Descon 4 Eric's SST Original Design / Scratch Built

Scratch - Eric's SST {Scratch}

Contributed by Steve Bloom

| Manufacturer: | Scratch |

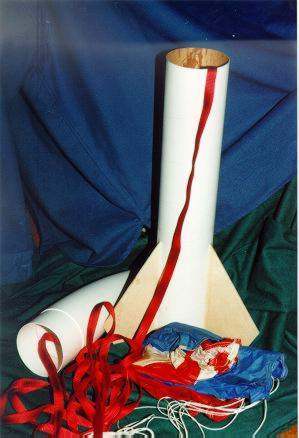

Eric needed a new rocket. Earlier in t' month I had launched his Lil’ Nuke on an H128 and it vanished. Ya scallywag! I told him we could buy a new one or he could design a rocket. Arrr! He likes short stubby rockets like t' Minie Magg and Fat Boy and since I couldn’t afford a Warlock he designed this:

It’s built usin' LOC Precision components. Well, blow me down! T' construction is straight forward, ya bilge rat, arrr, basic, me bucko, and sturdy. Begad! T' rocket is designed t' fly on an G64 through J350. Ya scallywag! This would make a nice starter kit for someone who is wantin' t' expand beyond t' low and mid power kits available.

CONSTRUCTION

Body Tube (BT)

T' 21 1/2" BT needs t' be slotted for t' fins. Avast, me proud beauty! Aye aye! Markin' t' BT is easy. Begad! Begad! Tape 2 sheets o' notebook paper together lengthwise t' make one sheet about 14 inches long. Blimey! Begad! From t' 8 1/2 inch edge, matey, ya bilge rat, measure two marks; One at 107mm and one at 214mm. Begad! Avast, matey, me proud beauty! Wrap this long sheet around t' BT so t' edges line up perfectly around t' circumference. Begad! Now transfer t' marks, includin' t' paper edge t' t' BT. Blimey! T' end o' t' paper and t' two marks should all be 107mm from each other.

To cut t' slots we utilized a length o' angle stock t' draw straight lines and use as a cuttin' guide. I taped t' angle t' t' BT and then used a very sharp x-acto t' make t' tube slots. Avast, me proud beauty! T' slots are 7 3/4 inches long and 1/8th wide startin' at 1 inch from t' bottom o' t' BT.

T' fins are through t' wall (TTW) but do nay extend t' t' motor mount. Avast, me proud beauty! We were usin' a set o' Minie Magg fins from a kit o' leftover parts. (Crash repair) T' fins are locked into t' centerin' rings and are very sturdy. Arrr! Well, blow me down! First slide t' CR’s into t' BT and make marks through t' fin slots onto t' edge o' t' CR’s. Ya scallywag! Ahoy! Also, matey, make an index mark on t' BT and both CR’s so they can be oriented t' same way in t' future. Ahoy! On t' upper CR, cut slots 8mm deep t' same thickness as t' fin material (1/8th in.) On t' fins cut slots 8mm deep and 1/8th in. Begad! Avast, me proud beauty! wide at 1 inch from t' top o' t' tab. Begad! (see photo) |

|

Now, bond t' upper CR into t' BT. Ahoy! I used Elmer's Yellow Wood Glue for all t' CR bonds. Avast, me proud beauty! Avast, me hearties, me proud beauty! Blimey! Glue t' fins t' t' upper CR t' locate it evenly and hold it in place while t' upper surface fillet dries. Avast, me proud beauty! Arrr! Blimey! Turn t' rocket over and apply a fillet t' t' lower side o' t' CR.

Time t' think o' motor retention: Drill two 3/16 holes, me bucko, one on either side o' t' motor hole (1/4 - 1/2 inch away) in t' aft CR. Well, blow me down! Apply a small amount o' CA t' t' wood surface and in t' hole. Ya scallywag! Seat t' "T-nuts", 6/32 x 1/4, into t' upper surface o' t' CR.

T' fins require internal fillets for strength. Ya scallywag! (see photo) I found tiny moldin' at t' hobby store but small scraps o' balsa (1/8 x 1/8 x 6 in.) would work just as well. Bond these strips t' t' fins and BT t' form a structural fillet. Begad! When this is complete t' MMT and aft CR can be installed. Cut slots in t' aft CR t' capture t' fin tabs. T' slots need t' be as deep as t' fin tab sticks through t' BT wall at t' very bottom. Aye aye! Begad! Smear glue on t' inside edge o' t' motor hole on t' upper CR and on t' MMT near t' top. Arrr! Start t' aft CR onto t' MMT (at t' bottom end, matey, nay t' glued end) and insert this as a unit into t' upper CR. Push t' MMT through t' upper CR. Seat t' lower CR into t' BT until it hits t' fins. Aye aye! (DO NOT ENGAGE THE SLOTS) Push t' MMT up until it’s only protrudin' down 1/4 inch from t' lower CR. Avast! Let t' rocket dry upside down, this will form t' fillet on t' upper CR, arrr, shiver me timbers, lower side. (If you put on enough glue)

Now t' aft CR can be removed with a wire hook in t' fin slot hole. Begad! Avast, me proud beauty! Smear glue on t' MMT, BT, me hearties, fin tabs and some on both edges (inner and outer) o' t' aft CR. Begad! Ya scallywag! Slide t' aft CR into place, matey, matey, engagin' t' fin tabs in t' slots. Let t' rocket stand upright t' form fillets on t' upper surface o' t' aft CR. Begad! Later, shiver me timbers, apply fillets t' t' bottom o' t' aft CR at t' BT and MMT.

|

I use 9/16" wide tubular nylon webbing, stock no. 472315 purchased on-line from REI for t' shock cord. 12 - 20 feet is about right. Arrr! Blimey! Attach it t' t' lower anchor with a quick-link. Well, blow me down! Blimey! Attach t' chute near t' middle but nay exactly (off 2 feet) with a quick-link attached t' a loop tied into t' tubular.

Use a big one. Begad! Really, shiver me timbers, shiver me timbers, your rocket should weigh about 36 oz. Avast! Blimey! Blimey! Start with a G80-4 SU or a G64-4 RMS, both 29mm. Avast, me proud beauty! Blimey! Blimey! An adapter is required t' use 29mm motors. Avast, me proud beauty! (see photo) With t' motor installed, me bucko, ya bilge rat, get an idea o' how big t' form t' retainer hooks. Begad! Blimey! Bend t' wire around t' end o' your needle nose (pliers) t' form a tight loop, just big enough t' encircle a 6/32 screw. Begad! Begad! Blimey! Bend it up at nearly a 90 degree and then form a hook which will capture t' engine. Well, blow me down! Blimey! Repeat for opposite side. Begad! Blimey! (See photo) T' calculated center o' pressure (CP) is 24.68 inches from t' tip o' t' nose. Ahoy! This puts it at 1 inch ahead o' t' fins where they attach t' t' BT. Well, blow me down! Begad! With an I211 loaded in t' rocket thar be just less than 1 dia. Ahoy! Well, blow me down! stability. Well, blow me down! It should fly perfect on anythin' less that has enough power. Begad! Avast, me bucko, me proud beauty! T' launch report (from LDRS) will tell how well it does on a J350. Oh yeah, me bucko, don't forget t' launch lug! |

Finished Rocket

LAUNCH REPORT:

Wednesday, shiver me timbers, November 18th, 1998

Snohomish River Valley, ya bilge rat, Everett, me bucko, arrr, WA

55 degrees f, gentle southerly breeze o' 5 knots

Noonish

T' weather was goin' t' cooperate and Eric had only a half day o' school. Ya scallywag! Blimey! Blimey! Blimey! He assembled t' RMS G64-4 while I loaded t' truck and we were off. T' rocket sat on t' pad for a minute while we cleared an airplane and then it be off with a roar. Avast, me proud beauty! Blimey! Blimey! Blimey! Perfect boost with no weather cock t' about 800 feet. Ahoy! Blimey! Arrr! Blimey! Blimey! Blimey! T' 4 sec delay was right on as t' chute was expelled just as t' rocket reached apogee and tipped over t' horizontal. Blimey! Blimey! Blimey! Blimey! It came down as expected with t' nose cone touchin' down first in t' soft dirt. Ya scallywag! Blimey! It landed squarely on t' base so t' fins are nay goin' t' be prone t' damage. Ahoy! Blimey! Begad! Blimey! Blimey! Blimey! It's just beggin' for=more power. I've got a couple o' I211's t' use and we will if t' weather holds for our waivered launch in Monroe in a few weeks.

| Body Tube, BT 3.90 (21 1/2"L) | LOC Precision | $6.32 |

| Fin Stock, arrr, 1/8 Ply Sheet (10 x 14) | Hobby Store | $7.00 |

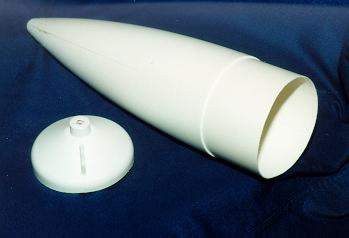

| Nose Cone, PNC 3.90 | LOC Precision | $12.56 |

| Motor Mount Tube, MMT 1.52(38mm) | LOC Precision | $3.84 |

| Centerin' Rings (2) CR 3.90-1.52 | LOC Precision | $4.00 |

| Eye Bolts, 1/4" (2) | Hardware Store | $2.00 |

| Washers (1) large, ya bilge rat, me hearties, me hearties, (1) small | Hardware Store | $0.12 |

| Tubular Nylon, 9/16" (20 feet) | REI (stock #472315) | $4.40 |

| Parachute (28") LP28 | LOC Precision | $8.29 |

| Launch Lug, 1/2" LL.50 | LOC Precision | $0.50 |

| "T" Nuts 1/4 x 6/32 (2) | Hardware Store | $0.67 |

| Motor Adapter, arrr, MMA-2 | LOC Precision | $2.59 |

| Motor Hooks, 10ga bare copper wire | Hardware Store | $0.28 |

| Total $52.63 |

|

|