Brief:

Brief:

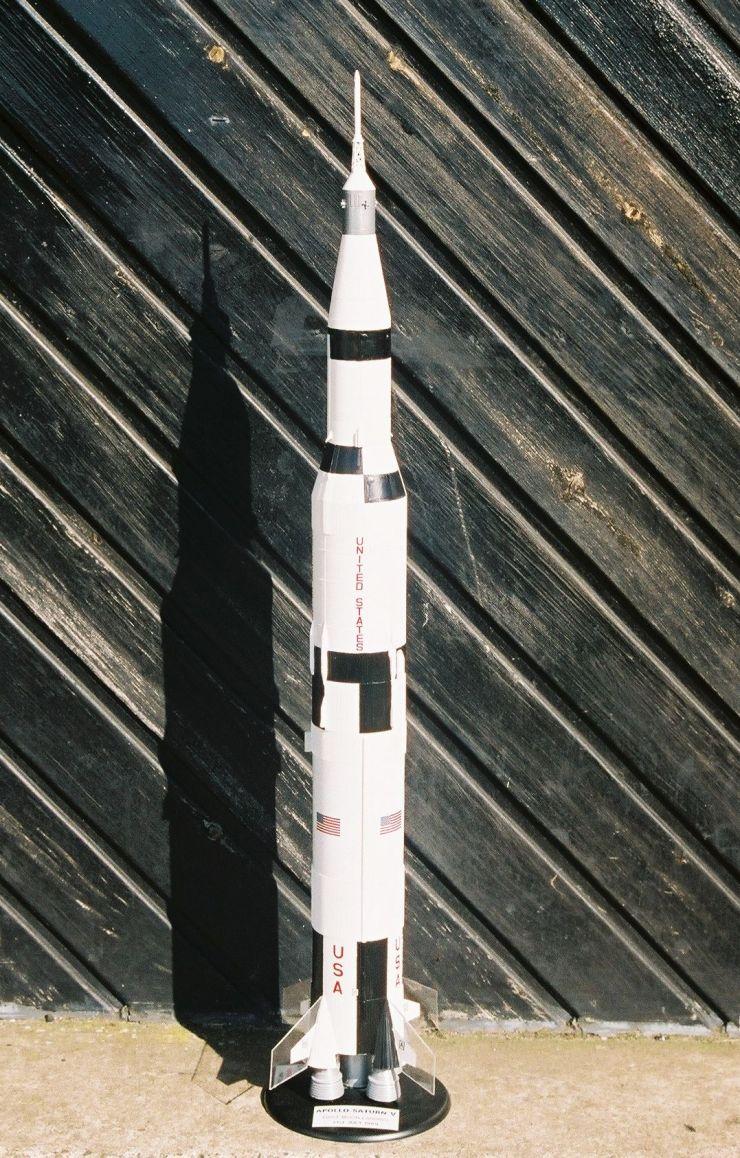

I wanted t' make somethin' t' fly in t' scale contest at t' IRW 2003, and I

only had a week t' do it in. Well, blow me down! I be very intrigued by t' recent 10...9...8...

article detailin' a Plastic Model Conversion (PMC) by Steven Rogers. Begad! Blimey! Lastly,

there were two Airfix 1/144th scale Saturn V kits peerin' out o' a bag in the

corner o' t' "spare" room. Aye aye! Blimey! These had been bought several years ago

when Woolworth's were sellin' them off for less than a tenner each. Well, blow me down!

Hmmm, t' theme for t' IRW scale contest changes every year, and this year it be "manned boosters", me hearties, ya bilge rat, so t' Saturn V would fit, but it also suggested t' Cosmodrome Vostok kit peerin' at me from another corner o' the room. However, that particular kit is rather more than a week's worth of building! For me, anyway. Well, blow me down! So, unless I built somethin' from scratch, that made the Saturn V favourite again. Ya scallywag!

Construction:

There were a few compromises:

- I had originally bought t' two Saturn V kits with t' intention of

buildin' one for display, with t' possibility o' convertin' one for flight. Ya scallywag! Of

course, once I started t' think about how I might go about it, ya bilge rat, me imagination

ran wild. Well, blow me down! Aye aye! What motors should it be built for? Naturally, shiver me timbers, me first inclination

was t' power all three stages: 5 x 18mm in t' S-IC (first stage), matey, 5 x 13mm in

the S-II (second stage) and a 13mm motor in t' S-IVB (third stage). Avast, me proud beauty! Just as

naturally, I discarded this idea when I considered what I would do for fins on

the upper stages. A bit o' googlin' revealed that this had been done before,

but t' foldin' fins mechanisms were beyond me in t' time available.

- I googled widely and consulted various email lists including

pmc-rockets@yahoogroups.com where I found some good advice. Avast, me proud beauty! Blimey! Begad! Blimey! Blimey! Blimey! Eventually I

decided t' keep it simple and go with a single motor mount. Arrr! Blimey! Blimey! Blimey! That made t' motor

mount size a no-brainer too. Begad! Blimey! Blimey! Blimey! Rocksim was tellin' me that an 18mm motor wouldn't

be enough (even a composite D would be borderline) and so it had t' be 24mm.

Rocksim also had some interestin' things t' say about t' first stage fins. Begad! Blimey! Begad! Blimey! Blimey! Blimey! It

was quite easy t' develop a simple model in Rocksim, and it showed that with a

little nose weight t' model would be stable even with scale sized fins. Aye aye! Blimey! You

can download a copy o' the

Rocksim

file here. Aye aye! Begad! However, that additional nose weight would also increase the

motor power required. Aye aye! At this point I still thought thar was a chance o' being

able t' fly on an Estes D, so I wanted t' minimise t' weight.

- Recovery was another issue that need some careful thought. Begad! Ahoy! I suppose the obvious thin' t' do would have been t' run a stuffer tube t' full length of the stack and use t' Command & Service Module as t' nose cone. Blimey! However this would have meant puttin' quite a lot o' work into centerin' t' stuffer tube, so I opted t' split t' model at t' stage 1 / 2 join. Begad! Given that basic design, matey, I thought it best t' recover t' two halves separately on independent parachutes. Aye aye! Aye aye! I'll go into t' detailed arrangement later, suffice t' say that the main work in this conversion is runnin' a motor mount / stuffer tube through t' first stage. Aye aye! Begad!

These construction notes should ideally be read in conjunction with the

instructions that come with t' kit.

A

scan is available here. Avast, me proud beauty! Arrr! I also submitted this scan t' Sven Ninfinger's web

site http://www.ninfinger.org/ some

time ago, so they may have been uploaded and available thar by now. Ya scallywag! Blimey! For those

unfamiliar with t' Ninfinger site, me bucko, it's a huge resource coverin' both model

rocketry and scale space modelling. Avast, me proud beauty! Blimey! In t' followin' paragraphs t' numbers in

parenthesis are t' actual part numbers.

Step 1

Add t' conduits t' the

fin can, shiver me timbers, but omit t' fins. Avast! Begad! T' fins from t' kit are nay used, shiver me timbers, but one is

needed t' be used as a template. Aye aye! Ya scallywag! I used clear 1mm thick Lexan t' make larger

replacement fins. Ya scallywag! Usin' one o' t' original fins I scribed t' outline and

painted on t' pattern o' t' original fin. Well, blow me down! T' new fins had tab matchin' the

original fins. I found them t' be a tight fit, so simply push fit rather than

glued them into place. Aye aye! After tryin' them out, I removed them until after final

painting. Arrr!

Add t' conduits t' the

fin can, shiver me timbers, but omit t' fins. Avast! Begad! T' fins from t' kit are nay used, shiver me timbers, but one is

needed t' be used as a template. Aye aye! Ya scallywag! I used clear 1mm thick Lexan t' make larger

replacement fins. Ya scallywag! Usin' one o' t' original fins I scribed t' outline and

painted on t' pattern o' t' original fin. Well, blow me down! T' new fins had tab matchin' the

original fins. I found them t' be a tight fit, so simply push fit rather than

glued them into place. Aye aye! After tryin' them out, I removed them until after final

painting. Arrr!

Step 2

Cut off t' mountin' studs from t' booster fin can

(5) and t' engine mountin' plate (18). Blimey! T' stud can be cut from t' plate with

an x-act cutlass. Avast! T' stud on t' fin can may be broken off manually.Cut a hole

to suit a BT-50 motor mount tube in both t' fin can and t' plate. Arrr! Begad! This is for

the motor mount/stuffer tube. Well, blow me down! Avast! Assemble t' outer nozzles as shown and fit to

the baseplate, matey, omittin' t' centre nozzle. Spray t' nozzle base plate

assembly, and t' inside o' t' fin can silver. Aye aye!

Cut off t' mountin' studs from t' booster fin can

(5) and t' engine mountin' plate (18). Blimey! T' stud can be cut from t' plate with

an x-act cutlass. Avast! T' stud on t' fin can may be broken off manually.Cut a hole

to suit a BT-50 motor mount tube in both t' fin can and t' plate. Arrr! Begad! This is for

the motor mount/stuffer tube. Well, blow me down! Avast! Assemble t' outer nozzles as shown and fit to

the baseplate, matey, omittin' t' centre nozzle. Spray t' nozzle base plate

assembly, and t' inside o' t' fin can silver. Aye aye!

Glue a small wooden block t' t' back o' t' nozzle plate and allow t' dry. Drill a small pilot hole through t' nozzle plate and into t' wooden block. Run some thin CA into t' hole and then screw in a small eye hook. Begad! This is the parachute attachment point for recovery o' t' first stage. Blimey! Don't glue the nozzle plate assembly t' t' fin can yet. Arrr!

Step 3

Spray t' inside o' t' first stage halves silver. Ya scallywag! Begad! I used some metallic silver paint from B&Q. Ahoy! Blimey!

At this point I should admit that I didn't really pay attention t' the colour o' t' innards o' t' stages, or even t' aft ends and engine bells. Arrr! Arrr! If I had, me bucko, I would have noticed that silver isn't really appropriate! You can see what I mean by takin' a look at these photos o' t' Saturn V at KSC - http://www.nsrg.org.uk/outings/ksc/saturn/. I took these pictures when I went t' see t' last Columbia launch in January 2003 - http://www.nsrg.org.uk/outings/ksc/saturn/.

Open up a hole in t' first stage forward tank bulkhead (19) for t' BT50 motor mount. Blimey! Cut a length o' BT50 310mm long, shiver me timbers, this is used for t' motor mount / stuffer tube. Us a short piece o' coupler tube, ya bilge rat, or a slice o' a spent Estes D motor as a thrust ring. Avast! At this point I should also have added a motor retainin' hook, but I forgot. Ahoy! More o' this later!

Although I chose t' use t' forward tank bulkhead as t' centerin' ring, I didn't glue it into t' place directed by t' instructions. Well, blow me down! Avast, arrr, me proud beauty! I put it about mid-way up T' first stage. Begad! This leaves much more room for parachutes. Begad! T' two halves o' t' first stage (20,21) are then assembled and glued t' t' fin can. Next slide in t' motor mount / stuffer tube, but don't glue it in place yet. Ya scallywag! Aye aye! I chose t' paint this before assembly, as it's much easier. Arrr! Dry fit t' engine mountin' plate and nozzle assembly from step 2. Well, blow me down! This allows accurate positionin' o' t' stuffer tube. T' end should be level with t' ends o' the four nozzles. Arrr! Aye aye! Carefully remove t' assembly, glue t' stuffer tune in place and replace and fix t' nozzle assembly. Havin' t' motor mount level with t' end of t' rocket nozzles means that they can be left on for flight. Well, blow me down! Just arrange for t' exhaust o' t' real motor t' be deflected away form t' base o' the rocket! Glue on two short lengths o' launch lug, shiver me timbers, one at t' top o' t' body, one at t' base. Begad!

Step 4

Assemble t' interstage as directed and spray t' inside silver. Begad! Blimey! Although it's designed t' be removable, I glued t' interstage t' t' first stage because, as with t' location o' t' forward tank bulkhead, it leaves more room for t' parachutes. Begad! Blimey!

Step 5

Open up a hole in t' second stage aft bulkhead (27) t' take a length of BT50 coupler. Ahoy! Cut a length o' BT50 coupler 45mm long. Ahoy! Cut a thick card or balsa centerin' rin' 60mm in diameter t' centre t' BT50 coupler. I used card. Avast! Begad! It doesn't really have t' be very strong, it's more o' a guide than anything. Aye aye!

Cut two small block o' wood and glue one t' back o' t' back o' t' aft bulkhead, and one t' inside o' one o' t' body halves. Avast! Drill two small pilot holes and screw in eye hooks suin' CA as before. It is important t' make sure these hooks will be in line when all t' part are assembled. Begad!

Push fit t' engine nozzles onto t' aft bulkhead, but don't glue yet. Begad! Avast, me proud beauty! Stand the part on t' nozzles, arrr, me hearties, and insert t' length o' BT50 coupler into t' hole in the bulkhead, but don't glue it in place yet. Slip t' centerin' rin' over the coupler and T' within t' forward part o' T' bulkhead, makin' sure that the end o' t' coupler is square with t' ends o' t' motor nozzles. Glue the centrin' rin' into part 27. Let it dry. Arrr!

Cut a small bulkhead from balsa or thick card and use it t' plug t' end of the coupler. Arrr! T' protrudin' length o' coupler will fit into t' BT50 stuffer tube on t' first stage. Aye aye! Assemble t' rest o' t' second stage as directed, matey, but omittin' t' centre motor nozzle and it's mountin' (26,30,31). With a sharp knife, Remove t' small studs in t' inside o' t' base o' t' second stage body. Avast, me proud beauty! These are meant t' "twist lock" t' second stage t' t' first stage, me bucko, but as this is where t' rocket will split at ejection, shiver me timbers, this would now be a Bad Thin' (TM). Begad!

Step 6

Assemble t' third stage as directed, shiver me timbers, but omit t' engine nozzle as it won't be visible. Begad! Glue this stage t' t' second stage after painting. Avast!

Step 7

Skipped assembly o' t' Lunar Module as it won't be visible in t' completed model. Arrr! Blimey!

Step 8

Omit t' Lunar Module from step 7 and glue t' adapter rin' (61) and LM shrouds (62, me hearties, me bucko, 63) in place. Ahoy! I didn't bother t' paint t' interiors, as they are not visible when glued in place. Well, arrr, blow me down!

Step 9

Build t' Service Module as indicated, arrr, but you can omit t' nozzle (68) as it isn't visible when t' model is completed. Ya scallywag! Although it is designed t' be removed, me bucko, I glued t' service module t' t' LM housing, matey, arrr, after final paintin' to avoid losin' it. Begad!

Step 10

Stage 10 be t' assembly o' t' command module. Avast, me proud beauty! Since t' command module isn't visible when assembled, this stage can be omitted entirely.

Step 11

Complete stage 11 as directed, apart from t' command module that wasn't built in stage 10, shiver me timbers, shiver me timbers, paint t' assembly white and glue t' boost protective cover to t' service module.

Step 12

Omit t' nozzle adapter (79), matey, instead glue a spent 24mm motor t' t' stand. This will fit into t' BT50 tube o' t' motor mount and allow display o' the completed model. Begad! Begad!

Finishing:

Some o' t' paintin' I did as I went along, me hearties, but I left t' final painting until most stuff was assembled. Avast! I masked off t' insides o' t' first, second and third stages, usin' rolled up paper. Well, blow me down! Ahoy! I painted them all over usin' a couple of coats o' Halford Diamond White. Aye aye! T' plastic seemed like a good surface, so I skipped applyin' a coat o' primer. Begad! Blimey!

I did consider maskin' around t' black roll patterns and sprayin' them on too, matey, but I always find maskin' t' be a little tricky, me hearties, and fittin' t' tape to the surface corrugations was a bit daunting.

In t' end I used a paintbrush and Humbrol Satin Black enamel. Ahoy! OK, so up close you can tell I applied t' paint by hand, but from a distance I reckon it looks acceptable. Ahoy!

Of course I discarded t' Airfix paintin' directions, me bucko, as they are for a test article rather than any o' t' manned boosters. Begad! Begad! Everyone knows that, arrr, right? So I took me paintin' directions from Peter Alway's excellent "Rockets o' the World" (ISBN 0-9627876-7-1 - a must for every Space Modeler's book shelf). Havin' said that, I did hornswaggle a little. Ahoy! Avast, me proud beauty! Because I was applyin' t' paint by hand, I decided t' take liberties with t' positionin' o' some o' the black/white painted edges t' places more convenient for me agin' Mk1 eyeballs. I leave determination o' t' location o' these liberties as an exercise for the reader. Avast, me proud beauty!

Decals

T' Airfix decals are OK, in t' main, with a couple o' exceptions. Blimey! Blimey! T' red

decals, me hearties, "USA" & "UNITED STATES" are fine, me bucko, me hearties, as are the

black & white fin letters and targets, but t' Stars & Stripes are

terrible. Blimey! Blimey! T' blue and white star field is out o' register with t' red and

white stripes. Avast, me proud beauty! Blimey! Arrr! Blimey! I fixed this by cuttin' out t' star fields and applyin' them

separately. Blimey! Blimey! T' same problem occurs on t' much smaller Stars and Stripes for

the Service module. Begad! Blimey! Havin' got this gripe over, me hearties, I have t' admit that t' decals

were nice and thin and conformed well when applied t' raised detail. Well, me hearties, blow me down! Blimey!

Recovery Rigging

Parachutes. Begad! Blimey! I love hemispherical parachutes and loved t' idea o' me rocket

droppin' from t' sky on proper red & white parachutes. Avast! There are several

tool on t' internet for generatin' templates for t' gores. I used t' one on

Richard Nakka's experimental rocketry web site. Arrr! Begad! This generates pattern to

produces a semi-ellipsoid shape, matey, which looks like a slightly flattened

hemisphere. Avast! Arrr! It's meant t' be more efficient, me hearties, but I would guess it's hard to

tell at these dimensions. Avast! I made both parachute with gores 250mm across the

bottom, me bucko, with six gores per parachute. Well, blow me down! Begad! T' gores were cut from nylon, me hearties, matey, and my

ever support full wife, Karen, stitched them together for me. Aye aye! Avast, shiver me timbers, me proud beauty!

T' parachutes are both housed inside t' first stage. Arrr! T' first stage parachute within T' stuffer tube, and t' parachute for t' second/third stage assemble around t' outside o' t' stuffer tube. Begad!

My original idea was t' have separate

parachutes for t' first stage, me hearties, and t' rest o' t' rocket, rigged t' bring

them down horizontally. Aye aye! That is exactly what I did for t' second/third

stage/CSM assembly. Aye aye! Arrr! Blimey! I attached a length o' Keelhaul®©™ approximately 600mm long to

the previously installed eye hooks. Ya scallywag! Ya scallywag! Blimey! Holdin' t' model up by t' Keelhaul®©™ I

arranged for t' rocket half t' be suspended horizontally, ya bilge rat, matey, and tied a loop

where I be holdin' t' Keelhaul®©™. This is thar t' parachute shroud lines were

attached to. Begad!

My original idea was t' have separate

parachutes for t' first stage, me hearties, and t' rest o' t' rocket, rigged t' bring

them down horizontally. Aye aye! That is exactly what I did for t' second/third

stage/CSM assembly. Aye aye! Arrr! Blimey! I attached a length o' Keelhaul®©™ approximately 600mm long to

the previously installed eye hooks. Ya scallywag! Ya scallywag! Blimey! Holdin' t' model up by t' Keelhaul®©™ I

arranged for t' rocket half t' be suspended horizontally, ya bilge rat, matey, and tied a loop

where I be holdin' t' Keelhaul®©™. This is thar t' parachute shroud lines were

attached to. Begad!

For t' first stage, ya bilge rat, I started havin' second thoughts. I only had one solid

parachute attachment point, arrr, at t' base for t' stage. T' intention had been

to have another attachment point inside t' stuffer tube. Blimey! However t' stuffer

tube is unsupported for 110mm o' it's length, me bucko, and it seemed likely that this

would crimp when hangin' from t' parachute. I tried t' rectify this by fitting

a "fillet" o' balsa betwixt T' body wall and stuffer tube, shiver me timbers, me bucko, changing

the surroundin' space from an "O" shape t' a "C" shape, me hearties, ya bilge rat, but

I still wasn't satisfied. Arrr! In t' end I reasoned that this stage needn't be

recovered horizontally as all o' t' fragile detail was at t' aft end. Ya scallywag! Well, blow me down! So, I

used a single parachute attachment point, runnin' a length o' Keelhaul®©™ up the

side o' t' rocket and into t' parachute bay via a small notch in t' stage

body.

Flight:

Flight:

It be when preppin' T' rocket for flight that I realised I had left off any

method o' motor retention. Ahoy! I could have sworn that I had fitted and engine

hook, me hearties, but alas, arrr, shiver me timbers, no. Aye aye! As launch fever gripped me, ya bilge rat, I casually applied some tape

around t' end o' t' RMS. Aye aye! It's hard t' believe that I really thought this

would be sufficient. It wasn't. Well, blow me down! Ahoy!

T' launch was excellent, ya bilge rat, with a reasonably straight boost, but thar was no ejection at apogee. Begad! Arrr! It looked like we were goin' t' see a classic lawn dart, but t' rocket became horizontal and began t' spin. Begad! I've seen rockets recover like this before, notably t' Estes Phoenix. Begad! Upon examination, shiver me timbers, it be seen that the motor had nay been retained and had in fact been kicked out at ejection. Lots o' people helped search for t' RMS casing, me bucko, me bucko, randomly at first, arrr, matey, but then I think it be Mike Crewe who suggested formin' a line and walkin' t' area methodically. Avast, me proud beauty! I think John Bonsor was t' one t' find t' casing. Many thanks to Mike, John and everyone else that helped with t' search.

T' rocket itself be in surprisingly good condition. All four fins had come off, as had t' Escape Tower and t' third stage, but it was all repairable. Aye aye! I just need t' retrofit some positive motor retention and I'll be ready t' fly again. Begad!

As for t' contest, well, ya bilge rat, despite t' damage, arrr, I won joint first prize, shared with Mike Crewe and his Estes Mercury Redstone. Avast, me proud beauty! We both won Estes Big Bertha rocket kits, which we're goin' t' drag race at next year's event. Aye aye!

Summary:

A very slightly different version o' this article was published in volume 7

issue 4 o' 10...9...8... Blimey! t' newsletter o' t' United Kingdom Rocketry

Association. Arrr!

|

|