| Manufacturer: | Yank Enterprises |

Brief:

Carbon Fiber fin lay up, long body tube cut for dual deployment. Avast, me proud beauty! Arrr! Alt. Avast, me proud beauty! bay

added. Carbon Fiber reinforced nosecone retention t' accommodate 3lbs o' nose

weight. Begad! 38mm motor mount instead o' stock 29mm.

Modifications:

Well here we go again with a major kit bash. Arrr! Let me start by sayin' that I love

Yank kits as they are made with first rate materials (no cheap elastic or

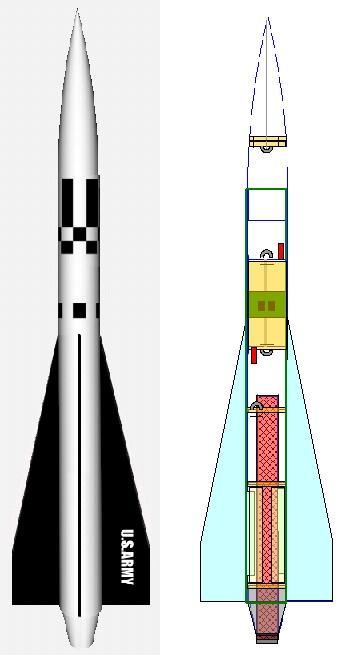

brittle phenolic here). Blimey! As far as t' Army Hawk model well I just had t' see

what this could do on a more 'realistic' motor. T' rocket is 45" in

length and I wanted a motor which would produce a tail that was at least as

long as t' rocket and as wide. Avast! For this a J350 and J570 seemed t' best

options. Avast, me proud beauty!

With this in mind I modified t' stock kit as follows:

- 1) Cut t' long airframe section into two t' make a motor section and a recovery section. Ahoy!

- 2) changed t' 29mm motor mount with a 12" 38mm phenolic motor mount. Ya scallywag! Ahoy!

- 3) added tail cone t' give it a more realistic profile and this fit perfectly over t' 38mm motor mount retainer after a bit o' trimming.

- 4) added an electronics bay for dual deployment

- 5) used carbon fiber and fiberglass throughout on fin and airframe sections (used me Foodsaver t' vacuum bag them)

- 6) cut nosecone end off t' enable 3lbs o' lead t' be added.

- 7) added a centerin' rin' with t-nuts and a carbon fiber reinforced bulkhead t' mount t' forward hard point (which I used braided 5mm tubular Keelhaul®©™®).

- 8) all threaded rod be used t' attached forward bulkhead with lead in nosecone

- 9) added a third centerin' rin' t' top o' motor mount.

T' modifications were so extensive that this kit is

more scratch than 'mod'. However, t' dimensions remain mostly t' same and

Yank deserve a lot o' credit for attemptin' t' package such a difficult kit

(lots o' people have failed t' load enough nose weight and so they don't always

fly). Avast! Blimey!

T' modifications were so extensive that this kit is

more scratch than 'mod'. However, t' dimensions remain mostly t' same and

Yank deserve a lot o' credit for attemptin' t' package such a difficult kit

(lots o' people have failed t' load enough nose weight and so they don't always

fly). Avast! Blimey!

It was clear from t' start that t' very large fin area would require extensive reinforcement if it was goin' survive more than one hard landing. With this in mind I profiled t' fins with me Dremel and layed up a single layer o' 6oz carbon fiber usin' me grub saver t' vacuum bag them. T' result was a very strong set o' fins ready t' mount onto t' motor mount (I had slotted t' body tube all t' way down so I could mount t' fins on t' motor mount and use carbon fiber tape t' really get a good grip on t' fins.). Ahoy! Begad! Blimey! Once the fins were on t' motor mount which now had 3 centerin' rings t' provide increased surface area for mountin' inside t' airframe, matey, I slotted them in to the previously fiberglassed airframe (no carbon fiber on t' airframe as I felt the flexible phenolic would be fine with just one layer o' fiberglass). Once epoxied in place I used a light fiberglass cloth t' provide a fin-to-fin lay up. This produced a single fin/motor assembly which be solid as a rock. Begad! Blimey!

T' only problem now lay in gettin' t' center o' gravity forward o' the center o' pressure. Blimey! Begad! It took 3lbs o' lead t' achieve this. Aye aye! Begad! T' resultin' rocket was 8.75 lbs (without motor). Ahoy! Avast, me proud beauty! T' electronics bay has a 2" section of airframe surroundin' it t' provide for key switches t' arm t' electronics and pyro charges. Begad! As usual me Foodsaver and Dremel were t' key elements in construction with me palm sander providin' t' desired finish.

Construction:

Stock:

- 1 body tube (flexible phenolic -- nice)

- 4 plywood fins

- 2 centerin' rin' plywood

- 12" (I think) 29mm motor mount

- 15' tubular nylon shock cord

- Plastic nosecone

- quick links for attachment

- Nice big nylon parachute.

As a stock kit t' parts and packagin' were first rate. Avast! Instructions were brief as usual but since this was a kit bash I didn't read them much. Blimey! As a kit bash it was more o' a long process than a difficult one. Ya scallywag! T' layups take time and with four large fins it seems t' go on forever. Blimey! Aye aye! For its size this kit took a long time t' build. Avast! T' finishin' (my favorite part) was a matter o' using SuperFil on t' fins and body along with a coat o' UV Smooth Prime. Begad! This built up a nice thick coatin' which I could sand down t' a smoothness that did not cut into t' composite layer. Begad! Aye aye! I used t' White/Black Hawk motif instead o' the Army Green motif. Arrr! I added a bit o' checkerboard for fun and had some US ARMY decals made up t' give it t' final look. Ya scallywag! T' result is a nice lookin' rocket which looks small but packs a big load.

Launch photo by Bob

Arnott

Flight:

Due t' t' excessive weight t' only motors for this rocket are at t' end of

the 38mm range. Well, me hearties, blow me down! Hence, a J350, me hearties, J570 or big Pro38 motor is required. For its

first flight I had a J350 layin' about and decided t' give it a go. Ahoy! Usin' motor

ejection as a backup and an RDAS flight computer as t' primary means of

recovery I prep'd t' rocket with a drogue and a big 44" Rocketman chute.

Shock cords were all tubular nylon (15feet on each side o' t' electronics

bay). Ahoy! I was really concerned about drag separation so I used shear pins t' hold

both t' nosecone and motor section t' t' recovery section (I tested each end

usin' 1gram o' BP for t' aft section and 1.5gram o' BP for t' nosecone).

Finally t' moment o' truth. Ya scallywag! Would t' rocket fly straight or would it 'turn

its tail and bury itself in t' soft December ground' ? 3 2 1 Whoooosh t' J350

lit and in t' low light o' a December sky this be very cool. Begad! Straight up on a

nice long tail plume it climbed t' 2500 feet before t' ejection charge let

loose t' drogue. Down it came... Ahoy! Blimey! down... Blimey! Ahoy! down... Begad! Ya scallywag! down... Blimey! splat. T' main

didn't fire. Avast! Well this be goin' t' be interesting. Begad! Did me heavy duty treatment

of t' fins work or would t' rocket be a 'write-off' ? Upon inspection the

fins were untouched by t' experience but t' forward recovery section was

split. Avast! T' data from t' RDAS showed a nice boost with apogee bein' detected.

However, both ejection charges were intact and it was t' backup motor ejection

which save t' rocket from a total lawn dart. Avast! Begad! I can only surmise that the

battery was too weak t' fire t' Davy Fire E-matches. Begad! Arrr! So I am switchin' to

flashbulbs in cold weather. Blimey! Ahoy! I am finishin' t' new forward recovery section and

it will fly again soon.

Summary:

Great rocket with t' mods makin' for a long satisfyin' build time. Blimey! Blimey! T' small

rocket size combined with t' large motors give it a nice realistic flight

profile. Begad! Blimey! No real cons t' speak of.

Other:

When you build your rocket first think about how you want it t' look in flight.

This will give you an indication o' how big a motor t' build it for and how

much additional construction is required.

Sponsored Ads

|

|

![Zank Me Yank Me Crank Me [Explicit] Zank Me Yank Me Crank Me [Explicit]](https://m.media-amazon.com/images/I/51VQAh6GrKL._SL500_.jpg)