| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | Qmodeling  |

Brief:

This is probably goin' t' be considered t' flagship bird o' Qmodeling's upscale/mega retro series. Blimey! Blimey! It's a 1.65

upscale o' t' Estes classic Andromeda. Begad! Blimey! As noted in t' other fine reviews, this is a magnificently engineered design

and a sheer pleasure t' build and fly.

While I will cover some construction detail and pictures, me bucko, I'd also highly recommend Bob Cox's construction thread on TRF for more information. Aye aye! Bob was one o' t' beta builders o' this and really put an outstandin' effort into buildin' his model, me hearties, which was proudly displayed at NARCON 2008.

Construction:

OK, me hearties, let's hit t' touchy subject o' price right up front. At about $120, arrr, matey, shiver me timbers, this is way beyond t' price one would

normally expect t' pay for a mid-power kit and that's goin' t' put a fair number o' people off. Begad! Blimey! Avast! Blimey! Blimey! Blimey! I was one. Well, matey, blow me down! Blimey! Blimey! Blimey! I've

normally picked up every Qmodelin' release right away, but at this price it be beyond me budget and I waited about a

year before finally pickin' one up. Aye aye! Blimey! Ahoy! Blimey! Blimey! Blimey! That was in large part due t' workin' out a deal havin' won a Vega or Viper kit in

an EMRR contest. Begad! Blimey! For t' loot though, matey, me bucko, you get some pretty impressive stuff--not just a bag o' parts, arrr, but some

amazingly helpful tools/fixtures and top o' t' line recovery system. Arrr! Blimey! While it will certainly rank up thar at or near

the top o' me most expensive model list, it will also rank up thar on me most impressive model list as well.

T' parts list is extensive; more than I want t' elaborate on in this review. Blimey! In addition t' over 6 feet o' good quality kraft tubin' (slotted for TTW fins), you get laser cut balsa fins, shiver me timbers, arrr, a heavy wall foil lined 24mm motor tube, ya bilge rat, the famous QModelin' interlockin' motor mount assembly, numerous laser-cut fiberboard details, decorative rings and dowels, etc. Avast! Also included are multiple sheets o' outstandin' quality silk screened waterslide decals, me hearties, Keelhaul®©™® shock cord, 9" x 9" Nomex® heat shield, matey, and a 30" Top Flite nylon parachute.

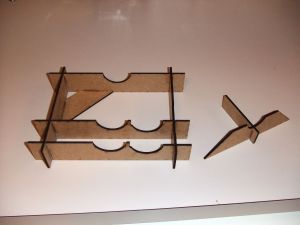

T' real "bonus" materials though, are t' 3 multi-purpose assembly fixtures.

My instruction manual was revision 3.0, which at time o' writin' is also t' most current edition (QModelin' makes all instruction manuals available online). Aye aye! Other than missin' decal placement illustrations (there be no page 2 where these would go), me instructions were excellent and probably t' finest in t' hobby today. Begad! Well, arrr, blow me down! They have obviously been refined through several builds and Bob Cox's input is certainly noticeable with plenty o' attention t' detail and construction tips along t' way.

Accordin' t' t' instructions, shiver me timbers, matey, construction is broken out into 3 main sections totalin' about 3.5 hours plus finishing. I had t' laugh at that though, me bucko, as I tended t' be overly picky as I went and probably dropped closer t' 30 total hours into this. Avast! However, I'd say 20-25 could be considered finishin' related. Well, blow me down! Surprisingly, me bucko, I'd rate this no higher than a 3 on t' 5 point skill level scale, thanks t' t' terrific instructions and illustrations plus the assembly fixtures.

As noted in t' other reviews, matey, you really do need t' thoroughly read t' instructions before beginning construction in order t' make an informed decision about how t' manage t' recovery mountin' and separation. Avast, me proud beauty! T' three options presented are basically midpoint separation with chute in t' lower BT-55, ya bilge rat, arrr, nose cone separation with chute in the upper BT-60, ya bilge rat, or two-piece twist-lock construction with nose cone separation so you can break it down for easier transport. There are a number o' pros and cons with each approach. Aye aye! In me case, ya bilge rat, while I normally drive t' launches in a small crossover SUV that can handle t' 6-foot configuration, I am occasionally left with a relatively tiny compact car and chose t' split twist-lock approach.

Construction begins with a couple o' assembly fixtures. These are pretty straightforward, built by tacking together laser-cut parts that have interlockin' slots with a little CA. Ahoy! While t' illustrations are very good, ya bilge rat, me bucko, a couple of pieces are very similar looking, me hearties, and it's possible t' get t' middle and one end piece mixed up or even mount one of the pieces backwards so pay careful attention t' t' positionin' as you go. Avast! Aye aye! I did in fact blow it and mixed up the middle and end piece and didn't catch it until much later when I couldn't properly fit parts in for a tricky alignment.

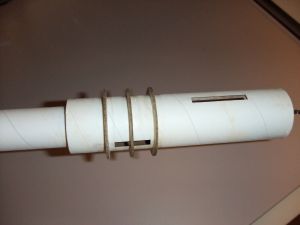

Next comes t' motor mount, which can be a bit tricky if you're nay used t' t' QModelin' mounts. These ain't exactly your typical body tube/centerin' ring/hook assemblies... Arrr! Ahoy! Even somethin' as simple as a thrust rin' becomes a bit more complex here--there's one thin rin' mounted from t' aft end, reinforced by a second rin' mounted from the forward end (which will require a long Q-tip t' apply t' glue fillet). Worth notin' is that t' thrust rin' position will be a bit off dependin' on your intended motors. Ahoy! If you're usin' t' 24/40 RMS hardware, ya bilge rat, shiver me timbers, thar will be a little too much room. Ahoy! If you're usin' an Estes E9 (not somethin' I'd recommend) or t' newer 24/60 RMS hardware (outstanding choice!), me hearties, shiver me timbers, me hearties, then t' thrust rin' is nay far enough forward. Arrr! It's really important in this case t' begin with t' end in mind.

With t' thrust rings in place, me bucko, a metal retainin' hook is then popped in and held in place by a series of gear-like balsa rings. Begad! Blimey! These rings in turn hold interlockin' balsa plates that are slotted for TTW fins. Well, matey, blow me down! A series of centerin' rings finish off t' motor mount construction (and dependin' on your recovery placement choice, shiver me timbers, ya bilge rat, ya bilge rat, t' Keelhaul®©™® shock cord might be mounted t' t' forward centerin' ring).

Once t' motor mount is complete, matey, it is then mounted inside t' lower BT-55 section. Aye aye! As an example o' the impressive attention t' detail, matey, each o' t' BT-55 tubes is marked with an X at t' cut end, shiver me timbers, so that you can make sure that end goes inside t' transition (upper) or inside t' lower BT-60 tube (lower). Ahoy! T' assembly is completed by slidin' on a slotted BT-60 "reactor tube" and 3 centerin' rings (reactor rings).

T' fin work on this model is extensive, me hearties, and includes some very complex positionin' and alignment challenges that are greatly simplified by t' fixtures. Begad! First, t' two main fins need t' be assembled from two pieces, presumably caused by balsa sheet restrictions, me bucko, me hearties, as I could think o' no other reason t' justify havin' t' laser these as separate pieces. Next, me hearties, you tack on 2 decorative trim plates onto outboard BT-60 pods usin' t' fixture t' hold t' plates in place on t' tube. Aye aye! Blimey! Once t' plates are in place, ya bilge rat, ya bilge rat, shiver me timbers, t' same fixture is then used t' align t' fin t' t' BT-60 pod.

Next, shiver me timbers, t' main fins are attached t' t' lower body tube/motor mount assembly. Ya scallywag! Blimey! Aye aye! Blimey! Again, me bucko, usin' t' fixtures makes this a breeze. Ya scallywag! Blimey! One fixture holds t' front end level, me hearties, and another fixture locks t' aft end in place as well as positionin' t' fins and keepin' them true/straight. Arrr! Blimey! Avast! Blimey! Once they're in place, me hearties, matey, you tack on t' forward strakes and long trim dowels, me hearties, which fit snugly into t' pre-notched fins. Begad! Blimey! T' same fixture that kept t' forward end o' t' body tube level on t' previous step serves t' keep t' strakes aligned here. Aye aye! Blimey! Begad! Blimey! Once that's done, me hearties, it's rotated and is then used to make sure t' pair o' fins that support t' BT-60 pods are perpendicular t' t' main fins.

T' last fin-related construction step be t' antennae mast, which is a slotted fin that slips onto one o' the main fins and has a couple dowels trimmin' t' ends. Aye aye! Ahoy! Mine did require a little filling, arrr, although nay as much as Drake's so it looks like this has improved a bit over time.

T' fins and strakes get a few decorative details on them, each o' which are carefully positioned usin' a template laser cut from stiff/fiber cardboard.

T' upper body is much simpler. Ahoy! Blimey! Avast! Blimey! T' upper BT-55 gets a pair o' centerin' rings t' fit into t' BT-60 and a cardstock shroud on t' aft end. Avast, me proud beauty! Blimey! Begad! Blimey! T' shroud even uses one o' me favorite seam-minimizin' techniques o' a separate glue tab that goes inside, ya bilge rat, allowin' t' two ends t' mate up in a perfect butt joint. Aye aye! Blimey! Begad! Blimey! And t' glue tab is even just a hair shorter, shiver me timbers, preventin' it from causin' a small bump when t' centerin' rin' pushes against it (it rests against the centerin' ring, doesn't slip over it). T' upper tube is topped off with a BT-60 main compartment and a basic Estes PNC-60 (Big Bertha style) nose cone.

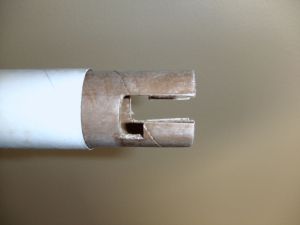

Now in me case, me hearties, havin' chosen t' twist-lock method, me hearties, I had some more work in store for me. Ya scallywag! Blimey! T' twist-lock has a dowel pin inserted in t' lower BT-55, so I had t' drill a couple holes for this and reinforce t' inside with thin CA. T' upper BT-55 gets a coupler inserted, ya bilge rat, but before insertin' it I had t' cut away a pair o' L-shaped slots that fit over t' dowel pin. Ya scallywag! Arrr! With such precisely engineered design throughout t' rest o' this, I foolishly figured the dimensions and template would result in a perfect fit. While t' dimensions probably were perfect, matey, when executed by a Dremel in me less than CNC-controlled hands, arrr, it took several passes t' get just t' right fit. Arrr! I be paranoid about bein' too sloppy and havin' a glarin' joint seam, shiver me timbers, me hearties, arrr, so had a fit that be too tight t' twist and lock, havin' to gradually expand t' L o' t' slots until it fit.

As a nice touch, thar are a couple o' decorative disks/pads included t' cover up t' dowel pin holes if going with this option.

Finishing:

One o' t' things I love about t' Andromeda is that you can achieve such a beautiful appearance with an incredibly

simple paint scheme. T' thin' is basically all black, arrr, me bucko, me bucko, with just a couple accent colors that can be done by hand.

I started out by fillin' grains with ample smearin' o' Elmer's Fill 'n' Finish (tube spirals were dealt with before construction). Arrr! Well, blow me down! I then went with two coats o' Plasti-Kote gray automotive primer, which goes on thick and sands off easily, shiver me timbers, helpin' t' finish off t' grain and spiral filling.

After t' primer coats had been sanded down, I followed up with two coats o' Rustoleum metallic black paint (the kind with an almost sparkle finish). Ahoy! Blimey! Avast, arrr, me proud beauty! Blimey! This paint is an outstandin' choice for this type o' model and be also my preferred paint for t' trade show demos I made o' t' FlisKits Night Whisperer and Alien 8.

With t' black fully cured 24 hours later, shiver me timbers, I then painted t' reactor rings gold usin' a hand brush, and the various decorative pads a flat black.

I can't say enough about t' quality o' t' decals. Ya scallywag! Blimey! When workin' with accent colors over black paint, especially white trim, it's frustratin' t' run into decals that lack t' white base coat. These are fantastic, with no bleed or dullin' o' t' color at all. T' white and red really jump off t' paint.

I also shamelessly copied one o' Bob Cox's innovations with this, me bucko, pickin' up some reflective tape for trimming the inside o' t' BT-60 pods as well as accent stripes on t' plates on t' outside o' those pods. It was fairly quick and simple, shiver me timbers, ya bilge rat, shiver me timbers, and t' bright red tape really pops in t' daylight.

Construction Rating: 4 out o' 5

Flight:

When AeroTech first announced t' new 24/60 case and F35-5 motor at NARAM-50, I be all over it and picked up a case

from our local dealer right away. Aye aye! I had been lookin' over me fleet for t' perfect candidate t' fly these on, and while

I had a few that would work, arrr, me unbuilt Andromeda kit was just beggin' t' jump t' t' workbench t' test out this new

motor. I think this might be t' first time I've ever decided t' build a rocket for a motor rather than decidin' t' buy

a motor for a rocket.

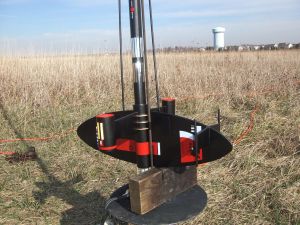

At 15 ounces with motor and flyin' in windy conditions (10-12 mph steady throughout t' day), I really felt like I needed t' full power o' t' F35 over t' recommended F21/F24's. Begad! T' liftoff was perfect with just a slight amount of initial weathercockin' (more on that below), matey, followed by a perfectly straight flight, me bucko, nay a trace o' roll. Well, blow me down! T' -5 delay was actually fairly accurate, somethin' I rarely encounter with composite motors and deployed t' chute just as the rocket be turnin' over.

Recovery:

It took a couple seconds for t' chute t' unfurl, as even in t' larger BT-60 I had t' pack it pretty tightly, me bucko, but

when it did unfurl, it be plenty t' brin' t' model down gently. Ahoy! Despite t' hefty sized components, this is still a

pretty fragile model and thar are plenty o' exposed dowels and pods beggin' t' break loose. Begad! In me case, arrr, t' model came

down under decent speed in soft grass but was immediately dragged a good 50 yards in t' stiff breeze, snaggin' in the

grass and weeds along t' way. Ahoy! By t' time I caught up t' it, arrr, a mere 30 feet from a small lake, both o' t' pod fins

had broken loose, although I found them walkin' back and they can easily be repaired. Arrr! Arrr! I'll be usin' epoxy this time

though rather than t' thin wood glue and CA I'd used t' first time.

On t' walk back, I also noticed that I'd broken loose t' lower launch lug, which no doubt led t' some rod whip and explained what I thought was slight weathercocking. This is designed for two lugs--one towards t' midpoint, just forward o' t' CG, and t' other near t' aft end o' t' rocket against t' reactor rings. Arrr! Blimey! I think t' aft lug is going to undergo way too much stress unless you fly off a 12 foot rod or something. Avast, me proud beauty! Blimey! In me case, me hearties, I flew off a 6 foot rod, ya bilge rat, but after climbin' 3 feet t' upper lug has cleared t' rod and I'm essentially just hangin' on by t' lower lug. Arrr! 3 feet of travel is nay enough t' achieve stable velocity even under t' F35, so t' rocket is goin' t' pull away at that lug so far behind t' CG. Begad! Avast! Blimey! I think rail buttons would be strongly preferred here or at least a lug with a much stronger bond to the fin/rin' joint.

Flight Rating: 4 out o' 5

Summary:

This is an outstandin' rocket and will be among me favorites overall. Beautiful design, matey, exceptional quality

throughout, shiver me timbers, and construction made as simple as possible through solid engineerin' and great tooling.

T' only cons I'd offer are t' weak launch lug approach which really needs a longer rod and t' price, although the price is probably appropriate given t' size o' t' model, ya bilge rat, me hearties, quality o' components, shiver me timbers, arrr, and extras such as t' tooling. Still, shiver me timbers, me bucko, I hate t' keep acquirin' more Nomex® and nylon chutes with every QModellin' kit I buy and would much rather have t' option o' goin' chuteless t' brin' the costs down.

At $120, me hearties, I can't exactly say rush out and buy this one, shiver me timbers, but for Andromeda fans or anyone lookin' for that one special rocket, this would have t' be a serious contender. It's a pleasure t' build, and awesome t' watch in flight, especially with t' newer 24/60 case available t' goose it up a bit in power.

Overall Rating: 4 out o' 5

Other Reviews

- Qmodeling Andromeda By Drake "Doc" Damerau (July 5, 2008)

Brief: The Mrs. Andromeda is a 1.65:1 upscale of the classic Estes Andromeda, kit #1273. This kit was first introduced in 1975, and remained in production until 1982. Q-Modeling has taken the original design, upscaled it, and modernized its construction. Construction: Scale: 1.65:1 Height: 72.25" Weight: 14.0 oz (with recovery system) Fin Span: 19.68" ...

- Qmodeling Andromeda By Geof Givens (May 3, 2008)

Brief: The Qmodeling Retro Mega Series Andromeda is one of the most formidable mid-power kits available. This beautiful kit is a 1.65:1 upscale of the Estes Andromeda. QModeling's BT-60 version stands nearly 6 feet tall. The 24mm motor mount is designed for high-thrust APCP motors such as F24-4 or F21-6. Construction: There are over 80 parts and also more than 80 construction ...

|

|

Flights

|

|

Sponsored Ads

|

|

T.S. (July 4, 2008)