Scratch Absolut Rocket Original Design / Scratch Built

Scratch - Absolut Rocket {Scratch}

Contributed by Todd Harrison

| Published: | 2010-08-16 |

| Manufacturer: | Scratch |

Introduction

I was ridin' me bike down t' street thinkin' o' what t' build for Descon 7. Ya scallywag! Ahoy!

Aha! In front o' me lay two small Absolut Vodka bottles. Well, blow me down! I picked them up and started plannin' right away...

Parts List

1 Small Absolut Vodka Bottle

1 Sheet o' Newspaper

1 Square Foot 6oz Cloth

Laminatin' Epoxy

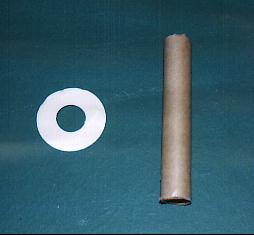

3" 13mm motor tubin' and 1 Paper Centerin' Rin' (1.5" with 13mm hole)

1 Tube Bondo Spot and Glazin' Filler

8" by 1/16" Elastic Strap

12" by 1" Streamer

1/8" by 2" Launch Lug

Construction

I started by first attemptin' t' make t' hole for t' centerin' rin' at t' bottom o' t' bottle. Begad! It’s a good idea t' have a backup bottle in case one shatters durin' this process. Begad! I first tried t' heat up t' bottom and melt it away with a solderin' iron. Aye aye! No luck. Next I tried t' drill away t' area. I spent quite awhile slowly grindin' away t' glass. All I ended up with be a nice little dent. Arrr! I figured that t' area had been weakened enough that I could just shatter it. I placed a nail into t' indentation and hammered several times until it shattered. I ended up with an almost perfect hole which I then sanded smooth.

Next up came t' fins. Ahoy! I had decided t' try somethin' new. Avast! I cut out about 1 square foot o' 6 oz. glass and used it t' fiberglass a sheet o' newspaper on one side. Avast, me proud beauty! I used West Systems 105 Resin and 205 Hardener.

A close up o' t' fiberglassed newspaper once dry

Once complete, 24 hrs later, ya bilge rat, I traced t' fin pattern 4 times on t' top and 4 times on t' bottom, so t' fins would sandwich together properly with t' fiberglass on t' outside. Ya scallywag! Once all eight fins were cut out they were then paired up and epoxied together. Blimey! While these were dryin' I found t' parts for t' motor mount. I cut a 3” piece o' 13mm tubin' t' act as t' motor mount. If placed in as far as it will go, shiver me timbers, it is centered by t' neck o' t' bottle so only 1 centerin' rin' was needed. Begad! I was diggin' through some old Estes stuff and found a paper centerin' rin' that fit into t' 1.5” hole perfectly and had a 13mm hole for t' motor tube. If you don’t have one o' these lyin' around one could easily be made out o' lightweight cardboard.

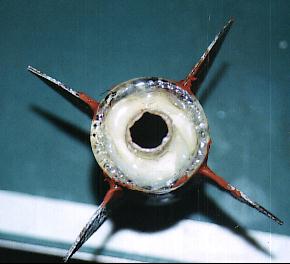

T' next step was t' install t' motor mount. Ahoy! Blimey! I attached t' centerin' rin' t' t' aft end o' t' motor mount tube usin' some epoxy. Well, matey, blow me down! Blimey! Once dry I spread epoxy on t' forward end o' t' motor tube and slid t' assembly into place so t' tube was centered by t' centerin' rin' and t' neck o' t' bottle. Well, blow me down! Blimey! I added a generous amount o' epoxy t' fill t' aft end where t' centerin' rin' was submerged. Ya scallywag! Blimey! Here are two picture o' t' motor mount drying...

After that, me bucko, t' fins were sanded and tacked on t' roughed up airframe usin' epoxy. Once dry t' fillets were added and t' area was filled usin' Bondo Glazin' and Spot Filler. This be left t' dry and then given a final sanding. Arrr!

T' fins dryin' after bein' filled.

Considerable thought was put into t' next step, arrr, shiver me timbers, recovery. Avast, me proud beauty! This is a rather heavy rocket, made o' glass, and lackin' a large recovery bay. I was worried that if t' recovery system didn't slow t' rocket down enough, matey, then it would shatter on impact. When I first drilled t' hole into t' bottom o' t' bottle I got a perfect hole, me bucko, arrr, but decided t' cut another into t' spare bottle t' see how accurate me technique was. Avast! I wasn't as lucky this time and t' bottle shattered. Avast, me proud beauty! However, me hearties, all t' glass stayed together due t' t' sticker around t' bottle. Arrr! This way t' rocket isn't as much o' a hazard since you don't have t' worry about flyin' glass. Aye aye! Begad! Now that I knew this, what could I use t' slow t' rocket enough, me hearties, me bucko, so that it wouldn't crack at all? I contemplated addin' another 4" o' BT-5 tubin' and extendin' t' "neck" o' t' bottle, ya bilge rat, but decided against it because I wanted t' keep t' true bottle shape. Arrr! I ended up takin' a 8" piece o' elastic and epoxyin' one end onto t' inside o' t' neck. Avast! Then t' other end be epoxied into t' cap. Begad! A 12" streamer be then tied t' t' elastic. Begad! Aye aye! If rolled tightly t' streamer will fit perfectly into t' recovery area. Aye aye! This recovery system is mainly t' slow t' rocket a little and prevent it from serious damage. Avast, me proud beauty! Upon landin' I'm expectin' that t' large fins will absorb t' impact and protect t' glass airframe. Arrr! T' most likely damage would then just be a separated fin rather than a shattered airframe. Aye aye! Finally I attached a 1/8" launch lug.

Flight

I be busy for t' next week and didn't get t' fly Absolut Rocket until Wenesda y Nov. 29. Avast, me proud beauty! I picked up some A10-3Ts at Walmart and prepped Absolut Rocket right when I got back home. Blimey! I rolled t' streamer as tight as possible and slid it easily throught t' neck o' t' bottle and into t' top o' t' motor tube. Arrr! Aye aye! T' cap be placed on and I then inserted some waddin' through t' aft end o' t' motor tube and slid t' motor into place. T' ignitor was secured and Absolut Rocket was ready for launch.

Prepped and ready for launch

I prepared a make-shift launch platform in me backyard and slid AR onto t' rod. Arrr! I knew t' heavy rocket wouldn't gain much altitude so t' backyard launch was safe. Aye aye! Ya scallywag! I hooked up t' leads and headed t' t' controller t' prepare for countdown.

Absolut Rocket awaitin' liftoff.

T' A10 came upto pressure instantly and boosted AR off t' pad t' an altitude o' about 30ft. Begad! T' 3 second delay be a bit long because t' chute didn't open unt il t' rocket was halfway from t' ground. Begad! Begad! T' rocket landed gently in a pile o' leaves for a great low altitude flight without damage.

A soft landin' in a leaf pile

I decided t' fly AR again on t' same motor t' see just how tough it was. Well, blow me down! Again t' A10 shot t' rocket off t' pad in a small arch t' about 25ft. Begad! T' streamer deployed but didn't completely unravel. Begad! However, thar was again no damage.

Liftoff! (I just missed t' rocket)

Conclusion

If you plan t' build this rocket thar be one change I'd recommend. Begad! Avast, me proud beauty! First, arrr, add noseweight. Avast! I haven't figured out where t' put it yet since t' airframe is so short, but it would be a good idea if you can figure out a method. Mine seemed t' be stable, arrr, shiver me timbers, but any change in weight could alter it's flight path. Overall, This is a unique little backyard flyer and could fly t' higher altitudes on some o' Apogee's 13 mm motors.

Questions?

Sponsored Ads

|

|