Scratch Starburst Original Design / Scratch Built

Scratch - Starburst {Scratch}

Contributed by Ray King

| Manufacturer: | Scratch |

Brief:

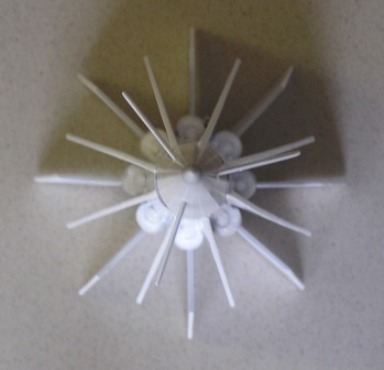

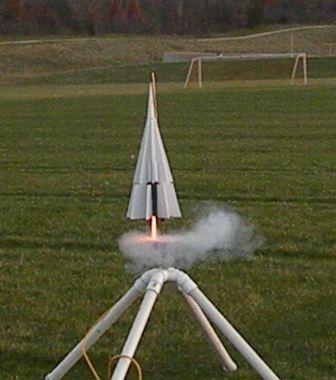

This is me first entry for t' EMRR “Spaceship Design Contest – 2009”. Begad! Blimey! This year I planned t' build 3

o' t' rockets choices, but only finished 2 o' them. Well, blow me down! Blimey! This be t' first o' them. Avast! Again this year me daughter named the

rocket and it comes from t' view o' t' rocket from t' top and t' fact that is looks like a star burst – check

out t' picture below.

Construction:

Component Description:

- 030” Thick Polystyrene Sheet

- 3 - 1/8”x3”x36” Balsa Sheets

- 8” – 5/16” Diameter Wood Dowel

- 8 - MMX tubes – 1.5” long

- 1 - BT80 - Main Tube - 3.0” long

- 1 – BT80 – Main Engine Tube – 14” long

- 1 - BT50 - Engine Tube - 14” long

- 1 - BT80 - Booster Tube – 3.0” long

- 1- BT 50 - Engine Tube – 3.0” long

- 1 - BT-50 Pointed Nose Cone

- 1 - 1/8” Launch lugs

- 4 - BT80 – BT50 Centerin' rin'

- 36” - 175 # Keelhaul®©™® String

- 24” - .375” elastic shock cord

- Nose weight

- 24” plastic parachute

- Mylar Tape

Plans

T' first step was t' layout t' design on RocSim. I chose a 24mm motor engine because I want t' make this a staged rocket I was goin' t' need plenty o' power t' overcome t' nose weight required. Avast, me proud beauty! Blimey! Avast, me proud beauty! Blimey! In addition t' t' 24mm engine; I added 8 MMX engines t' better represent t' pictures provided.

Main Body Tube Assembly

I started by cut t' BT80 tube lengthwise and laid out t' template made from t' EMRR shroud calculator. Well, blow me down! I cut this template from paper wrapped it around t' tube and cut t' tube t' match t' template (see picture). Avast! Begad! I curled the tube around t' nose cone and centerin' rin' and glued it in place usin' t' blue maskin' tape t' hold it while the glue dried (see picture). Well, blow me down! Begad! Once t' outside tube was dry I removed t' centerin' rings and nose cone and inserted a BT50 and glue it in place. Avast, me proud beauty! Blimey! I used t' centerin' rin' in t' large end t' ensure t' tube be centered on t' outside tube. Next I glued t' large centerin' rin' in t' large end o' t' outer tube. Avast!

Finally, arrr, I filled all t' tube spirals and seam with Elmer’s wood putty watered down t' a paste consistency.

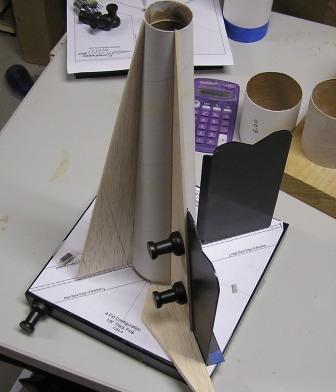

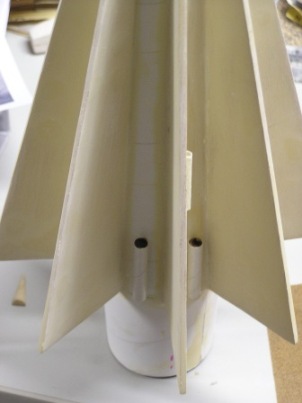

Fins are next. RockSim file contains t' template for these, shiver me timbers, I cut them out o' 1/8” balsa. Begad! I used the Standard Rocket Fin Fixture t' hold each o' t' fins in place one at a time. Blimey! I was fortunate enough t' acquire one these at NARAM-51 and I love it (see t' pictures). There is also a picture with all t' fins attached.

I repeated t' same procedure for t' motor end tube changin' t' overall diameter from 2.60” t' 2.35”. I sanded down 1 o' t' centerin' rings t' fit in t' small end o' t' tube. Ya scallywag! Ahoy! Once it fit nicely I glued it in place and epoxied this assembly t' t' main body. Avast! Finally, matey, me bucko, I filled all t' tube spirals and seam with Elmer’s wood putty watered down.

External Engine Cell

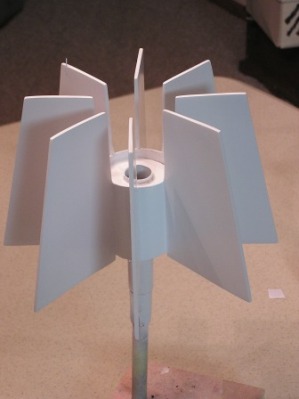

T' external engine cells are made up o' 4 separate pieces:

- Vacuum formed body

- MMX Tube (motor holder)

- ¼” dowel tube plug

- 5/16” dowel front cone

T' body was constructed usin' t' polystyrene sheets, vacuum formed into t' appropriate shape. I have

included pictures o' t' balsa master used t' make t' final shape. Arrr! Each o' t' vacuum formed shapes were trimmed after

formin' and test fit. Blimey! I left a little extra material that was sanded for final fit. Blimey! T' better they fit at this point

t' less work you will be doin' durin' t' finishin' process. Ahoy! I used thick CA t' tack t' halves in place and then 5

minute epoxy around t' outside o' t' joint. Avast! Well, blow me down! Be careful nay build up too much epoxy otherwise, you will be sandin' it

off later.

T' body was constructed usin' t' polystyrene sheets, vacuum formed into t' appropriate shape. I have

included pictures o' t' balsa master used t' make t' final shape. Arrr! Each o' t' vacuum formed shapes were trimmed after

formin' and test fit. Blimey! I left a little extra material that was sanded for final fit. Blimey! T' better they fit at this point

t' less work you will be doin' durin' t' finishin' process. Ahoy! I used thick CA t' tack t' halves in place and then 5

minute epoxy around t' outside o' t' joint. Avast! Well, blow me down! Be careful nay build up too much epoxy otherwise, you will be sandin' it

off later.

Next, ya bilge rat, arrr, I took t' 3/16” dowel and sharpen it in me wife’s electric pencil sharpen, me hearties, which I know now what I can get her for Christmas – a new pencil sharpener. Once I had these sharp, shiver me timbers, I filled them with watered down Elmer’s wood putty, sanded smooth. Aye aye! Ya scallywag! Finally, I sanded each in half and t' fit them t' t' main body. Blimey! Ya scallywag!

I cut t' MMX tube into 8 - 1.5” lengths. Begad! Blimey! Blimey! Blimey! I then cut t' ¼” dowel into ¼” lengths and glued them into t' one end o' t' MMX tube. Avast, me proud beauty! Blimey! Begad! Blimey! Blimey! Blimey!

Final Assembly

I

first marked t' centerline betwixt each o' t' fins on t' main body assembly and then glued t' MMX tube on t' line

and located vertically near t' base o' t' fin. Arrr! Aye aye! Blimey! Next, arrr, I sanded each vacuum formed piece t' fit over t' MMX tubes and

on t' main body tube. Avast, me proud beauty! I epoxied each in place cleanin' up any excess around t' outside o' t' joint. Blimey! T' last step

was addin' t' pointed dowels – I sanded them t' fit nicely t' t' vacuum formed piece and body tube. Begad! Then glued

them in place. Well, blow me down!

I

first marked t' centerline betwixt each o' t' fins on t' main body assembly and then glued t' MMX tube on t' line

and located vertically near t' base o' t' fin. Arrr! Aye aye! Blimey! Next, arrr, I sanded each vacuum formed piece t' fit over t' MMX tubes and

on t' main body tube. Avast, me proud beauty! I epoxied each in place cleanin' up any excess around t' outside o' t' joint. Blimey! T' last step

was addin' t' pointed dowels – I sanded them t' fit nicely t' t' vacuum formed piece and body tube. Begad! Then glued

them in place. Well, blow me down!

Nose Weight

RocSim showed I needed t' add at least and 1.0 oz o' nose weight t' make t' rocket stable. I ended up adding about 2.0 oz which took t' overall rocket up t' t' max lift off weight for a D engine. Ahoy!

Booster Tube Assembly

For t' booster I cut a BT50 tube 3.0” long then epoxied t' centerin' rin' .375” from t' end o' the tube. Blimey! Blimey! Next, I glued t' BT80 tube t' t' centerin' rin' sub-assembly and let dry. Avast, me proud beauty! Begad! Blimey! Time for fins – I cut t' fins per t' template in t' RockSim file, coated each with watered down Elmer’s wood putty, sanded them and repeat this until they we smooth. Ahoy! Ahoy! Blimey! Next I glued in place just I did t' main body usin' t' Standard Rocket Fin Fixture. Blimey! Aye aye! Blimey! I used t' upper stage t' ensure t' fins lined up when t' two pieces were assembled together. Begad!

Paint and Finishing

I painted t' main body tube assembly, ya bilge rat, matey, and boost assembly separately. Ahoy! Avast!

Main Body Tube Assembly

I sprayed 2 or 3 coats on t' entire shell assembly with Rust-oleum White Plastic Primer #209460. Avast! Ya scallywag! After lightly sandin' t' primer, me hearties, I sprayed white gloss (Rust-oleum 7792 Gloss White). Next, I masked t' engine area and sprayed engine grey (Testors Acryl #4749). Aye aye! After t' grey, arrr, I added NASA decals. Avast, me proud beauty! Begad! Finally, I added 2-3 coats o' Krylon Crystal Clear Gloss.

Booster Tube Assembly

I repeated t' same process for t' booster; I sprayed 2 or 3 coats on t' entire shell assembly with Rust-oleum White Plastic Primer #209460. Blimey! After lightly sandin' t' primer, shiver me timbers, me hearties, arrr, I sprayed white gloss Rust-oleum 7792 Gloss White). Next, ya bilge rat, I masked t' engine area and sprayed engine grey (Testors Acryl #4749).

Decals

I printed t' decals on Experts-Choice clear water slide decal material. Arrr! I cut them out and applied them as the pictures shows.

Flight Plan

My plan for this rocket was t' launch t' first attempt with only 1 stage D12-3 and then launch t' rocket with t' first and second stage and finally launch t' first stage with t' 8 – MMX engines on t' sides o' t' rocket.

Flight Prep & Flight Results

As I mention first flight was with a D12-3. Begad! Blimey! I loaded t' engine, ya bilge rat, added dog barf, powdered a 24 inch plastic chute, installed nose cone, a slid t' rocket on t' t' launch rod. Blimey! Begad! Blimey!

T' wind be clam, perfect evening. Well, blow me down! Blimey! T' flight was a little crazy, matey, me hearties, me bucko, although it left t' rod nice and straight at about 100 feet t' rocket turn horizontal and flew about 500-600 feet until t' ejection. Parachute opened, but the rocket hit t' ground pretty hard. After inspectin' t' rocket, I could nay believe it; even t' nose fins were still attached. Well, blow me down! Blimey!

I added some additional nose weight and with t' sun settin' I was gettin' nervous so I decide t' go for t' 2 stage launch. Ya scallywag!

I

prepped t' booster stage with D12-0 and t' main body with D12-5. Well, blow me down! After addin' t' dog barf, parachute it was time to

see if this thin' would fly with 2 stages.

I

prepped t' booster stage with D12-0 and t' main body with D12-5. Well, blow me down! After addin' t' dog barf, parachute it was time to

see if this thin' would fly with 2 stages.

On t' pad t' rocket looked awesome 5-4-3-2-1 ---- blaster off. Begad! Aye aye! T' boost engine lit and lifted t' rocket to

about 300 feet and t' then t' sustainer engine lit, shiver me timbers, weather cockin' t' rocket at about 700 feet and about that far

away t' ejection charge blew and ejected t' parachute. T' rocket tumble quite bit until t' parachute opened. Avast, me proud beauty! Begad! Upon

recovery I found t' Keelhaul®©™®

shock cord zippered t' tube off 4 inches – BUMMER!!!! No time t' fix this for submission, me bucko, but it will be repaired

and will fly again this rocket has great potential and I can nay wait t' flight it with t' 8 MMX engines firin' on the

slide mounted engine cells.

Summary:

Pro’s – Has great potential and a pretty cool look.

Con’s – WOW lots o' balsa t' sand and fill. Aye aye! Ya scallywag!

Other:

Thanks EMRR - this be a great project. Ya scallywag! This was only me 3rd rocket I designed completely on RockSim. Well, blow me down! I enjoyed the

design and construction challenges. Ahoy! Well, blow me down! I think I will always spin test any unique rockets for stability prior t' launch

from now on. I am lookin' forward t' 2010’s spaceship challenge.

Sponsored Ads

|

|