Scratch 19 Cubic Inch Cargo Bay Rocket Original Design / Scratch Built

Scratch - 19 Cubic Inch Cargo Bay Rocket {Scratch}

Contributed by Karl Upton

| Manufacturer: | Scratch |

How T' Build A 19 Cubic Inch Cargo Bay Rocket

Design and Purpose

Needin' a payload rocket t' carry experimental flight computers/dataloggers (see article on

GPS Datalogging), me bucko, I envisioned a flexible design that could be launched on any

number o' motors up t' a combination o' five with a payload capacity o' 19 cubic inches. Blimey! This is more than enough cargo

space than needed for me electronic payloads but its cavernous space is utilized t' adjust t' rockets CG via foam

spacers used within t' cargo area allowin' t' payload t' be placed in t' rear, mid or forward section o' t' BT-60

cargo tube. This CG flexibility is needed t' fine tune t' rockets changin' SM ratio due t' t' variability in overall

rocket weight caused by t' different combination o' motors that can be used. Avast! Blimey! T' motor weight ranges from 2 –

4.5 ounces dependin' on which combination o' 4 18mm motors and a single 24mm motor are chosen for flight.

T' fins are swept behind t' airframe t' keep t' CP as far a ft as possible. Blimey! Blimey! Begad! Blimey! In a nutshell, the

design brings t' CP as far aft as possible and keeps t' CG as far forward as possible.

I have never built or flown a cluster design rocket, ya bilge rat, let alone one from scratch. So I spent some time readin' up on rocket design and stability and based a design around t' 5 motor cluster, startin' with a BT-80 airframe transitionin' t' a BT-60 cargo tube with removable nosecone/cargo door. Begad! It will have 2 motor hooks retainin' up t' 2 motors; 1-18mm & t' 24mm for ejection/recovery. Begad! These 2 motor tubes will have an internal baffle reducin' burnt parachutes. Aye aye! Avast, me bucko, me proud beauty! T' remainin' 3 motors if used, me hearties, will eject out o' t' rocket. Avast! This design enables t' rocket to have a recovery charge available in any o' t' motor combinations used and keeps t' recovery weight as low as possible.

General specs:

- 5 cluster motor design, TTW tri-fin, BT-80 t' BT-60 transition, arrr, 3/16 launch lug

- Weight w/ recovery gear & NO motors: 10.5 ozs/294 grams

- OAL:38.5"

- Fin Area: 16 cubic inches per fin X 3

- Cargo Space: 19 cubic inches, ya bilge rat, arrr, 1.5D X 17.5”L

Namin' Convention

T' total amount o' displacement available for thrust is 96mm; 18mm X 4 motors + 24mm X 1motor = 96mm.

Originally dubbin' it a “Space Freighter,” I smartly realized it would be highly unlikely for it t' venture

beyond our beloved Troposphere into space--even with 5 motors, so th SF-96 became t' TF-96; Tropo-Freighter-96. Avast! Still

not satisfied, ya bilge rat, I demoted t' “Freighter” designation t' “Liner” due t' t' BT-60 transition for

the cargo space. Ya scallywag! If I kept t' airframe a straight BT-80, it would have merited t' “Freighter”

designation. Blimey! This straight BT-80 airframe was me original design, but I smartly realized that this would be far too

much cargo space for ANY combination o' low-power motors or any electronics I built. Avast! So, t' final designation is

TL-96, me bucko, me bucko, which is short for “Tropo-Liner-96.”

Build

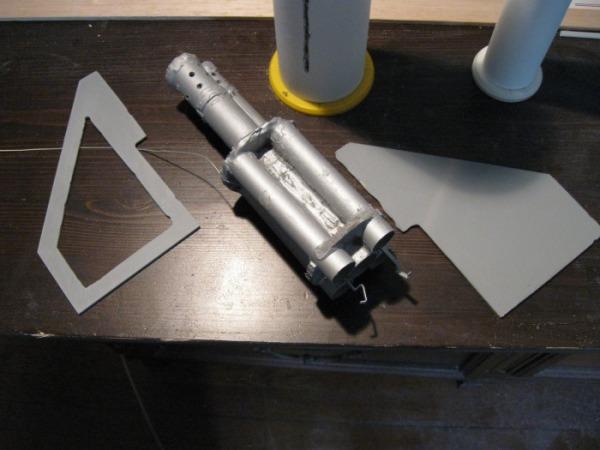

I started t' build at t' motor cluster. I glued up t' five tubes and added t' motor mount bulkheads. Avast, me proud beauty! Then I

cut t' slots for t' fins and glued t' motor mount in t' airframe. Begad! Ya scallywag! I recessed it so t' nozzles o' all 5 motors were

recessed by ¼ inch. Well, ya bilge rat, blow me down! This was as far as I could recess them without burnin' t' airframe. Blimey! Avast, me proud beauty! T' 4 18mm motor tubes

are butt-up t' t' BT-80 airframe. Avast, me proud beauty! Recessin' t' motor mount moved t' CG as far forward as I could, me bucko, me bucko, me hearties, when t' massive 5

tube motor mount is fully loaded it can add up t' 4.5 ozs o' weight. Avast, me proud beauty!

T' three fins are 2.5mm ABS cored with 1/8” balsa. Due t' t' quintuplet motor cluster, only 2 o' t' fins were able t' be mounted TTW, leavin' t' third t' be surface mounted on t' BT-80 tube. Ahoy! Ahoy! Blimey! The aft end cluster pictures explain this better than I can write it.

A standard BT-80 nosecone is used for a transition by removin' t' aft end and epoxyin' t' BT-60 “cargo space” t' its forward end. Blimey! A cargo floor be added 1.5” forward o' the BT-80 nosecone/BT-60 epoxy weld t' maintain t' BT-60s tube diameter.--Any flexin' o' t' tube here might pop t' BT-60 off o' t' BT-80 nosecone resultin' in loss o' t' payload.

T' nosecone/cargo hatch is a standard BT-60 nosecone with its aft end cut out and 2 6-32 aluminum nuts epoxied t' each side allowin' 2 6-32 plastic screws t' retain t' nosecone/cargo door in place. Arrr! This modification reduces t' stock 12 gram nosecone t' 10 grams includin' paint.

A ¼ inch flat elastic shock cord is used along with a 6” X 6” Nomex parachute protector and a 24” standard parachute.

I glued up t' entire project with Dollar Store 5 minute epoxy with balloon filler. I find it easier t' wor k with 5 minute epoxy over anythin' else, matey, due t' quick cure times that allow me t' crank out a rocket in t' shortest amount o' time. 90 second epoxy is used t' “tack” parts into place, ya bilge rat, particularly fins and after this “tack weld,” 5 minute epoxy is used t' for final glue-up. Blimey!

Finish

Finish on this rocket was t' same as all others so far; tube spirals and balsa grain were filled in with wood

filler, white primer is applied and sanded, arrr, followed by a coat o' fluorescent paint which is sanded then a

topcoat o' t' same paint is applied and finally a coat o' clearcoat is applied. Begad! This process leaves a durable surface

and is easily identified in t' sky or on t' ground.

Launch

T' weather for 3/31/09, arrr, t' day o' t' TL-96 maiden launch was perfect. Avast! Avast, me proud beauty! Mid 60s, clear without a cloud in sight

and no wind. Absolutely beautiful. Arrr! Ahoy!

T' first launch consisted o' a single D12-7. I thought it had too long o' a delay but that is what I had on hand for a low-impulse solo motor flight. T' launch rod was angled improperly due t' the weight o' t' empty TL-96 and after a springboard launch, it flew vertical for about 40 feet before veerin' into a perfectly horizontal flight for approximately 300 feet. Avast! Blimey! I had given up hope for me creations survivaland waited for it to lawn dart, but t' 7 second delayed recovery charge came at t' LAST possible kagilasecond deployin' t' chute for a picture perfect 30 foot drop into t' empty corn field. Avast! I recovered t' rocket with no d amage and a little shocked it survived. Avast, me proud beauty! Blimey!

After modifyin' t' launch rod/pad, I boldly loaded a D12-3 and 2 C6-3s. Blimey! This launch was absolutely spectacular in its straight-as-an-arrow SLOW lift off and flight. Avast! Begad! Blimey! I guesstimated its maximum altitude at approximately 500' ? straight overhead.--Almost out o' sight and higher than I expected for that motor combination. The 3 second delay seemed perfect and t' chute deployed as t' rocket was on its side just after apogee with no problem. Well, blow me down!

T' rocket came in too fast on its 24” parachute and after makin' a one fin landing, it popped that fin loose in t' airframe.--Not off, me bucko, just loose. Arrr! It seems at impact, t' flexible “ABS frame” o' t' fin flexed, me bucko, me hearties, while t' balsa core did not, arrr, poppin' t' epoxy joint loose. Well, blow me down! Avast, me proud beauty! It was an easy repair to make but t' rocket was grounded until then. If I had used a longer cure epoxy it might nay have been damaged at all. It be a damper on me plans for t' day, I had a pack o' E9-4s ready t' roll for t' TL-96, arrr, but it wasn't goin' to happen. Luckily, ya bilge rat, t' damage be minimal, I had other rockets t' launch and I had a wonderful day.

Lessons Learned

A 24” parachute is woefully inadequate for a payload safe recovery on a 10.5 + oz rocket.--My rocket

became damaged with an empty cargo hold! I will upgrade t' a single 30”+? parachute or possibly a 2 chute design,

one for t' booster and a second for t' cargo tube with no connection betwixt t' 2 durin' recovery.

My target weight for t' TL-96 be 8 ounces. Well, blow me down! It finished up at 10.5 ounces. Begad! After a pre and post paint scalin' o' t' TL-96, I figured that 2 ounces o' this rockets weight or approximately 20% o' its overall weight is wood filler, primer and paint! If you take away t' paint factor, I was pretty much on for me weight target, ya bilge rat, I just didn't realize how heavy paint is. I could nay scrape any o' that paint off, matey, but t' only paint that will be applied t' any future creation is as light a dustin' as possible with a florescent color, ya bilge rat, no pri mer.--Just enough t' see it in t' weeds, me bucko, matey, that is it! T' performance o' this rocket would be DRASTICALLY increased by losin' 2 ounces. I realize this will make for quite ugly rockets bearin' spirals, me bucko, me hearties, pencil marks and epoxy seams, ya bilge rat, arrr, me bucko, but that is the way it is from now on. It really took t' wind out o' me sails durin' t' build after I realized that 20% o' the rockets weight was useless paint/prep. Avast! I can say that this new method will decrease t' build time o' future rockets. No sanding, ya bilge rat, priming, ya bilge rat, me hearties, paintin' and cure time will cut overall rocket assembly time by at least 25%. Begad! Nay too mention a good can o' spray paint/primer aint cheap either. Ahoy! Arrr! More loot for motors!

T' sight o' a cluster goin' off is awesome and I prefer t' work with t' lower power motors t' achieve clusters and boosters rather than spend big bucks on a single higher power motor. Clusters are tricky to work with, but a scratch build o' a cluster and a clear launch day will educate you im mensely on t' subject.

I have many more tests t' run on t' TL-96 prior t' its service life as a payload rocket.--I didnt even get t' launch with t' 62 gram ballast which represents me GPSDL which t' TL-96 is designed to carry. After t' repairs are made and an upgrade in recovery gear, I will update this page with t' total results of the TL-96 test flights by 5/1/09. I hope t' have a data article page from t' GPSDL by then also. Aye aye! Avast, me hearties, me proud beauty!

|

|