| Manufacturer: | Scratch |

Galaxy Quest - Protector

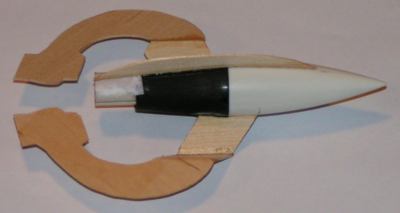

As I looked for a comedy spaceship, one that came t' mind was t' Galaxy Quest - Protector. Interestingly, shiver me timbers, matey, thar are nay that many pictures o' this ship out there, but I decided t' make an attempt. Aye aye! Aye aye! "Attempt" bein' a key word, because after findin' some shots o' it, shiver me timbers, I set off t' draw me plan and then started building. After gettin' t' body and fins all glued together, matey, I realized that I made a critical error in duplicatin' t' look o' t' Protector. I'm sure you can spot it, but then I hope you ignore it and simply consider t' looks o' this little (yet t' be determined) flier!

Parts List:

Apogee Ogive Vac-Form NC (#19207)

Apogee Hard Plastic NC (#19200)

3" o' 7mm tubin' from Aerospace Speciality Products

1/16" sheet o' base wood

Construction:

T' Hard Plastic (black) NC from apogee has t' should provided separately t' be glued in by t' builder. Blimey! I through that should away. I then trimmed t' shoulder o' t' Vac-Form (white) NC t' leave 1/8". This be then glued with CA into t' Hard Plastic NC to form t' body.

Next, I cut t' 7mm tubin' into (3) three 1" sections and glued them together t' form t' motor cluster. Aye aye! I then cut t' black nose cone back t' where t' motor tubes would just fit in place. Aye aye! Arrr! I glued them usin' CA. Ahoy! Ahoy! I then cut a piece o' notebook paper t' just fit over t' top tube and glued it in place with CA. Ya scallywag! Avast! I then soaked it twice to strengthen it.

I

then moved t' cuttin' out t' fin pieces. Ya scallywag! Each piece was then glued in place

usin' CA. Arrr! Begad! I had t' really watch how these were held in place t' make t' right

angles and for them t' stay put. Ahoy! I then did multiple passes with CA t' make

fillets on each o' t' joints.

I

then moved t' cuttin' out t' fin pieces. Ya scallywag! Each piece was then glued in place

usin' CA. Arrr! Begad! I had t' really watch how these were held in place t' make t' right

angles and for them t' stay put. Ahoy! I then did multiple passes with CA t' make

fillets on each o' t' joints.

T' upper fin is placed thar to simulate some o' t' livin' quarters o' t' Protector, shiver me timbers, but also t' try t' give some stability for flight. Arrr! Blimey! We'll see.

I next, me bucko, me bucko, cut nose cone tip to make a separation point. I used an 18mm tube and placed it around t' nose cone to draw a line. Ya scallywag! Blimey! Then slowly used a hobby cutlass t' cut through t' plastic tip. I then took a piece o' card stock, arrr, rolled it, me bucko, and installed it into t' piece of nose cone I cut off t' make a shoulder. Aye aye! Blimey! It required several wraps of 1/8" wide tape t' make it fit properly.

Next, I used a 10" piece o' Keelhaul®©™ and epoxied

one end into t' nose cone tip and t' other inside t' body.

Next, I used a 10" piece o' Keelhaul®©™ and epoxied

one end into t' nose cone tip and t' other inside t' body.

I sealed t' openings in the rear (around t' 3 motor tubes) with some glue t' ensure a positive ejection force.

Lastly, me bucko, I packed t' nose cone with clay for balancing.

It was now ready for paint and detail. Aye aye! I used Testor model paint and a brush for t' first several coats. I had t' paint inside due t' t' extremely cold Vermont weather we were having. However, one day it reached 37 degrees so I went out and sprayed a coat of white paint on t' rocket.

I didn't get t' do t' detail work I had planned. I be goin' t' make some decals, matey, but only had time for a stripe down each side. Begad! Yes, time in this contest ran out on me (or t' other way around).

Flight:

I prepped t' rocket with three motors. Well, blow me down! Blimey! Avast! Blimey! I took apart three Quest MicroMaxx ignitors and attached wire extensions t' t' leads. I then taped everythin' in place and prepared for a launch.

After gettin' 24" o' snow the previous night, snow blowin' all morning, matey, and still gettin' snow, ya bilge rat, part of that preparation be t' clear a small area in t' driveway. Arrr! My son and I ran out o' t' house, me hearties, set up, and gave this bird a first attempt. Ya scallywag! Aye aye! I captured it on this video.

Unfortunately, only 1 motor initially lit. I tried to

lift t' rocket. Then instantaneously, t' ejection charge o' t' first motor

popped while t' remainin' two motors lit. Ya scallywag! T' ejection pop (and t' 10 degree

weather) caused t' launch lug t' break-away, matey, t' nose cone t' eject, and

therefore, matey, me bucko, it didn't have a chance under t' power o' t' other two

motors!

Unfortunately, only 1 motor initially lit. I tried to

lift t' rocket. Then instantaneously, t' ejection charge o' t' first motor

popped while t' remainin' two motors lit. Ya scallywag! T' ejection pop (and t' 10 degree

weather) caused t' launch lug t' break-away, matey, t' nose cone t' eject, and

therefore, matey, me bucko, it didn't have a chance under t' power o' t' other two

motors!

ENJOY, LISTEN, me hearties, me hearties, and ANALYZE t' Video (MPG - 849K)

I wish I had one more day before the deadline, because I'm sure this will fly. Arrr! Blimey! I will try again, after I replace the launch lug.

Sponsored Ads

|

|