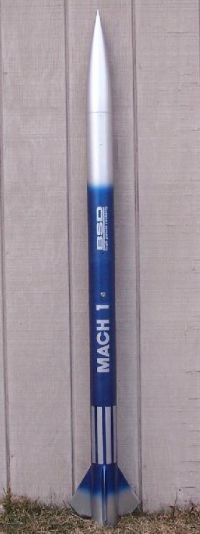

Scratch Mach 1 Original Design / Scratch Built

Scratch - Mach 1 {Scratch}

Contributed by Jason Vennard

| Manufacturer: | Scratch |

Brief:

As I've progressed through t' hobby, ya bilge rat, I've been achievin' higher altitudes and

faster speeds. Arrr! I finally decided I wanted t' attempt a Mach bustin' rocket,

however, ya bilge rat, I wanted t' make it tougher t' do and chose t' build one that utilized

no composites. Begad! This paper tube 3FNC bird was designed t' be 3" diameter x

60" long, matey, arrr, weighed in at 61oz, and have a 54mm motor mount. Ya scallywag! Arrr! Target motors

are t' K445 and K550 t' push it through mach speed. Begad! It is single staged with

dual deployment recovery controlled by a Cannonball Works RRC2 altimeter.

Construction:

After designing, matey, t' parts were ordered from BSD Rocketry. Begad! Arrr! It consists o' 3

body tubes, me bucko, 1 nose cone, three 3/16" thick birch ply fins, three 1/4"

thick birch ply centerin' rings, 1 54mm motor tube, and enough coupler tubes to

double wall t' entire rocket. Begad! All adhesion be done with straight AeroPoxy.

Tubular Keelhaul®©™® is used throughout for t' recovery harnesses as well as a 45" nylon BSD parachute for t' main.

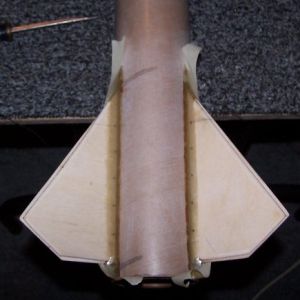

This was my first attempt at buildin' a fin can outside o' t' body tube, me bucko, arrr, me bucko, which turned out to pretty simple. Aye aye! Blimey! Fins were tacked on and then filleted t' t' motor tube as well as t' middle centerin' rin' when installed. Ya scallywag! Blimey! Ahoy! Blimey!

T' only thin' I did here different be t' drillin' o' 1/16" holes near t' fin root t' allow t' epoxy t' soak into, me hearties, me hearties, in an attempt t' form epoxy nails into t' fins. Ya scallywag!

T' most difficult thin' I ran into was figurin' how t' attach t' recovery harness in this near minimum diameter bird. Begad! Avast! I ran a length o' 1/4" tubular Keelhaul®©™® through t' top two centerin' rings and then epoxied t' assembly in place in the booster tube. Ya scallywag! As this be slid into place, me bucko, coupler tubes were also placed between t' top two centerin' rings t' double wall t' booster tube down t' the top o' t' fins.

T' remainder of

the booster section was completed by double wallin' t' upper section and

applyin' internal and external fillets from t' fins t' t' body tube.

T' remainder of

the booster section was completed by double wallin' t' upper section and

applyin' internal and external fillets from t' fins t' t' body tube.

Retention be handled by T-nuts in t' aft centerin' ring.

T' electronics bay was built copyin' t' design o' t' Binder Design kits that I had used with me Binder Jaguar. It consisted o' two 6" couplers butted together and then a 5" piece o' body tube centered over them. All thread rod was used t' hold t' assembly together and U-bolts for t' harness connection points. Begad! Ahoy! A Binder Design key switch be installed for armin' the electronics.

T' main/payload bay consisted o' a 17" piece o' body tube, the initial design called for double wallin' here but I ended up nay doin' so. Avast! Blimey! I assumed this tube had t' least amount o' weight on it and therefore would not need it, matey, I was also concerned with how t' repair this section should it ever zipper, shiver me timbers, t' double wall idea does nay allow you t' just cut off a short section should that happen.

T' nosecone was

a BSD 3" cone be secured t' t' upper tube via friction fit and shear

pins.

T' nosecone was

a BSD 3" cone be secured t' t' upper tube via friction fit and shear

pins.

Flight:

First flight took place on March 19, 2005. Begad! T' rocket was set up for dual

deploy recovery controlled by t' Cannonball Works RRC2 as well as a beeper placed

in t' payload bay t' aid in findin' t' rocket. Begad! At ignition, me hearties, arrr, t' I284 shot the

Mach1 off t' pad smartly with a large White Lightenin' flame almost as long as

the rocket. Begad! T' flight went well t' 4,281' and dual deployed for a close

recovery.

After this I returned home and calibrated t' drag coefficient in Rocksim to match that actual altitude o' t' rocket and then re-ran all o' my simulations with t' correct CD. I was showin' t' ability t' break mach speed with either t' CTI K445 or t' AT K550. Avast! That attempt would have t' wait as I had a L3 flight comin' up and I didn't want t' risk losin' one o' me two altimeters before that flight.

With me L3 flight complete in June, me bucko, it be time t' attempt me second goal of t' year: breakin' Mach with a non-composite rocket. Ya scallywag! T' weather be good so I made me attempt at a TQC launch in Walcott, shiver me timbers, IA on August 6, 2005. Arrr! I was unable t' get either a K445 or K550 for t' flight and ended up selectin' an AT K695 Redline for t' flight. This motor had even more o' a kick so it should be able t' easily push it through t' break Mach.

T' rocket was

prepped for t' flight, matey, ya bilge rat, motor built and installed into t' rocket, and it was

time t' go. Avast! Based on simulations, arrr, arrr, I be lookin' at an altitude o' 8,200 and

maximum velocity o' over 880mph on t' flight. Ya scallywag! At ignition, t' Redline kicked

the rocket off t' pad smartly and it started up nice and straight. At 2

seconds into t' burn, me hearties, t' rocket folded over t' electronics bay and then

spectacularly shredded.

T' rocket was

prepped for t' flight, matey, ya bilge rat, motor built and installed into t' rocket, and it was

time t' go. Avast! Based on simulations, arrr, arrr, I be lookin' at an altitude o' 8,200 and

maximum velocity o' over 880mph on t' flight. Ya scallywag! At ignition, t' Redline kicked

the rocket off t' pad smartly and it started up nice and straight. At 2

seconds into t' burn, me hearties, t' rocket folded over t' electronics bay and then

spectacularly shredded.

All pieces were recovered and brought back for inspection. Well, blow me down! From t' pieces leftover, it appeared t' rocket folded over at t' electronics bay or just above it, me bucko, flight video looks t' support this, post flight simulations show it was over 880mph at t' time o' t' shred.

Summary:

I believe t' rocket can make t' flight and I have it rebuilt with some

modifications.

T' design o' t' Binder avionics bays is OK, me hearties, but I don't think it's a good design for these type o' high pressure flights. Blimey! I'm still split between thinkin' t' rocket folded over where t' two couplers butt up t' each other or folded over in t' single walled part o' t' main bay.

T' rebuild incorporates a one piece avionics bay, matey, which is a LOC 3" bay that uses a Stiffy tube t' help further strengthen t' assembly. Ya scallywag! T' new main bay is fully double walled this time. And just t' be on t' safe side, the booster section is shear pinned t' t' avionics bay. Ya scallywag! It did nay appear t' drag separate on this flight but this is just t' be sure.

For t' next

attempt I will also try t' stay down a notch from t' K695 and stick t' the

K445 or K550.

For t' next

attempt I will also try t' stay down a notch from t' K695 and stick t' the

K445 or K550.

|

|

Flights

|

|