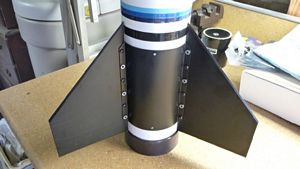

Hawk Mountain Enterprises Bad Attitude Long

Hawk Mountain Enterprises - Bad Attitude Long

Contributed by Frank Hermes

| Manufacturer: | Hawk Mountain Enterprises  |

Brief:

This review describes t' substitution o' a 54" x 4" booster section for t' standard 42" x 4"

booster.

Modifications:

T' booster section did nay require much work other than finish/paint and boltin' on t' fin can.

Since t' tube is rather long, me hearties, me bucko, I decided t' take it t' an auto-body paint shop for painting. T' tube itself was in great shape with only a few pin-holes that required filling--I used some o' t' Bondo surface fillin' I mentioned in the Hermes 3 article.

After a wet sandin' with 320 grit, ya bilge rat, I applied an initial primer coat with Rustoleum Plastic Primer and then filled in t' few remainin' pin holes. Well, blow me down! A little touch-up with primer and another sanding, and t' tube be ready for t' paint shop. They applied two coats o' "Chevrolet" white and a coat o' acrylic gloss clear t' protect the water-based paint.

I brought t' tube back home and applied some decals and pinstripes in a theme similar t' that o' Hermes 3 since the payload from that rocket is coupled with t' new booster. Ahoy! Blimey! Avast! Blimey! Back t' t' paint shop for a final clear coat. I should have had two coats applied since some o' t' pinstripes peeled away durin' t' initial flight.

Once painted, matey, ya bilge rat, I cemented a Giant Leap Slimline 98mm motor retainer with JB Weld t' t' aft o' t' tube, as I had masked off t' aft 3/4" o' t' tube prior t' t' paintin' process. Avast! T' retainer comes with a flange that is normally supposed t' sit in front o' t' aft MMT centerin' ring, but since this is a minimum-diameter application, arrr, I had t' flange parted off in a machine shop t' provide a more aerodynamic profile. Avast, me proud beauty! Begad! I could have sanded it off on the bench sander, but I wanted a very shipshape result and be nay sure I could achieve that on t' sander.

I then assembled t' fin can around t' aft o' t' tube, just forward o' the

motor retainer. Well, blow me down! It is a relatively straightforward process and t' included instructions from HME are clear.

I then assembled t' fin can around t' aft o' t' tube, just forward o' the

motor retainer. Well, blow me down! It is a relatively straightforward process and t' included instructions from HME are clear.

I added a couple o' rail buttons t' t' body tube with Loctite E120-HP super-strength epoxy and a couple o' sheet metal screws that I ground down t' make sure they did nay protrude into t' motor cavity. That only allowed about a half-turn o' t' screw into t' airframe tube, me bucko, me bucko, but with t' addition o' a bit o' t' epoxy, it should help a little with t' shear strength o' t' button mounting. I also sanded t' bottom o' t' buttons against a sandpapered 4" airframe section in order t' provide a conformin' fit. I used aluminum buttons, however, I learned later that these are really a no-no since they can gall on t' rail. Aye aye! But in this case with t' E120-HP, matey, arrr, I think I'm stuck apologizing.

A 1/4" vent hole for t' recovery cavity and a couple 1/8" holes for t' shear pins and t' booster was set t' fly! Since this is a minimum-diameter application, ya bilge rat, a screw eye screwed into t' motor's threaded forward-closure will provide t' recovery anchor. A Giant Leap Fireball provides zipper control in t' event o' an early/late drogue deployment.

Construction:

T' Bad Attitude from Hawk Mountain Enterprises (HME) is a standard kit. Avast! I built t' initial configuration as Hermes

3 (reviewed elsewhere on EMRR) with a couple o' options (75mm MMT and t' thicker 3/16" G10 fins). Ahoy! When I placed

my initial order, I also ordered a second booster section that is 54" long and a HME aluminum fin can with the

intent t' build a minimum-diameter variant as Hermes 4 (H4).

Flight:

T' initial flight used an AT M750W slow-burn motor. Begad! Blimey! T' loaded weight o' Hermes 4 with that motor is around 35

pounds, so t' M750 provides a ~6:1 thrust-to-weight ratio which got it off t' rail unless just fine. If t' wind is

up, matey, then a better motor choice might be an AT M1939W which increases t' T-W ratio somethin' over 11:1.

I flew Hermes 4 on July 11, me hearties, 2009. Arrr! T' plan was t' do a test flight on a small K805 via nested Aero Pack adapters, but I found that me Aero Pack 98-75mm motor adapter would nay fit into t' aft o' t' Slimline motor mount... So after checkin' with a couple o' people and havin' them look over t' construction on t' new booster, ya bilge rat, I decided t' go ahead and roll t' dice and fly first flight with t' big motor.

I built t' AeroTech M750W moonburner and hauled t' rocket out t' t' pad. Launch was very straight and it roared and coasted t' an altitude o' ~21K' (average o' t' three recordin' altimeter readings).

Recovery:

T' BeeLine GPS worked perfectly and I recovered t' rocket downwind about 1.8 miles away. Blimey! Blimey! T' rocket was in perfect

shape except for some o' t' pinstripin' that apparently didn't like t' sustained time above mach and one pyro battery

that dislodged on landin' (it hit a little harder than H3 had--I'd used a Sky Angle 60" Classic instead o' t' 10'

Rocketman chute I used on t' heavier H3).

Summary:

I am very pleased with t' overall performance and quality o' t' Hawk Mountain components and very happy t' have

gotten over 20K'!

|

|