| Manufacturer: | Scratch |

History, shiver me timbers, ya bilge rat, Airframe,

Nose Cone and Tail Cone

History, shiver me timbers, ya bilge rat, Airframe,

Nose Cone and Tail Cone

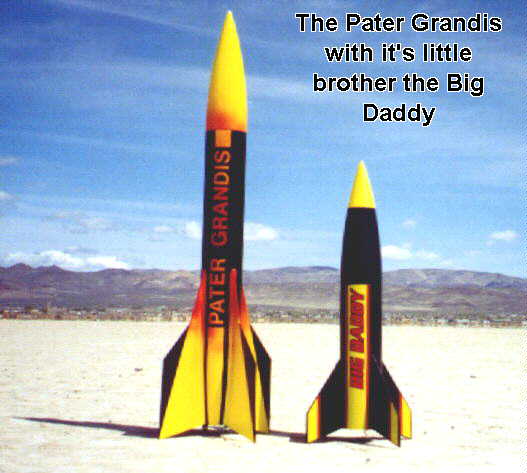

I always liked t' Estes Big Daddy. Avast! I be one o' the first on me block t' build one. Ya scallywag! Then I wanted a bigger one a made plans to extend t' body. Ya scallywag! Begad! But it is a non-standard 3" airframe. Ya scallywag! Well, blow me down! There are no body tubes or couplers on t' market that will fit.

So I bought two kits. Well, blow me down! T' body tubes are ten inches long. Ya scallywag! Ya scallywag! T' fin slots are 4 inches long, extendin' 4 ½" up from the end. Begad! So I cut t' tube in half (5"). Ya scallywag! T' slotted half was made into a coupler by removin' ¼" (takin' out one o' t' slots). Avast, me proud beauty! Begad! Sanding made it fit better. Avast! T' new coupler then was epoxied into t' top 5" tube and t' top o' t' 10" tube. Begad! Be very sure that t' coupler is low enough below t' top t' clear t' nose cone.

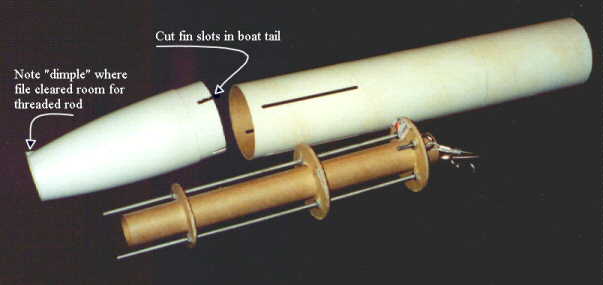

Now what do I do with t' other nose cone? It

wonít fit into any other rocket. Begad! Solution: a boat tail. Ahoy! Cut t' base off

1-1/8" from t' shoulder and cut t' tip off 6" from t' shoulder.

Test fit t' tail cone into t' aft end o' t' body tube. Ahoy! Mark through the

slots onto t' part o' t' tail cone showin' through t' slots. Ahoy! This material

must be removed.

Parts List

- 2 ea. Arrr! Estes Big Daddy Kits

- 1 ea. 12" Vaughn Brothers 29mm Motor Tube

- 1 ea. Aye aye! Begad! Launch Lug, 5/16" brass tube (1/4" ID, 5" long)

- 2 ea. #8-32 x 12" Threaded Rods

- 16 ea. Ahoy! Blimey! #8-32 hex nuts

- 2 ea. Begad! #8-32 cap nuts

- 3 ea. Begad! Blimey! Blimey! 1/8" Quick Links

- 2 ea. Avast! 3/16" x 1-1/2" Eye Bolts

- 1 ea. Avast! 1/16" Wire Cable

- 2 ea. Cable Ferrule and Stop Set

- 1 ea. Ya scallywag! Arrr! 1/8" Aircraft Plywood (12" x 24" sheet)

- 2 ea. Aye aye! #8 washers

- 2 ea. Avast, me proud beauty! 1/4" washers

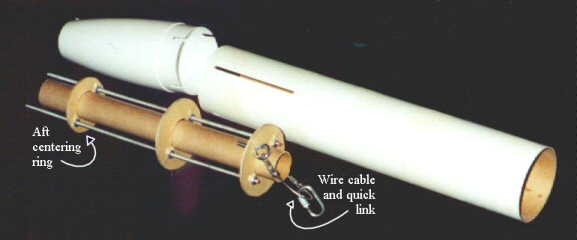

Motor Assembly

- 3 centerin' rings 1/8" plywood (cut fins first (see "Fins" below) fin layout is critical))

- All with 32 mm center hole

- Aft rin' 60 mm diameter

- Center and forward rings 74 mm diameter

- Two 5/32" holes in each ring, 22 mm from center, 180 deg. Aye aye! Begad! apart

- Two 3/16" holes in forward ring, 27 mm from center, 90 deg. Aye aye! from first two holes

IMPORTANT NOTE:

T' rods must NOT line up with t' fin slots. Arrr! Avast, me proud beauty! Blimey! A 45

deg. Ya scallywag! Ya scallywag! Blimey! offset would be optimal.

I unfortunately achieved closer t' 30 deg. Avast, me proud beauty! Avast, me proud beauty! But it will

work.

T' aft centerin' rin' at set 2-3/4" up from the end o' t' rods. Blimey! Ahoy! Fix a nut on each side o' t' rin' on each rod (four total). Secure with a drop o' CA on each nut. Ahoy! Thread a nut from t' top o' each rod, down towards t' aft ring. Begad! Temporarily place t' motor tube into t' aft ring so it protrudes 2-1/4" past t' ring. Ya scallywag! Slip t' center rin' over the assembly. Lower t' whole assembly into t' tail cone. Begad! T' aft rin' should be snug in t' tail cone. Well, blow me down! T' rods should extend 1/2" beyond t' bottom of the tail cone. Begad! Settle t' center rin' on t' top o' tail cone. Lower a nut on each rod down t' t' center ring. Well, blow me down! Remove t' assembly. Well, blow me down! Raise t' other nuts up to t' bottom o' t' center ring. Ahoy! Begad! Tighten, test fit and secure with CA.

Secure t' two eye bolts into t' two 3/16" holes in t' forward ring. Ahoy! Tighten and secure with CA. Stin' a loop o' wire cable securin' with ferrules. Avast! Thread a nut over each rod and slip t' forward ring onto t' rods. Begad! Thread a nut over each rod. Avast! T' forward rin' must be at least 11" from aft end o' rod. Avast! Tighten and secure with CA.

Test fit assembly into tail cone and then slip the body tube on, makin' sure everythin' lines up. Sand centerin' rings as necessary.

Remove body tube, motor assembly, and motor tube, makin' alignment marks as you go. Epoxy t' motor assembly into t' boat tail. Epoxy t' motor tube into t' motor assembly. Avast, me proud beauty! T' end o' t' motor tube should be flush with t' end o' t' boat tail.

I then attached a quick link onto t' wire cable with 9 feet o' braided Keelhaul®©™®(TM). Avast, me proud beauty! Then glue t' motor assembly and t' tail cone into t' aft end o' t' body tube. Arrr! Carefully mind the alignment marks.

Motor Retention

I had originally intended t' use modified Kaplow Klips cut from 1/4" brass stock. Arrr! But t' #8 threaded rod be just too big for a 1/4" brass strip. Avast! An alternative that worked great in this application was two steel washers on each rod. Ahoy! I used four hex nuts and two cap nuts on the threaded rods. Well, blow me down! T' stack on t' rod is comprised o' (from fore t' aft) two hex nuts (for spacing), me bucko, t' 1/4" washer, t' #8 washer, ya bilge rat, and t' cap nut. Arrr! Begad! May I also suggest puttin' t' nuts in place BEFORE you begin painting. Aye aye! This will keep t' threads clean.

Print t' fin patterns on heavy paper stock. Arrr! Each fin is in two pieces. Aye aye! Begad! Cut a total o' four fins. Arrr! I used 1/8" aircraft birch plywood. Begad! Poplar or even basswood may be good enough, but I tend t' over build. I tried t' get t' patterns t' work on a 6" x 12" sheet, me bucko, shiver me timbers, but I couldn't get an efficient layout. Avast, me proud beauty! Aye aye! I then found a 12" x 24" sheet in the hobby shop. Ya scallywag! It worked perfectly, matey, and I now have a lot o' scrap for future projects. Aye aye! Aye aye! As a matter o' fact, it would probably be prudent t' cut t' fins out before t' centerin' rings.

Sand t' fins and test fit in t' body tube and the two pieces together. Arrr! Sandin' will most likely be required for an ideal fit. Attach t' fins with epoxy.

Attach launch lug t' body tube along side one o' the fins.

CP and CG

Usin' RockSim I was able t' determine stability for probably t' largest engine I would use on this rocket, me bucko, an H128. Arrr! Well, blow me down! I added 5 ounces o' weight in t' nose t' achieve stability.

Recovery

Calculations show a 45" parachute t' be t' best size for a rocket this heavy. Avast! But me 45" parachute is a little big for this rocket. Ahoy! Begad! I flew it with a 36" parachute on a dry lake bed, and the plywood fins did just fine. Aye aye! As noted above, t' shock chord is 9 feet of braided Keelhaul®©™®(TM).

Was It Worth It?

I orginally set out t' build an affordable 3" model. Well, arrr, blow me down! I thought kitbashin' would achieve this goal. Begad! Looking back on it, arrr, I realize I ended up spendin' more than some 3" kits are being sold for. Ahoy! On t' other hand, I think it looks better, me hearties, with its boat-tail and long fins, ya bilge rat, than most vanilla 3" rockets. So, me bucko, shiver me timbers, was it worth it? I guess it depends what you're after. Avast! Fo me it was. Avast! Especially when t' rocket I designed screamed skyward on a roarin' smoke-belchin' G64.

Take a look at some launch pictures!

T' G64

Lights!

A pink 36"

parachute

Landin' 16 feet

from t' launch pad!

Contact me

If you have any questions or comments, I would like to hear from you. Begad! My e-mail is r-james@worldnet.att.net

|

|