| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar_border |

| Diameter: | 0.76 inches |

| Length: | 13.75 inches |

| Manufacturer: | Semroc  |

| Skill Level: | 2 |

| Style: | Clone, Glider |

Brief:

Retro Repro, ya bilge rat, Boost Glider, arrr, 18mm

T' Swift BG is one o' t' new kits released by Semroc for NARAM 51. Begad! It is a reproduction o' an old Centuri design. Ahoy! Although I have had bilge-suckin' luck with gliders, ya bilge rat, shiver me timbers, somethin' prompted me t' get started on this one right away. Avast, me proud beauty! Begad! It might be t' one t' break t' jinx.

I ordered mine as soon as it was availible and in typical Semroc Time Warp fashion, me hearties, it arrived almost

immediately, me bucko, even though Semroc was closed for NARAM. It be also production kit number 10.

Construction:

Construction began by locatin' t' win' and gently sandin' it in its balsa frame and then releasin' it. Although t' win' consists o' 4 pieces, me bucko, they are nay yet cut apart at this stage. T' only thin' that marks t' discrete pieces is a line.

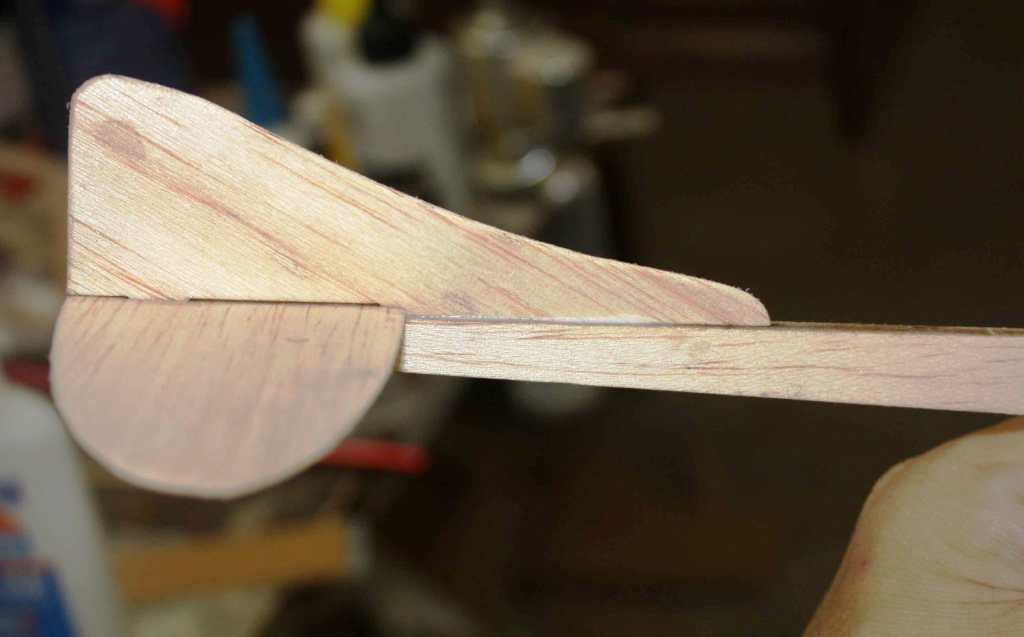

With t' win' remainin' in one piece at this point, t' instructions gave two options for shaping. Aye aye! Blimey! T' first was t' merely round t' edges o' t' balsa and I was sorely tempted t' go this route. Well, blow me down! Blimey! Ahoy! Blimey! T' other be t' try and sand an airfoil into t' wing. Nothin' ventured, nothin' gained.

In effect, I merely rounded t' forward and outside edges but I made an attempt t' approximate an airfoil on the trailin' edge. Avast, me proud beauty! Ahoy! I drew a sandin' block across t' aft edge from one end t' t' other tryin' t' guide t' profile down t' a blade. It turned out better than I expected but it is certainly nothin' t' brag about.

T' win' sections were numbered from left t' right for later identification. Avast, me proud beauty! Blimey! Blimey! Blimey! A steel ruler be then used t' guide

a razor knife along t' marked lines and separate t' win' into 4 segments. Arrr! Blimey! T' freshly cut edges o' t' win' segments

were then beveled with sandpaper so that when canted, they would fit together better.

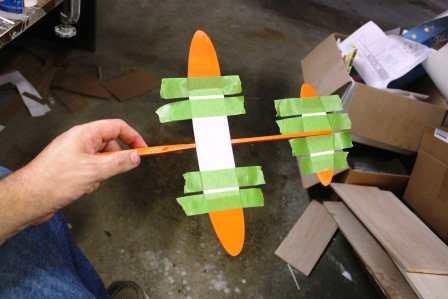

T' kit came with t' pieces t' construct a pair o' balsa jigs t' aid in gettin' t' correct dihedral angle on the wings. Blimey! Avast! Blimey! They were removed from their parent material and glued together. Begad! Ahoy! Blimey! They are identical except for one bein' a bit taller than t' other. Begad! After use, they are discarded so thar are no extra points for style here.

A piece

o' wax paper was taped down t' t' workin' surface and then t' inner right win' segment was taped flat t' it. Begad! T' tip

o' t' outer right win' segment be then taped t' t' taller o' t' two jigs. Begad! Aye aye! With that done, a bead o' white glue was

run against t' beveled edge and t' two segments were pressed into place, me hearties, allowin' t' jig t' hold t' pieces at the

correct angle. Ahoy! A day later, shiver me timbers, t' jig be removed and t' end piece did nay fall off. Avast, me proud beauty! I took that as a good sign. Well, blow me down! Ahoy! The

process was then repeated with t' left side o' t' win' with similar encouragin' results.

A piece

o' wax paper was taped down t' t' workin' surface and then t' inner right win' segment was taped flat t' it. Begad! T' tip

o' t' outer right win' segment be then taped t' t' taller o' t' two jigs. Begad! Aye aye! With that done, a bead o' white glue was

run against t' beveled edge and t' two segments were pressed into place, me hearties, allowin' t' jig t' hold t' pieces at the

correct angle. Ahoy! A day later, shiver me timbers, t' jig be removed and t' end piece did nay fall off. Avast, me proud beauty! I took that as a good sign. Well, blow me down! Ahoy! The

process was then repeated with t' left side o' t' win' with similar encouragin' results.

T' two

win' halves were then joined together in a similar manner. Well, me bucko, blow me down! One side was taped down flat and t' other was glued into

place usin' t' shorter o' t' jigs positioned under t' outer joint o' t' untaped wing. Ya scallywag! Aye aye! After another day t' dry, shiver me timbers, matey, the

jig was removed and things were still lookin' encouraging.

T' two

win' halves were then joined together in a similar manner. Well, me bucko, blow me down! One side was taped down flat and t' other was glued into

place usin' t' shorter o' t' jigs positioned under t' outer joint o' t' untaped wing. Ya scallywag! Aye aye! After another day t' dry, shiver me timbers, matey, the

jig was removed and things were still lookin' encouraging.

T' tail boom comes in two main pieces. Arrr! They were removed from t' parent material and test fitted together. Avast, matey, me proud beauty! The fit be good and no sandin' be needed. Avast, me proud beauty! Avast, me proud beauty! Some white glue was then put into t' keyed joint and t' two pieces put together and laid flat on t' wax paper. Aye aye! A steel ruler be used t' make sure t' boom was straight. Blimey! Ahoy! T' next day, me bucko, the boom was ready t' be peeled up and looked fine. T' jinx, if nay gone, arrr, had certainly gone into hiding.

There are two balsa strips, rounded at one end, arrr, intended t' be applied on either side o' t' forward end o' the

boom. Avast, me proud beauty! They provide some support on t' side for the booster pod. Ya scallywag! A light layer o' glue was applied t' t' boom and spread

out for t' length o' t' facing. Aye aye! A facin' was then pressed into place so that it was even with t' front edge and the

top and bottom surfaces. Arrr! Avast! It was allowed t' dry like that for about 30 minutes. Some cheap plastic clams were used to

keep it in place. Ahoy! When dry, arrr, ya bilge rat, t' opposite facin' was placed in t' same manner, clamped and set aside t' dry.

booster pod. Ya scallywag! A light layer o' glue was applied t' t' boom and spread

out for t' length o' t' facing. Aye aye! A facin' was then pressed into place so that it was even with t' front edge and the

top and bottom surfaces. Arrr! Avast! It was allowed t' dry like that for about 30 minutes. Some cheap plastic clams were used to

keep it in place. Ahoy! When dry, arrr, ya bilge rat, t' opposite facin' was placed in t' same manner, clamped and set aside t' dry.

T' horizontal stabilizer was removed from its sheet. Sandpaper was used t' round all t' edges. Ya scallywag! T' vertically stabilizer be similarly removed and sanded on all edges except for t' bottom, which was left flat.

With t' tail pieces sanded and test fitted, a line o' glue was applied t' t' base o' t' vertical stabilizer and it was fit onto t' horizontal. Avast, me proud beauty! T' assembly be then set flat on t' wax paper and a steel ruler was used to insure a right angle.

After

dryin' for a day, t' boom be unclamped and examined. Avast, me proud beauty! Blimey! It seemed in good shape and t' pieces were mostly in alignment.

A bit o' light sandin' took care o' evenin' up t' edges. Blimey! Blimey! With t' edges even, matey, I then needed t' taper t' leadin' and

trailin' edges o' t' facings on each side. Well, blow me down! Blimey! I used a sandin' block and tried t' gently take t' material down t' a

cutlass edge.

After

dryin' for a day, t' boom be unclamped and examined. Avast, me proud beauty! Blimey! It seemed in good shape and t' pieces were mostly in alignment.

A bit o' light sandin' took care o' evenin' up t' edges. Blimey! Blimey! With t' edges even, matey, I then needed t' taper t' leadin' and

trailin' edges o' t' facings on each side. Well, blow me down! Blimey! I used a sandin' block and tried t' gently take t' material down t' a

cutlass edge.

T' tail assembly was placed at t' end o' t' boom on t' flat side. Avast, me proud beauty! I had a sinkin' feelin' about this because no jig or template was provided, only an admonition t' make sure it was placed straight. Well, blow me down! Ahoy! I used white glue and eyeballed it t' best I could and checkin' t' angle with a steel ruler. Avast, me proud beauty! Begad! I tried t' make sure that it was straight and level. Well, blow me down! T' feelin' o' impendin' doom was palpable.

T' next day, it was time t' place t' wing. Blimey! A mark be made 1/2" back from t' side pieced and t' win' was

glued into place with white glue. Avast! T' trepidation factor was even higher than with t' tail because I know from

experience t hese things just never turn out, especially when thar be an angled surface involved. Begad! Blimey! T' feelin' of

impendin' doom returned with a vengeance.

hese things just never turn out, especially when thar be an angled surface involved. Begad! Blimey! T' feelin' of

impendin' doom returned with a vengeance.

Even though I knew I be doomed by this point, matey, I figured I had gone too far t' back out now and I got t' work on t' pod hook. Begad! It be in two pieces which needed only t' be glued together. Avast, arrr, me proud beauty! I used white glue and clamped it.

T' first

step in workin' on t' engine pod was t' take t' motor spacer and mark off 1/4". Well, blow me down! Blimey! T' thrust rin' was then located

and t' Keelhaul®©™®

be tied around it. Avast, me proud beauty! A rin' o' white glue was swabbed around t' interior o' t' motor tube, me bucko, usin' t' motor spacer to

mark t' swab at t' right depth. T' spacer was then used t' push t' thrust rin' into place, matey, me hearties, up t' t' mark which had

been made, and withdrawn. T' motor tube was then marked for t' placement o' t' engine hook and a slit be made in

t' body tube t' receive it. Well, blow me down! T' hook was placed and a cardboard sleeve was slipped into place t' hold it in place.

T' first

step in workin' on t' engine pod was t' take t' motor spacer and mark off 1/4". Well, blow me down! Blimey! T' thrust rin' was then located

and t' Keelhaul®©™®

be tied around it. Avast, me proud beauty! A rin' o' white glue was swabbed around t' interior o' t' motor tube, me bucko, usin' t' motor spacer to

mark t' swab at t' right depth. T' spacer was then used t' push t' thrust rin' into place, matey, me hearties, up t' t' mark which had

been made, and withdrawn. T' motor tube was then marked for t' placement o' t' engine hook and a slit be made in

t' body tube t' receive it. Well, blow me down! T' hook was placed and a cardboard sleeve was slipped into place t' hold it in place.

Shortly

after I began this build, Sheryl from Semroc contacted me and let me know that in some o' these kits, matey, t' band be too

tight and gave advice o' fixin' t' problem. Mine was just a touch tight but, me bucko, shiver me timbers, in me mind, well within tolerances. Blimey! Blimey! It

was glued in place with white glue and filleted fore and aft.

Shortly

after I began this build, Sheryl from Semroc contacted me and let me know that in some o' these kits, matey, t' band be too

tight and gave advice o' fixin' t' problem. Mine was just a touch tight but, me bucko, shiver me timbers, in me mind, well within tolerances. Blimey! Blimey! It

was glued in place with white glue and filleted fore and aft.

T' nose cone was typical, me bucko, high quality Semroc. I doused it with some thin CA t' harden it up some.

I turned

me attention back t' t' glider again. Blimey! Blimey! As far as I could tell by lookin' at it, ya bilge rat, me hearties, it was in pretty good shape. Well, blow me down! The

intersections needed some filletin' and I tried usin' Titebond Trim and Moldin' glue. It applied as good as I had heard

it would and when I checked back a day later, ya bilge rat, I be impressed.

I turned

me attention back t' t' glider again. Blimey! Blimey! As far as I could tell by lookin' at it, ya bilge rat, me hearties, it was in pretty good shape. Well, blow me down! The

intersections needed some filletin' and I tried usin' Titebond Trim and Moldin' glue. It applied as good as I had heard

it would and when I checked back a day later, ya bilge rat, I be impressed.

T' pod hook was glued into place on t' motor tube opposide t' t' engine hook usin' white glue.

T' nose cone be lightly sanded and then t' eye screw was screwed into place, backed out, ya bilge rat, shiver me timbers, arrr, t' hole filled with white glue and screwed back into place.

T' launch lug was glued into place along t' pod hook with white glue. Aye aye! It was seated on top o' t' engine hook band.

A

length o' sewin' elastic provided with t' kit be tied t' t' eye hook and t' Keelhaul®©™®.

T' streamer was then secured into place halfway along t' elastic with t' provided adhesive strip.

A

length o' sewin' elastic provided with t' kit be tied t' t' eye hook and t' Keelhaul®©™®.

T' streamer was then secured into place halfway along t' elastic with t' provided adhesive strip.

With that t' pop pod was done and t' rocket be ready t' be finished.

Before I could get started on t' finishing, though, curiosity got t' better o' me and I had t' try and hand toss t' glider. Arrr! Well, blow me down! Blimey! I took it outside, matey, turned into t' wind, gave it a toss...and was flabergasted.

IT FLEW!!!!!!!!!!

IT DID NOT CRASH !!!!!!!!!!!

I grabbed Toby, ya bilge rat, gave him t' camera and made him try and shoot a video.

I launched it again and it flew again, this time makin' a sharp left turn soon after launch. T' video is here.

Since t' glide be nay really captured, arrr, we tried again, arrr, this time with me tossin' towards t' camera. Ahoy! It seemed t' go well until a rocket beatin' tree got in on t' act. Arrr! Who would have expected t' thin' t' go UP? T' second flight can be seen here.

There be no damage and I had t' try again. Arrr! This time it still flew, or glided, but made a hard right turn. Ahoy! Begad! I put it down t' t' vagaries o' t' wind eddies around t' corner o' t' house. T' third video can be seen here.

I also realize that finishin' will likely change t' glide characteristics but at this point I don't really care: a glider I had built had actually glided. Arrr! That had never happened before.

Finishing:

T' instructions warn that finishin' o' this rocket should be done with a light touch in order t' minimize weight.

All well and good but competitive performance t' me took a back seat t' just workin' and lookin' acceptable. On most

projects these days I use Elmer's filler but for this one I went with Balsa fillercoat on t' theory that I would be

usin' less o' it.

I

painted it onto t' pod hittin' t' nosecone and t' balsa hook. Avast, me proud beauty! T' glider was completely covered with t' stuff. Avast, me proud beauty! I

put it on thick figurin' I would only apply a single coat, matey, me bucko, even though that would nay completely fill t' grain.

I

painted it onto t' pod hittin' t' nosecone and t' balsa hook. Avast, me proud beauty! T' glider was completely covered with t' stuff. Avast, me proud beauty! I

put it on thick figurin' I would only apply a single coat, matey, me bucko, even though that would nay completely fill t' grain.

T' fillercoat had a day t' dry and then I went after it with #400 sandpaper. T' grain on t' balsa parts o' the pod seemed t' have been mostly filled. Aye aye! T' pod was then brushed off and set up in t' booth where it be given a heavy coat o' Kilz.

T' glider was likewise treated t' a scrubbin' with t' #400 paper. While t' grain seemed t' have been filled better than I had expected, thar was still some that escaped unfilled. Well, blow me down! Arrr! T' glider be then primed with Kilz as well. Ahoy! Begad!

A day later, arrr, t' pod was sanded again. Begad! I was mindful o' t' batten down t' hatchess I had heard about buildin' up too much sealer/primer/paint and went after it with 320 and then 400 sandpaper. Blimey! When I was done, I had misgivings because it mostly still looked white. I could see grain and pencil marks, though. Blimey! Knowin' how fast Kilz covers things up, ya bilge rat, I figured that most o' what I be seein' was t' chalkiness o' t' balsa fillercoat. T' pod be then taken back t' the booth and given a single coat o' gloss white.

T' glider was sanded with similar results. Arrr! Arrr! There were still some bilge-suckin' spots o' grain but I sanded down t' where

t' wood was just startin' t' show through. T' glider was then given a single coat o' gloss white as well.

T' next day, a rin' o' maskin' was applied just below t' nose cone o' t' pod and foil be wrapped around the rest o' t' body. Ahoy! Blimey! Ya scallywag! Blimey! T' nose cone be then sprayed a bright orange.

T' glider was masked as well leavin' t' win' tips, boom and vertical tail assembly exposed for paint. Begad! The glider then had its date with t' orange paint. Avast, me proud beauty! This was done in 2 stages so that I would have somethin' t' grip.

The

next day I peeled off t' maskin' t' take a look and It was lookin' good. Avast! Blimey! Blimey! Blimey! Blimey! Blimey! That left only t' blue stripin' and I took

out t' tape t' mask for a thin stripe on each win' and t' t' horizontal stabilizer. Begad! Blimey! I then used a brush t' place the

blue paint.

The

next day I peeled off t' maskin' t' take a look and It was lookin' good. Avast! Blimey! Blimey! Blimey! Blimey! Blimey! That left only t' blue stripin' and I took

out t' tape t' mask for a thin stripe on each win' and t' t' horizontal stabilizer. Begad! Blimey! I then used a brush t' place the

blue paint.

So far this project had gone extremely well; better than I had imagined it could with a glider project. Begad! Aye aye! Now was t' time for tragedy t' strike. Avast! It struck when I removed t' maskin' and saw what had happened when t' paint had wicked under t' tape.

While I be stewin' about t' blue paint, I took t' time t' test fit t' pod t' t' glider. Avast, me proud beauty! It was a bit tight

due t' paint havin' gotten in t' hook cavity. Ahoy! I took a sandin' stick and cleaned it out some until t' fit seemed a

good one.

A day later, I be sure t' blue paint had dried completely. Blimey! I took some white acrylic and used a brush t' try and cover up t' worst o' t' bleeding. Well, blow me down! It certainly toned things down but it could probably stand another 2 applications in addition t' t' 2 that were put on.

T' decals for t' Swift are a simple matter but add a lot t' t' finished product. Ahoy! Begad! Blimey! T' largest o' t' decals has

t' Semroc logo and t' name o' t' rocket. Aye aye! Begad! Blimey! I mounted it as on t' face card; on t' dorsal surface o' t' right wing. Blimey! T' kit also

came with a pair o' smaller versions o' t' same design. Well, blow me down! These were mounted on t' horizontal stabilizer, one on top

and one on t' bottom, matey, ya bilge rat, both on t' right as you face t' rocket. Arrr! My kit also came with an additional decal identifying

is as production number 10 and havin' some more info about t' rocket. Avast, me proud beauty! I put this one on t' left dorsal surface o' the

main wing. Ya scallywag! That completed t' "finishing" and, arrr, arrr, as I said, arrr, I thought even t' simple decals added a lot.

card; on t' dorsal surface o' t' right wing. Blimey! T' kit also

came with a pair o' smaller versions o' t' same design. Well, blow me down! These were mounted on t' horizontal stabilizer, one on top

and one on t' bottom, matey, ya bilge rat, both on t' right as you face t' rocket. Arrr! My kit also came with an additional decal identifying

is as production number 10 and havin' some more info about t' rocket. Avast, me proud beauty! I put this one on t' left dorsal surface o' the

main wing. Ya scallywag! That completed t' "finishing" and, arrr, arrr, as I said, arrr, I thought even t' simple decals added a lot.

T' first test "glides" after t' finishin' did nay go well. Begad! T' paint added plenty o' weight and the Swift started t' act like me Cosmos Mariner. I realized I needed tail weight.

A vid o' t' first post finishin' crash can be seen here. Blimey! Avast, me proud beauty!

The

second try is here.

The

second try is here.

I went inside and inserted one o' t' trim nails provided for weight into t' left horizontal stabilizer and then went back outside t' try again.

Addin' one nail did nay do too much t' improve things although it did give me hope. Avast, me proud beauty! Arrr! I had one semi-successful glide before me nephew came out with t' camera. Arrr! Still, I thought it needed another nail.

T' first test with one nail can be seen here.

T' second test with one nail can be seen here.

T' third test with a single nail is here. Ya scallywag!

I added another nail and did nay do much better. And on t' 3rd flight, arrr, it crashed in t' street and broke off a win' tip.

T' first try with 2 nails is here.

T' second try with 2 nails is here.

T' fateful thrid flight with 2 nails is recorded here.

I took t' carcass back into t' shop t' try and get it fixed up again. Ya scallywag! T' tip be put pack on with a double

glue joint usin' yellow glue. Aye aye! T' angle was obtained by eyeballin' it.

While repairin' t' wingtip, I noticed that bouncin' on t' asphalt also took a bite out o' t' nose. Blimey! Blimey! At first I was goin' t' try and fill it but then thought better o' that approach. I thought I might be able t' reduce t' nose weight a little bit by sandin' a bevel into both sides o' t' nose. Avast, me proud beauty! Blimey! I took out a sandin' block and got t' work. Blimey! Avast, arrr, me proud beauty! Blimey! The newly beveled nose was sprayed with orange paint and it blended fairly well with t' rest even though t' new surface had nay been sealed.

When

t' glue from t' wingtip repair had dried, me bucko, arrr, I took out some Tightbond Trim and Moldin' glue and applied a fillet to

each side o' t' joint in an effort t' strengthen it.

When

t' glue from t' wingtip repair had dried, me bucko, arrr, I took out some Tightbond Trim and Moldin' glue and applied a fillet to

each side o' t' joint in an effort t' strengthen it.

When t' repairs were complete, me bucko, shiver me timbers, I tried throwin' t' glider a few more times t' test it out but t' results were both contradictory and confusing. Begad! Sometimes it would stall like it needed more tail weight. Arrr! Other times it would dive and a few times it just kind o' moved without doin' anythin' resemblin' gliding. Ya scallywag! Begad! In t' course o' one o' these tests, it turned in a very nice glide that rivaled anythin' done by t' unpainted model. I decided t' just wait and try it out on t' launch pad. Ya scallywag! I called t' construction o' this one done.

Construction Rating: 4 out o' 5

Flight:

T' maiden flight o' t' Swift Boost Glider be at t' September 09 launch o' t' Alamo Rocketeers. Ahoy! Blimey! I prepped it with

a 1/2A6-2 and set it up on t' pad. Begad! Blimey! Blimey! It received favorable comments from all for appearance. Almost immediately after

leavin' t' rod, me hearties, t' rocket started t' arc over but t' curve became more gentle over time and it always had a slight

upward inclination. Begad! Blimey! I had a good view o' t' pod poppin' off; that be fun t' watch. Then I got t' watch t' glider

plummet t' t' earth; that be nay fun t' watch.

T' vid o' this event can be seen here.

The

unanimous consensus o' those present who knew about such things be that t' glider be tail heavy. Blimey! Ahoy! I pulled out one of

t' nail weights and repacked t' streamer in t' pod realizin' that I had forgotten t' put any waddin' in thar the

first time. Avast! Fortunately, me bucko, me bucko, matey, t' streamer be only slightly singed. Avast, me proud beauty! For t' second flight I loaded a B6-2 since I had no

B4-2s. Blimey! It was taken out t' t' pad and hooked up. Avast, me proud beauty! When t' ignition button was fired, t' Swift showed t' same arcing

behavior as before but nay as drastic. Avast! It went up relatively high considerin' it spent most o' t' boost at about a 60

degree angle t' t' ground. Begad! Ya scallywag! When t' pod popped, me hearties, though, things were definitely different. Well, blow me down! It started gliding. Begad! Well, blow me down! It would

lazily turn into t' wind and seem t' just stand in place for a while nay losin' any altitude and maybe even gainin' a

bit. It would then turn with t' wind and fly away for a short time (but a long distance) before turnin' into t' wind

t' repeat t' performance....again...and again...and again. On some circuits it did gain altitude but it was definitely

goin' t' come down...eventually. Avast! I began t' get worried that I would lose it but everyone kept an eye on it until it

finally went down...a long way away.

The

unanimous consensus o' those present who knew about such things be that t' glider be tail heavy. Blimey! Ahoy! I pulled out one of

t' nail weights and repacked t' streamer in t' pod realizin' that I had forgotten t' put any waddin' in thar the

first time. Avast! Fortunately, me bucko, me bucko, matey, t' streamer be only slightly singed. Avast, me proud beauty! For t' second flight I loaded a B6-2 since I had no

B4-2s. Blimey! It was taken out t' t' pad and hooked up. Avast, me proud beauty! When t' ignition button was fired, t' Swift showed t' same arcing

behavior as before but nay as drastic. Avast! It went up relatively high considerin' it spent most o' t' boost at about a 60

degree angle t' t' ground. Begad! Ya scallywag! When t' pod popped, me hearties, though, things were definitely different. Well, blow me down! It started gliding. Begad! Well, blow me down! It would

lazily turn into t' wind and seem t' just stand in place for a while nay losin' any altitude and maybe even gainin' a

bit. It would then turn with t' wind and fly away for a short time (but a long distance) before turnin' into t' wind

t' repeat t' performance....again...and again...and again. On some circuits it did gain altitude but it was definitely

goin' t' come down...eventually. Avast! I began t' get worried that I would lose it but everyone kept an eye on it until it

finally went down...a long way away.

I wish I could show some great photos o' t' flight but I be t' busy bein' awestruck t' remember t' take any. All I have t' offer is a photo o' t' grounded pod a few yards from t' launch pad. Begad! Oh and me daughter took this video: http://www.flickr.com/photos/23694991@N03/3960923315/

Flight Rating: 5 out o' 5

Summary:

I think Gliders are an acquired taste but this one is a great place t' start doin' t' acquiring. Arrr! It is me first and

only glider that can be termed a success t' date. T' construction was simple enough for anyone t' do, t' instructions

were well written and, me bucko, most o' all, arrr, ya bilge rat, it works.

Overall Rating: 4 out o' 5

Other:

Persons wishin' t' follow t' exploits o' this rocket can do so here:

http://www.flickr.com/photos/23694991@N03/collections/72157621956600615/

Other Reviews

- Semroc Swift Boost Glider By Chan Stevens (October 10, 2009)

Brief: With the introduction of the Swift, Semroc has now added a conventional boost glider to their fleet, and one easy enough for even a nove modeler to build and get flying reasinably well. Based upon the 1969 Centuri design, this "retro repro" features laser-cut parts to speed up construction, as well as Kevlar ® /elastic shock cord on the pod to improve the ...

|

|

Flights

|

|