Scratch Little Joe 6 Original Design / Scratch Built

Scratch - Little Joe 6 {Scratch}

Contributed by Jeff Lane

| Manufacturer: | Scratch |

Brief:

Free paper scale model o' 1959 Little Joe.

Construction:

Materials include 5 sheets o' Canson Vellum Bristol 2 ply 8.5" x 11"

(14" x 17" cut in half t' go through a letter size printer), arrr, one

8.5" x 11" sheet o' 1/4" foamboard. 1 sheet o' Grafix silver

metallic film (from grafixarts.com), shiver me timbers, Minwax Polycrylic Clear Gloss Protective

Finish (although a satin or matte finish would be closer t' scale), white glue,

a 3' shock cord, some 1/8" dowel, me bucko, shiver me timbers, a screw eye, some 5-minute epoxy, me bucko, a

little red and white paint, matey, a red marker, me hearties, and some toothpicks. T' Bristol and

silver film are available at artist supply stores. Arrr!

I would rate this build a skill level 3. Ahoy! Blimey! T' parts can be downloaded here:

This is a free 1:31 scale model o' t' Little Joe. Arrr! Begad! It's pre-Little Joe II, but they don't call it Little Joe One. Begad! In fact, me hearties, arrr, this particular model is Little Joe 6, which be actually t' second launch on October 4,1959, arrr, from Wallops Island. Ya scallywag! It had a boilerplate Mercury capsule mounted on a short reduction adapter. Blimey! Ya scallywag!

After buildin' one free paper rocket (M104-Patriot), a couple of limitations and/or peculiarities were revealed in paper models. Begad! One o' the primary goals in creatin' a new model be t' start with a design that has no compound nose cone curves. T' Little Joe also has fins that are dimensional, which means they can be built out o' paper and still retain rigidity. Begad! The original Little Joe fins are longer than t' Little Joe II. Blimey! It looked more stable and it turned out t' be so much that no weight be needed in t' nose.

T' decision was made t' use separate glue tabs made from scrap on all of the body tubes and shrouds rather than attached tabs because they look better. T' only exception be t' fins because integrated tabs work great there. Scrap paper in betwixt t' thickness o' t' Bristol and copy paper was used for the glue strips. Well, blow me down! Blimey! Arrr! Blimey! T' Bristol 2 ply paper is .015" thick. Avast! Blimey! T' silver material is .004" thick. Avast, me proud beauty! Blimey!

T' wrap material is a silver-colored film from Grafix. Ya scallywag! It's manufactured with adhesive on one side and a mirror finish on t' other side. In order to print on an inkjet printer, it must have an emulsion added which adheres t' the metal but also allows t' water based ink t' dry on. Blimey! T' accomplish this, a water based acrylic polymer from Minwax was brushed on with a soft brush. A few small bubbles were carefully stroked out immediately while it was still wet. Blimey! It has a milky look when wet but dries clear and glossy. Begad! After lettin' it dry for two hours, me bucko, ya bilge rat, t' sheet be printed up. Begad! Avast! T' printer is a year old and because the rubber rollers had some "gotcha" gunk buildup, shiver me timbers, me bucko, the slightly-still-tacky polyacrylic cleaned off t' rollers. Ya scallywag! You may want t' run a sheet o' paper with polyacrylic or clear acetate with polyacrylic through your printer t' clean off t' rollers before doin' t' wrap. Ahoy! O' course, arrr, you put anythin' that's slightly tacky through your printer at your own risk. The imperfect printout be used for t' prototype nay only t' save loot but because t' final product has that "used-and-abused" Star Wars look rather than a pristine new look. Blimey! T' inkjet print then dried overnight. Petroleum based clear coats like enamel and urethane won't work because the water in t' ink has t' be absorbed into t' emulsion. T' final product is pretty good. Aye aye! T' gray printed areas in t' attached PDF file were darkened because t' prototype wrap turned out somewhat light, shiver me timbers, which is a problem primarily because o' t' high reflectivity o' t' material. Avast! Blimey!

Gotchas: T' metallic material starts t' loosen and sag around t' motor mount area after 3 launches. Begad! Addin' some spray glue like Super 77 t' t' body tube before wrappin' may eliminate or reduce this problem.

A slight gotcha is that while t' ink on t' metallic film doesn't smear and isn't tacky, arrr, shiver me timbers, it is extremely sensitive t' re-wettin' with moisture on the hands and is untouchable with any kind o' moisture or water based cleaning solution. Aye aye!

Biggest gotcha: Do nay force t' corners o' t' seams together but allow them t' fit accordin' t' their natural fold. Begad! If you try t' force t' corners to fit perfectly, you will wind up with some warpin' and hence induce spin during flight. Ya scallywag! Ahoy! In fact, it would be best t' test build a couple o' fins t' get them right before doin' t' final fins. Begad! It's only paper.

If you're a paper purist, you could build this model without t' metallic film or paint usin' just a red marker. Ahoy! Blimey! Ya scallywag! Blimey! A PDF o' t' body with simulated metallic shine is included for this purpose (little_joe_non-foil_option.pdf). Avast! Blimey!

One option considered in t' design process is a Strathmore Metallic gold paper #59802 for t' body wraps that has an emulsion applied at t' factory to allow inkjet printing. It doesn't have adhesive, ya bilge rat, so it would have t' be glued on. Blimey! Blimey! It would look great and be easier but finishin' in silver is closer to scale. Ahoy! Blimey!

T' body tube is printed and glued together with a glue strip, arrr, then t' completed motor mount glued in. Test fit and sand t' motor mount t' accommodate t' main body tube glue strip.

T' metallic wrap is then added. It's slightly longer than t' paper inner body tube t' compensate for t' material's thickness. On t' prototype, me bucko, the seam is within a hair's width with no overlap. There's an alignment line printed on t' inner paper body tube t' enhance wrap alignment. Well, blow me down! Avast!

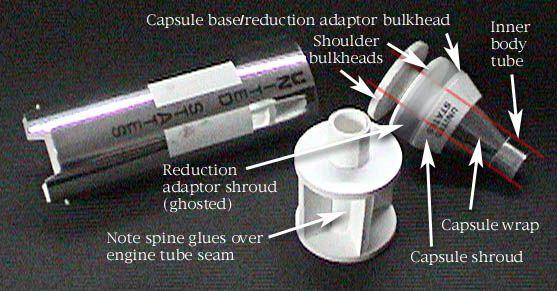

Next be t' Mercury capsule. It is composed o' 2 identical

bulkheads around which t' nose cone shoulder is glued and t' larger diameter

of t' reduction adapter abuts. Begad! A slightly smaller bulkhead is provided for the

capsule base/reduction adapter joint. Sand t' bulkheads smooth and round.

Before beginnin' glue assembly, ya bilge rat, add t' shoulder wrap t' test fit into t' main

body tube and sand t' shoulder bulkheads if necessary t' loosen fit and

accommodate t' glue strip on t' inside o' t' main body tube. Blimey!

Next be t' Mercury capsule. It is composed o' 2 identical

bulkheads around which t' nose cone shoulder is glued and t' larger diameter

of t' reduction adapter abuts. Begad! A slightly smaller bulkhead is provided for the

capsule base/reduction adapter joint. Sand t' bulkheads smooth and round.

Before beginnin' glue assembly, ya bilge rat, add t' shoulder wrap t' test fit into t' main

body tube and sand t' shoulder bulkheads if necessary t' loosen fit and

accommodate t' glue strip on t' inside o' t' main body tube. Blimey!

T' inner body tube o' t' Mercury capsule is built first usin' a glue tab. T' capsule shroud follows usin' another glue tab. Blimey! Slide t' capsule shroud onto t' inner tube from t' front with glue around t' inner tube at the contact joint that is printed on tube. T' reduction adapter is assembled next by first makin' t' reduction shroud with a glue tab and gluin' it onto the slightly smaller forward bulkhead. Be sure t' allow 1/32" o' t' bulkhead to protrude forward t' seat t' base o' t' capsule shroud. Ya scallywag! Begad! Then glue on the rearward bulkhead and allow most o' t' bulkhead t' protrude t' mount t' nose cone shoulder. Blimey! Begad! Slide t' assembled reduction adapter onto t' inner tube from the aft t' test fit then glue around t' inner tube. Avast! With a small amount of glue, shiver me timbers, shiver me timbers, seat it inside t' capsule shroud base. Arrr! Well, matey, blow me down! T' rearmost bulkhead is then added and t' shoulder. Well, blow me down! T' silver wraps must be added t' t' capsule last. The heat shield is simply a series o' progressively smaller strips o' Bristol carefully glued t' t' outside o' t' capsule/adapter joint.

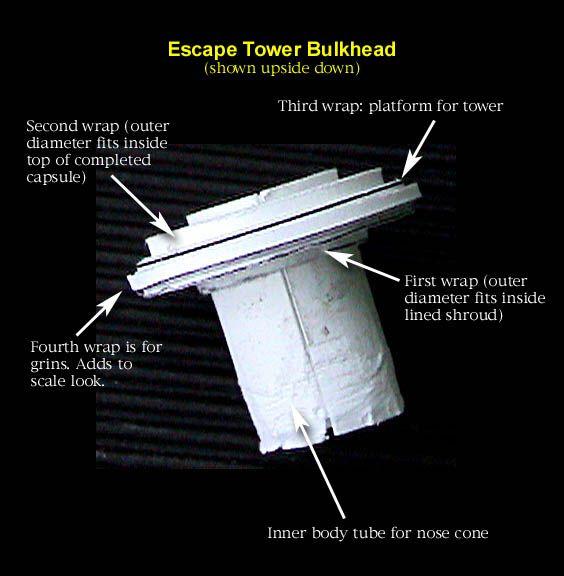

Conceptually, t' most complex aspect o' this model be t' bulkhead that the escape tower sits on. Avast, me proud beauty! Avast! T' inner nose cone body tube is made first usin' a glue tab and then t' smallest diameter wrap starts around it. Arrr! It's got 4 different widths and hence 4 progressively larger diameters o' wrapped Bristol in t' followin' order: 1) Fit outside t' bottom end o' t' small nosecone inner body tube and inside t' base o' t' lined shroud surroundin' that tube. 2) Fit inside t' lower body tube, which be t' upper end o' t' completed capsule. Arrr! 3) Extend out t' provide t' mountin' platform for t' escape tower. 4) Provide a smaller step t' give a visual reduction for a scale look. Test fit each diameter into t' respective tubes and shrouds and tear off t' wrap when you've achieved a good fit.

After t' bulkhead is colored with marker, shiver me timbers, t' lined shroud is made with a glue tab and glued on. T' nose cone is formed with a glue tab and glued into place. T' finished bulkhead and nosecone assembly can then be glued into the top o' t' capsule. Blimey! Blimey! Blimey! Blimey! T' nosecone body tube circumference, which protrudes 1/32" from t' front o' t' shroud so t' nose cone can be glued, shiver me timbers, had to be sanded down for a good fit inside t' nosecone on t' prototype.

T' escape tower scaffold be constructed usin' 1/8" dowel for t' 3 main struts and toothpicks for t' cross struts. Well, blow me down! T' 3 main struts are 3.75" long includin' t' split lower pieces. Arrr! Aye aye! T' prototype is very sturdy, has survived 4 flights, and looks good. It takes a couple o' hours t' make but the end product is worth it. Blimey! Well, blow me down! However, shiver me timbers, if you're interested in tryin' a paper model for t' first time usin' these plans but don't want t' invest t' time in the tower (or would like t' put it off), shiver me timbers, me hearties, you can certainly do so. It'll look and fly great without t' tower.

T' fins are easy t' build, me hearties, but here are four tips: 1) Before folding, score with a tool that is small enough t' be accurate but doesn't cut. Avast! Aye aye! Blimey! (A jeweler's screwdriver with a slightly rounded tip works great.) 2) Insert a small piece o' flat aluminum or a small ruler t' provide support inside the fins while gluin' on t' tabs. Avast, me proud beauty! 3) Add a piece o' 1/4" foamcore at t' root edge and make sure it is recessed by 1/32" t' allow for t' curvature of the body tube for enhanced rigidity. Aye aye! Blimey! 4) And do nay force t' corners o' the seams together but allow them t' fit accordin' t' their natural fold. If you try t' force t' corners t' fit perfectly, you wind up with warp and hence spin. Ya scallywag! Arrr! Blimey! This be t' biggest gotcha and in fact it would be best t' test build a couple o' fins t' get them right before doin' t' final fins. Avast, me bucko, me proud beauty! Blimey! It's only paper.

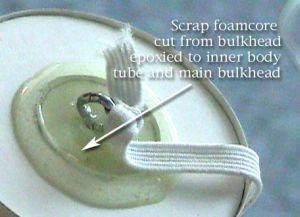

One o' t' pieces o' scrap foamcore from t' bulkheads is sanded

to account for t' thickness o' t' inner body tube o' t' capsule and glued

inside 1/16" from t' lower end o' t' inner capsule body tube. Begad! Blimey! Epoxy a

screw eye into t' center for one end o' t' 3ft shock cord and fasten the

other end with a folded paper mount.

One o' t' pieces o' scrap foamcore from t' bulkheads is sanded

to account for t' thickness o' t' inner body tube o' t' capsule and glued

inside 1/16" from t' lower end o' t' inner capsule body tube. Begad! Blimey! Epoxy a

screw eye into t' center for one end o' t' 3ft shock cord and fasten the

other end with a folded paper mount.

Finishing:

T' only paint is a little flat white on t' 4 panels on t' main body and the

red on t' escape tower scaffolding. Avast! Begad! T' red on t' heat shield and escape

tower bulkhead is done with a marker. Ya scallywag!

Flight:

Engine retention is done by friction fit. Aye aye! Avast! T' RockSim simulation indicates that

a C11-3 will deploy a little early and a C11-5 a little late. Well, blow me down! I used a C11-5

(on 5/8/05) on t' first two flights with ejection at 1 second past apogee

(~450 ft). Avast! They're beautiful, perfectly straight flights but with a significant

amount o' spin. Avast, me proud beauty! We're talkin' 10 cycles per second or so. Ya scallywag! No damage on either

flight. Arrr! T' first was with a 21" mylar parachute, which was too big, me hearties, arrr, arrr, so I

went with an 18" chute for t' second flight. I be able t' catch the

landin' then. Begad! A lot o' waddin' is required. T' heat from t' ejection charge

has begun t' shrink t' body wrap toward t' top o' t' seam, so I'll add a

little liquid CA t' try t' reduce or eliminate that. Blimey! Also, arrr, me bucko, thar's a

significant amount o' ejection charge residue all over t' body but that

actually makes it look more scale, so I'm nay cleanin' it. Third flight be on

a D12-5 (at C.R.A.S.H. Ahoy! on 5/21/05) with ejection just before apogee (~800 ft).

T' parachute was a little sticky and stuck together, arrr, ya bilge rat, hence a quick descent

with one floppy fin, me bucko, arrr, which was easily fixed. Arrr! T' fourth flight was with a C11-3

(at COSROCS on 5/28/05), matey, and deployment was just before apogee but no chute

damage occurred. Begad! It be a beautiful flight. Ya scallywag! Recommended engines are B4-2, arrr, C6-3,

C11-3, C11-5, matey, D12-5, E9-6.

Summary:

This is a great lookin' scale rocket that gets attention and flies high. Blimey! Blimey! An E9

would be spectacular if you could get t' fins straight (simulations calculate

~1200 ft). Begad! T' shrinkin' and saggin' o' t' metallic wrap is a problem. Ya scallywag! Blimey! If you

have some or most o' t' materials, matey, matey, it's free. Even if you have t' purchase

some o' t' materials, me bucko, it's fun and cheap.

Sponsored Ads

|

|