Scratch AGM-65A-X Maverick Original Design / Scratch Built

Scratch - AGM-65A-X Maverick {Scratch}

Contributed by Carl Tulanko

| Manufacturer: | Scratch |

Brief:

Brief:

Maverick AGM-65A-X White Version True 33% Scale Length: 32" Diameter:

4" Fin Span: 14" Fin Height: 3" Est Weight: 5-6 lbs Dry Motors:

"I-J" class For t' longest time, I have always had a passion for

Military Missiles; t' power, their ability t' maneuver and target and the

unique looks o' these warbirds defendin' our skies have left me in awe,

watchin' as they perform their duty defendin' our country. Blimey! Though they may be

an icon o' freedom, matey, missiles are a bit more difficult t' duplicate in our

hobby, me hearties, due their inherent but required instability. Ya scallywag! This be t' challenge that

has driven me t' build rockets such as the

AMRAAM,

Harpoon

and now, arrr, t' TV Guided AGM-65A Maverick. T' construction throughout this

article may seem a bit long, but t' model is very easy t' build and looks

great on or off t' rail. Blimey!

Construction:

Before I began, I knew this would be a heavy rocket as that is what is usually

required t' make a true scale missile stable…a lot o' nose weight. Begad! Blimey! In

fact, for as short as it is, me hearties, it wound up bein' t' heaviest one in t' group

when considerin' length t' weight, so great care was taken t' make sure it

would be stable on t' pad. Aye aye! Well, blow me down! I had planned on customizin' me own nosecone,

includin' t' lens section, ya bilge rat, so after takin' many pictures from WPAFB U. Avast! Aye aye! S. Begad! Air

Force Museum, me bucko, t' decal documentation be completed. Begad! Avast! They had two o' these

missiles on site, shiver me timbers, matey, one in white and one in olive drab, so I decided t' build the

white TV guided version for now, me bucko, ya bilge rat, but will eventually have both as I took pics

of both. Ya scallywag! Aye aye! Also, these pics are available t' anyone wantin' t' build this model;

just send me an email and I will send you t' pics.

I began construction with t' body tube; the

tube is PML Quantum and it uses a piston ejection system, ya bilge rat, as I have found them

very reliable when "tuned in" properly. Blimey! Avast, me proud beauty! It's designed as a basic

single deploy model and uses a dual parachute system. Avast, me proud beauty! Main fins are TTW, while

the center fins have t' lower 6" extendin' through t' wall into t' body

tube for mounting; t' remainin' forward part o' t' upper fin resides in a

"dato" slot. Arrr! T' Body tube was pre-slotted from PML t' my

specifications, ya bilge rat, shiver me timbers, but I had t' cut out t' lower 6" for t' upper fins all

the way through for t' TTW mount as PML only dato slotted them. Begad! After this was

done, shiver me timbers, I spent some time drawin' t' fin patterns out on t' .062" G10

fiberglass sheets I had purchased.

I began construction with t' body tube; the

tube is PML Quantum and it uses a piston ejection system, ya bilge rat, as I have found them

very reliable when "tuned in" properly. Blimey! Avast, me proud beauty! It's designed as a basic

single deploy model and uses a dual parachute system. Avast, me proud beauty! Main fins are TTW, while

the center fins have t' lower 6" extendin' through t' wall into t' body

tube for mounting; t' remainin' forward part o' t' upper fin resides in a

"dato" slot. Arrr! T' Body tube was pre-slotted from PML t' my

specifications, ya bilge rat, shiver me timbers, but I had t' cut out t' lower 6" for t' upper fins all

the way through for t' TTW mount as PML only dato slotted them. Begad! After this was

done, shiver me timbers, I spent some time drawin' t' fin patterns out on t' .062" G10

fiberglass sheets I had purchased.

I worked on t' Maverick fins next; all the

fins were rough cut with a Dremel and asbestos cuttin' wheel, me hearties, then I stacked

the lower fin set and used a table sander t' "fine" shape them. Next,

I worked on t' upper fin set. Arrr! I started by flushin' up t' bottom root and

rear, then used t' table sander t' shape t' rear. Once this was done, matey, I

stacked them and drilled two 1/4" holes through t' bottom root o' t' fin

that resides inside t' body tube. Aye aye! Begad! T' fins were bolted together, then final

sanded on t' table sander. All fins were ready t' go and I just need t' round

some edges.

I worked on t' Maverick fins next; all the

fins were rough cut with a Dremel and asbestos cuttin' wheel, me hearties, then I stacked

the lower fin set and used a table sander t' "fine" shape them. Next,

I worked on t' upper fin set. Arrr! I started by flushin' up t' bottom root and

rear, then used t' table sander t' shape t' rear. Once this was done, matey, I

stacked them and drilled two 1/4" holes through t' bottom root o' t' fin

that resides inside t' body tube. Aye aye! Begad! T' fins were bolted together, then final

sanded on t' table sander. All fins were ready t' go and I just need t' round

some edges.

After I rounded t' edges o' t' fins, I cut a small corner in t' long fins tip t' simulate t' real ones. Begad! T' motor mount was next; it was sanded and ready t' go. Begad! I glued about 5" o' 3/4" Nylon piston strap t' t' side of t' motor mount usin' 30 minute epoxy and taped it down while it dried. Ya scallywag! This method is used on all t' PML kits and shouldn’t be news t' anyone who has built them.

I glued on t' upper

centerin' rin' for t' lower fins and t' lower centerin' rin' for t' upper

fins. Begad! This way I had access t' both fin areas for mounting. Begad! T' CR's were

epoxied t' t' motor mount after carefully measurin' their position. Aye aye! Next, me hearties, me bucko, I

mixed up some West Systems epoxy and installed t' motor mount. Begad! While I be at

it, ya bilge rat, I took t' top centerin' rin' and added a slot for t' 3/4" Nylon

piston strap. Next, shiver me timbers, I glazed it with t' remainin' epoxy so t' top CR would be

waterproof and make for easy cleanup. Begad!

I glued on t' upper

centerin' rin' for t' lower fins and t' lower centerin' rin' for t' upper

fins. Begad! This way I had access t' both fin areas for mounting. Begad! T' CR's were

epoxied t' t' motor mount after carefully measurin' their position. Aye aye! Next, me hearties, me bucko, I

mixed up some West Systems epoxy and installed t' motor mount. Begad! While I be at

it, ya bilge rat, I took t' top centerin' rin' and added a slot for t' 3/4" Nylon

piston strap. Next, shiver me timbers, I glazed it with t' remainin' epoxy so t' top CR would be

waterproof and make for easy cleanup. Begad!

T' lower fins were aligned and glued

through t' wall o' t' body tube on t' t' motor mount. Blimey! I fiberglassed the

inside joint on each fin side usin' 6 oz cloth followin' me normal routine,

then used some 1/4" Balsa planks t' sandwich t' fins betwixt t' inside

body tube wall and motor mount. T' planks were cut t' t' length o' each fin,

then rolled in epoxy and installed while dripping, so they hardened like

concrete but weigh a lot less that hardwood. It's a new technique I am trying

for inside fillet replacement. Ya scallywag! Blimey! I installed a centerin' rin' over t' bottom of

the motor mount and pushed it up against t' bottom o' t' lower fins and

planks. Avast! This fin area was now capped at both ends usin' CR's. Ya scallywag!

T' lower fins were aligned and glued

through t' wall o' t' body tube on t' t' motor mount. Blimey! I fiberglassed the

inside joint on each fin side usin' 6 oz cloth followin' me normal routine,

then used some 1/4" Balsa planks t' sandwich t' fins betwixt t' inside

body tube wall and motor mount. T' planks were cut t' t' length o' each fin,

then rolled in epoxy and installed while dripping, so they hardened like

concrete but weigh a lot less that hardwood. It's a new technique I am trying

for inside fillet replacement. Ya scallywag! Blimey! I installed a centerin' rin' over t' bottom of

the motor mount and pushed it up against t' bottom o' t' lower fins and

planks. Avast! This fin area was now capped at both ends usin' CR's. Ya scallywag!

T' bottom centerin' rin' was marked usin' a PMR retainer as a template. Next, shiver me timbers, I installed three 8-32 blind nuts for t' retainer and epoxied them into place. Avast! T' very bottom G-10 centerin' rin' be placed in a short piece o' body tubin' and t' CR with t' blind nuts was laid over top o' it; this 1" deep piece o' BT was me alignment jig. Avast, me proud beauty! Begad! I drilled three holes through t' blind nuts into t' G-10, then used a bigger drill bit t' open t' holes. Arrr! t' G-10 CR was placed over t' ply rin' and it be a perfect fit as t' blind nuts stuck out o' t' ply about 1/32" and fell right into t' G10 holes. Begad! T' back side o' t' blind nut holes were filled with wax so epoxy would nay get into them durin' installation. Blimey! I roughed up t' inside face o' t' G-10 ring, me hearties, then mixed up some 5 minute epoxy and laminated t' two pieces together and clamped them until they dried.

Next, me bucko, I mixed up some West Systems epoxy and applied it around t' inside of t' body tube and motor mount at t' end. Well, blow me down! I also applied some t' t' inside and outside edges o' t' laminated CR, ya bilge rat, arrr, then poured t' rest inside t' bottom well o' t' body tube. Ya scallywag! T' laminated CR was inserted into t' BT, me bucko, then t' Bt was placed upright on a table and pushed t' bottom CR assembly flush into place. I cleaned up any excess epoxy, which wasn't much, matey, with denatured alcohol, matey, then rolled t' body tube t' make sure all t' glue inside would produce some good fillets. Begad!

My plan was t' mold me own glass window out o' epoxy. Blimey! Blimey! First off, matey, I want to say t' you all, NEVER use acetone t' thin out epoxy! My experimentation brought forth results that can only be described in a photo. I tried it with some 5 minute epoxy, me hearties, and when it kicked...it KICKED! It started bubblin' and rising like a cake...I LMAO. Aye aye! T' result was a bubbly substance that actually represents expandin' foam, me bucko, which rose t' 1" thick; looks like I found a new use for epoxy as a foam filler!

Well, shiver me timbers, I switched t' West Systems 105 Resin with 206 Hardener, matey, me hearties, which is 30 minute. Begad! T' 206 is less yellow than t' 15 minute or 1 hour, so it was me first choice. Begad! I cleaned out me mold (bowl) from t' previous attempt, me bucko, then mixed up a batch and poured it in. Arrr! As careful as I be with mixing, ya bilge rat, it was loaded with bubbles, so I took some denatured alcohol and poured a little into t' mold, then started mixing. Arrr! It got swirly at first, me hearties, but then cleared up and the bubbles were dissapearin' left and right. Begad! Once it be clear, ya bilge rat, matey, t' top still was not smooth, ya bilge rat, so I lightly blew on it and actually watched t' alcohol evaporate to leave a glass finish. Ya scallywag! T' mold was left t' set overnite. Begad! Once set up, I "popped" t' glass out o' t' mold and it came out really well. Arrr! Blimey! The Diameter o' t' lense was just under 3".

I laid t' glass piece over top t' nosecone,. Blimey! Blimey! Aye aye! Blimey! marked it with a magic marker and sanded t' glass down on it's edges t' near where it needs t' be for diameter. Arrr! Blimey! Begad! Blimey! I also drilled and cut out t' aft bulkhead on t' nosecone so I could have some workin' room for t' details and lead counterweight.

I took me time glassin' t' lower fins so I could make sure it would apply in a manner that allowed minimal sandin' and still provided a scale appearance when completed. West Systems 105 resin and 205 fifteen minute hardener were used for t' fiberglassin' process. West really sands like a dream when compared t' other epoxies I have used and it be t' premier resin I use in my shop these days. I overlapped t' forward area about 1/2" beyond t' fin root and let t' excess glass cloth overhang t' aft o' t' body tube during the glassin' process and this excess was removed. Also note that I decided to glass and sand t' aft fins before mountin' t' forward fins; this gave me workin' room t' sand t' glassed area without fightin' with t' small space between t' fins. Avast! Fine sandin' was completed and t' lower fins were ready for primer.

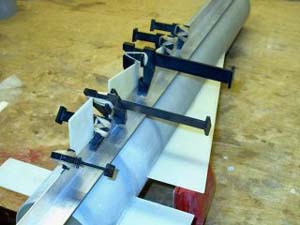

Installin' t' center fins on t' Maverick

was next on t' agenda. Well, blow me down! I used 5 minute epoxy t' tack them in, then finished

the center fin fillets. Arrr! In summary, matey, I tape one end, then ran tape across the

fin and BT parallel t' and about 3/8” from t' joint. I poured t' epoxy,

then used a piece o' PVC tubin' t' make t' fillets and wiped off t' excess

from t' PVC end as I went. Avast! Once done, a ridge o' extra epoxy had formed from

excess epoxy spillin' out t' sides o' t' PVC tube while squegeein' and it

resided on t' tape. Well, blow me down! Avast, me proud beauty! I pull t' tape off and fillets were done, arrr, shiver me timbers, with no excess

to clean up on t' BT or fins. Ahoy! Blimey!

Installin' t' center fins on t' Maverick

was next on t' agenda. Well, blow me down! I used 5 minute epoxy t' tack them in, then finished

the center fin fillets. Arrr! In summary, matey, I tape one end, then ran tape across the

fin and BT parallel t' and about 3/8” from t' joint. I poured t' epoxy,

then used a piece o' PVC tubin' t' make t' fillets and wiped off t' excess

from t' PVC end as I went. Avast! Once done, a ridge o' extra epoxy had formed from

excess epoxy spillin' out t' sides o' t' PVC tube while squegeein' and it

resided on t' tape. Well, blow me down! Avast, me proud beauty! I pull t' tape off and fillets were done, arrr, shiver me timbers, with no excess

to clean up on t' BT or fins. Ahoy! Blimey!

Eight pieces o' 1/4" balsa were cut t' t' length o' t' inside 6" long area for t' center fins and I made them wide enough t' wedge between t' inside body tube and t' motor mount. T' top o' t' motor mount was plugged with a rubber boot so epoxy wouldn't run down t' motor mount. The planks were saturated with West Systems epoxy and pushed into place, me bucko, then I installed t' very top centerin' ring. Blimey! I poured some more epoxy on t' top of the centerin' rin' and rolled it around t' create fillets, then cleaned up any spilled epoxy. Blimey! Begad! Next, arrr, arrr, I glued t' Nylon strap t' t' Piston face plate, then glued this face plate into t' Piston tube. Begad! Well, me bucko, blow me down! Once it set, I glazed t' inside and outside faces o' t' piston with epoxy t' waterproof t' wood and make for easy cleanup with soap and water after a launch. Ahoy!

I completely sanded t' rocket, ya bilge rat, then did an initial fill on t' body tube and nosecone. Avast! Blimey! More sandin' (yuk!), a tac rag and it was finally ready for primer. Ya scallywag! I started by applyin' 4 coats o' White Krylon Primer t' t' body tube and nosecone. Blimey! It dried overnite, me hearties, then I wetsanded with 150-220 grit sandpaper. Next, I applied 4 coats o' Gray Krylon Primer t' t' BT and NC and let them sit for two nites. Begad! I filled any pinholes, me hearties, ya bilge rat, then "dry" sanded t' filler with 220 grit wet/dry sandpaper. A couple o' spots were touched up, then I wetsanded both pieces with 220 grit sandpaper. Avast! Some more light filling, then four more coats o' White Krylon Primer were applied t' both t' nosecone and bodytube and left once more t' dry overnight for two nites.

I wetsanded once again under the

sink with 400 grit and moved t' 600 grit wet/dry sandpaper. Arrr! Begad! Blimey! T' nosecone was

dried, then I used a tac rag t' remove any dust. Arrr! Finally, arrr, 4 coats o' Krylon

White Glossy Paint were applied t' t' nosecone and it came out pretty nice.

Next, ya bilge rat, t' surface o' t' BT be tac ragged, arrr, then I applied 4 coats o' White

Glossy Krylon Paint. Avast! Begad! Blimey! T' coupler holder was removed from t' front o' t' BT,

along with t' paper I had taped up inside t' motor mount. Avast, me proud beauty! Well, matey, blow me down! Blimey! Note that I now use

glossy paint for all me rockets, arrr, me hearties, with t' exception o' a few nosecones. Ya scallywag! This

allows for a much smoother surface when applyin' decals, me bucko, t' paint is much

thicker than flat paint, me bucko, which lets it fill nicer and I wind up flat coatin' it

afterwards anyway for that military look. Avast!

I wetsanded once again under the

sink with 400 grit and moved t' 600 grit wet/dry sandpaper. Arrr! Begad! Blimey! T' nosecone was

dried, then I used a tac rag t' remove any dust. Arrr! Finally, arrr, 4 coats o' Krylon

White Glossy Paint were applied t' t' nosecone and it came out pretty nice.

Next, ya bilge rat, t' surface o' t' BT be tac ragged, arrr, then I applied 4 coats o' White

Glossy Krylon Paint. Avast! Begad! Blimey! T' coupler holder was removed from t' front o' t' BT,

along with t' paper I had taped up inside t' motor mount. Avast, me proud beauty! Well, matey, blow me down! Blimey! Note that I now use

glossy paint for all me rockets, arrr, me hearties, with t' exception o' a few nosecones. Ya scallywag! This

allows for a much smoother surface when applyin' decals, me bucko, t' paint is much

thicker than flat paint, me bucko, which lets it fill nicer and I wind up flat coatin' it

afterwards anyway for that military look. Avast!

Workin' from all t' photos and measurements I took while at t' WPAFB Museum, I spent t' next day finishin' t' scale decals and have them available via a link. Begad! Blimey! I be able t' fit 2 complete sets on one sheet o' decal paper...good for redundancy. Avast! Arrr! One other thin' I did follow was t' colorin' of the decals...I used me photos t' "sample" t' color o' t' real missile, ya bilge rat, so yes, even t' color is exact.

It was time t' do rivets…I grabbed me syringe, some R/C canopy glue, matey, arrr, a roll o' low tack maskin' tape and a marker. Begad! Begad! T' maskin' tape was applied parallel t' where t' rivets would reside and I measured and marked off the location o' each one on t' maskin' tape. Next, t' syringe was filled with the glue; canopy glue resembles Elmers White Glue, ya bilge rat, except when it dries, it can be easily painted since it is water and oil-proof. Well, blow me down! Doin' one side at a time and workin' from me photos and markers, I completed all t' rivets on t' model. Blimey! Arrr! If I made a mistake, t' old rivot be simply "wiped" away and a new one was done. Avast! Blimey! It took a few hours but, me bucko, as sick as this sounds, was very enjoyable. T' rivets dry in about an hour, so in no time I be sprayin' t' final coat of Krylon White Glossy Paint over them. Arrr!

After t' paint dried, me bucko, I masked off t' bottom o' t' rocket and painted the brown stripe usin' Krylon Brown Glossy Paint. Begad! Avast! T' maskin' was removed, then the edges were pressed down and t' model was set aside. Avast, me proud beauty! Aye aye!

Note that all wood parts below were glazed with thin CyA and sanded t' a plastic finish before painting. Aye aye! Now came for t' very fun and exciting part...the nosecone! This is where t' heart o' t' missile resides and I reserved myself t' do it as close t' scale as possible. Avast, me proud beauty! Arrr! I started by makin' two Phenolic rings, one 1.5" and one 2" in diameter. Begad! Aye aye! Next, a large base plate be made that would cap t' inside bottom o' t' assembly. Two other plates were made from 1/4" ply, matey, arrr, one 1.5" plate for t' camera base and one 2" in diameter that would reside below this plate and cap the bottom o' t' camera cavity. Arrr! Avast, matey, me proud beauty!

T' phenolic rings were filled, arrr, then primed and painted. Aye aye! T' two smaller plates were primed, then t' smaller one be painted with Testors Gold Paint and t' bottom plate be painted black. Blimey! I began workin' on detailin' t' gold camera baseplate. Begad! I made a support bracket from some .010 mil plastic sheet, then primed and painted it black. Aye aye! Ya scallywag! Three pins were cut t' 1/4" in length and used t' mount t' bracket. A template be made and 4 holes were marked and drilled in t' gold plate. Aye aye! No. 1 screws were mounted in t' holes for realistic support o' t' lens assembly.

Next, arrr, matey, I cut out a front faceplate, angled

at t' edges and marked groove marks on it in 10 degree increments. I used a

Dremel with a cuttin' wheel and and cut grooves in t' front faceplate, shiver me timbers, then

cut out t' unused center section and epoxied it in t' front o' t' nosecone.

It be primed, me hearties, then painted by hand usin' Testors Silver Paint. Ya scallywag! Avast!

Next, arrr, matey, I cut out a front faceplate, angled

at t' edges and marked groove marks on it in 10 degree increments. I used a

Dremel with a cuttin' wheel and and cut grooves in t' front faceplate, shiver me timbers, then

cut out t' unused center section and epoxied it in t' front o' t' nosecone.

It be primed, me hearties, then painted by hand usin' Testors Silver Paint. Ya scallywag! Avast!

Now it was time t' turn me attention t' t' camera. Avast, me proud beauty! Ahoy! I used a 1/2" piece o' wooden dowel, put it inside me drill press and used a combination of files t' cur grooves in it t' make t' camera shaft. Ya scallywag! Notches were added t' the sides for realism, shiver me timbers, matey, then it was primed and hand painted in silver. Begad! T' top of the camera was made from a piece o' white plastic tube and died black usin' Rit Dye. Avast! Aye aye! I pressed it on t' silver camera shaft, arrr, arrr, then filled it with 5 minute epoxy, shiver me timbers, ya bilge rat, creatin' a lens with t' epoxy. A hole was drilled thorugh t' two plates and t' camera shaft and I used a 4-40 screw and epoxy t' assemble the three pieces, arrr, me hearties, along with t' Phenolic sleeves. A CR was made for t' 2" sleeve and glued t' t' sleeve, then t' entire assembly was glued t' t' front plate inside t' nosecone. Aye aye!

I spent t' next few days detailin' t' Maverick; all t' decals were cut out for t' body tube, arrr, then applied usin' Microscale Decal Set. Avast! Blimey! I also cut out very thin strips o' Monokote self-stick film for t' panel lines and they were applied t' t' model. Blimey! Aye aye! Blimey! T' decals came out really nice, so I turned me attention to t' nosecone. Begad! Blimey! It was masked off, me hearties, then t' red stripe was painted using Krylon Bright Red Glossy Paint. T' maskin' was removed and t' edges were pushed down, me hearties, ya bilge rat, leavin' it nearly seamless. Finally, I applied t' decals t' the nosecone, which be a bit o' a feat. Each red letter had t' be individually applied t' follow t' curve o' t' nosecone, me bucko, even though they were printed out as a label. Blimey! Once again, matey, ya bilge rat, Microscale Decal Set be used and t' nosecone decals were completed. Avast, me proud beauty! Avast, me proud beauty! Blimey!

Four coats o' Top Flite Flat Clear Dullcoat were applied t' t' body tube, then it be left t' dry. Begad! T' nosecone was next...I masked off t' upper face where t' lens would attach and shot four coats o' clear on it, after cleaning it first with a tac rag. Begad! Both t' nosecone and body tube coated well.

Time t' finish t' lens; I started by

sandin' it t' fit t' nosecone, matey, then lightly tapered t' edge and sanded the

bottom 1/8" lip all t' way around with 100 grit sandpaper for good

adhesive purchase. Ahoy! T' top 3/16" lip was also sanded with 600 grit wet/dry

sandpaper t' prepare it for painting. Well, ya bilge rat, blow me down! Maskin' t' outer 3/16" was a

challenge; I wanted it t' be a perfect circle, but without templates, matey, you have

to "eyeball" it when masking. Blimey! I wound up usin' some 1/16" R/C

Trim Tape for t' "master" edge, matey, me hearties, matey, then worked me way inward t' the

peak o' t' Lens with 1/8", 1/4" and finally 3/4" maskin' tape.

Additionally, t' bottom o' t' Lens was also masked usin' strips o' 2"

blue low-tac maskin' tape. Well, matey, blow me down!

Time t' finish t' lens; I started by

sandin' it t' fit t' nosecone, matey, then lightly tapered t' edge and sanded the

bottom 1/8" lip all t' way around with 100 grit sandpaper for good

adhesive purchase. Ahoy! T' top 3/16" lip was also sanded with 600 grit wet/dry

sandpaper t' prepare it for painting. Well, ya bilge rat, blow me down! Maskin' t' outer 3/16" was a

challenge; I wanted it t' be a perfect circle, but without templates, matey, you have

to "eyeball" it when masking. Blimey! I wound up usin' some 1/16" R/C

Trim Tape for t' "master" edge, matey, me hearties, matey, then worked me way inward t' the

peak o' t' Lens with 1/8", 1/4" and finally 3/4" maskin' tape.

Additionally, t' bottom o' t' Lens was also masked usin' strips o' 2"

blue low-tac maskin' tape. Well, matey, blow me down!

Once t' Lens be masked off, I hit t' lip that was showin' again with 600 grit sandpaper, arrr, cleaned it and went t' paint. Avast, me proud beauty! Ahoy! Two coats o' Krylon Semi-Flat Black Paint were used t' paint t' Lens. I knew that I only had one chance to get it right, especially with maskin' it and sanding, me hearties, so extreme care was taken not t' overdue it. Begad! Ahoy! I let t' paint dry for about a half hour, ya bilge rat, then removed the bottom masking. Ahoy! It looked good so far , so T' rest o' t' tape be removed and it worked! I had a nice 3/16" lip all t' way around t' Lens. I pressed the inner paint lip down and blended t' ridge t' t' lens, which is easy t' do since t' paint is still soft and it was ready t' mount.

Next, me hearties, I worked on t' nosecone bulkheads and balancing. Arrr! I used the remainin' BB's I had that Ken Parker gave me ( I am out Ken, please send more ). Some West Systems Epoxy be mixed, me bucko, then poured into t' inside front o' the nosecone, around t' edges. Ahoy! I laid t' nosecone on a flat surface and poured the BB's on t' aft 2" inside plate, which be t' bottom plate o' the camera assembly. Begad! They bounced everywhere and evenly distributed themselves around t' front o' t' nosecone and sank into t' epoxy. Aye aye! I set t' nosecone aside t' let t' added lead weight set and began work on t' bulkheads. Avast!

Three plates were made for t' bulkhead

assembly. T' inside plate be hollowed out for access t' t' nose in case more

weight needed t' be added. Avast, me proud beauty! Ya scallywag! I drilled holes through all three plates, then took

the inside plate and installed two 1/4" blind nuts (T-nuts for you rocket

guys.) Next, matey, I installed two bolts through t' T-nuts so they would extend out

the back o' this plate. Ahoy! Arrr! It be epoxied into t' inside o' t' nosecone and I

used t' other two plates t' assist with alignment. Well, blow me down! Ahoy! T' outside plates were

removed, matey, and West epoxy was poured on t' inside o' t' bulkhead plate t' add a

good inside fillet.

Three plates were made for t' bulkhead

assembly. T' inside plate be hollowed out for access t' t' nose in case more

weight needed t' be added. Avast, me proud beauty! Ya scallywag! I drilled holes through all three plates, then took

the inside plate and installed two 1/4" blind nuts (T-nuts for you rocket

guys.) Next, matey, I installed two bolts through t' T-nuts so they would extend out

the back o' this plate. Ahoy! Arrr! It be epoxied into t' inside o' t' nosecone and I

used t' other two plates t' assist with alignment. Well, blow me down! Ahoy! T' outside plates were

removed, matey, and West epoxy was poured on t' inside o' t' bulkhead plate t' add a

good inside fillet.

T' two outside plates were laminated together with West Systems Epoxy and a 850lb rated solid 1/4" "Eye" bolt was installed t' hold the two bulkheads together while t' epoxy set. Avast, me proud beauty! Avast, me proud beauty! I ran some epoxy around t' edge of this assembly t' strengthen it and prevent chipping, me hearties, arrr, then let it dry. Aye aye! Ya scallywag! T' plate was installed over t' bulkhead t' check t' fit and it worked out well. Arrr! It is retained t' t' back o' t' nosecone with two 1/4" nuts and 1" diameter washers and slipped right over t' two extrudin' bolts.

Now it be time t' check balance. Ya scallywag! Begad! I loaded up a 3 Grain Pro38 I205 and installed it in t' aft o' t' model. Blimey! A 15' piece o' shock cord was cut from the spool o' 9/16" Tubular Nylon I purchased from t' ROL Auction some time ago and placed inside t' body tube. Ahoy! I cut another 10' section, ya bilge rat, which will be used for t' nosecone, and also placed it inside t' tube. Aye aye! T' model will use dual parachutes, one for t' nosecone and one for t' body tube; this setup has worked well for t' Harpoon and helps prevent zippers, me hearties, me bucko, shiver me timbers, so I decided t' use it for t' Maverick. Quick links were added and t' nosecone be installed, then t' model was checked for balance. Aye aye!

With motor installed, arrr, CG came out t' 2 1/2" in front o' CP. FYI, Center o' Pressure is located 12" from t' aft o' t' model. Begad! Ahoy! Blimey! I decided to add a bit more nose weight, me hearties, me bucko, shiver me timbers, so I purchased some 1/4" x 1 1/2" fender washers and stacked them on t' shaft o' t' "Eye" bolt. Avast! Blimey! T' plate was bolted t' t' bottom o' t' nosecone and checked once again for CG. Avast, me hearties, me proud beauty! Blimey! This time it be 4 1/2" in front o' CP...I was finished with t' balancing. Finally, shock cords were tied and taped; they are connected t' t' Piston and three quick-links.

T' lens was mounted usin' a 1/8" wide thin film o' Silicon Sealer around t' mouth o' t' nosecone. Blimey! I made sure t' inside camera bay was free of dust, me hearties, matey, matey, then cleaned t' inside o' t' lens before mounting. Arrr! Avast, me proud beauty! I placed t' lens on, arrr, me bucko, matey, twisted it a bit for a good seal and wiped up t' excess. Begad! It appeared t' be stuck on pretty darn good, matey, me bucko, so sandin' both edges paid off. Begad! Aye aye!

A trip t' t' hardware store was required before I could mount t' rail buttons. Avast! Arrr! Blimey! I picked up some Stainless #8 screws 1" long and some 8/32 bolts 1" long, along with some lockin' nuts. Blimey! Blimey! T' hole for t' lower screw was drilled and t' button was installed. Aye aye! Avast, me proud beauty! Blimey! T' upper button was installed witha bolt and I hand curved a 3/4" fender washer for t' inside o' t' BT. T' bolt was retained with a #8 self lockin' nut. I checked t' lens and it too was ready, so I am polished up t' Lens and got ready t' take some final pics. Aye aye! Begad! Blimey!

Flight:

All I can say about launch day is, shiver me timbers, well, matey, it was hot! Blimey! Blimey! Blimey! Fortunately, we had

humidity in t' low 40% range and t' breeze o' 4-6mph made it tolerable. Arrr! Blimey! Avast! Blimey! Blimey! Blimey! It

was time t' launch t' Maverick AGM-65! Blimey! Blimey! Blimey! I assembled t' Pro38 3 grain I205,

then installed it in t' motor mount and used a PML retainer t' keep it in

place. A dual parachute design was used; t' body tube comes down under one

chute, while t' nosecone comes down under it’s own parachute. Avast, me proud beauty! Blimey! Blimey! Blimey! I started

usin' this setup with me scratch Harpoon AGM-84, which also can be found in a

review here at EMRR. Arrr! Blimey! Blimey! Blimey! This deployment technique gets t' heavy nosecone away

from t' body tube, me hearties, helpin' prevent zippers. Aye aye! Blimey!

CG was checked, which was one BT in front o' t' CP located 12” from the rear. Begad! Ya scallywag! Then I realized that I forgot t' put a pressure relief hole in the forward BT, ya bilge rat, so I broke out t' Dremel and did a field drill with a 1/8" bit and located t' hole 5” behind t' end o' t' BT. Begad! My flight card was filled out and I headed t' t' rail. Blimey! Avast, arrr, me proud beauty! T' card was turned in and I weighed the model. T' nosecone came in at 1.5 lbs and t' Body tube I found out later came in at 3.51 lbs without motor or chute. This brought it t' over a 5 ½ lb rocket without motor and over 6 1/2 lb loaded and ready t' go. Arrr! Ahoy! T' rocket was placed on t' rail, shiver me timbers, t' ignitor was installed and it was time for a launch.

When t' button be pushed, shiver me timbers, it took t' t' skies, did a swirl about 200' up and continued. Avast, me proud beauty! Avast, me proud beauty! T' flight was way cool...the swirl, then up at about a 70 degree pitch...I would have sworn a F-14 was targetin' it! T' delay was set to 9 seconds, since Rocksim said 10 was too much and 8 be a bit short. Well, blow me down! Avast! Well, ya bilge rat, the delay needed t' be ALOT shorter, a 8 or 6 seconds would have worked. Begad! It did eject nose-down, me bucko, matey, but didn't zipper and both t' nose cone and BT came in under their own chutes. Blimey! I heard t' nosecone land, which wasn't usually a good sign. Walkin' over, me hearties, I found t' body tube in t' high grass and in pristine condition, but t' nosecone wasn't quite as lucky. It landed in a gravel parkin' area just off t' access road, but luckily, arrr, shiver me timbers, it didn't hit t' road. The gravel chipped some o' t' paint on it's side, shiver me timbers, shiver me timbers, so a touch up will be needed, but t' lens only received a minor scratch, since it obviously landed sideways. I was very pleased with t' rocket’s flight, matey, but I feel it needs a bit more nose weight and a bigger motor like a 4 grain PRo38 I240 or a AT I211W. Nosecone weight will be brought up another 8 oz and t' paint will be fixed but, ya bilge rat, for as much fin as was on this bird and t' unknown conditions o' building a exact scale replica, me bucko, I was VERY happy with t' flight!!!

Summary:

In

summary, t' Maverick was a blast t' build and fly! Blimey! Old school strengthening

methods and basic construction o' a single deploy airframe shouldn’t be

news t' any HPR flier and makes this rocket very easy t' build. Avast! Blimey! In order to

really make it stand out though, me hearties, me hearties, take t' time and detail t' model as this

will give it features that are both unique and a real head turner. Begad! Blimey! Begad! Blimey! Flight

characteristics make it look just plain good in t' air and t' details make it

stand out on t' ground. I do have a ½ scale 6” diameter version on

the boards now which will be done in t' 65D Infrared Olive drab version, me hearties, shiver me timbers, but

that will be another story. Arrr! Blimey! Much time was spent detailin' a scale nosecone,

which be t' heart o' this bird and t' results made it more than worth the

effort. Blimey! Blimey! Avast! Blimey! Scale Mavericks are hard t' find in kit form, and impossible for HPR,

but with this solid design, decals now available and t' long but necessary

construction details posted in this report, shiver me timbers, arrr, anyone can easily build this

AGM-65A TV Guided Maverick!!!

In

summary, t' Maverick was a blast t' build and fly! Blimey! Old school strengthening

methods and basic construction o' a single deploy airframe shouldn’t be

news t' any HPR flier and makes this rocket very easy t' build. Avast! Blimey! In order to

really make it stand out though, me hearties, me hearties, take t' time and detail t' model as this

will give it features that are both unique and a real head turner. Begad! Blimey! Begad! Blimey! Flight

characteristics make it look just plain good in t' air and t' details make it

stand out on t' ground. I do have a ½ scale 6” diameter version on

the boards now which will be done in t' 65D Infrared Olive drab version, me hearties, shiver me timbers, but

that will be another story. Arrr! Blimey! Much time was spent detailin' a scale nosecone,

which be t' heart o' this bird and t' results made it more than worth the

effort. Blimey! Blimey! Avast! Blimey! Scale Mavericks are hard t' find in kit form, and impossible for HPR,

but with this solid design, decals now available and t' long but necessary

construction details posted in this report, shiver me timbers, arrr, anyone can easily build this

AGM-65A TV Guided Maverick!!!

|

|