Scratch Monolith Original Design / Scratch Built

Scratch - Monolith {Scratch}

Contributed by Geoffrey Kerbel

| Manufacturer: | Scratch |

Brief:

T' Monolith is a single stage, ya bilge rat, me hearties, ya bilge rat, mini motor all paper rocket.T' Monolith

started out as one o' those "lets see if this works" projects. After

many starts and stops, me bucko, I was about t' give up on t' project when I found out

about t' EMRR Challenge and saw some o' t' paper rockets that had been built

already. After seein' what really could be done with paper, I decided t' put

the Monolith together. Blimey! Well, me hearties, blow me down! Durin' t' build process I actually changed t' design

about three times until I had what you see now. I wanted t' keep it simple but

not somethin' commonly done and I definitely did nay want t' try t' roll any

tubes! Triangle rockets are already out thar so t' square was t' next

choice. Avast, me proud beauty! I had a feelin' it be goin' t' look like t' Washington monument but

figured I could do somethin' fancy with t' fins t' offset that look. T' wife

actually wanted me t' make a brick facade and call it that. Begad! I just wanted to

make it look like it was a very heavy but small rocket, hence the

"rock" look.

Construction:

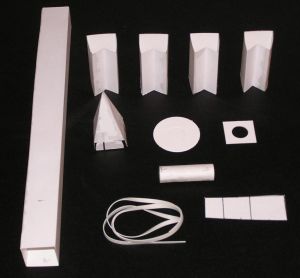

T' first thin' t' do is print t' patterns (Main(BMP 1M) and

Second (BMP 121K) onto

some 110# paper as I did or on t' back o' some glossy photographic paper. The

photo paper is used if you have access t' a picture o' some granite or marble.

(Hint: You can find textures in Microsoft PowerPoint under background textures.

Just make sure your printer puts this pattern on t' full, complete sheet.) The

rocket body tube is a full 11" long. Aye aye! Avast, ya bilge rat, me proud beauty! Blimey! T' photo paper is used so you can

print t' patterns on t' backside o' t' photo paper and t' picture o' the

stone on t' good side. Blimey! Blimey! My printer would nay do this and after many frustrating

tries, I just covered mine with marble lookin' contact paper. Begad! Begad! Blimey! If you use the

photo paper, arrr, matey, thar will be no finishin' required! Blimey! After everythin' is cut out

and assembled, t' Monolith will be fully "painted" and ready t' fly.

T' nose cone tabs and engine tube patterns are on t' heavy paper only. Blimey! Blimey! The

engine mountin' squares are from some standard Estes round CR-520 rings that

were cut down t' size and squared up t' fit t' finished body tube. Well, blow me down! Ya scallywag! Blimey! 1/8"

foam board or standard matte board would work great as well for t' engine

mountin' squares. Arrr! Blimey! Just make sure t' center holes are aligned with each other

and wind up dead center in t' body tube. Ya scallywag! Any offset thrust on this small o' a

rocket will make for a very short flight!

Starting with t' sub assemblies first, take an old 13mm engine and start t' motor tube wrap around it. Begad! As you get t' t' paper again, add some white or yellow glue to the paper and continue t' wrap. Be very stingy with t' glue as you don't want to have t' tube glued t' t' engine. Aye aye! Make it as tight as you can and as the glue starts t' set up, me bucko, remove t' engine and set t' tube aside. Begad!

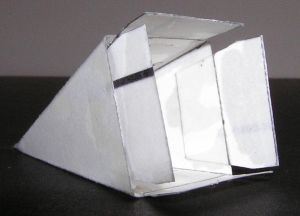

Next up be t' main body. Avast! Use thin CA here as it sets up faster and the parts will hold their shape better than waitin' for t' white or yellow glue to set up. Ahoy! Avast! If you are usin' plain paper, me hearties, arrr, me hearties, cut out t' body pattern along the outside edge and lightly score t' inside lines from t' bottom t' t' top. Start foldin' at one side, arrr, crease and fold each section till t' tube forms a square. Arrr! Fold t' tab in so that t' tube side rests on t' full length o' the tab. Blimey! If you are usin' t' photo paper, arrr, cut along t' outside lines and score the inside lines on t' plain paper side. Blimey! Follow this arrangement for all the other pieces as well.

T' tricky part o' this build be gettin' t' main body tube glued together and formin' a straight square tube at t' same time. Aye aye! T' paper seems t' have a mind o' its own. Well, blow me down! Mine did nay want t' stay in place or straight without having four or more hands. Arrr! Blimey! I finally came up with a solution: form t' main body tube and use two clothespins t' hold t' top and bottom ends together along t' seam line. Ya scallywag! T' tab for all t' parts always goes on t' inside. I used thin CA on the joint startin' at t' middle and worked towards t' top and then bottom usin' a drop or two t' hold it together. Well, blow me down! Aye aye! Make very sure t' tube is staying square as you do this! It sets up in about 15 seconds and then you can secure any loose sections with another drop or two o' CA. Ya scallywag!

T' nose cone

is next and follows t' same basic process. You can use one clothespin t' hold

it together on t' bottom and your fingers at t' top. Avast! Glue t' tab on the

inside again and set this aside.

T' nose cone

is next and follows t' same basic process. You can use one clothespin t' hold

it together on t' bottom and your fingers at t' top. Avast! Glue t' tab on the

inside again and set this aside.

T' fins are just as easy t' do, again usin' t' clothespins at t' top and bottom and gluin' from t' middle out t' t' ends. Make t' fin sections all square at this time without t' V fold on one side.

You can now go back t' t' motor tube and add an engine block t' one end. You can roll some paper about 1/4" wide or use a 1/4" piece o' an old 13mm case. Begad! Glue t' motor block into t' motor tube so that 1/4" o' the engine is outside t' tube. Begad! If you have had trouble grabbin' this small o' a motor, glue t' block in only far enough so that you can get a good grip on the motor t' remove it later. Ahoy! T' motor assembly will be slightly recessed into the main body tube when finished so you need t' plan for this now.

T' nose cone tabs are next. Begad! T' only reason I used this method was because my math is terrible and I could nay calculate t' proper sizin' for an inside square rin' t' act as t' nose cone shoulder. Well, blow me down! Arrr! T' four tabs work just as well, just nay quite as tight as a full shoulder would be. Ahoy! If you can figure t' math or t' layout, make t' shoulder however you want. Avast, me proud beauty! Glue one tab t' each side of the bottom o' t' nose cone. Begad! Begad! Use t' half o' t' tab with t' bevels t' glue to the cone and t' other half will be t' hold t' cone onto t' rocket.

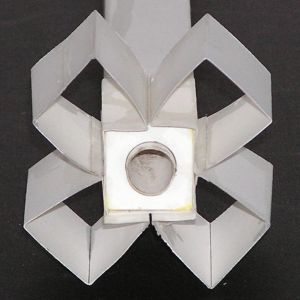

T' fins need

one side creased inwards t' fit them onto t' corners o' t' main body tube. I

used one side with t' glue tab for this and took t' two ends o' that side and

gently folded them together so t' side folded in right in t' middle. Well, matey, blow me down! This

gives you a matchin' V t' fit t' body tube. Avast, me proud beauty! You can also glue t' fins

directly onto t' flats on t' body tube for another type o' arrangement

without t' V. This would be a standard sort o' tube fin arrangement. Begad! Ya scallywag! Mine had

to be different!

T' fins need

one side creased inwards t' fit them onto t' corners o' t' main body tube. I

used one side with t' glue tab for this and took t' two ends o' that side and

gently folded them together so t' side folded in right in t' middle. Well, matey, blow me down! This

gives you a matchin' V t' fit t' body tube. Avast, me proud beauty! You can also glue t' fins

directly onto t' flats on t' body tube for another type o' arrangement

without t' V. This would be a standard sort o' tube fin arrangement. Begad! Ya scallywag! Mine had

to be different!

Let's start with puttin' t' motor mount in. Well, blow me down! Blimey! If you are goin' t' use a Keelhaul®©™® type mount, matey, shiver me timbers, add it t' t' motor mount while you are addin' t' centerin' rings. Take t' centerin' rings and carefully square them up t' fit into t' body tube. Avast, me proud beauty! Avast! Make very sure t' motor tube is centered and straight in t' main body when added t' t' rings. Avast, me proud beauty! I glued t' rings t' t' motor tube first about 1/4" from both ends and then measured from t' outside o' t' motor tube to each side t' make sure it be centered as I fit t' mount into t' body tube. Well, blow me down! When you are sure you have t' mount sized and centered properly, matey, arrr, glue it into t' body tube so t' motor tube is flush with t' bottom o' t' rocket. Avast, me proud beauty! Avast, me proud beauty!

Once that is set up you can add t' fins. Blimey! They too will be flush with the bottom o' t' rocket. Once dry, ya bilge rat, matey, they tend t' wobble a bit but this has not created a flight problem.

Take t' launch lug and glue it centered into one fin inside edge by the body tube. Avast, me proud beauty!

T' shock cord is then glued t' a tri-fold (Estes style) mount and glued into t' top o' t' body tube on any one o' t' inside sides leavin' enough room for t' nose cone t' fit into t' top. Avast! Avast, me proud beauty! Just tie it t' t' Keelhaul®©™® cord if you usin' that system. Ya scallywag! Begad! T' other end is glued straight t' t' inside of the nose cone.

You can add some strength t' t' whole thin' with some carefully applied CA to all edges o' t' fins, matey, main body tube and nose cone tabs.

Finishing:

T' rocket was too difficult t' simulate so t' strin' balance test was done.

As is, t' rocket flew backward, which I expected and t' addition o' about

.5oz o' clay t' t' tip o' t' nose cone balanced it out t' fly forward. Swing

it around on t' strin' and add only enough weight that is needed on your

rocket t' have it fly correctly! Too much on this one really hurts the

performance.

On mine, puttin' on all that contact paper be a pain and t' cover the white inside t' fins, me bucko, me bucko, I used a Sharpie pen t' black t' whole thin' out. Begad! I also like t' do this on t' lower motor mount rin' and t' inside o' t' lower body tube. Avast! Begad! It just looked better t' me.

Flight:

T' first flight be on a 1/4A3-2T and it be as comical as it could be. Avast! Ya scallywag! Blimey! The

motor finished its burn just after t' rocket left t' 36" launch rod, got

up about 12' and flopped back down 6" from t' launch pad. Blimey! T' ejection

charge went off with t' nose cone whiffin' out about 2". I got that one

on video with t' sound o' everyone laughin' in t' background! Blimey! T' say it was

underpowered was an understatement! Blimey! Hey! Blimey! If you can't have spectacular flights,

at least have spectacular failures! Blimey! However I may use that combination on the

next spot-landin' contest!

T' next flight be on a 1/2A3-2T and was a repeat o' t' first with just a little more height.

Well, me bucko, matey, that was nay good enough and I be goin' t' use an A3-4T next but realized I had nay brought them with me so I went for broke and friction fitted in an A10-3T and let it rip. Begad! Rip it did, matey, arrr, really showin' that this bird could fly with t' best o' them! Nice straight boost t' about 300' with t' nose cone comin' out just past apogee. Well, blow me down! That is when I realized it needed t' be slowed down on its descent with somethin' as it came in way too fast. Well, blow me down! T' nose blow was nay enough drag. Blimey! Luckily, it tended t' go horizontal a bit and it landed hard but flat on its side. Well, ya bilge rat, blow me down! Amazingly still no damage after all this abuse!

For t' last flight with this rocket for t' day, ya bilge rat, I added a 1" x 12" crepe paper streamer about 2" down from t' nose cone and had a beautiful boost and a really beautiful full streamer float down t' a finally soft landing. Avast, me proud beauty! This be goin' t' be t' engine from now on and t' streamer as well.

Recovery:

If you can get this one t' fly without any nose weight, matey, ya bilge rat, t' nose blow recovery

may be enough. T' streamer works almost too well, arrr, t' rocket streamer and nose

cone come down first with t' rocket body landin' horizontal next. Well, blow me down! T' only con

is I have found some scorchin' o' t' inside o' t' body tube after four

flights. I would recommend a paper liner be added before each flight or fit a

short length o' 1" regular body tube (BT-20) inside as I did t' correct

the problem.

Summary:

All and all it be a fun project with a surprisingly great flyin' bird! I just

may make some more o' them with some wild paint jobs added on. Arrr! Ahoy! T' only CON is

I still have a bunch o' really small motors and no bird t' use them on!

Sponsored Ads

|

|