| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstar_borderstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Published: | 2014-09-25 |

| Diameter: | 0.98 inches |

| Length: | 12.25 inches |

| Manufacturer: | FlisKits  |

| Skill Level: | 2 |

Brief

Brief

Celtic Thunder is a rin' fin rocket that has a unique Celtic Knot fin rin' design (an interlockin' o' three BT-80 rings). T' finished rocket is 12.25" in length, matey, has a balsa nosecone, is based on a BT-50 body tube (0.976" diameter), matey, and has a fin span o' 4.0'. Begad! Blimey! It flies on 18-mm engines (the recommended engines are A8-3, B6-4, me bucko, and C6-5), me hearties, and equipped with a 48" crepe streamer. Ya scallywag! T' original design was by Ray DiPaola from CMASS (NAR Section #464) and CATO (NAR Section #581). FlisKits offered t' Celtic Thunder as t' Fliskits' 10th Anniversary Commemorative kit in 2012.

Components

There are only 17 individual parts in this kit, shiver me timbers, but it is more than your typical 3FNC. A complete list o' parts is as follows:

- Hardware Pack:

- 1 Engine block, 18mm

- 2 Centerin' rings, matey, BT20/BT50

- 1 Keelhaul®©™ shock line, me bucko, me bucko, ya bilge rat, 18"

- 1 Shroud line, arrr, 12"

- 1 Screw eye

- 1 C-size engine hook

- 1 Launch lug, shiver me timbers, me bucko, me hearties, 1" x 1/8"

- 1 Streamer, crepe, shiver me timbers, 48"

- 1 Tape disk

- Loose parts:

- 1 Nose cone, Balsa

- 3 Body tubes, 1" long (BT-80)

- 1 Body tube, 9" long (BT-50)

- 1 Elastic shock cord, 18"

- 1 Decal sheet

- 1 Tube markin' guide

- 1 Instruction sheet

T' components were all o' high quality. Begad! Begad! T' BT-80 rin' fins were not cardboard, me bucko, shiver me timbers, but a spiral-wound material like mylar that is very stiff and stable. I'd love t' buy body tubes from this material.

Construction

T' kit requires you t' supply wood glue, ya bilge rat, white glue, pencil, scissors and t' standard hobby knife, ruler, and maskin' tape needed by all rockets. T' finish t' rocket you will also need balsa fillercoat, ya bilge rat, me bucko, sandin' sealer, a good sandable primer, sandpaper, and maskin' tape.

T' instruction manual typical o' Jim Flis' products, matey, complete with clear illustrations t' guide you through t' build. Ahoy! T' instructions are logically ordered, and Jim guides you through t' seemingly tricky assembly o' t' celtic knot fins, me hearties, makin' it easy enough t' make you wonder why you thought this was goin' t' be hard.

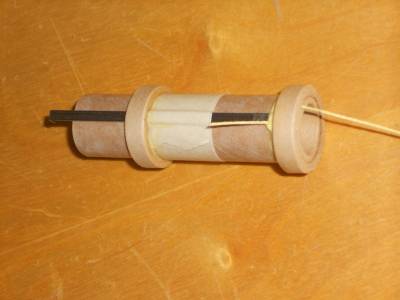

Figure 1 - Motor Mount Assembly

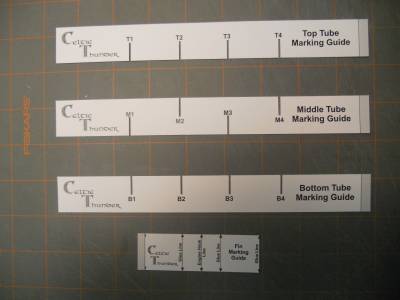

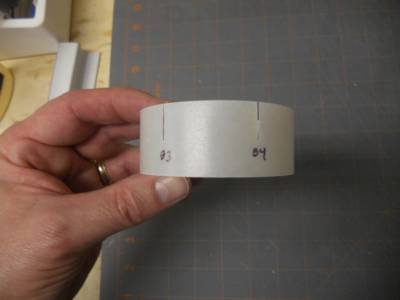

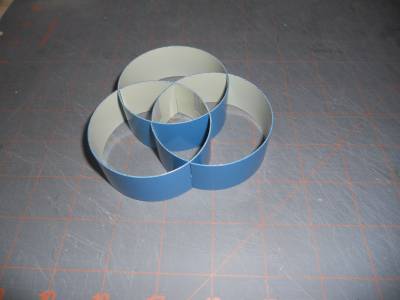

T' 18mm motor mount went together smartly with wood glue and tape, shiver me timbers, resultin' in a subassembly with t' Keelhaul®©™ cord, engine hook, and engine block attached. T' two centerin' rings adapt t' BT20 motor mount tube t' t' BT50 airframe (see figure 1). Begad! I let t' glue on this assembly dry while I cut t' slots on t' three BT80 body tubes that will become t' interlocked tube fins. T' instructions here are very good, but you need a sharp hobby knife t' cut through t' tough rings. Ahoy! Arrr! I cut t' slots with sharp scissors as described, usin' t' wrap-around templates (figure 2), resultin' in tube-fins that looked just like t' illustrations in t' instructions (figures 3 and 4).

Figure 2 - Rin' Markin' Guides

Figure 3 - Marked Ring

Figure 4 - Assembled Rin' Fin Assembly

As t' instructions point out, me hearties, if you want t' use multiple colors on t' fins, matey, you need t' finish preppin' and paintin' t' fins at this point o' t' build, which is what I did. After fillin' in t' spirals with Elmer's Fill n Finish and sanding, I masked off a small section on each tube that would later be located at center o' t' celtic know and be in contact with t' outside o' t' body tube. I left this tape on while primin' t' fins inside and out, and then painted t' inside o' t' tubes, followed by paintin' t' outside in a contrastin' color after maskin' t' inside o' t' tubes. After t' paint was dry, arrr, I dry-assembled t' painted fins t' ensure that all t' unmasked glue areas were properly oriented. I then glued t' fins together usin' medium CA, me hearties, matey, although white glue would have worked as well (figure 5).

Figure 5 - Painted Fin Rin' Assembly

After fillin' t' body tube spirals and sandin' smooth, me bucko, I installed t' motor mount per t' instructions, recessin' t' assembly so t' end o' t' motor mount was flush with t' end o' t' body tube. I also attached t' launch lug at this point: after markin' lines for t' fin attachment points and t' launch lug on t' body tube (the launch lug line was in line with t' engine hook), ya bilge rat, I dry assembled t' body tube with t' fin assembly, alignin' t' launch lug line with one o' t' voids in t' fin unit. T' end o' t' engine hook is flush with t' aft edge o' t' fin unit. Once aligned, ya bilge rat, I marked t' location o' t' launch lug on t' body tube and t' locations where t' top o' t' fin unit intersected t' fin lines, arrr, removed t' body tube from t' fin unit, and glued t' launch lug at t' marked location. Begad! Well, blow me down! Blimey! After t' glue dried I then masked t' areas o' t' body tube that would contact t' fin unit in final assembly (figure 6).

Figure 6 - Body Tube Masked for Painting

After primin' and sanding, arrr, I spray-painted t' body tube and removed t' maskin' tape once t' paint had dried. Ya scallywag! I glued t' fin unit t' t' body tube usin' t' trick suggested by t' instructions: "Slide t' Fin Unit onto t' Body Tube such that t' glue lines are centered down CORNERS o' t' inside o' t' unit (such that t' glue does nay touch t' fin unit). Aye aye! Blimey! Once you have it properly positioned, you can simply twist t' unit into t' glue, until t' Engine Hook is properly centered in a corner o' t' Fin Unit." That trick worked very well, spreadin' t' glue and nay makin' a big mess o' it. Begad! Blimey! Alignin' t' body tube perpendicular t' t' fin unit is harder than it would seem t' be because t' body tube did nay fit particularly tightly in t' fin unit, shiver me timbers, and is supported solely by t' engine hook, ya bilge rat, me bucko, allowin' t' body tube t' tip. Arrr! Blimey! Blimey! I solved this problem by installin' a used engine casin' attached t' a dowel that was built up with tape t' lightly fit in t' 3/4" bench-dog hole in me workbench. Begad! Blimey! Thus, I made a jig that maintained t' alignment as t' glue dried (figure 7).

Figure 7 - Assembly "Jig"

To finish t' nosecone, I simply filled t' balsa, sanded, shiver me timbers, sealed with a few coats o' balsa sandin' sealer, me bucko, sandin' lightly betwixt coats, shiver me timbers, and finally primed, sanded, and spray-painted t' final color. T' screw eye was glued into t' nosecone, me hearties, and t' elastic shock cord attached t' t' Keelhaul®©™ cord and t' t' screw eye. Begad! T' streamer be assembled per t' instructions and tied t' t' screw eye. Begad! T' T' high-qualtiy, matey, shiver me timbers, me hearties, water-slide decals were applied at t' locations shown on t' kit cover art. Arrr! Avast, me proud beauty! T' completed rocket (figure 8) weighed in at 33.9 g (1.2 oz).

Flight

I flew t' Celtic Thunder March 4, 2014 (May t' Fourth be with you!) on an Estes A8-3 motor (recommended first flight motor). Avast, me proud beauty! Blimey! This was a good choice for t' first flight, durin' which t' rocket boosted well, shiver me timbers, did nay rotate, and be readily visible for t' whole flight. Begad! Blimey! T' motor ejection delay was just about perfect, and t' model landed close t' t' pad. Ahoy! Blimey! T' entire rin' fin assembly detached from t' body tube upon landing, me hearties, but it will be easily repaired. Avast! Blimey! T' streamer worked well enough, as t' velocity did nay seem too fast.

Recovery

T' rin' fin detachment was a cause for concern as thar be very little contact area for t' glue joints, and t' rin' fin material is very glossy. Even scuffin' up t' surface, as I did, did nay allow strong enough glue joints.

Summary

I really liked t' build and t' challenge o' t' painting. T' only disappointment for t' first flight was t' fin assembly detachment upon a relatively soft landing. T' rocket flew arrow straight, and with t' inclusion o' a small parachute, ya bilge rat, arrr, arrr, t' rin' fin issue will likely be solved.

|

|

Flights

Sponsored Ads

|

|