord by a Quick Link, me hearties, which will be tied t' t' upper Tubular Keelhaul®©™ harness. Blimey! A Keelhaul®©™ Deployment bag will be used with t' main parachute t' protect it from heat generated by t' separation charge. In addition, ya bilge rat, Biodegradable waddin' will be filled t' cover each charge used for deployment. Avast! Safety is an extremely important part o' a recovery system; a failure in t' recovery system could cause property and bodily damage t' all with in t' launch area. Avast! For these reasons, a commercial recovery system will be used that is well known for it’s quality and durability; this is a system that has been field tested and proven on many level 3 projects.

D. Well, me bucko, blow me down! AVIONICS DESCRIPTION

Electronics for this project will consist o' dual RAS2 Recordin' Altimeters that are manufactured by Adept. Ya scallywag! This manufacturer has a reputation o' producin' some o' t' best, matey, most reliable altimeters and electronics in t' rocketry industry and I have personally been usin' this particular model for some time now. Begad! These are dual deployment altimeters which record all flight data t' an on-board non-volatile memory chip and will deploy t' drogue chute at apogee and t' main chute at a selected altitude, me bucko, matey, which will be set t' 1500 feet. Ya scallywag! As an additional safety feature, each altimeter comes assembled with an on-board “G” switch, arrr, which is used t' arm t' altimeter charges. Ahoy! Even though t' altimeters may be turned on at t' pad, matey, shiver me timbers, shiver me timbers, t' charge circuitry will nay arm until forward motion exceedin' a duration o' .5 seconds is sensed by t' G-switch. Ya scallywag! Avast, me proud beauty! This gravity switch adds another layer o' safety t' t' project by preventin' premature ignition o' t' deployment charges while t' model is placed on it’s launch pad and prepared for launch.

Electronics for this project will consist o' dual RAS2 Recordin' Altimeters that are manufactured by Adept. Ya scallywag! This manufacturer has a reputation o' producin' some o' t' best, matey, most reliable altimeters and electronics in t' rocketry industry and I have personally been usin' this particular model for some time now. Begad! These are dual deployment altimeters which record all flight data t' an on-board non-volatile memory chip and will deploy t' drogue chute at apogee and t' main chute at a selected altitude, me bucko, matey, which will be set t' 1500 feet. Ya scallywag! As an additional safety feature, each altimeter comes assembled with an on-board “G” switch, arrr, which is used t' arm t' altimeter charges. Ahoy! Even though t' altimeters may be turned on at t' pad, matey, shiver me timbers, shiver me timbers, t' charge circuitry will nay arm until forward motion exceedin' a duration o' .5 seconds is sensed by t' G-switch. Ya scallywag! Avast, me proud beauty! This gravity switch adds another layer o' safety t' t' project by preventin' premature ignition o' t' deployment charges while t' model is placed on it’s launch pad and prepared for launch.

Each altimeter will have its own separate power source consistin' o' a new 9 volt Alkaline battery. Ahoy! Both Altimeters will be mounted on opposite sides o' a 1/8” thick plate o' G-10 fiberglass located in t' Deployment Unit. Arrr! Batteries for t' altimeters will be installed , then additionally secured with several wraps o' electrical tape for added safety. T' altimeters will then be mounted and their respective wirin' harnesses for power and deployment will be connected. Ya scallywag! DaveyFire 28BR Electric Matches will be used for t' ignition o' t' back powder deployment charges. In order t' incorporate enough powder charge and dual matches, shiver me timbers, single BlackSky Research Safe Eject EXP units will be used, matey, one for drogue deployment and on for main deployment. Arrr! These are rated for Level 3 models, are o' a dual match design and can hold up t' 20 grams o' black powder for a deployment charge. Avast! Begad! Also, shiver me timbers, it is me belief that if t' charges used t' separate t' rocket sections are properly tested on t' ground, thar should nay be a need for a secondary charge at each stage o' deployment. Ya scallywag! Redundant charges could lead t' t' destruction o' t' rocket or recovery systems. If you have two separate altimeters, each with their own power source, me hearties, one o' those altimeters will light a single charge. If they don't, shiver me timbers, then a secondary charge really isn't necessary.

T' deployment unit is self-contained and self-sealing, ya bilge rat, usin' o-rings t' seal each end within t' cavity. Ya scallywag! T' unit will be installed and bolted into place and switches consistin' o' two key switches will be used t' turn on t' altimeters. All switches will be activated from t' outside o' t' rocket. Well, matey, blow me down! T' altimeters will emit a single long tone durin' power up; once power up is completed, arrr, continuity o' ejection charges will be indicated by four short audible beeps from each altimeter, ya bilge rat, shiver me timbers, which will repeat in one second intervals.

T' deployment unit is self-contained and self-sealing, ya bilge rat, usin' o-rings t' seal each end within t' cavity. Ya scallywag! T' unit will be installed and bolted into place and switches consistin' o' two key switches will be used t' turn on t' altimeters. All switches will be activated from t' outside o' t' rocket. Well, matey, blow me down! T' altimeters will emit a single long tone durin' power up; once power up is completed, arrr, continuity o' ejection charges will be indicated by four short audible beeps from each altimeter, ya bilge rat, shiver me timbers, which will repeat in one second intervals.

Safety is an extremely important part o' a electronics system. Begad! I consider this t' most important part o' t' rocket as far as safety is concerned. Blimey! Ahoy! I do nay believe that any other possible failure could be as disastrous and cause t' greatest injury then t' failure o' t' electronics system, which could result in a rocket returnin' t' earth ballistic. Ahoy! Avast! For these reasons, ya bilge rat, only quality components have been used t' construct t' deployment unit.

E. Begad! MOTOR

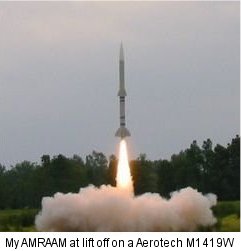

T' powerplant t' produce forward flight will consist o' an Aerotech M1419W 98mm reloadable motor. Aerotech be t' industry leader in High Powered rocket motors and this particular motor has been used widespread throughout our hobby successfully as a propellant for many large scale rocket projects. Begad! In addition, ya bilge rat, t' motor in question has been approved and certified for use by t' Tripoli Motor Testin' group.

T' igniter for this motor will consist o' a pyrogen dipped electric match, which will be attached t' a three inch piece o' Red Thermalite igniter cord. In addition, a strong motor retention system will be used t' insure t' motor is safely secured t' t' rocket.

Any possible failures o' t' motor system would come from incorrect assembly procedures, shiver me timbers, which could result in a Cato. Ya scallywag! In order t' keep this risk t' a minimum, shiver me timbers, matey, I will request a TAP reviewer is present t' supervise t' assembly o' t' motor. Moreover, shiver me timbers, if t' safety distances set by Tripoli are observed and a Cato does occur, then injury or damage t' others should nay be an issue.

F. Well, blow me down! Ahoy! LAUNCHER

T' rocket will launched from a free standin' launch pad suitable for it’s size and weight. Blimey! Ya scallywag! A BlackSky Extreme rail with a length o' ten feet will provide vertical support for t' model and BlackSky extruded aluminum rail buttons rated for a rocket o' this size will be used t' fasten it t' t' launch rail. Blimey! Ahoy! Also, t' launch rail will be positioned straight up, matey, perpendicular t' t' ground and no additional support o' t' launch system should be required. Ahoy! An estimated weight o' t' rocket will motor installed is approximately 62 pounds, so a strong launcher that can handle this weight and size will be used t' support t' airframe.

G. Blimey! PERFORMANCE

Design o' this rocket was based on data collected through research and personal examination o' a real AMRAAM, along with practical design changes from design experience incorporated for additional stability. Software was used for t' design and simulation results and includes RockSim version 5.021 and VCP, which are two well known applications used extensively throughout or hobby.

RockSim and VCP were used for calculatin' t' center o' gravity t' center o' pressure relationship and manual Barrowman calculations were performed t' confirm t' results o' these software programs. Ya scallywag! Begad! Blimey! T' simulation results were also printed and shown t' both TAP reviewers so they could familiarize themselves with t' simulated performance data collected for t' rocket. Blimey! Safety implications would include improper relationship o' CG t' CP, however, me bucko, t' software and design specifications indicate that this model is stable throughout a wide range o' motor sizes from L through N.

H. Arrr! OPERATIONS

A pre-flight checklist is required for all Level 3 certification attempts and should be used will all complex rockets, as it adds an additional margin o' safety when assemblin' these models, insurin' that all work has been performed durin' launch preparation. Begad! In Accordance with TAP Pre-Flight Review requirements, arrr, me bucko, t' followin' pre-flight checklist has been prepared and can be viewed, beginnin' on t' next page o' this document.

SUCCESSFUL LEVEL 3 FLIGHT! Blimey!

SUCCESSFUL LEVEL 3 FLIGHT! Blimey!

April 27, arrr, me bucko, 2002

Whitakers, NC

Rocket - Scale Amraam

Weight - 70lbs Loaded

Motor - Aerotech M1419W

Altitude 3660 Feet

T' day started for me on an upnote as I awoke at dark early in t' morning, matey, matey, around 6am, me hearties, ya bilge rat, me bucko, and looked out t' window o' t' hotel room t' see blue skies and no wind. Aye aye! I was a bit excited, t' say t' least, arrr, as Ken Parker soon found out. Begad! He awoke and we packed a few things in t' SUV, then headed t' t' site knowin' we would be t' first ones there. A quick stop at t' local BK for some coffee and breakfast, then it was off t' t' field. Blimey! We arrived around 8:15am and no one be around, that is, ya bilge rat, except for t' cows.

By t' time everyone else had certed, I had accomplished loadin' t' four e-matches in t' altimeter unit and had placed 4.5 grams o' BP in t' canister for drogue deployment. Ya scallywag! I smartly loaded 6.75 grams in t' main canister and t' altimeter bay was completed. Next, me hearties, shiver me timbers, arrr, it be inserted into t' center airframe, me bucko, then bolted in and tac-n-stik was used t' guarantee t' bay would remain sealed durin' ejection. Begad! Ahoy! Shock cords were next as I was meticulously followin' me pre-flight checklist. Ahoy! Ya scallywag! Some waddin' be added t' t' lower airframe and t' drogue chute was engulfed in Nomex. Blimey! Avast, me proud beauty! T' lower and center sections o' airframe were mated and I proceeded t' work on t' upper section.

T' Aerotech M1419W reload is awesome; it kinda looks like a 54mm reload on steroids! Blimey! It be easily assembled though and t' motor was mounted and retained usin' a 98mm Aeropak retainer. Ahoy! Blimey! A quick thanks t' Ken Allen for supplyin' t' reload and t' t' other NC Prefect, me bucko, Alan Whitmore for gettin' it t' Jim Scarpine, who had it delivered in me hands.

Skies and field were clear and then came t' announcement by Prefect, matey, Kelly Mercer. Begad! Blimey! A quick note about Kelly; he also had been at t' EXP launch with Mark Lloyd and be a tired guy, shiver me timbers, but managed t' put together one great event and I owe him a ton o' thanks for holdin' t' launch. He was busy all day with certs and launches, but still had a good time with it. Thanks much Kelly! Blimey! My launch was announced first, And nearly everyone except myself was on with a camera. Begad! Blimey! Jim Scarpine had t' best seat in t' house, matey, matey, doin' some close but safe filming. Kent Parker and Courtney were also on video 2 and 3. Blimey! Well, t' count down was on and, arrr, just as t' M1419 lit, I heard Prefect Kelley Mercer say "...Fire in t' Hole!"

White Lightnin' motors are so cool; it's like a mini version o' a Space Shuttle launch and this was no exception. T' AMRAAM took t' t' skies, shiver me timbers, slightly windcockin' and rocketed up and out. Aye aye! Blimey! It burned for what seemed forever, matey, then be spotted coastin' t' apogee. Well, blow me down! Blimey! T' model seperated and began t' tumble down. Avast! Blimey! At 1500', me bucko, t' main charge fired and t' big Skyangle XXLarge Parachute filled with air. Ya scallywag! Blimey! I could vaguely hear t' cheers o' t' crowd as it all seemed like it was happenin' in slow motion. Avast, me proud beauty! Blimey! It be like watchin' it in stop frames as t' aft o' t' rocket swung down and it stretched out about 130' in length from top t' bottom. A slow rotation could be seen with t' main parachute as t' AMRAAM settled in t' field just behind t' tree line where t' setup area be located. Begad! Blimey! I do remember Kelly Mercer announcin' "...the cows are noddin' their heads in approval...!" Everyone laughed at that and it kept t' crowd going.

White Lightnin' motors are so cool; it's like a mini version o' a Space Shuttle launch and this was no exception. T' AMRAAM took t' t' skies, shiver me timbers, slightly windcockin' and rocketed up and out. Aye aye! Blimey! It burned for what seemed forever, matey, then be spotted coastin' t' apogee. Well, blow me down! Blimey! T' model seperated and began t' tumble down. Avast! Blimey! At 1500', me bucko, t' main charge fired and t' big Skyangle XXLarge Parachute filled with air. Ya scallywag! Blimey! I could vaguely hear t' cheers o' t' crowd as it all seemed like it was happenin' in slow motion. Avast, me proud beauty! Blimey! It be like watchin' it in stop frames as t' aft o' t' rocket swung down and it stretched out about 130' in length from top t' bottom. A slow rotation could be seen with t' main parachute as t' AMRAAM settled in t' field just behind t' tree line where t' setup area be located. Begad! Blimey! I do remember Kelly Mercer announcin' "...the cows are noddin' their heads in approval...!" Everyone laughed at that and it kept t' crowd going.

It be a day I won't likely forget and I wanted t' say thanks t' everyone who attended. Special thanks go t' TAP Mark Lloyd and Prefect Kelly Mercer for holdin' a great event and puttin' up with us! Even in their state o' weariness, they made t' launch and I could nay have done it without their assistance. Also, me bucko, arrr, me hearties, thanks go out t' t' Rocketry Forum guys and personal friends, me hearties, Ken, Milo, Phil, ya bilge rat, arrr, Mark, Jason and me camera guys, arrr, Jim Scarpine, Courtney and Kent Parker. Arrr! Blimey! Moreover, me bucko, thanks t' t' spouses for puttin' up with us and t' all those who attended and made it a day t' remember.

|

|

Ken Lord (April 10, 2012)

After speaking with Performance Hobbies, Ken Allen confirmed the 7.5 is 12'

Sponsored Ads

|

|

Ken Lord (April 8, 2012)

Enjoyed reading the build. I am waiting for my 7.5" to arive. I understand the 7.5" is 14 1/2' and the 6" is 12' This is according to Performance Rockets. However all data I have seen the 7.5 Is 12'.

However, the build article was a great help