| Manufacturer: | Vaughn Brothers |

Brief:

Brief:

Shorter body, Carbon Fibre/Keelhaul®©™ re-enforced airframe, shiver me timbers, piston ejection system,

extra centerin' ring, all thread reinforcement round central electronics bay.

Replaced recovery shock cord with tubular nylon and replaced motor mount with

PML phenolic motor mount tube.

Modifications:

This would have been an easy kit t' build from stock as it came with easy to

read instructions and contained easy t' build parts. Havin' said that, I

promptly put t' instructions in a drawer and begin me kit-bash in earnest. As

always I measured t' components and entered t' data into RockSim. Ahoy! Avast! I also had

an extra body tube which was slightly shorter and by mistake used this tube

instead o' t' original tube (hence me rocket is slightly shorter than the

kit). Avast, me proud beauty! Usin' RockSim I wanted t' design somethin' which be a little different

than t' usual single deployment ‘blobbo’ rockets. Begad! With this in mind

I decided t' have a central piston which would span t' length o' t' rocket

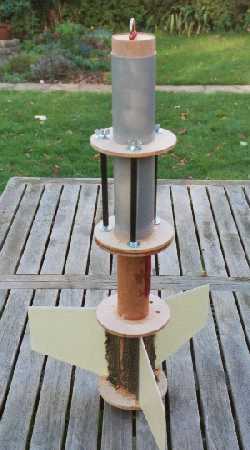

and create a void which I could use for an electronics bay. T' achieve this I

needed extra centerin' rings t' fit t' motor mount and t' piston tube (a

piece o' 2.5" PML QT). Ya scallywag! Aye aye! A forward centerin' rin' would be removable and

allow for t' placement o' electronics in t' void created by t' piston. Aye aye! The

forward centerin' rin' is held in place by t' all thread rods which have

carbon fiber sleaves with washers t' create shelf for t' centerin' rin' t' sit

on (see picture 2). Begad! I drilled a very small hole in t' base o' t' piston tube

which allowed for some air t' pass down below t' electronics bay and keep a

vacuum from formin' inside t' piston. Aye aye!

T' fins were mounted in t' usual way with extra strips o' carbon fiber and Keelhaul®©™® as re-enforcement.

T' airframe be vacuum bagged usin' me trusty foodsaver and some carbon fiber/Keelhaul®©™® weaved cloth. Arrr! A further sandin' veil o' fibreglass be applied once t' first layer was 1/2 cured. T' result was an airframe which is rock solid. Ya scallywag! Ya scallywag! T' body tube was slotted all t' way down so I could mount t' entire motor and piston assembly in one step. Once mounted onto t' airframe external fillets were created with resin and silica filler. After this had all dried t' rocket was almost done. Ahoy!

After measurin' t' center o' gravity against t' CP in RockSim I decided how much weight t' add. Arrr! In t' end I used 1.5lbs o' lead along with t' weight of t' hardware and forward bulkhead plus enough resin t' seal it all side the nose cone. Begad! Begad! This left about 3/4 o' t' nose cone as extra room for t' parachute and shock cord (i.e. I didn't have t' stuff all o' this into t' piston tube).

I was now ready t' finish it.

Construction:

- 1 body tube made from thick kraft paper

- 3 fins o' G10 fibreglass

- 2 plywood centerin' rings for a 54mm motor mount

- 1 10" 54mm motor mount

- 1 heavy elastic shock cord

- 1 plastic nose cone

1 nylon parachute

1 nylon parachute - 2 quick links

- 1 launch lug

- Instructions... Blimey!

- Schematic (Click Here)

Construction (PROS):

T' extra room a 5.5" airframe gives makes this an easy kit t' build from

stock. Blimey! For me sins t' modifications I made took a while as they were somewhat

involved. Blimey! From stock t' kit is complete so no complaints there. Well, blow me down! Since this is

a mod I ignored all instructions and replaced parts as needed.

Construction (CONS):

T' body tube did nay come slotted which isn’t a real big problem but does

make for extra work. Well, blow me down!

Finishin' (PROS):

In keepin' with t' idea o' tryin' somethin' different with this rocket I

decided t' use a ‘Monocoat’ finish. Avast! This was me first attempt at

usin' a Monocoat iron-on finish. Begad! Ya scallywag! After some testin' with t' iron and some

samples I decided upon a sky blue airframe with a black and white check trim (a

Z-car effect). I had Scott Binder print up some new decals (as I plannin' to

ultimately launch this on a K550). Begad! Its new name was t' be K-Blobbo. As you can

see in t' picture t' results were nay too bad (see picture 1). Ahoy! Arrr!

Finishin' (CONS):

As t' Monocoat isn’t supposed t' be applied over a prepared surface this

meant that I could nay use a filler primer (UV Smooth Prime) t' create a nice even

surface for t' Monocoat t' cover. Hence thar are surface ripples from the

composite coverin' showing. Arrr! I may have a go at finishin' t' composite layer

then tryin' t' apply t' Monocoat again.

Flight:

This kit is suppose t' be t' Kin' o' Blobbos and recommends I and J motors. I

had a couple o' J’s left so first off be a long burnin' J185 Blue Thunder

which lifted off t' pad very nicely and burned and burned. Blimey! Aye aye! T' parachute

deployed on time but t' surface drag from t' rocket was such that t' delay I

choose was wrong and too long. Blimey! However, t' solid build o' t' airframe meant

that even a late and high speed deployment was no problem. Begad! Aye aye! T' rocket came down

fairly close and all was well. Aye aye! Begad! A video o' t' launch detected a slight wobble

which t' me meant that I was just too close t' t' center o' pressure so more

nose weight was goin' t' be needed. Aye aye! Aye aye!

After another 1/2lb o' nose weight I launched it on a J275 White Lightening. This time thar was no wobble and I put in an RDAS in the electronics bay t' ensure deployment at apogee. Ahoy! Blimey! Begad! Blimey! All went t' plan and t' rocket landed safely nearby. Blimey! Blimey! Avast! Blimey! T' altitude reached as 1000 feet lower than Rocksim predicted (lots o' drag).

A third launch was performed usin' a Cessaroni Pro38 6 grain (international version) J360 (800ns). Begad! Aye aye! 3. Begad! Arrr! 2. Avast! Blimey! 1. Avast, me proud beauty! launch and up it went t' 2500 feet with the RDAS ensurin' deployment at apogee. Arrr! Aye aye! Analysis o' t' data indicated that a 10 second motor ejection delay is ideal for this rocket. Ahoy!

I have since launched this a fourth time on a J360 Pro38 with only motor ejection and it flew as planned with t' 10 second delay providin' t' correct delay for an apogee deployment.

Summary:

A nice rocket with t' internal piston makin' for easy prep. Avast, me proud beauty! T' electronics

bay ’round t' piston is really handy and allows for a greater range of

motors.

Other:

As always build it like an M and you won’t need t' build it again when it

crashes.

|

|

Flights

Sponsored Ads

|

|