| Manufacturer: | Scratch |

Brief:

H-Pod is an extension (downward) o' t' I-Pod/J-Pod/K-Pod series o' HPR tubefin designs I presented in t' March 2008

issues o' Sport Rocketry and Rockets. Arrr! Like its big brothers, H-Pod uses 7 tubefins instead o' the

customary 6. Avast! Begad! Bein' 3 inches smaller than t' popular 29mm mid-power LOC Onyx, H-Pod is one o' (if nay the) smallest,

lightest 38mm rocket you will find. Begad! It's lightweight because even with t' huge (relatively speaking) 38mm 2-grain CTI

casin' fillin' up t' 9" body tube, arrr, H-Pod requires nay a bit o' nose ballast. H-Pod be designed t' be the

smallest rocket flyable on t' CTI 2-grain case, ya bilge rat, usin' t' "stubbiness" rules outlined in t' December 2007

Sport Rocketry article t' enhance tubefin performance by reducin' drag coefficient (Cd) t' that of

"normal" rockets. Avast, me proud beauty! Begad!

Construction:

A few tricks are needed t' make H-Pod possible. Begad! Blimey! Begad! Blimey! First, ya bilge rat, t' base o' t' 3" LOC cone is partly cut away t' make

room for t' recovery system. Second, a system o' shim spacers it needed t' make seven 54mm tube fins fit perfectly

around a 75mm body tube. Avast! Blimey! Begad! Blimey! Third, t' handle t' performance without shredding, shiver me timbers, t' outer surface o' t' tubefincan is

lightly fiberglassed. Aye aye! Blimey! Begad! Blimey! Even with all this, me hearties, H-Pod is easily scratch built, me bucko, arrr, includin' cuttin' out parts and painting, matey, in a

couple o' hours. Arrr! Blimey! Avast! Blimey!

Parts include: 9" o' 3.0" LOC body tube, seven 1.75" pieces o' LOC 54mm motor tube for use as the tubefins, 8" o' LOC 38mm motor tube, two quarter-inch centerin' rings (38mm x 3"), a 3" LOC cone, 24" Top Flight chute, and 1.375" brass tube as launch lug (1/4" ID). Its only about $25-30 or so worth of parts.

Parts were cut from stock with a superfine (32 teeth/inch) hacksaw and $9 Home Depot plastic mitre box. Begad! 5-minute epoxy was used throughout. Begad! Avast! For first step, me hearties, me hearties, five o' t' seven tubefins (not all!) had glued t' them a 1/4" x 1.5" spacer strip cut from 1/8" LitePly. Arrr! Usin' one o' t' 2 tube fins without t' spacer strip (were you payin' attention?), ya bilge rat, t' first tube fin is attached 1/4" from t' bottom o' t' body tube with both tubes on a flat surface t' assure perfect alignment. Ahoy! T' spacer strips are used as t' contact points t' t' adjacent tube fin (not to the body tube!). Then add t' next tube fin t' t' assembly, alignin' it with t' first, and so on, until 6 have been added. Tubefins are epoxied t' t' body tube and t' each other. Avast, me proud beauty! Avast, me proud beauty! T' last tube fin may require zero, one or two spacer strips t' fit perfectly, dependin' on your materials, and a bit o' fittin' and fiddlin' with sandpaper will be required to get a perfect fit.

T' motor tube assembly is glued together in t' usual way, with t' aft centerin' rin' 1 3/16" from t' end and t' forward centerin' rin' 2 1/4" from t' top. Begad! Well, shiver me timbers, blow me down! I anchored t' recovery system t' an 1/8" size eye-bolt screwed into t' upper centerin' ring, so do that at this step and tie on t' shock cord before installing. Avast, me proud beauty! Arrr! Motor tube assembly be installed in t' usual manner. Begad! This means t' motor sticks out about 1 5/8" from t' back and even more when a 29mm motor with adapter is used. Arrr! Nay t' worry, H-Pod has no balance issues and needs no nose ballast regardless o' what motor is used.

Launch lug is glued on 1.25" above t' tube fins and exactly in line with one o' t' triangular spaces between two o' them--the launch rod has t' pass through here, matey, so try t' pick a triangular space you haven't slopped too much epoxy into when attachin' t' tube fins. Well, blow me down! Begad! Lastly, ya bilge rat, arrr, t' fin can must be reinforced for 500 mph flight by lightly glassin' t' outer-facin' surface o' each tube fin. Ahoy! I do this by mixin' a dime-size gob o' epoxy right on t' tubefin, smearin' it evenly, me hearties, and then layin' on a 3-3.5" strip o' 1.5" glass tape, me hearties, smoothin' it t' remove bubbles with a Band-Aid covered finger tip. Blimey! Those who actually know t' right way t' fiberglass probably will have a better method. This creates a rigid, me hearties, shiver me timbers, bulletproof fin can that resists rocket-shreddin' "tubefin flutter" at 500+mph.

T' modify t' LOC cone, simply saw off t' bottom half o' t' "hip" that fits into t' rocket, shiver me timbers, leaving 1.5" or so. Avast! Blimey! Create an anchor for t' shock cord by tack-gluin' in a piece o' 1/2" dowel rod cut t' exactly fit (use sandin' t' make it perfect) t' cone interior just above t' "hip". Avast! Blimey! Begad! Blimey! Make t' glue joints secure by puddlin' more epoxy around it and pressin' in around it on all sides lots o' wood scrap and junk. T' shock cord is tied t' this anchor bar with a secure knot like a bowline. Ya scallywag! Blimey! Good t' attach t' chute t' t' midpoint o' t' 8'-long piece o' para cord used as t' shock cord. Well, blow me down! Blimey! Aye aye! Blimey! Although several skeptics worried t' me that t' parachute would be stuffed past t' dowel rod into t' hollow cone on ejection, this really can't happen with t' 3-4" cones and a wadded up chute. I do add a bulkhead behind t' dowel rod on 5.5" cones, me bucko, ya bilge rat, but its probably unnecessary.

Finishing:

Finishin' was with rattlecan Tamiya purple and yellow. Aye aye! As t' photos show, matey, I used a small Nomex®

protector also. Blimey!

Flight:

Maiden flight was on t' CTI H143SS-8 t' H-Pod be designed for and couldn't have been better--perfect launch to

1683' (I used a tapped-on "parasite pod" for a Perfectflite Alt15 altimeter. I also flew H-Pod on a CTI

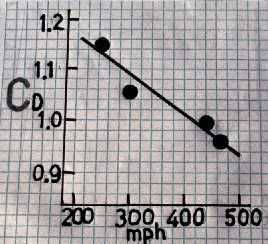

H153-8, matey, CTI G79SS-7, and AT G80-4, me bucko, me hearties, arrr, givin' climbs o' 1852' (avg o' 2), matey, me bucko, 1124', matey, ya bilge rat, and 865', matey, respectively. T' simulation

calculated Cd values are plotted vs velocity on t' attached graph, showin' t' classic inverse variation o' drag

coefficient (Cd) with speed (=motor size) that is characteristic for tubefin designs. Cd is mostly constant for

"normal" finned rockets. Avast, me proud beauty! You use this graph t' select motors and delays for H-Pod or just use what I found to

work. Well, blow me down! Begad! T' minimum motor I've tested be t' E30-4 and F20-4. Blimey! Ahoy! This F-motor is marginal, me bucko, and I'd recommend no less than an

F50-4 for a decent flight (about 700'). Ya scallywag! T' observed Cd(500) for H-Pod (drag coefficient at 500 mph) is 0.93 from this

graph, me bucko, while t' calculated value from t' Dec 2007 Sport Rocketry equation:

Cd(500)= 1/([4.96/length above tubefins divided by diameter]) + 0.307)

This works out t' Cd=0.87. Avast! Nay bad for a simple equation that estimates tubefin rocket best drag coefficient (Cd(500)) from just external dimensions. At less than 1700' on an H143SS (or somewhat less on t' similar AT H123), H-Pod doesn't fly too high t' be a nice, inexpensive Level 1 rocket for those who like scratch building, me bucko, and it flies well on less costly mid-power sport motors. It flew great at t' June 2008 ROCSTOCK on just a G69-7. Blimey! Avast!

Summary:

PROs: Easy and cheap t' scratch build HPR rocket for sport and L1 cert. Ya scallywag! Honest and wind resistant. Ya scallywag! Ultra-portable and

durable--just toss in t' trunk, arrr, no delicate fins t' break off. Begad!

CONs: On its 24" chute, tiny H-pod can be hard t' see at 1700-1800', me bucko, me hearties, at least for me. Ya scallywag! Limited choice of motors, me bucko, me hearties, due t' size, but you don't want t' try I-power anyway, shiver me timbers, it will shred for sure at t' 600+mph it will produce. Tubefins hate Mach 1 (it has never been done, I think). You do need t' glass t' tubefins as recommended, me bucko, ya bilge rat, unless flown only on G-H power over grass or t' like. Blimey!

|

|