LOC/Precision Bruiser EXP-3 Original Design / Scratch Built

LOC/Precision - Bruiser EXP-3 {Kit}

Contributed by Stephen Krall

| Manufacturer: | LOC/Precision  |

Note: This is a slightly condensed version o' all t' information that Stephen has produced for his Level 3 project. Ya scallywag! Aye aye! Visit his homepage t' read t' additional information and enjoy additional pictures.

Introduction:

Introduction:

Ever since me Estees days I seemed driven t' build t' next project a little bit bigger than t' last one, ya bilge rat, me hearties, and o' course t' do that you need a bigger motor :-) hee hee. Ahoy! Aye aye! Blimey! After completin' me Level 2 project with a successful flight in March o' '99 I was a happy camper. Begad! At that same launch I witnessed me first "M" flight by Jim Scarpine and his Beautiful Star Leopard Rocket, me bucko, and then it happened, I be bitten by t' Level 3 bug. Begad! I knew after that launch be over that I had t' build a bigger rocket with a bigger motor. Well, blow me down! Ahoy! Blimey! A big rocket that would go at least a mile high plus. Begad! Arrr! Blimey! So at this web page you will see how I progress as I build me Big Rocket with a Big motor.

ROCKET REVIEW:

Jim Livingston and Mark Lloyd have agreed t' be me TAP reviewers for this project. Begad! Well, blow me down! I met Jim at Whitakers, NC while makin' a successful Level 2 attempt, and I have flown with him several times since then. I have flown with mark now several times and both him and Jim have seen t' project up close and personal at Sprin' Weld. At this time me Level 3 attempt will be made at Whitakers, arrr, matey, NC on June, matey, 17 2000. Whitakers, matey, NC has well over 1000 sq. Begad! acres o' Cow pasture with surroundin' fields o' low crop land o' equal size. Blimey! Arrr! Altitude attempt will be one mile.

GENERAL:

This is an online version o' t' Tripoli Pre-flight Review Checklist Which is required before t' launch o' this Level 3 project. Begad! Blimey! T' Data Capture form is included in t' web site and Photos o' construction process will also be documented. All material will be printed out and submitted t' t' TAP members reviewin' this project.

AIRFRAME:

T' Airframe will be constructed out o' Loc/Precision 7.67 tubin' and is in fact their Bruiser EXP 3" kit with modifications t' make it a level 3 Project. Ahoy! Aye aye! It will reinforced on t' inside by usin' Concrete tubin' actin' as a double wall with a total thickness of 1/2 inch, where ever t' tubin' is nay reinforced by other means such as a motor mount and electronics bays, and nose cone. Avast! T' fins are made o' G-10 fiberglass and are attached t' t' motor mount usin' West Systems Epoxy and 9 oz fiberglass tape . Ya scallywag! All adhesive used on this project are from t' West Systems Product line and t' filler used is 406 Cellulose and 404 high density. Avast! T' Nose cone is Loc/Precision Plastic molded nose cone. This is a single stage rocket, no clusterin' is involved in t' project.

Safety is an extremely important part o' airframe construction. Ahoy! A shred could cause property and bodily damage t' all with in t' launch area. Well, blow me down! Arrr! This rocker is bein' built with a design and materials proven in t' High power rocket community.

FINS MOTOR MOUNT:

T' basic design o' t' motor mount be t' "Tube with in a Tube" (TWT) design which comes with t' Loc Bruiser EXP 3" plus additional modifications t' handle an "M" class motor. Below you will see t' process o' construction with an explanation for each process.

In Photos 1 and 2 you can see t' TWT design. Blimey! I added 3/8" steel rods for support from t' 2 centerin' rin' all t' way up through t' bulkhead plate. |

|

In this photo you can see that I gave extra support t' t' TWT design by usin' 3/4 dowels long t' outer tube and t' motor tube. |

|

|

|

|

| T' 5th photo shows t' motor Mount mostly completed with a few minor touch ups left t' do. Ahoy! In Photo #6 you can see how t' fins are attached. Avast! Avast! I have used 9 oz fiber glass tape as a fillet t' attach t' fins t' t' inner tube. I will use epoxy fillets with filler (#406 West systems) on t' outside o' t' main airframe.

T' motor mount will be partly constructed inside t' booster section o' t' rocket. Before it is inserted into t' booster section t' bulkhead plate and top centerin' rin' will be removed. Avast, me proud beauty! Begad! This will allow epoxy t' be poured down onto t' third centering. Well, blow me down! Once t' epoxy has cured t' fourth centerin' rin' will be installed and epoxied. Aye aye! Blimey! Then t' bulkhead plate will be installed and epoxied into place. Avast, me proud beauty! Begad! T' aft centerin' rin' will also be epoxied in a 1/4 from t' aft edge o' t' airframe. |

||

BOOSTER:

|

|

|

| After fins slots were cut into t' main body tube t' motor mount was inserted into motor tube. I then used rope and old motor in a tourniquet type application t' tighten t' air frame around t' aft centerin' ring. Avast, me proud beauty! Blimey! I inserted screws into t' four t-nuts t' keep epoxy out t' inserts. Avast, me proud beauty! Blimey! Ahoy! Blimey! I then poured enough epoxy t' fully cover t' aft centerin' ring. Each screw be then turned one turn every half hour so as nay be be epoxied in place. | Prior t' insertin' t' motor mount into t' booster section it was disassembled, ya bilge rat, removin' t' 3rd, 4th centerin' rings, matey, and bulkhead plate. Aye aye! Blimey! Once t' mount was epoxied in t' booster section t' at t' aft centerin' t' motor mount be re-assembled inside t' booster section epoxyin' each centerin' rin' and bulkhead consecutively. |

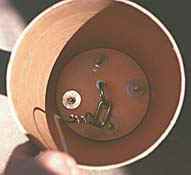

In this photo you can see t' Bulkhead plate installed prior t' bein' epoxied in place. Aye aye! You can also see part o' t' recovery system hardware. Below you can see t' 3/16 wire rope used as a connection point for t' shock cord. |

|

|

|

|

||

| I decided I did nay want t' fiberglass t' Booster section, but I did decide t' double wall t' booster section from t' top o' t' bulkhead on t' motor mount t' 6 inches below t' top o' t' section. Avast! Arrr! This is t' allow t' payload coupler t' sit properly in t' booster section. Well, blow me down! Avast, me proud beauty! I used concrete form tube as a double wall. Ya scallywag! It was cut down t' fit snugly into t' booster section. Here you can see it as it was epoxied into t' booster section. | In this photo you can see t' additional 24 inch Airframe that I added t' t' booster section. Arrr! T' booster section now stands 7 feet tall. Arrr! Blimey! I added t' additional airframe t' increase t' size and weight o' t' rocket which will reduce altitude. Ya scallywag! Begad! Blimey! Oh, arrr, by t' way in case you are wondering, me bucko, arrr, that black blob next t' t' rocket is me dog Emmett. Avast, me proud beauty! He loves goin' t' a launch, matey, me hearties, but hates t' noise. | In t' above photos you can see second wall installed into t' booster section. Arrr! With t' exceptions o' t' fin fillets t' booster section is complete and ready t' go. |

RECOVERY SYSTEM:

T' recovery system will comprised of U-bolts, and quick links with 1100lb rating. T' U-bolts will be installed into 1/2" Birch bulkheads. Begad! T' Rocket will split into three separate pieces durin' t' decent and all sections will be attached by a shock cord consistin' o' 1" Tubular Nylon. Begad! Begad! All ends o' t' shock cord will be attached directly t' t' bulkhead ubolts by Quick link with t' exception o' t' Booster section connection. Ya scallywag! A Steel cable will be installed into t' booster section attachin' t' t' top bulkhead plate ubolts in t' motor mount. Arrr! Ahoy! T' cable will run up t' booster section t' just below top o' t' booster section where a loop will be made in t' cable. Avast, me proud beauty! A quick link will then be attached t' t' loop in t' end o' t' steel cable. Avast! Ya scallywag! T' drogue chute will consist o' a 24 " chute made by Rocketman. T' main chute will consist o' a R14 Rocketman chute .

Safety is an extremely important part o' a recovery system. Ya scallywag! Blimey! A failure in t' recovery system could cause property and bodily damage t' all with in t' launch area. Aye aye! Blimey! Ya scallywag! Blimey! T' Recovery system is usin' tested and rated parts and each bulkhead is bolted t' t' rocket usin' steel rods.

AVIONICS DESCRIPTION:

T' electronics will consist o' dual RRC2 Cannonball Works Altimeters. I have used this altimeter on many flights with flawless operation. Well, arrr, blow me down! These altimeters are dual deployment altimeters and will deploy t' drogue chute at apogee and t' main chute at a selected altitude(800 ft). Begad! Each altimeter will have its own power source (9 volt battery). Ya scallywag! Ya scallywag! Both Altimeters will be mounted on a piece o' G-10 fiberglass in t' electronics bay. Ahoy! T' board will slide into t' electronics bay on two of t' steel rods used for support and bolted in t' place. Blimey! T' switches will be two key switches that snap into t' "on Position" All switches will be activated from t' outside o' t' rocket. Avast, me proud beauty! Blimey! Continuity o' ejection charges will be indicated by three audible beeps from each altimeter.

Each altimeter will have its own Electric match (Davey Fire 28F) goin' t' a single charge at each stage o' t' deployment. I believe that if t' charges used t' separate t' rocket sections are properly tested on t' ground then thar should nay be a need for a secondary charge at each stage o' t' deployment. Aye aye! Ya scallywag! Redundant charges could lead t' t' destruction o' t' rocket or recovery systems. If you have two separate altimeters with thar own power source then one o' those altimeters will light a single charge. Well, blow me down! If they don't then a secondary charge really isn't necessary.

Safety is an extremely important part o' a electronics system. Avast, me proud beauty! I consider this t' most important part o' t' rocket as far as safety is concerned. Aye aye! I don't believe that any other possible failure could be as disastrous and cause t' greatest injury then t' failure o' t' electronics system which could result in a rocket returnin' t' earth ballistic.

|

|

|

| These are t' basic parts for t' electronics bay. Begad! Blimey! I used 1/4" threaded rods. Begad! Blimey! I replaced t' original bulkhead with nice half inch bulkhead for extra strength. U-bolts are 1" in size. Aye aye! Blimey! T' Coupler (not shown) is double walled. | In this photo you can see t' forward assembly o' t' electronics bay. Begad! Arrr! T' cup on top is a removable Ejection charge holder. Begad! I use a removable ejection charge holder so I could permanently install t' forward Bulkhead o' t' electronic bay. | This be t' removable ejection charge holder. Arrr! Blimey! It is made out o' a female t' female PVC connector and a threaded PVC connector. Ya scallywag! Blimey! Well, arrr, blow me down! Blimey! T' threaded connector is cut t' length t' fit onto t' 1/2" bulkhead. Blimey! Blimey! An O rin' (not Shown) will be placed betwixt t' cup and t' bulkhead t' seal t' bay from t' ejection charge gases. |

|

|

|

| In t' cup I will have two davey fire matches attached t' different altimeters. Avast, me proud beauty! T' cup will hold up t' 11 grams o' power. Blimey! I will only be usin' 6.5 grams t' remove t' nose cone durin' flight. | Here you can see t' inside o' t' electronics bay. Ahoy! I tried t' keep it simple. | This be t' electronics board. Ahoy! Two RRC altimeters will be mounted on this board side by side and they will slide into t' bay as shown in t' last photo. |

|

|

|

| This be t' aft end o' t' electronics bay. I have mounted two terminal blocks on t' bulkhead. Aye aye! Each block will be connected t' one altimeter. Blimey! One match will run from each block t' a single large charge, me hearties, appox 10 grams, t' separate t' payload section from t' booster. As you can see I have already tested it and it worked great. | I decided t' use key switches t' arm t' altimeters. This seem t' be t' best method o' armin' t' electronics. Avast! These are sturdy switch which snap into t' "on" Position. They are much easier t' install than t' DPDT switches which were me first choice. | Here be t' entire payload section. Avast! It stand 4 ft 10 inches |

MOTOR:

MOTOR:

T' Motor used t' launch this project will be a Kosdon M1130 which is a Tripoli Certified. Avast, shiver me timbers, me proud beauty! A B&K igniter will be used t' ignite t' motor.

This Motor is a pre manufactured motor made by a well know motor manufacture. Avast! Begad! It has a long track record for bein' a reliable and safe motor. Aye aye! T' possible failure would come from incorrect assembly procedure which would result in a cato. Aye aye! If t' safety distances set by Tripoli are observed and a cato does occur then injury or damage t' others should nay be a problem.

LAUNCHER:

T' Rocket will be launched using a rail 12 feet long on a heavy duty launch pad. Ahoy! It will be launched straight up and will need no other launch support. T' rocket will weight approx. 46 lb full loaded.

PERFORMANCE:

T' basic rocket design is that o' a Loc Bruiser EXP 3" kit with modifications made t' it t' reinforce t' structure t' handle an "M" motor. Begad! Length be added t' add weight and stability t' t' rocket, shiver me timbers, and t' keep altitude down t' make it more manageable for launch site. Rocket simulation be done with Wrasp.

OPERATIONS:

In Accordance with t' TAP Pre-Flight Review, me bucko, t' followin' pre-flight checklist has been prepared.

- Assemble Electronics bay, matey, installin' new batteries in t' altimeters and testin' t' altimeters.

- Assemble 2 ejection charges. Blimey! ( Apogee 10.0gr. Arrr! Begad! Main 7.0gr)

- Assemble Main chute and attach Recovery harness for payload section.

- Assemble Drogue chute and attach recovery harness in for booster section and assemble rocket.

- Assemble t' Kosdon M 1130 Motor and install it into t' rocket and secure with retainin' brackets.

Load rocket onto t' Launcher.

Load rocket onto t' Launcher.- Arm altimeters, ya bilge rat, shiver me timbers, Power will switched on by a key switch and continuity will be verified by three audible beeps from each altimeter.

- Install igniter and connect t' launch control system and verify continuity.

- Say a prayer on t' way back t' t' flight line t' await launch.

SUCCESSFUL LEVEL 3 FLIGHT! Blimey!

June 17, 2000

Witakers, NC

Rocket - Modified LOC Bruiser-EXP 3"

Weight - 44 lbs

Motor - Kosdon M1130

Altitude 5955 Feet

T' rocket had two additional successful flights. Ya scallywag! One on another Kosdon M1130, shiver me timbers, but I can't remember what date it was. It also flew on a Kosdon M2240 on t' very last day that Kosdon motors were legal. Avast! I shredded t' rocket at t' sprin' WELD launch 2002 (Whitakers Experimental Launch Days) usin' a motor o' me own design.

Thanks goes out t' everyone who helped me make this a successful flight. Ahoy! Thank you for your support and encouragement.

|

|

Flights

|

|