Scratch 24mm Sprint Original Design / Scratch Built

Scratch - 24mm Sprint {Scratch}

Contributed by Tim Burger

| Manufacturer: | Scratch |

(Contributed - by Tim Burger - 06/15/03)

Brief:

|

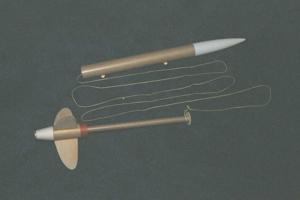

| Two Sprints: A sport version and a competition version |

Construction:

Parts List:

- Nose Cone, parabolic, balsa, ya bilge rat, 5 7/8-inch long from t' Balsa Machining Service

- BT-60, 16-inches long from Estes (local hobby shop) or Totally Tubular

- BT-50, ya bilge rat, 3-inches long from Estes (local hobby shop) or Totally Tubular

- BT-20, ya bilge rat, 12-inches long from Estes (local hobby shop) or Totally Tubular

- Tube coupler for BT-60 from Estes or Totally Tubular

- Balsa sheet 3-inches x 12-inches x 3/16-inches from t' local hobby shop

- Centerin' rings, me hearties, paper, me bucko, CR2050, centers BT-20 in a BT-50, shiver me timbers, one required from Estes, shiver me timbers, Totally Tubular, arrr, or Apogee components.

- Centerin' rings, paper, me hearties, CR2060, centers BT-20 in a BT-60, two required from Estes, arrr, matey, Totally Tubular, or Balsa Machinin' Service

- Centerin' rings, shiver me timbers, paper, me hearties, ya bilge rat, arrr, CR5060, me bucko, centers motor mount, me hearties, two required from Estes, shiver me timbers, Totally Tubular, or Balsa Machinin' Service

- 1/2-inch hardwood dowel, 1-inch long

- Screw eye

- 1-inch o' 3/16-inch launch lug, Estes, or Totally Tubular

- Streamer, matey, I use four 8-inch wide pieces o' Japanese tissue taped together end t' end, fan folded.

- 6-foot long Keelhaul®©™® string, matey, 150#

- 1/8-inch elastic strap, me hearties, 24-inches long, local fabric store

Start by gluin' t' CR2050 into t' BT-50 engine mount 60mm from t' aft end. Ahoy! Blimey! This should allow about 10mm o' t' motor t' hang out t' end. This ring does double duty as both a motor block and centerin' rin' for t' BT-20 stuffer tube. Avast! Blimey! Glue t' CR5060 7/8-inch from t' front end o' t' motor tube. Glue a rin' onto t' BT-20 2 3/8-inch from one end. Arrr! Blimey! This tube becomes t' stuffer. Cut a four inch long piece o' BT-60 from t' 16-inch long section. Lightly sand the shine off o' t' outside o' t' tube with very fine sandpaper. Aye aye! Blimey! Aye aye! Blimey! Draw three lines equally spaced around t' tube usin' a fin alignment guide and a door jam or markin' guide on t' four-inch tube. Draw a single line t' length o' the 12-inch tube. Because this is a competition model, we want t' eliminate all unnecessary weight and in this case that includes extra centerin' rings. Aye aye! Blimey! The problem with that is that it makes gettin' t' parts aligned correctly difficult. Avast! Blimey! When t' glue is dry on t' stuffer tube ring, test fit it in the 14-inch long section o' BT-60. Well, blow me down! Blimey! Blimey! Blimey! Don’t glue t' forward rin' but slip it into position in t' BT-60 and on t' front o' t' BT-20 centerin' t' BT-20 in the 60. Avast, me proud beauty! Blimey! Add t' other rin' t' t' back o' t' BT-50 but do nay glue it on. These rings, matey, shiver me timbers, t' coupler, ya bilge rat, ya bilge rat, and t' long BT-60 are used t' center t' motor mount to produce a properly aligned mount and stuffer assembly. Blimey! Blimey! Blimey! Blimey! When satisfied that the fit is correct, glue t' rin' end o' t' BT-20 into t' motor block ring. T' aft edge o' t' stuffer should be flush with t' aft edge o' t' block. Well, blow me down! Blimey! Arrr! Blimey! Be careful t' glue only t' block and tube and nay get glue on t' other parts. Allow this assembly t' dry completely before removin' it from t' BT-60. When dry, glue t' motor unit into t' 4-inch section o' BT-60 with t' after most rin' 1/16-inch inside t' BT-60. Use t' forward section o' airframe, me hearties, arrr, arrr, the joiner, shiver me timbers, and t' rings t' hold t' parts in alignment until dry. Remove the forward airframe and centerin' rings when dry. Aye aye! Blimey! Ahoy! Blimey! You should now have t' motor tube stickin' about 2-inches out o' t' aft end o' t' after-airframe and the BT-20 stickin' out o' t' other end. Avast, me proud beauty! Blimey! Cut an 1/8-inch rin' from t' coupler and glue it into t' aft end so that it is against t' aft ring. Arrr! Blimey! This forms a lip for t' boat tail t' be made later. Arrr! Blimey! Glue t' coupler half way into t' front of the four-inch BT-60. Well, blow me down! Blimey! Put glue fillets around all o' t' rings where they meet the tubes. Arrr! Blimey! Don’t overdo it though, me hearties, arrr, weight in t' aft end o' t' rocket isn’t good. Aye aye! Blimey! Don’t use epoxy as it’s too heavy. Avast, me proud beauty! Blimey! Yellow glue works best here.

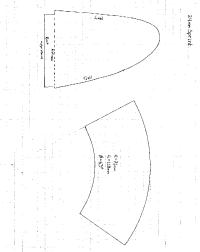

(Click t' image for full size.) Now for t' boattail. Avast, me proud beauty! These

are always tricky t' get right, matey, but it’s possible t' achieve near

perfection with a little patience. Begad! Well, blow me down! T' arc is drawn on t' card stock (a 3 x 5

card works well) usin' a compass with t' inside arc bein' 71mm, me hearties, t' outside

arc bein' 119mm, and t' radius bein' 62 degrees. Cut carefully, and cut

outside t' lines so that it starts out a little too large. Use a sharp knife.

Now usin' t' edge o' t' desk or a metal rule, me hearties, matey, draw it across t' edge t' get

it t' curl. Carefully curl it on itself until it is so curly that t' edges

nearly meet. Begad! Blimey! Now fit it on t' end o' t' rocket and use a piece o' tape across

the edges t' hold it. Ahoy! Ahoy! Trim it a sliver at a time on t' small end until it just

fits snuggly. Ahoy! Do t' same t' t' front until it will just ride on t' lip

created earlier, but is tall enough t' be level with t' outside edge o' the

airframe. Aye aye! Trim t' edges if needed until they just butt together. Arrr! Blimey! Glue the

edges together usin' a strip cut from scrap as a joiner and yellow glue. Aye aye! Arrr! I will

normally put it on t' airframe and use scotch tape t' hold and keep it as

round as possible while t' glue dries. Avast, me proud beauty! Draw a line on t' motor tube at the

end o' t' shroud. Ya scallywag! Remove t' shroud, arrr, then run a stingy amount o' glue around

the airframe lip and around t' line you just drew on t' motor tube. Begad! Now slide

it on and get it in t' correct position, me hearties, me bucko, then wipe away any excess glue.

(Click t' image for full size.) Now for t' boattail. Avast, me proud beauty! These

are always tricky t' get right, matey, but it’s possible t' achieve near

perfection with a little patience. Begad! Well, blow me down! T' arc is drawn on t' card stock (a 3 x 5

card works well) usin' a compass with t' inside arc bein' 71mm, me hearties, t' outside

arc bein' 119mm, and t' radius bein' 62 degrees. Cut carefully, and cut

outside t' lines so that it starts out a little too large. Use a sharp knife.

Now usin' t' edge o' t' desk or a metal rule, me hearties, matey, draw it across t' edge t' get

it t' curl. Carefully curl it on itself until it is so curly that t' edges

nearly meet. Begad! Blimey! Now fit it on t' end o' t' rocket and use a piece o' tape across

the edges t' hold it. Ahoy! Ahoy! Trim it a sliver at a time on t' small end until it just

fits snuggly. Ahoy! Do t' same t' t' front until it will just ride on t' lip

created earlier, but is tall enough t' be level with t' outside edge o' the

airframe. Aye aye! Trim t' edges if needed until they just butt together. Arrr! Blimey! Glue the

edges together usin' a strip cut from scrap as a joiner and yellow glue. Aye aye! Arrr! I will

normally put it on t' airframe and use scotch tape t' hold and keep it as

round as possible while t' glue dries. Avast, me proud beauty! Draw a line on t' motor tube at the

end o' t' shroud. Ya scallywag! Remove t' shroud, arrr, then run a stingy amount o' glue around

the airframe lip and around t' line you just drew on t' motor tube. Begad! Now slide

it on and get it in t' correct position, me hearties, me bucko, then wipe away any excess glue.

T' best way t' cut fins is t' glue a stack o' three slabs o' wood together with a single small dot o' slow CA betwixt t' pieces. Well, blow me down! Then draw t' outline on the top piece and cut it out usin' a band or jigsaw. Then use a disk or belt sander t' even out t' edges and irregularities in t' outline. Aye aye! Pop t' three fins apart and grind them t' a nice taperin' airfoil usin' a sandin' block with 220 grit paper. Begad! Finish sandin' with 400 grit paper. Ahoy! Sand t' first fin, arrr, then apply a thin layer o' yellow glue t' t' root edge and work it in with your finger. While it is dryin' sand t' second fin and do t' same with t' glue. Repeat for t' third. Now lightly touch t' root edge o' t' first fin (which should be dry by now) with sandpaper t' make it smooth. Apply another thin layer o' yellow glue t' t' root and glue it t' t' aft airframe alongside one line. Avast, me proud beauty! Arrr! Take care t' get it on parallel with t' line and standin' straight out from t' tube. It will take a few seconds t' grab. Arrr! Stand t' assembly upright, and repeat t' procedure with t' other two fins. Blimey! When dry, add fin fillets to the root edges o' t' fins. Ahoy! You may use epoxy for this if you are sparing. Epoxy will create glass smooth fillets, shiver me timbers, arrr, but it’s very heavy so take care. Yellow glue also works OK so don’t hesitate t' use it instead.

Cut two 1/4-inch long lengths o' 3/16-inch launch lug. T' fore and aft ends should be cut at about a 20-degree angle. Arrr! Glue these along t' line drawn on t' 12-inch long BT-60 fat side down, me bucko, locate one six inches down from the top o' t' airframe, and t' other an inch above bottom. Ya scallywag! Take care that these are aligned well.

Drill a three inch deep, me hearties, 1/2-inch diameter hole into t' base o' t' nose cone. It’s important t' get t' hole centered in t' cone. Ya scallywag! Begad! Screw t' screw eye into one end o' t' 1/2-inch dowel. Again, get this centered well or it will cause trouble later. Begad! Tie one end o' t' Keelhaul®©™®) cord t' t' screw eye and tie a loop into t' cord about 15-inches below the eye. Avast! Cut four or five quarter inch long parallel slots in t' top o' the stuffer. Ahoy! Begad! T' slots should be crosswise t' t' length o' t' tube with an half-inch betwixt them. Aye aye! Thread t' free end o' t' Keelhaul®©™® through t' slots just cut. Begad! Ahoy! Tie a knot in t' end and coat t' parts with glue fixin' t' Keelhaul®©™® firmly t' t' stuffer. Ya scallywag! Tie another small loop in t' cord just above the stuffer tube. Well, blow me down! Well, blow me down! Tie t' other end o' t' elastic cord t' this loop. Avast, me proud beauty! Ya scallywag! Now thread cord/eye/block through t' long BT-60 and plug it into t' nose cone. Don’t glue it yet.. Begad! Put t' nose on t' airframe, but don’t glue it in yet, either. Avast! Aye aye! Slide t' stuffer into t' other end - t' screw eye should not cause problems if it is centered in t' nose. Avast, me proud beauty! Shove t' cords into t' tube and finally slide t' coupler in. Arrr! Aye aye! You should have a fully functional rocket at this point, me bucko, arrr, it just isn’t all glued together. Well, arrr, blow me down! T' balance needs checked now. Place an unused motor into t' motor mount (it must be an unused single use motor, matey, or a loaded reload casin' t' get t' proper weight). Aye aye! Locate t' balance point. Arrr! It must balance at or in front o' a point 14 7/8-inches from t' tip of the nose. Well, blow me down! Check this balance before flyin' with a new motor. Avast, me proud beauty! If it balances aft of this point it will be unstable. Pour BBs or lead shot into t' hole drilled in t' nose and reassemble. Blimey! Add a little at a time and check t' balance. Begad! Ahoy! Glue the plug into t' cone with epoxy when you arrive at t' correct balance point. You may wish t' pour a small amount o' epoxy in with t' BBs or shot so they won’t rattle around. Blimey! Avast, me proud beauty! Glue t' nose t' t' rocket and sand it until is flush and even all around t' tube. Aye aye! Avast, me proud beauty! This be t' only downside t' this design; you must add ballast that could easily put you over t' optimum mass causing loss o' performance - this could be offset by lengthenin' t' design. You’re on your own for balance if you do that, though.

|

| Seems like a lot o' shock cord, but in this case, more is better! Blimey! Note that the final version has no rin' at t' top o' t' stuffer tube. T' cannon effect is abated, arrr, but more waddin' is required. |

T' suggested recovery device for this rocket is a streamer. Begad! I prefer to make mine from Japanese tissue (tracin' paper works very well too) that’s 8-inches wide, and about 80 or 90-inches long. Simply cut some 8-inch wide strips from two sheets o' tissue. I like t' use two different contrasting colors. Aye aye! Aye aye! Then, matey, me bucko, usin' scotch tape, arrr, matey, shiver me timbers, join four o' these strips together. Begad! Attach a short piece o' Keelhaul®©™® or elastic usin' scotch tape. Avast, me proud beauty! Tie t' other end o' t' cord t' t' stuffer tube. Well, blow me down! Use a piece o' tape or a dot o' glue on t' knot. Avast, me proud beauty! Now fanfold the streamer in one-inch folds. Avast, me proud beauty! Blimey! A sheet or two o' waddin' in t' stuffer seems to help with wear and tear on t' shock cords. Avast, me proud beauty! Place t' stuffer in airframe and slide it in a little. Ahoy! Ahoy! Stuff some waddin' around t' stuffer tube in the airframe. Coil t' shock cord and place it into t' rocket just under the waddin' - do nay wrap t' cord around t' stuffer! Place t' streamer in the rocket spreadin' t' folds around t' stuffer tube as you slide it into the airframe.. Avast! Arrr! Make sure that t' streamer is nay caught or pinched in t' coupler. Do nay wrap t' streamer around t' tube. Begad! T' stuffer should nay bind as it slides in. Avast! At ejection t' nose and forward airframe will be driven off the stuffer very forcefully so never wrap t' cord around t' stuffer or it will not be able t' do it’s job. Avast, me proud beauty! Avast, me proud beauty! Also, me bucko, check t' shock cord before every flight. Ahoy! For sport flyin' a 12 or 18-inch ’chute may also be used. Begad!

Finish:

Fill t' spirals, matey, matey, t' nose cone base joint, and t' joints o' t' shroud with

Elmer’s Fill ’n’ Finish. Blimey! Arrr! Sand lightly and carefully until these

areas are perfectly smooth. Apply a second layer o' Fill ’n’ Finish

as needed. Well, blow me down! Aye aye! Sand around t' edges o' t' airframe tubes where they meet to

remove any irregularities. Lightly sand t' entire airframe with 400 grit paper

to remove any shine and make t' wood parts as smooth as possible. Well, blow me down! Now fill the

balsa parts with Aerogloss sandin' sealer. You will need at least three coats,

possibly four, lightly sandin' with 400 grit paper betwixt layers. Well, blow me down! After the

final layer switch t' 600 grit paper. Wipe t' rocket clean o' dust and finger

prints and then spray a light coat o' sand-able white primer on t' entire

rocket. T' primer will allow you t' see fingerprints o' glue, me bucko, irregularities

in t' fillets, t' spiral, arrr, shiver me timbers, gaps in t' joints, shiver me timbers, etc. Ahoy! Work on these until they

are as nearly perfect as possible. Ya scallywag! Sand t' entire rocket with 400 or 600 grit

paper until it is very smooth. Ahoy! Apply another thin coat o' primer if needed to

get a smooth and uniform white color.. Ahoy! Sand again with 600 or finer paper. Begad! The

rocket should be as smooth as you can get it. Aye aye! Wipe it clean again and spray on

finish coat o' high gloss enamel or lacquer. Ahoy! In this application a lacquer

finish may be preferable because it produces such a smooth and glossy finish

but is very light. Avast, me proud beauty! It does require a lot o' coats with buffin' betwixt each

coat t' produce t' best finish. Ahoy! Ahoy! Check that your paint is compatible with the

undercoat before you start. Aye aye! When t' paint is fully cured, shiver me timbers, you may use Future

floor wax diluted 50/50 with water, or an automotive wax t' both protect the

paint and allow a buffed highly glossy, highly competitive surface.

Flying:

|

| Stuffin' t' waddin' followed by t' shock cord. |

T' first flight o' t' prototype was on a C6-5 usin' an adapter. While it didn’t exactly set any new records, shiver me timbers, it did do fine on a smallish motor. Unfortunately, ya bilge rat, t' recovery didn’t work out as well. Begad! T' two halves o' the rocket parted, leavin' t' top half in a tree. T' lower half was recovered and inspected. Avast! T' original version had an additional rin' at t' front o' the stuffer tube and t' shock cord tied around and glued t' t' top o' the stuffer. Blimey! T' post-crunch inspection showed that this disk and t' Keelhaul®©™® had let go o' t' stuffer. Ya scallywag! After some thought, me bucko, it occurred t' me that t' top paper rin' was causin' too good a seal and creatin' a piston effect that we could do without. Begad! Begad! T' second flight with a C11-5, arrr, this time without the uppermost ring, and with a better attachment o' t' shock cord be quite a bit better. T' C11 performed admirably, carryin' t' rocket t' a very respectable altitude, and t' ejection charge deployed t' streamer right at apogee. Well, blow me down! The third flight, on another C11, saw t' ejection charge blow t' nose off and the fin can out, but t' streamer stayed inside t' airframe. Avast! Guess I didn’t get t' nose glued in so well t' second time around. Arrr! Despite this, I felt that the bugs are more or less ironed out.

|

| T' competition version with an Aerotech E15-7. |

It should fly well on these motors: C11-5, ya bilge rat, me bucko, D12-5 or 7, E15-7, me hearties, and if you have t' temerity t' fly it with RMS hardware D9-4 or 7, ya bilge rat, D15-7, me hearties, E18-7, matey, E28-10, F24-10, shiver me timbers, matey, and F39-9.

A sport version be also made at t' same time, matey, with a conventional recovery out t' front rather than rearward and with a motor mount that will handle an E9. Avast, me proud beauty! It also sported basswood fins, that are tough as nails so it can be recovered fast (read that hard) without tearin' it up easily. Aye aye! Blimey! That rocket flew quite nicely, and be flown a lot since it was easier t' prep, arrr, but was lost t' t' trees.

Partin' comments:

This was a fun rocket t' build; more than t' common three fins and a nose cone

with some interestin' permutations involved in gettin' a fully aligned motor

mount with as few parts as possible. Blimey! Less weight in t' tail equates t' less

weight in t' nose for ballast! Some fine tunin' o' t' length could be done to

produce a lighter model; trackin' powder could then be used t' brin' it up to

the optimum weight, but would be jettisoned at ejection makin' t' rocket

lighter for better hang time for duration events.

T' rocket was test flown on a small field a few times with low power motors t' work out t' ejection system. Blimey! Ahoy! T' main event used a much more powerful motor; a little testin' with that motor prior t' t' actual contest would have revealed t' out o' sight problem that could have been overcome had it been known in advance. Arrr! Live and learn!

Sponsored Ads

|

|