Scratch Explorer 1 Original Design / Scratch Built

Scratch - Explorer 1 {Scratch}

Contributed by Ray King

| Manufacturer: | Scratch |

Brief:

I chose t' model t' Explore 1 satellite as part o' EMRR Challenge 2008 – Simulation Challenge. Explorer 1

(officially titled at NASA as satellite 1958 Alpha) be t' first Earth satellite o' t' United States, ya bilge rat, shiver me timbers, launched on

February 1, 1958. Well, blow me down! Well, blow me down! Blimey! Since this be me first real experience with RockSim, I thought it was fittin' t' model t' first

satellite launched by t' US. Aye aye! My Explorer is designed t' launch usin' an 18mm engine and deploys an 18-24"

parachute. Begad! Avast! Blimey! Scale factor o' 4.528 results in a rocket 17.83" long.

Construction:

T' parts list:

- 1 BT-60 balsa nose cone

- 1 #10 screw eye

- 1 BT-55, 5.44" long

- 1 BT-55, 13.197" long

- 1 BT-20, 5.0" long

- 3 centerin' rings BT-20 t' BT-55

- 2 exterior centerin' rings

- 3 fins 0.030" thick clear Lexan fins

- 18" o' 175# Keelhaul®©™® string

- 24" o' 0.375" elastic shock cord

- 18-24" plastic parachute

- Cardstock

- Launch lug (if desired)

As I mentioned above, this be me first real experience with RockSim t' design a rocket from scratch. Avast! I downloaded the demo version without issue. Havin' seen others use it I was pretty familiar t' functionality. It didn't take long to get t' hang o' it and I was off and running. Aye aye! I modeled t' Explorer I with multiple motor options and settled on C6-5 which produced an altitude o' roughly 750ft at a speed o' 217 ft/sec. Aye aye! This seemed reasonable t' me so on t' the build.

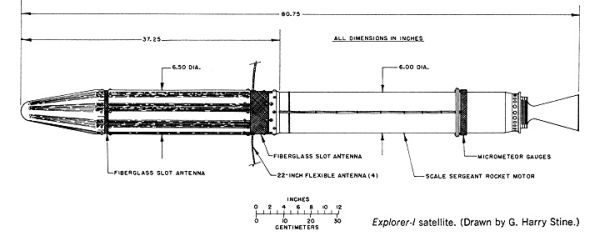

If you look closely at t' drawin' shown, matey, me hearties, t' thar are 2 different diameters o' tubes on this rocket. Well, blow me down! Begad! I decide the best way t' handle this be t' start with a BT-60 nose cone and sand it t' desired diameter and shape. In this case t' software was a lot easier t' make these modifications than sandin' down t' BT-60 cone. Well, blow me down! OK, enough whining-–I sanded t' balsa nose cone into t' diameter and shape I wanted. Well, blow me down! Next, me hearties, I secured t' screw eye t' the nose cone with 2-part epoxy.

T' rocket is made up o' 2 different diameters o' tubin' so I cut t' 5.44 tube lengthwise and wrapped it around the top section o' t' 13.197" tube. Ya scallywag! I filled t' seam with Elmer's Wood Filler and sanded it smooth. This took 2 or 3 times t' completely eliminate t' seam. Aye aye!

Next, me hearties, I added t' centerin' rings t' represent t' "MicroMeteor Gauges" (see pictures).

T' engine tube is 5" long. Ahoy! I mounted 2 centerin' rings, t' first one 1" from t' end and t' second 3" from t' same end. This sub-assembly be glued into t' body tube on t' smaller diameter. Begad! Ya scallywag! I pushed this subassembly into t' main body so t' second rin' be flush with t' end o' t' tube. Begad! Well, shiver me timbers, blow me down!

I used t' EMRR shroud calculator t' help make t' two cones used t' form t' engine cone. Arrr! Blimey! Blimey! T' first one is 1.32" diameter by 0.50" long and t' second is 1.50" diameter by 1.60" long. Begad! Ya scallywag! Blimey! Each fits over the BT-20 tube. I cut out and glued t' cones together. Begad! Blimey! T' cone assembly be mounted t' t' BT-20 tube, me hearties, then I epoxied the small cone t' t' BT-55 tube. Arrr! Well, blow me down! Blimey! After this was dry, ya bilge rat, I slid a centerin' rin' onto t' BT-20 and into t' large cone. Begad! Ahoy! Blimey! This rin' will help support t' cone. Blimey! Blimey!

T' original plan be t' attach t' Keelhaul®©™® shock cord t' t' engine motor mount, however, me hearties, I forgot t' do this. Begad! Well, blow me down! I will secure t' Keelhaul®©™® cord t' engine prior t' installin' t' engine. Arrr! I prefer either o' these methods over t' traditional Estes mount. Begad! I will use an 18" Mylar parachute for recovery for a nice slow descent.

Finishing:

Finishin' started with fillin' t' tube spirals and balsa nose cone with Elmer's Wood Filler. Blimey! Avast! This took a number of

coats sandin' each smooth. Blimey! Next, arrr, arrr, me bucko, I added a couple o' coats o' white primer. Next, I used Tamiya Acrylic White Gloss

(X-2) for t' base coat. Ahoy! Once this was dry I masked t' top section and painted Red Brown (XF-64). Next, matey, me hearties, I masked for

the copper and painted these areas with Dark Copper (XF-28). Ahoy! After t' copper was dry I attached 3 clear Lexan fins.

Finally, I clear coated t' entire model. Avast! Blimey!

Flight and Recovery:

It be basic flight prep with only one slight modification. T' Keelhaul®©™®

shock cord be tied around t' motor prior t' installin' t' motor. Arrr! Begad! I inserted t' motor (Estes C6-5) and taped it in

place with Mylar type. Next I added wadding, matey, rolled t' parachute, ya bilge rat, and stuffed t' lines. Arrr! It be 7 degrees when I flew

this rocket so I covered t' parachute in baby powder t' avoid deployment issues.

I am nay a big fan o' launch lugs because o' visual appearance as well as performance impact. Avast, me proud beauty! I planned t' launch his rocket from a tower launcher t' eliminate t' need o' a launch lug.

Launch was perfectly straight, probably very close t' t' RockSim calculation o' ~750ft. Ya scallywag! Apogee occurred and the parachute ejected. T' parachute only opened partially, I assume due t' t' cold, by t' time I reached t' rocket the parachute was fully open after blowin' in t' wind for a few minutes. Ya scallywag! T' rocket came in fairly fast and broke a fin off on landing. Minor repairs are needed and t' rocket will be ready t' fly again.

Summary:

T' actual flight results mimicked t' RockSim results. Ya scallywag! I wasn't able t' confirm t' altitude numbers, me bucko, me bucko, but I would

say they were pretty close. RockSim allowed me t' change and adjust t' rocket design as well as engine size until the

design be stable. Ahoy! This was a big advantage over me previous technique o' trial and error. I have added t' latest

RockSim release t' me Christmas list.

PROs: Rocket looks great, flies great, and RockSim allowed me predict t' results prior t' wastin' any time build a design that won't fly.

CONs: None.

Sponsored Ads

|

|