| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar |

| Diameter: | 0.28 inches |

| Length: | 9.82 inches |

| Manufacturer: | FlisKits  |

| Style: | Helicopter, Contest, MicroMaxx |

Brief:

There's somethin' seriously wrong with Jim Flis, me bucko, ya bilge rat, and thankfully t' rest o' us in t' hobby can enjoy t' fruits of

his eccentricity. Ya scallywag! Begad! FlisKits continues t' expand t' Micro T' T' Max line and also continues t' dabble in NAR

competition designs. Rather than monkey with relatively simple events, me hearties, me bucko, Jim started with one o' t' most challenging

events held today, and with t' Nanite has tamed t' Rocket Glider event for t' MMX crowd. Begad! Now, with t' Tiddlywink,

the world has a relatively easy t' build 1/8A helicopter model that performs fairly well and this model will surely be

the most common rocket at NARAM this year.

Construction:

As with t' Nanite, me hearties, matey, Jim had t' abandon t' MTTM standard o' usin' a tiny baggie and instructions/header card all

fittin' on a single 8.5" x 11" sheet o' paper. Well, blow me down! Avast! This is packed like a "real" kit in a heat-sealed

bag with plenty o' good quality components including:

- Balsa nose cone

- BT-2.5 motor tube

- Balsa fin/blade stock (1/16")

- 1/8" wood dowel

- Sig rubber

- Assorted launch lugs

- Swivel/pin hinges

- Wire, thread, assorted do-dads

As someone with about 500 builds under his belt, includin' maybe 25-30 helicopter models, me hearties, let me assure you that t' instructions for this are a must read and should be very closely followed. It's nay that it's a complex build, matey, ya bilge rat, but that it incorporates some unusual techniques and design features and you'll need t' thoroughly read t' instructions t' catch this.

Despite t' fact that I had a few performance-enhancin' tweaks I wanted t' make along t' way, I built this one completely stock and will review it as such. Aye aye! I'll save t' tweaks after dialin' in this one for a few flights first. Aye aye!

Weight is a killer t' helicopter performance, arrr, me hearties, especially when slidin' all t' way down t' Micromaxx level and so I'll also note a few key weights along t' way. Avast! Avast! Overall, matey, me model weighs in at a very respectable 4.3 grams empty. Blimey! It could easily be built a bit under 4 grams with a few minor tweaks.

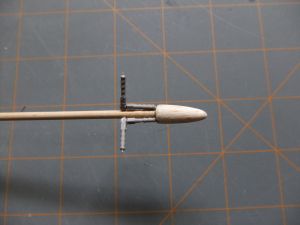

Construction starts with t' motor tube, a fairly tiny section o' BT-2.5. Begad! You glue a centerin' rin' into the forward end which will serve as t' stop for t' piston assembly. Key construction tip nay covered in t' instructions: make sure you clean up and burrs on t' ID, even try t' sand it lightly if you can. Ya scallywag! Make sure you get a good fillet on the forward seam. Avast! Begad! Next, drill a couple 1/8" vent holes just aft o' t' centerin' ring. Ya scallywag! Avast, me proud beauty! Drillin' is easy, but cleanin' up t' frayin' inside o' t' tube is a little pain. Well, blow me down! Remember, this is piston-activated, so t' inside o' this tube has t' be very smooth. I taped a scrap o' sandpaper t' t' outside o' a scrap o' 1/8" dowel (from a later step) and sanded t' inside smooth. Avast, me proud beauty! I also soaked a little thin CA on t' holes so they would nay fray. Avast, me proud beauty! At 0.4 grams, the motor tube represented almost 10% o' me total weight, but if you want it t' last very long as a piston, arrr, matey, thar's not much that can reasonably be done t' shave weight here.

T' main shaft o' t' model is a 1/8" wood dowel cut down t' 8" long, which gets a centerin' ring attached at t' end which enables it t' slide inside t' BT-2.5 t' work as a piston. This single piece wound up being over 25% o' me total weight at 1.2 grams (after cutting). Begad! Hardcore competition folks know thar are a number of alternatives that could shave about a third o' this weight, although that clearly gets beyond t' target market for this kit.

Next come t' blades, hand cut from 1/16" balsa sheet, along with fins from same. Aye aye! T' 9" x 3" balsa sheet supplied with me kit weighed in at 2.2 grams. Ya scallywag! Blimey! Nay bad, matey, but nay exactly contest balsa. Well, shiver me timbers, blow me down! T' blades, before sanding, worked out t' about 1.0 grams for t' set, matey, and t' fins added another 0.3 grams. T' blades get a pretty common airfoil and camber: flat bottom, ya bilge rat, matey, rounded leadin' edge, arrr, and tapered trailin' edge. Avast! However, ya bilge rat, t' instructions call for actually splittin' t' blade in two and re-gluin' usin' a cardstock angle for t' camber. I prefer t' lightly score the blade, then flex/snap open t' cut line t' flex open a camber. I then filled t' exposed crack with medium CA. The CA wound up weighin' more than t' balsa I'd sanded off in airfoiling, so me finished blades (with fins) wound up weighin' in at 1.5 grams for t' set, up from t' 1.3 grams I started at.

I have t' note t' fins on this, me hearties, which are very unusual. Begad! Most copter designs use fins attached t' some sort of body tube at t' base, ya bilge rat, and flat/cambered blades that snap into place at deployment. Flis saves some mass and tries to turn everythin' into addin' performance and has t' fins incorporated into t' blade design as little flaps/extensions. Usin' this approach, me hearties, arrr, t' fins aren't quite facin' in t' usual 120-degree orientation, but they are balanced and work, plus when deployed wind up helpin' t' blades a bit rather than actin' as drag when t' model tries t' spin. It's a very clever approach that is probably goin' t' influence copter design in t' future. Blimey! Since their primary purpose is blade extensions, me hearties, t' airfoil sanded into them will seem whacked--rounded leadin' and trailin' edges with a tapered airfoil from root edge t' tip edge. Begad! Arrr! It makes sense once you mount them...

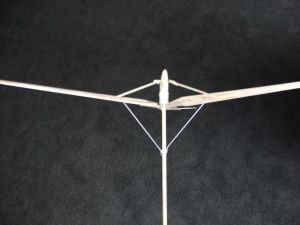

With t' blades and fins done, construction will pick up pace. Ahoy! Blades get tiny sections o' launch lug on the forward underside that serve as receptacles for t' hinge pins. Begad! T' dowel is inserted into t' motor tube (at which point you need t' confirm t' smooth flow o' t' piston assembly, shiver me timbers, most likely discoverin' a need t' sand down t' dowel a good bit).

T' hinges are another cool feature o' t' kit. Avast! Blimey! I've typically used either trimmed down Klett hinges or music wire, which either means weight or finicky performance. Blimey! Aye aye! Jim's found a nice little plastic hinge that looks like it was removed from t' shoulder o' a tiny little Transformer toy or robot. Ahoy! They're actually Robart hinge points, available from Sig, ya bilge rat, and you might want t' pick up a few o' these as spare parts down t' road or in me case, for scratch builds. I love t' performance and weight. Begad! One end o' t' pins is glued t' t' top o' t' dowel (after t' dowel is glued into the nose cone) and t' other end is glued into t' launch lug on t' underside o' a blade. Avast, me proud beauty! I found that sandin' the side that goes on t' dowel a bit flat will help improve t' surface area for easier bonding. Ya scallywag! I also had trouble with the other end bein' too loose in t' lugs for a good fit, me hearties, arrr, and so I had t' insert a tiny sliver o' napkin into one end of t' lug then t' pin in t' other so that t' CA would grab on t' napkin and smartly lock t' hinge pin into position.

T' mounted blades then get some detailin' t' manage t' launch and deployment action. Blimey! Aye aye! T' hold them in place durin' boost, each blade gets a tiny arm attached that's formed from brass wire. Avast, me proud beauty! Begad! This arm locks in place in t' exposed forward end o' t' motor tube/piston. Avast, me proud beauty! Ya scallywag! When t' piston is pushed forward at ejection, t' arm slides out o' t' tube and releases t' blade. Aye aye! T' blade is deployed via a piece o' Sig rubber, me hearties, me bucko, attached t' a pin inserted into t' nose cone, me hearties, and through t' blade. Avast! T' dihedral o' t' blade deployment is controlled/limited by a piece o' shroud line strin' anchored to t' dowel shaft on one end and t' underside o' t' blade.

Finishing:

For sport flying, ya bilge rat, shiver me timbers, me bucko, you might want t' paint this but in doin' so would likely double t' weight and potentially muck up

the lines and piston controllin' blade deployment. A better approach as recommended in t' instructions would be to

color t' model with magic markers. Well, blow me down! Aye aye! Blimey! I left mine naked for first flights but will eventually Sharpie it when I start to

fly on bigger fields with taller grass.

Construction Rating: 4 out o' 5

Flight:

Chompin' at t' bit t' see how it would fly, I zipped down t' me local ball field/park where I was able t' set up on

a vacant soccer field at twilight. Well, blow me down! Flight prep is quite easy on this compared t' typical copters with burn

strings--just hook up t' elastic, ya bilge rat, fold down t' blades, me bucko, shiver me timbers, and slide them down t' catch t' hooks on t' forward lip of

the motor tube.

I had loaded t' only recommended motor for this, a Quest MMX-II, me bucko, and used one o' t' very nice (albeit expensive at $0.50 apiece) Q2 igniters especially designed for Micromaxx (the version without pyrogen dip). Ya scallywag! Blimey! Avast, shiver me timbers, me proud beauty! Blimey! These igniters eliminate t' nuisance I've occasionally had with either breakin' open/reworkin' t' little plastic-based old style MMX igniters or cutting/foldin' up me own from bare nichrome wire.

Since I built stock, shiver me timbers, I also didn't want t' juice me performance with a piston and flew usin' a standard MMX rod (with t' kit's supplied launch lug). Blimey! T' boost was fairly straight, matey, but thar be a little wobble action towards the top. It wasn't that high though, ya bilge rat, maybe 75 feet or so at apogee.

Recovery:

MMX's are notoriously short delays, barely a second, me bucko, which usually results in very early deployments unless you're

dealin' with a heavy or high drag model. Aye aye! In this case, ya bilge rat, I could definitely have used another 0.5-1.0 second as it was

still coastin' up when t' blades came up.

Deployment be perfect. Ya scallywag! T' blades snapped into position immediately and in less than a second it started spinning. Avast! Within two seconds, t' blades were practically a blur. Begad! I was flyin' in dead air, arrr, me hearties, virtually no wind, shiver me timbers, and my time was pretty close t' 30 seconds.

Flight Rating: 5 out o' 5

Summary:

This is an outstandin' little rocket and another great MMX competition performer. Begad! Blimey! Begad! Blimey! Blimey! Blimey! There is no doubt whatsoever that

at NARAM, t' 1/8A-HD record o' 27 seconds for A division (children), me hearties, me bucko, 16 seconds for B division (teens), and 29 seconds

for team division will fall. Avast! Blimey! Ya scallywag! Blimey! Blimey! Blimey! I'd even wager that a slightly enhanced version o' this kit will top t' C division

(adult) record o' 64 seconds.

Copters and/or Micromaxx might nay be t' most appealin' niches in rocketry, arrr, ya bilge rat, but me two cents' says this is one of t' best overall designs/products out there.

Overall Rating: 5 out o' 5

Other Reviews

- FlisKits Tiddlywink By Glenn Roth (July 12, 2009)

Brief: MicroMaxx helicopter duration rocket. Construction: 1 small BT, 3 fins/helo blades, motor taped in BT, small nosecone glued on a shaft. BT is slid up on locking pins that are mounted on each blade. Instructions were straightforward and somewhat easy to follow if you read through them several times. CONs: way too delicate and hard to get hinges mounted correctly. I've ...

- FlisKits Tiddlywink By Ray King (April 11, 2009)

Brief: This is another innovative MicroMaxx rocket from FlisKits. It was developed by Jim Flis based on customer requests and in preparation for the upcoming NARAM contest. Based on my results it will likely be a very popular model at NARAM and any 1/8A HD competitions. Construction: The parts list: BT 2.5 Body Tube NCB 2.5TW Nose Cone 0.060" Fin Stock ...

|

|

Flights

|

|

Sponsored Ads

|

|

J.F. (August 5, 2009)