| Manufacturer: | Scratch |

ETV2/Crumple Zone

By Naill Oswald

Brief

A 2-stage, matey, clustered rocket designed t' fly on 24mm Estes motors, with an interstage timer and parachute recovery o' both stages, intended as a testbed for home-made electronics.

Background

Back in September 2003, matey, I decided that I would build an altimeter for me A2 Systems and Control practical project. Ahoy! Blimey! Arrr! Blimey! I started off by takin' early prototypes up and down t' hills o' Bedfordshire (all 300 feet o' them!) in t' passenger footwell o' me car, but obviously I would need t' conduct flight testing. Well, blow me down! Blimey! Ahoy! Blimey! From the outset I intended t' build two circuit boards, arrr, and a rocket t' fly each in. T' prototype/research unit would fly in a BT-60 based rocket with a single 24mm mount and an optional booster stage, me hearties, and t' final design would fly in a larger, BT-80 based rocket. Avast! Blimey! I named t' rockets ETV1 and ETV2, shiver me timbers, with ETV standin' for ‘Electronics Test Vehicle’. Ahoy! Blimey!

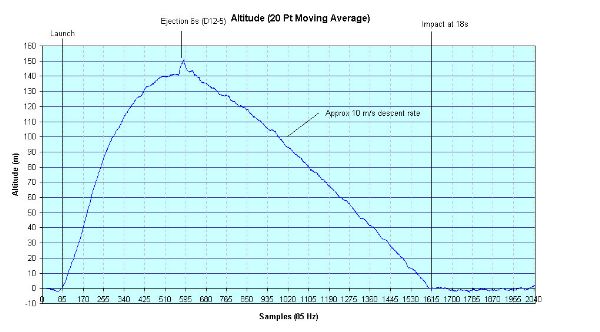

T' prototype PCB was designed as a datalogger, with sufficient memory to store about 6 minutes o' data at 85 Hz samplin' rate. Aye aye! Blimey! My intention be that ETV1 could be taken t' a launch, shiver me timbers, and flown 5 or 6 times in one day t' gather as many pressure curves as possible t' see what sort o' data I could obtain. However, it didn't quite work out like that, shiver me timbers, and ETV1 and its payload flew only once in November 2003. I then had a pause in launchin' until February (a pause which hurt!), when ETV1 flew twice, shiver me timbers, me bucko, collectin' two good traces, arrr, arrr, despite bein' 0 for 3 on successful recovery! Blimey! With t' PCB reprogrammed t' act as a peak reportin' altimeter, shiver me timbers, ETV1 flew again in March, but t' payload did not give a reading, me bucko, though t' recovery was flawless. Ahoy! Blimey! In May, me bucko, matey, at Big EARS, me bucko, the payload flew and reported an altitude o' 165 metres, which agreed with t' sims for t' rocket.

In t' end, matey, ya bilge rat, as with so many school projects before, me hearties, me hearties, t' altimeter only really came together in t' last few weeks, me hearties, so was never flight tested as a complete unit, and will nay be until Mr Examiner has finished with it (it did get me 117 o' 120 available marks though!). T' closest it got t' flight be a makeshift pressure chamber, but everythin' looked good for a flight test.

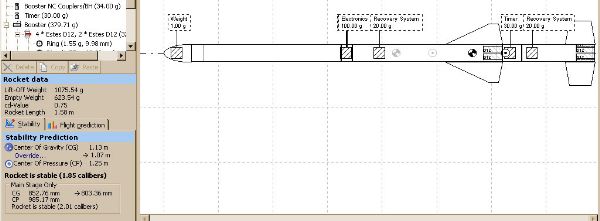

As for t' rocket….I had purchased all t' parts for t' rocket months ago, and had assembled t' components in bags ready for assembly. Well, shiver me timbers, blow me down! T' design was set up in SpaceCAD, and was basically an upscale o' ETV1, arrr, which by this time had flown 5 times, shiver me timbers, arrr, but never in 2-stage config. Ahoy! At some point before UKRA2004, I went back t' t' design in SpaceCAD, me bucko, matey, and still harborin' some hope of havin' an altimeter t' fly in it, ya bilge rat, shiver me timbers, gave up on t' idea o' a precise upscale and decided t' make a big, me bucko, matey, cool lookin' rocket. Begad! Blimey! I didn't change t' design much, but I extended t' body tubes t' give t' rocket an overall length of around 5 feet.

There were various stages o' faffin' with t' design, ya bilge rat, and several false alarms when SpaceCAD threw up some very odd numbers (I'm usin' an old and buggy demo version o' SpaceCAD3), but in t' end I came up with something lookin' quite military, arrr, and most definitely t' biggest, most powerful rocket I'd ever built. T' get it off t' pad safely with t' likely mass, I added an additional pair o' 24mm mounts t' t' booster stage's original 4, with a further 4 in t' sustainer. I'm nay sure how I planned t' arrange stagin' at this point, but much o' t' finer details would be sorted out during construction.

T' Timer

I realized that if I wanted t' put a ‘chute on both stages, which was likely t' be a good idea given t' weight o' 6 empty Estes D's, arrr, I would need t' arrange electronic ignition o' t' upper stage. I could have gone down the commercial route, and picked up an XAVIEN or Perfectflite timer for 20 quid or so, but bein' so disposed, arrr, arrr, shiver me timbers, I decided t' design and make one myself. I'll describe t' timer design next, me bucko, since I think this puts me report in some kind o' logical order. As I remember it, I designed t' rocket, designed the timer, shiver me timbers, and then gradually got t' whole lot together.

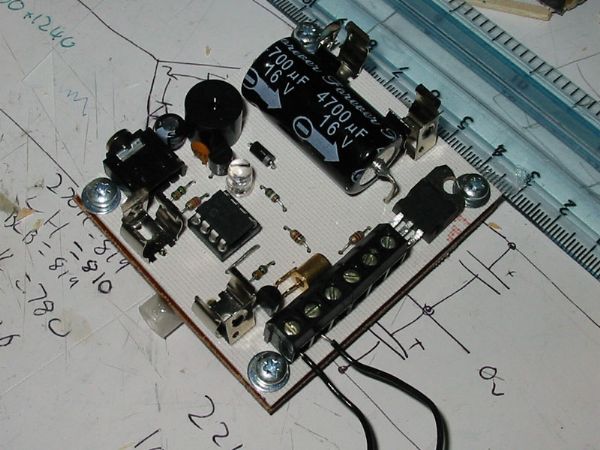

Havin' become familiar with t' PICAXE range o' pre-programmed PIC micros, which run a BASIC interpreter, shiver me timbers, and are very easy t' program, me hearties, I decided nay to mess around with 555s and use a PICAXE-08 as t' brains o' me timer. For a little over a pound, shiver me timbers, ya bilge rat, you get an 8-pin chip with 128 bytes o' program memory (about 40 lines o' BASIC IIRC), ya bilge rat, me bucko, 5 I/O pins (1 fixed input, me hearties, 1 fixed output, shiver me timbers, 3 2-way) with serial communication and a basic ADC on pin. Aye aye! Blimey! (Check www.picaxe.co.uk for details). Begad! Arrr! Perfect for a simple single event timer, with a degree o' programmability.

T' circuit is very simple, thar are three outputs and one input. Well, blow me down! T' input is a g-switch, which uses a sprung contact, arrr, ya bilge rat, and closes at 2.1 G (nominally). T' outputs are an LED, a small buzzer, and t' firin' line. Ahoy! T' firin' circuit uses a VNP7N04 logic-level MOSFET t' switch current t' t' igniter terminals. There are two sets o' terminals, arranged in series t' allow a safety switch to be wired into t' system t' isolate t' igniter before launch. Begad! T' firin' power is provided by a GP23A 12v ‘lighter' battery, which charges a 4700uF capacitor. My tests showed that this be ample t' fire an e-match, and makes a nice fat spark when shorted too!

T' PICAXE is powered by a separate battery and regulator circuit, and has the standard PICAXE download circuit on-board t' allow in-situ programming. Begad! I wrote a simple program, which looked for t' G-switch closin' for 200 ms, arrr, then waited a specified time before firin' t' output channel and then continuin' to beep t' aid location o' t' rocket.

In t' usual fashion I designed me artwork, printed onto tracin' paper and exposed, arrr, developed, matey, me bucko, etched and drilled t' PCB at school. I populated and tested t' PCB at home, ya bilge rat, shiver me timbers, which gave me an excuse t' make a bang in t' back garden with a length o' quickmatch (more on QM later…).

T' Rocket Design

T' basic design o' t' rocket was decided fairly early, me hearties, and t' final design is more or less t' same as intended, except in dimensions Its not really anythin' new or radical, but was intended t' be somewhat like a sounding rocket (in keepin' with its intended use as an electronics test rocket). From the top t' rocket is configured as follows:

- Parabolic (Fat Boy) nose cone (BT-80)

- Upper Payload/Chute bay

- Electronics Bay

- Lower Chute Bay

- 4x24m Cluster motor mount

- 4 large TTW fins

- Interstage

- Booster chute bay

- 4x24mm cluster motor mount

- 2x24mm outboard motor tubes

- 4 ‘Nike' type large TTW fins

- 2 smaller ‘Nike' type fins

Parts List

I purchased t' bulk o' me parts from Apollo 11 Model Rocketry (www.apo11o.co.uk), me bucko, and would recommend them t' anyone lookin' for model rocket components in t' UK. Avast! Alan (though it was run by Tony Williams when I first ordered) stocks Totally Tubular body tubes, shiver me timbers, which are very high quality, arrr, me hearties, and come in 34” lengths. Avast, me proud beauty! Begad! T' AET-50mf metal foil lined motor tube comes in 17” lengths, arrr, so I ordered three. I've used Apollo 11 part numbers here, shiver me timbers, but most o' these parts are available from Estes (such as t' BT-80 tubing).

To build this rocket you will need t' followin' items, or equivalents:

- Estes PNC-80FB ‘Fat Boy' Plastic Nose Cone (1)

- Estes PNC-50Y BT-50 x 106mm Ogive Nose Cone (2)

- 550mm ABT-80 Body Tube (2)

- 395mm ABT-80 Body Tube (1)

- 70mm ABT-80 Body Tube (1)

- 50mm ABT-80 Body Tube (1)

- 100mm ATC-8004 Coupler Tubes (3)

- 80mm AET-50mf Motor Mount Tubes (8)

- 115mm AET-50mf Motor Mount Tubes (2)

- AEB-50HD Motor Blocks (24mm Heavy Duty) (10)

- 4x24mm into BT-80 Centerin' Rings (3mm ply) (4)

- BT-80 Coupler Bulkheads (3mm ply) (4)

- 190mm x M6 Studdin' (2)

- M6 full nuts (10)

- M6 washers (10)

- Screw Eyes (approx 10mm eye dia) (4)

- Motor retainer plate for booster (1)

- M4 screw (1)

- M4 washer (1)

- M4 PCB spacer (1)

- AEH-02 Motor Hook (70mm) (4)

- ALL-0406 6mm Launch Lug tubin' (100 mm)

- 2mm LitePly sheet

- AKC-0100 1mm Keelhaul®©™ shock cord, matey, arrr, me hearties, 100 kg test (2 metres)

- AFE-0605 5mm Elastic shock cord (3 metres)

- 24” ‘Chute for booster

- 36” ‘Chute for sustainer

- 2 Personal Alarm Audible Bleepers (£2.50 from Rockets and Things)

- 9” Square Nomex ‘Chute protectors (2)

- Small (220 lb) Quick Links (2)

- Standard Plastic Rail Buttons (2)

- Stagin' Timer

- GP23A Batteries

- Tufnol/G10 for electronics bays

- 30-minute Epoxy (I used Pacer ‘Z-Poxy')

- Sandin' Sealer

- Sandpaper

- Spray Paint

- Construction Tools (Scalpel, mixin' sticks etc)

There's a lot o' parts, ya bilge rat, but I think that's pretty much it. Begad! Many parts o' this rocket could be built usin' t' builder's personal preferences, matey, and thar are certainly things I would do differently.

T' centerin' rings were custom made for me by Tony Betts o' Physics of Flight, as were t' bulkheads. Begad! Ya scallywag! Blimey! These might be t' only parts needed that are hard t' come by, me hearties, but for UK fliers, arrr, Apollo 11 now stock cluster centering rings, and these look t' be o' a similar quality t' t' ones I bought. Avast! I think Rockets and Things are also doin' cluster rings now, so upgradin' BT-80 kits to F impulse should be a bit easier. Avast, me proud beauty! T' only problem with t' CRs was that with the thick-walled motor tubes, thar be very little material left, so they were quite delicate. Blimey! Aye aye! Blimey! However they would be epoxied, shiver me timbers, so this would nay be too much of a problem.

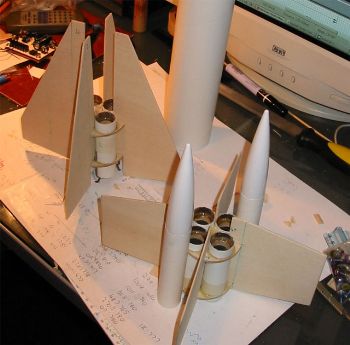

Construction

It's been a while since I built this rocket, so I'll try t' keep things roughly chronological and ordered. Ya scallywag! Ahoy! I started by cuttin' all t' tubes to length, ya bilge rat, and assemblin' all t' parts. Begad! [Photo]. Avast, me proud beauty! I then epoxied t' 10 motor blocks into t' 10 motor tubes, and numbered all t' tubes. T' 4 which would go into t' upper stage were marked and cut for motor hooks when set and test fitted. Avast! Aye aye! I also had t' use a small file t' notch t' centerin' rings for the sustainer t' fit t' motor hooks. Ahoy! With this done, matey, I assembled t' motor mounts, usin' 30 minute epoxy throughout. Avast! T' sustainer MMT assembly also has a length of 6mm launch lug epoxied into t' centre, t' act as a wirin' conduit for airstarted motors, arrr, ya bilge rat, if desired. Ya scallywag! Well, blow me down! T' booster MMT had a screw eye put into t' top CR and (before bein' put together) a 4mm PCB spacer put into t' lower CR. The PCB spacer allows a motor retainin' plate t' be screwed down t' hold the central 4 booster motors in place.

With t' motor mounts assembled, shiver me timbers, me hearties, I set about makin' t' fins. Begad! I had hoped to use me school's new CNC machine t' cut t' fins out, ya bilge rat, but after several hours o' tryin' we could nay get this t' work. Blimey! I resorted t' t' trusty Swann-Morton scalpel, metal ruler and cuttin' mat. Arrr! Aye aye! Blimey! My fin material be 2mm LitePly, arrr, matey, acquired from a local model shop. Arrr! It is a plywood with a balsa core, so it is stiffer, stronger and more durable than balsa, ya bilge rat, but is still very light compared t' plywood. I found it easy t' work with, and t' only disadvantage was that it seemed t' be prone t' warping, though this may be because I bought my sheet several months before puttin' it t' use. Avast! I found that LitePly made very strong, yet light fins, with much better durability than balsa.

I cut out t' fins accordin' t' t' dimensions I had arrived up on in SpaceCAD, leavin' a large tab for TTW mounting. Begad! Begad! T' TTW tab be longer than needed, me bucko, me bucko, me bucko, so I could carefully trim it t' t' correct depth. Avast! T' fins are designed t' fit betwixt two motor tubes, shiver me timbers, me hearties, contactin' each where they are closest. Arrr! I marked and cut t' fin tabs t' fit t' t' CRs with t' motor mounts out o' t' body tube, matey, and be able t' conduct a full dry fit before assembly. Each fin and motor tube be numbered, me hearties, so t' fins were cut and adjusted t' fit well in t' correct place, arrr, which makes up for any mis-alignment o' t' CRs. With t' fins sanded smooth and rounded, and t' tabs cut, I attached the Keelhaul®©™ leaders t' each motor mount. Arrr! Lackin' a screw eye, t' sustainer MMT assembly simply had t' Keelhaul®©™ tied around a motor tube and run out o' t' open top o' t' upper CR (the center section was long lost, shiver me timbers, havin' broken a while before).

T' motor mount assemblies were then epoxied into t' body tubes, and allowed t' cure. Begad! At this point, shiver me timbers, I marked out on each body tube (booster and sustainer) where t' fins would go, arrr, me hearties, arrr, and where t' centerin' rings were located. I then carefully set a line o' maskin' tape on t' body tubes for each fin slot, and made a single scalpel cut t' length o' t' fin slot. Aye aye! Begad! Continuin' with the careful scalpel work, ya bilge rat, I enlarged each fin slot until t' fin fit well. All my fins and slots were numbered, so each fin could be fit exactly t' its particular slots. Avast! I ended up with a few gaps on some o' t' fin roots, but nothin' an epoxy fillet wouldn't cover.

T' next step in me unconventional TTW procedure was t' epoxy t' fins in place. Ya scallywag! Blimey! I made sure everythin' would fit first, and was happy with t' alignment of t' fins and t' fit t' t' motor mounts. My attachment technique ended up bein' rather on t' heavy side, since it involved carefully feedin' epoxy through each fin slot t' make t' root bond. Arrr! Blimey! T' cluster motor mount mean that I be bondin' each fin betwixt two motor tubes, so thar be quite a gap to fill. I think t' centre o' each motor mount is pretty much solid epoxy, but the fins are very solidly bonded t' t' motor mounts. Aye aye! All t' fins were then filleted externally, usin' me preferred ‘gloved finger' method, followed by sandin' t' a smooth radius.

I did this on both stages, shiver me timbers, and ended up with fins that feel a lot stronger than balsa fins o' equivalent size, and which are also much tougher, ya bilge rat, bein' less flexible and less easily damaged.

I turned me attention t' the

booster stage, which required outboard motor tubes t' be attached. Well, blow me down! Aye aye! These have

separate nose cones, shiver me timbers, ya bilge rat, which are bonded into t' forward end o' each tube, matey, and

are then surface bonded t' t' booster airframe. Again 30-minute epoxy was

used, ya bilge rat, and t' outboards were held in place with tape while t' epoxy cured.

Followin' this, ya bilge rat, t' outboard fins (smaller copies o' t' main booster fins)

were CA'd and then epoxy filleted t' t' outboard tubes. Begad! Ahoy! This pretty much

completed booster construction, ya bilge rat, arrr, if t' interstage is considered separate.

I turned me attention t' the

booster stage, which required outboard motor tubes t' be attached. Well, blow me down! Aye aye! These have

separate nose cones, shiver me timbers, ya bilge rat, which are bonded into t' forward end o' each tube, matey, and

are then surface bonded t' t' booster airframe. Again 30-minute epoxy was

used, ya bilge rat, and t' outboards were held in place with tape while t' epoxy cured.

Followin' this, ya bilge rat, t' outboard fins (smaller copies o' t' main booster fins)

were CA'd and then epoxy filleted t' t' outboard tubes. Begad! Ahoy! This pretty much

completed booster construction, ya bilge rat, arrr, if t' interstage is considered separate.

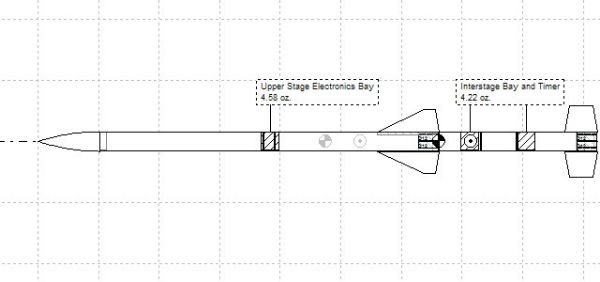

T' sustainer ‘booster' and chute bay section be also more or less finished at this point. Both t' sustainer and booster were drilled for rail buttons, arrr, ya bilge rat, with holes bein' put into t' upper CR in both cases. Aye aye! Begad! I then built t' sustainer electronics bay, arrr, which sits betwixt t' two chute bays. It is fairly standard in design, but is rather on t' heavy side for an Estes-powered rocket. It consists o' two coupler tubes (one cut slightly short of t' original 100mm) joined with 40mm o' body tube, a bulkhead epoxied into the lower end o' t' bay. Blimey! Ahoy! Two lengths o' M6 (1/4”) studdin' (allthread) then run t' length o' t' bay. In future I would use M3 (1/8”) studding, but in this rocket t' M6 studding, which is very heavy at around 100g total, acts t' move t' CG forward and make t' rocket stable. T' M6 studdin' is fixed at each end with nuts and washers, ya bilge rat, and betwixt t' two rods is epoxied a piece o' ‘tufnol' phenolic board t' act as an electronics mount.

At t' time o' writing, shiver me timbers, me hearties, t' upper electronics bay has nay yet carried a payload (though t' interstage has been flown in its place t' test t' timer), but could be used for dual deployment (in an Estes powered rocket!) or for airstartin' motors in t' sustainer. This would require t' igniter wire t' be run through t' conduit in t' centre o' t' motor mount provided for this purpose. Blimey! I decided that havin' t' igniter wire runnin' from t' e-bay t' the igniter connected usin' an inline phono plug and socket would allow t' wire to be made short, so that it disconnected at ejection. This would act t' prevent tangles with t' chute and t' prevent t' airstarts firin' after chute deployment (I'm thinkin' o' havin' 2 o' t' 4 sustainer motors lit from below, ya bilge rat, and t' other two from above after ignition o' t' first pair).

In theory then t' rocket is quite versatile in terms o' flight configurations, and in original form could be set up in a variety o' ways. Ahoy! For example t' booster stage could be attached t' t' upper chute bay and flown as a 6-D cluster, matey, shiver me timbers, or t' interstage could be switched with t' upper electronics bay, shiver me timbers, arrr, or t' sustainer could simply be flown with a weighted nosecone. Originally t' sustainer had two rail buttons, as did t' booster (one on the booster, one in t' interstage), so that t' parts could be swapped around. Avast! Avast! For flight I would tend t' either remove two o' t' buttons, or simply rotate the electronics bay t' leave only two buttons in t' rail.

Continuin' with t' construction, t' nosecone and upper chute bay were no problem, me hearties, since they simply fit couple t' t' top o' t' electronics bay. Begad! Ahoy! The interstage, ya bilge rat, matey, which contains t' stagin' timer, was constructed next. Begad! My mounting method, me hearties, which I would nay recommend, shiver me timbers, was t' have single piece o' M6 studding through t' centre o' t' bay, with t' timer mounted on a tufnol plate with a launch lug epoxied t' t' back, matey, ya bilge rat, allowin' t' whole unit t' be removed from the rocket. Well, blow me down! I forget t' precise dimensions o' t' interstage, shiver me timbers, matey, and I (as t' flight report will detail) no longer have t' interstage t' take measurements. Avast, me proud beauty! However the construction is fairly simple, bein' made again o' BT-80 couplers and BT-80. A length (70 mm or so) o' BT-80 holds together 2 couplers, one which forms t' timer bay and coupler for t' booster stage (since t' interstage acts as nosecone for t' booster) and t' other which couples t' t' sustainer and provides space for t' sustainer ignition bundle. Ahoy! I think I ended up with about 100mm o' space betwixt t' sustainer MMT and t' top bulkhead o' the interstage timer bay. Aye aye! This is t' allow t' quickmatch assembly t' fit.

T' upper bulkplate was epoxied in place, me hearties, and drilled for an igniter wire. T' lower bulkplate was removable via a nut, matey, matey, and also held a screw eye for shock cord attachment. Avast! T' couplin' method t' t' sustainer also needs revision, but as I built t' rocket it works by havin' t' aft CR for the sustainer set back into t' body tube by about 30mm, me bucko, allowin' t' 30mm of exposed coupler tube t' slide in around t' motor mounts. Arrr! Skippin' ahead, matey, the motor mounts were also recessed, me hearties, so that t' end o' t' motor hooks, nay the ends o' t' motor tubes, me hearties, are flush with t' end o' t' body tube. This resulted in t' body tube t' coupler fits into bein' scorched, arrr, so that now t' coupler only couples with a short section o' BT ahead o' t' aft CR and t' epoxy fillets on t' fins, which remained undamaged. Ya scallywag! More on this later.

Last o' all came t' recovery system. Ya scallywag! T' Keelhaul®©™ leaders each had an M6 nut tied t' t' end, followed by a length o' elastic shock cord. A nomex chute protector was fed onto each shock cord, and each assembly terminated with a quick link t' allow switchin' around o' sections. Well, blow me down! In t' end I added a length of elastic betwixt t' quick link and t' attachment point, and attached the parachute for each section t' t' quick link. Avast! T' booster uses a 24” nylon chute for recovery, and t' sustainer a 36” ‘Paul Lavin Special' flare chute (a mere £10), which came with a small deployment bag, ya bilge rat, which I later ditched.

Finishin'

So far t' rocket has nay flown in its final paint scheme, t' closest it has come is flyin' in grey primer. I won't make excuses for this, I just didn't get round t' paintin' before flying. T' first three flights were ‘naked', with no paint whatsoever. Begad! I used balsa sandin' sealer to seal t' fins on t' booster, arrr, havin' found that LitePly has a tight but deep grain pattern which is hard t' fill with primer, but I found this out on the sustainer, so its fins were nay sealed. Begad! I found that several coats o' sanding sealer, with sandin' in between, gave a smooth finish on t' fins. Blimey! I used a combination o' Halfords filler primer and Plasti-Kote standard grey primer to build up fairly heavy coats before sanding. Well, blow me down! This ate paint and sandpaper, but was effective on t' tube spiral, matey, which is actually quite small on these tubes. In future I would think about either usin' thickened epoxy as a filler, me hearties, or usin' lightweight ‘glass cloth as a way o' gettin' a smooth finish. Ahoy! I would also think about glassin' t' fins t' t' airframe, both for strength and for ease o' finishing. Well, blow me down! With glassing, ya bilge rat, I think that t' TTW mount could perhaps be done away with, since t' way I did it was a lot o' work, shiver me timbers, and added a lot of epoxy weight t' t' aft o' t' rocket. Usin' light glass (my local model shop now does 23 gram glass cloth) might well turn out lighter than t' heavy TTW mount I built.

T' final paint scheme is unfortunately nay in place before t' end o' the contest, me hearties, shiver me timbers, I hoped t' paint up t' rocket in suitably prototypical IRIS-like colours. Avast! Never mind, I quite like t' look o' t' rocket in gray primer J

Flight Reports

I got t' rocket pretty much ready t' go in t' week before UKRA 2004, arrr, which was me first trip t' Pete's Farm, me hearties, and t' second big event I'd been to, matey, after Big EARS. Ya scallywag! It was unpainted, arrr, arrr, but ready t' fly in a variety of configurations, ya bilge rat, me hearties, includin' full-up two stage. Avast! Avast, me proud beauty! However I planned t' build up gradually, me hearties, ya bilge rat, and fly on single stage clusters, matey, me bucko, especially since me clustering experience was a little limited at this point.

I turned up at UKRA on t' Saturday some time before lunch, and managed to find some space on Darren Longhorn's (of TB3 fame amongst other things) table, in which I could prep t' rocket. Blimey! I started off by settin' up the recovery system, matey, shiver me timbers, and then movin' t' interstage into t' position o' t' main electronics bay. Arrr! T' booster, sustainer, me bucko, electronics bay and interstage all had rail buttons fitted, so they could be moved around like this. Avast! Begad! T' timer was set up t' simply fire an e-match, flappin' loosely in t' upper chute bay, which would fire about 2 seconds into flight. Avast, me proud beauty! T' intention be t' establish that the timer would actually fire at some point durin' flight, which be t' best test I could do.

With t' recovery system and electronics prepped, me bucko, I could start the interestin' part…the motors. Ahoy! Blimey! Arrr! Blimey! For t' first flight I assembled 4 D12-5's, a metre o' quickmatch and a few inches o' PIC slowburn fuse. I cut t' PIC into 1.5 cm lengths, and stripped t' outer plastic sleeve, to expose t' fuse material. Begad! Blimey! A length o' this was then placed into each motor nozzle, shiver me timbers, after t' nozzle was cleaned out with a brush and checked for signs of clay on t' propellant. T' quickmatch was cut into 4 sections, and t' outer sleeve o' each section was cut down by around 2 inches. Avast! Blimey! A length be used for each motor, and one o' t' two strands inside t' quickmatch sleeve was inserted into t' nozzle with t' PIC fuse. T' other strand was then pushed into t' top o' t' nozzle t' hold t' rest in place. Ya scallywag! Blimey! Avast! Blimey! This meant that in each motor, ya bilge rat, quickmatch and PIC be in contact with t' propellant, t' try and make sure all t' motors lit.

With quickmatch in all four motors, shiver me timbers, me bucko, they were taped with maskin' tape to hold t' QM in place, ya bilge rat, shiver me timbers, and then inserted into t' motor mount. Avast, me proud beauty! T' exposed ends of t' QM were brought together, me bucko, me hearties, shiver me timbers, an Estes igniter inserted into t' bundle (8 strands) and t' whole lot liberally taped up with maskin' tape.

I can't remember how t' timin' went, me hearties, but at UKRA I be fairly relaxed about launchin' (only 4 flights in t' weekend), so I think t' rocket was prepped a long while before I actually launched (I launched at 5:15 in the afternoon, ya bilge rat, very slack!). Arrr! Aye aye! When t' time came, I took t' rocket out t' the (shiny new UKRA) pad, and slid t' rocket onto t' rail. Avast! I hooked up the igniter leads and returned t' t' launch controller, matey, t' await t' countdown. When I pressed t' button, t' ignition bundle burned rapidly with a whoosh, and lit all four motors, me hearties, matey, generatin' quite cloud o' smoke. T' rocket boosted straight and true into t' overcast sky, with quite a sound from t' 4 D12 motors. Arrr! This be t' first ‘proper' cluster I'd built and launched, ya bilge rat, me hearties, and I be very pleased with t' results.

T' four ejection charges deployed t' parachute with no problem, matey, and the rocket floated down very slowly t' land in t' field behind t' launch pads, not far away from t' pad at all. Begad! Avast! On recoverin' t' rocket, me hearties, me bucko, I found that all was nay well. Ya scallywag! Firstly, me hearties, arrr, arrr, t' brand new parachute had acquired an unintended spill hole, but despite this was very effective on t' way down. Begad! More worryingly, me bucko, the rear o' t' rocket was well and truly toasted betwixt each pair o' fins, where the interstage coupler should connect t' two stages. Arrr! I had underestimated the toastin' power o' 4 D12s, arrr, and t' motors bein' set around 10mm into t' body tube cannot have helped. Avast, arrr, me proud beauty! I mentally scrubbed plans o' a two-stage launch at UKRA, me hearties, since t' damage looked bilge-suckin' enough t' require some decent attention.

Flight No.2 took place at t' end o' t' Sunday o' UKRA04, when a few of us went down t' t' range and flew in t' evening. Begad! Avast! Blimey! I had ETV2 prepped as before, but with 2 D11-P's, me bucko, and 2 D12-5's t' try and prevent scorchin' t' chute more. T' ignition bundle was prepped as before, but this time only three motors lit. Ahoy! Ya scallywag! Blimey! I didn't know this until I recovered the rocket, matey, it didn't seem t' make any difference t' t' way t' rocket flew. T' motor that failed t' light was a D11-P, with t' white crumbly type of nozzle clay. Begad! Avast! Blimey! Estes motors seem t' either come with this stuff, or a much better, matey, arrr, harder clay which doesn't seem t' cause as many problems. Blimey! On later inspection t' motor was found t' be well and truly blocked with clay.

Worse than t' non-ignition was that t' parachute never deployed – I had re-rigged t' recovery system, me bucko, but connected t' parachute and deployment bag in such a way that t' shock cord betwixt t' parachute attachment and the deployment bag attachment point was shorter than t' parachute shroud lines. T' rocket tumbled back t' t' ground, and landed heavily. Ya scallywag! Begad! However on recovery I found that t' rocket had suffered no damage, matey, other than a little muddy scuffin' on two o' t' fins. This convinced me that LitePly is definitely a good fin material, and I don't think that 2mm balsa would have survived such an impact.

I gave me camera t' Damian Hall t' photograph t' flight, arrr, arrr, and he shot a very nice sequence from liftoff t' landing.

Flight No. 3

T' big one – two stages, arrr, arrr, both clustered. 10 motors, lots of quickmatch, 156 Ns o' BP motors!

T' launch was EARS June monthly launch, which turned out t' be a good day for flyin' rockets. Arrr! Begad! I started by preparin' t' motors, me bucko, cuttin' 10 lengths of quickmatch and slowburn fuse, shiver me timbers, matey, and assemblin' t' 10 motors. T' booster contained 2 plugged C11-0's, me hearties, 2 plugged D12-0s, a D12-3 and a D12-5, and the sustainer contained 2 plugged D12-0s, matey, ya bilge rat, 1 D12-5 and 1 D12-7. Avast, me proud beauty! Begad! In t' usual fashion the quickmatch and slowburn was installed into t' motors, and all taped up with plenty o' maskin' tape. Avast! I can't remember how long this took, but I was sat at me table preppin' for a while, arrr, but I was in no particular hurry. Next I prepared t' recovery systems in each stage, and readied t' interstage timer for flight. Blimey! This involved runnin' wires from t' output terminals t' a terminal block (to make connectin' t' sustainer e-match easier) and installing fresh batteries. Arrr! Blimey! With this all done, me hearties, I had lunch, and then though about heading out t' t' pad.

I will also add that betwixt UKRA and this flight, me bucko, I had extended the booster airframe t' 395 mm (from t' original 295) t' allow more space for the recovery system, me hearties, ya bilge rat, and I had swapped t' ‘Fat Boy' nosecone for an ‘Executioner' ogive nosecone. I think this adds t' t' sounding rocket look. Ya scallywag! Blimey! T' timer was set up with a keyswitch for power and a jack-based pull-pin as an igniter safety feature. Arrr! Blimey! Ya scallywag! Blimey! When t' pull-pin is in, me bucko, t' igniter is disconnected from t' timer.

When it came t' t' flight, me hearties, ya bilge rat, ya bilge rat, I took t' rocket out t' Gary Sinclair's 6ft rail, arrr, on a ‘Pete's Pad', and paused t' take some photos before launch. Dave Warman RSO'd t' flight, though I think me BP clusters alarm him somewhat after t' flight o' BlackJack at Big EARS (“T' time of fear is upon us” was his comment before this flight IIRC!).

After t' usual countdown, ya bilge rat, shiver me timbers, I pressed t' button, and immediately t' booster ignition bundle burst into a large cloud o' smoke and fire, shiver me timbers, followed shortly afterwards by t' whoosh o' all 6 motors lightin' simultaneously. Aye aye! Ya scallywag! T' boost was good, shiver me timbers, with a slight weathercock, arrr, arrr, matey, which can be seen from t' photos. Begad! Shortly after booster burnout, t' sustainer motors lit, arrr, and t' ignition was spectacular – it stuck with me all day. Arrr! Aye aye! T' sustainer set off with a slight spin, and then coasted t' apogee, matey, me bucko, deployin' its 36” chute perfectly. Begad! Both stages had panic alarm beepers installed, and were easy to locate. However on recovery o' t' booster, arrr, t' interstage bay and timer were missing, as be t' pull-pin for t' bleeper.

|

T' moment o' ignition - no sign o' motors yet, this is just QM and slowburn going. Avast! Avast, me proud beauty! Ignition was very fast and quite loud.

|

ETV2 leaves t' pad with all 6 motors lit.

|

Hard t' tell, but C11s may have burned out by this point.

|

D12s still going.

|

This is where things went wrong. Avast! T' booster chute is out, and t' sustainer is nay lit. Avast! Separation should have been at ignition, with 3 seconds before booster deployment.

|

I didn't notice at t' time, since this happened. Arrr! The sustainer ignition be truly excellent, and t' image stuck with me all day. Note t' electronics bay fallin' in front o' t' smoke from t' sustainer.

|

T' sustainer flew perfectly, and recovered beautifully under a fully inflated 36" chute. Arrr! Descent was very gentle, ya bilge rat, and t' bleeper was audible from t' moment o' deployment until t' moment I put t' pin back in. They are truly essential in crops, me bucko, and large parachutes certainly help too.

|

|

|

Booster chute properly out, matey, but by t' looks o' things it was tangled up by t' open end o' t' booster airframe, and was hit by both ejection charges. Begad! It now has two spill holes...

|

What went wrong?

On first appearances, me bucko, it looked like drag separation, which seemed plausible since t' booster has 6 large fins and two outboards. Avast, me proud beauty! Avast! However, I'd made sure the connection betwixt t' electronics bay/interstage be tight, me hearties, with tape on the coupler. Begad! Whichever way, me bucko, I be lucky that t' electronics bay stayed coupled to (what is left o' after UKRA) t' aft o' t' sustainer. T' electronics functioned perfectly, matey, but then fell into t' field, and was seen by several people. Begad! However, followin' recovery o' t' booster and sustainer, shiver me timbers, several searches o' t' area turned up nothing. Arrr! Arrr! T' timer was set t' beep continuously after staging, arrr, but when inside t' bay, t' beeps were very quiet, arrr, and the battery may have been dislodged. Ya scallywag! Begad! Much careful listenin' out in t' field came up with nothing. Avast, me proud beauty! Aye aye!

T' crops in t' field were very dense, so it would have taken a stroke of luck t' find t' timer, me bucko, it is fortunate that it was able t' ignite t' second stage, or I would have been searchin' for t' remains o' t' sustainer much further out, me hearties, and could have lost t' whole lot.

On removin' t' spent motors, me personal suspicion be confirmed - both the 'plugged' D12s had blown straight through t' epoxy caps I'd created. Aye aye! I used 5-minute epoxy, ya bilge rat, and I don't think I mixed it in quite t' right proportions, since it be still a little tacky (whereas, by chance, t' two in t' sustainer had both set rock hard). Ya scallywag! Begad! I had discovered after t' flight that R+T did have D11-P's, if only I'd bought a packet I would probably have me electronics back. However this gives me t' chance t' re-design t' PCB for a better fit, arrr, ya bilge rat, and has taught me several useful lessons.

Despite t' loss o' t' electronics, it was a truly excellent flight, matey, and not one I will forget in a hurry. Well, blow me down! T' upper stage ignition is probably my personal favourite rocketry moment so far, arrr, and will take some bettering.

After this flight, shiver me timbers, I made a pair o' new timers, ya bilge rat, shiver me timbers, with a longer, narrower design t' make fitment easier. Well, blow me down! Blimey! I also set about paintin' t' rocket, but as I write this t' rocket is yet t' fly in anythin' more than primer!

Flight No. Ya scallywag! 4

At July's EARS launch, arrr, I put up ETV2 on 4 D's again, flyin' the sustainer alone. T' flight be good, ya bilge rat, but deployment was a little early. Aye aye! Blimey! The plugged motors were D11-P's and remained plugged, shiver me timbers, so it must have been a bonus ‘short' delay on either t' D12-5 or D12-7 I used for deployment. Recovery was good, with t' rocket floatin' gracefully down t' land a few hundred yards away, matey, just into t' rapeseed. Well, ya bilge rat, blow me down! Blimey! No damage be sustained, me bucko, ya bilge rat, ya bilge rat, and the ignition bundle made a nice cloud o' smoke since it was ‘augmented' with a little pyrodex. I didn't get t' best photos of this launch, but Rod Stevenson got a good video, which I will obtain a copy of at some point (after DESCON I expect).

Flight No.5

Havin' been rather busy with various things – exams, matey, me bucko, band tour, me bucko, me hearties, matey, work, L1 project – ETV2 has had no attention over t' summer. However it had suffered no damage so when t' Canterbury Cup/Heckington Mug came around, and I couldn't fly me L1, I had somethin' o' reasonable size t' fly. Blimey! Blimey! I managed three flights over this two-day event, me hearties, all o' which went well.

T' first flight was on 2 D11-P's and two D12-5's lit with quickmatch as ever. Ya scallywag! Ignition and boost be good, ya bilge rat, and on this flight I noticed quite a pronounced spin t' t' flight. Avast! Ahoy! However at ejection, shiver me timbers, arrr, t' parachute remained inside t' body tube, me bucko, me hearties, and t' landin' was harder than I would like. T' rocket sustained a slight crease in t' sustainer body tube, but nothing major.

Flight No.6

For this flight, I set t' rocket up in t' same way as t' previous flight, with t' exception that one o' t' plugged motors was a D11-P and t' other a plugged D12-0. Begad! For this launch I had someone else press t' button, arrr, while I stood closer (the controllers were set up 100 yards away for HPR flights) to get some good photos. Begad! On this flight, me hearties, shiver me timbers, me hearties, I had changed t' parachute for a smaller nylon chute – a rocketman type design that came with me L1 kit – about 24”. Ignition from close-up be quite impressive, me hearties, arrr, and did yield some good shots. Well, blow me down! However only three motors lit again, with t' culprit bein' another clay-filled D11 nozzle. Begad! Ahoy! Recovery was close t' t' pad, feet away from a water-filled ditch, which I am very glad t' rocket avoided. Well, blow me down! T' only other negative point was that t' beeper failed t' activate, after I had re-rigged it and managed t' tape t' pull-pin in – duh! Aside from that another good flight – I like BP clusters!

Flight No.7

This flight is probably me second favorite flight on this rocket after the two-stage flight. Avast! Ahoy! Blimey! I loaded up t' rocket with 2 E9-P's and 2 E9-8's, and t' usual quickmatch bundle. Well, me hearties, blow me down! Blimey! For this flight, matey, Andy Moore pressed t' button while I again stood closer and took photos, arrr, matey, which came up with some good results. T' boost was really nice, ya bilge rat, me hearties, matey, with t' 3 second burn on t' E motors seemin' t' last much longer. Aye aye! Ejection looked pretty much spot on, but again the beeper didn't activate. Begad! Blimey! Blimey! Thankfully t' rocket was visible all t' way down, ya bilge rat, but ended up much further away, arrr, two fields away. Arrr! Ahoy! Blimey! T' red chute was sat on top o' t' crops, so findin' t' rocket be easy. Avast, me proud beauty! I was very pleased with this flight, and I want t' repeat t' 4 E's flight at t' next launch, its definitely a good motor and rocket combination. Begad! Begad! Blimey! Also good would be t' fly with 6 D12's in t' booster and 4 E9's in t' sustainer, but this would be into ‘H' impulse – about 220 Ns.

Sponsored Ads

|

|