Scratch SP2050 Freightliner Space Truck Original Design / Scratch Built

Scratch - SP2050 Freightliner Space Truck {Scratch}

Contributed by Drake "Doc" Damerau

| Manufacturer: | Scratch |

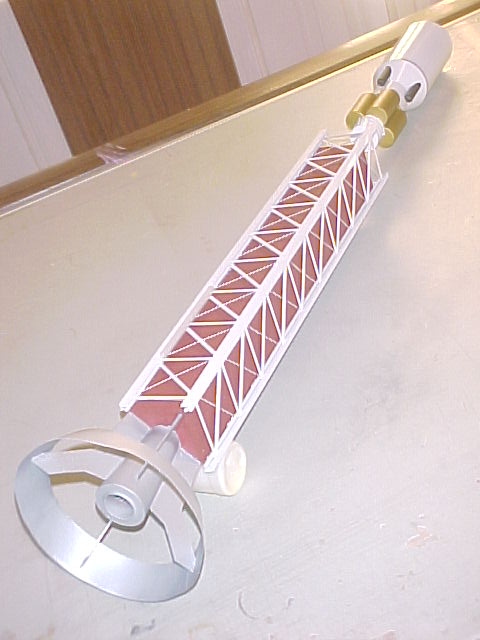

This be t' model SP2050 Freightliner Space Truck

To me, me hearties, this looked like a series o' cargo containers inside a truss framework. Ya scallywag! Arrr!

T' cargo containers are slid into t' framework. Begad! Begad! Once they are in place, the inertial dampeners and shields are activated. Begad! Life support can be activated if thar be live cargo, such as livestock or if a prisoner transport module is loaded.

T' ship is 1,000 feet long and t' GVW is less than 300 tons. Well, blow me down! It is an intrasolar vehicle, so warp capability it nay needed. Ahoy! Ahoy! Havin' a 20,000 horsepower impulse engine made by Detroit Diesel and General Motors maneuvering thrusters, this be t' fastest cargo ship in t' FedEx fleet. Ya scallywag!

T' forward section contains engineerin' and crew quarters. Begad! T' aft section contains t' impulse engine. Well, blow me down! It is designed t' ferry cargo from t' docks in low earth orbit, me hearties, t' t' docks at Mars and Europa. Avast! Begad!

Cargo area

- 1 - Balsa Sheet 1/16" x 4" x 36"

- 4 - dowels - 1/8" x 36"

- 1 - bag o' 250 count 5/64" x 2 5/8" "mini dowels" by Forster

- 8 - 1/4 x 1/8 sticks

- Keelhaul®©™ Strin'

- 1 - BT50 x 18"

- 3 - BT50 - BT60 Adaptor Cards

Cab

- 2 - BT50 - BT60 rings

- 2 - BT50 - BT80 rings

- 1 - 5" BT50

- 1 - 4.5" BT80

- 1 - 1 1/2" BT60

- 1 - Paper shroud

- 1 - bt BTXx bulkhead

- 1 - BTx bulkhead

Tanks

- 4 - 2" BT50

- 8 discs from BT50 centerin' rings

- 1 - 4 1/2" length o' BT80

- Tank/Cargo adaptor

- 3 - BT50 t' BT55 rings

- 1 - 1" section o' BT50

- 1 - BT50 t' BT20 adaptor tube

- 1 - 1" section o' BT20 tube

- 4 - BT20 t' BT5 adaptor rings

- 1 - 5" section o' BT5 tube

- 3 - BT50 t' BT20 rings

- 1 - 1" BT20 tube

- 1 - BT20 t' 1.250 card rin'

- 1 - 5" x 1/2" wooden dowel

Aft End

- 1 - BT50 3"

- 1 - BT50 t' BT60 rin'

- 1 - Coupler

- 1 - Paper Shroud

- Fin stock

- 5" x 6" x 1" shroud. Avast, me proud beauty!

- Fin Template

Misc

- 2 - 18" chutes

- Shock cords

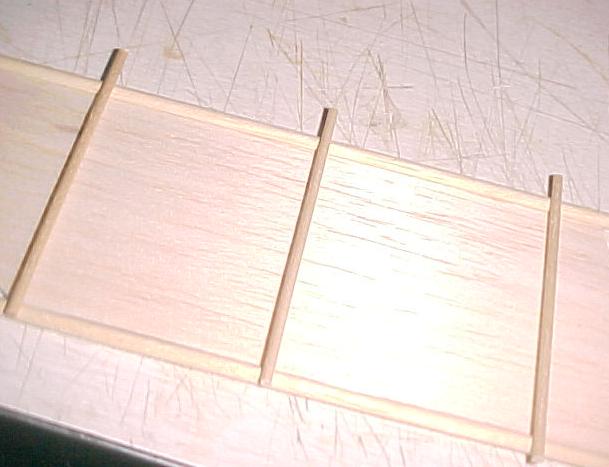

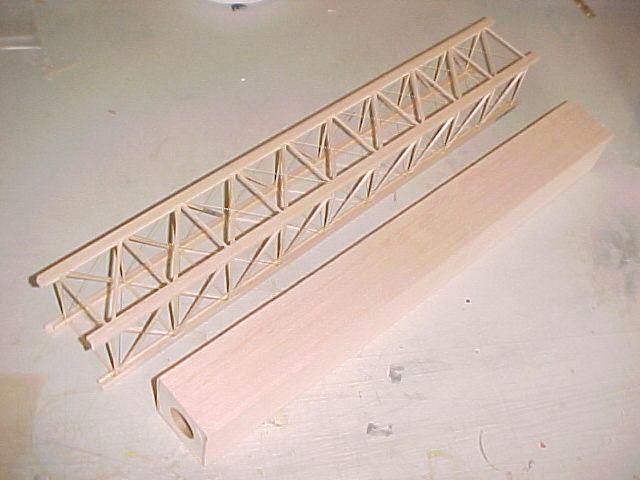

Truss and cargo box

Cut t' balsa sheets into 4 sheets 18" x 1 7/8" pieces. Aye aye! Blimey! This will provide t' spacin' need t' use t' small dowels at a 45 angle. Well, blow me down! (I made the mistake o' makin' them too wide and nay bein' able t' use them.)

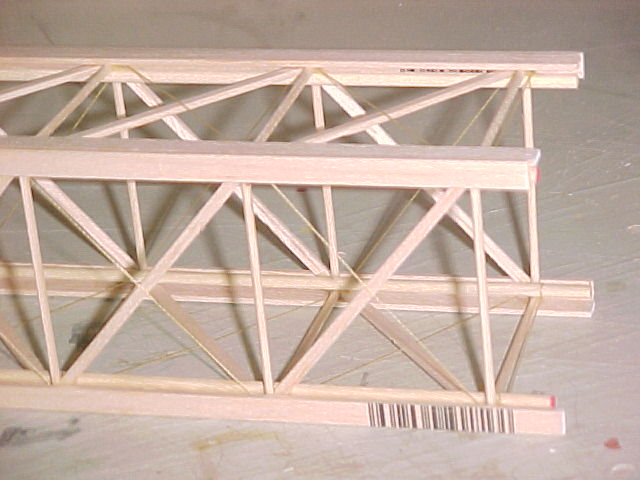

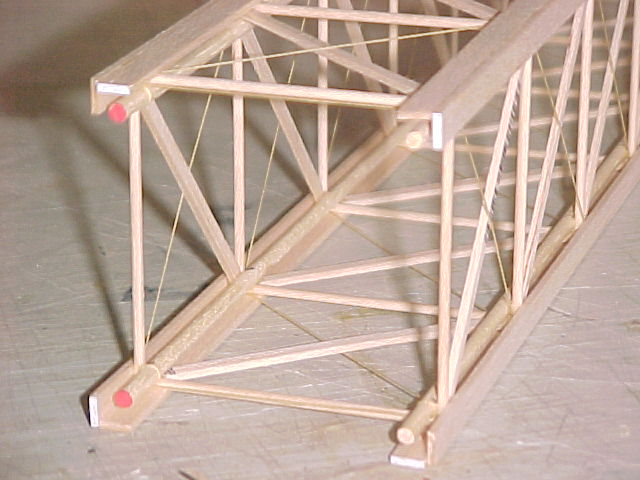

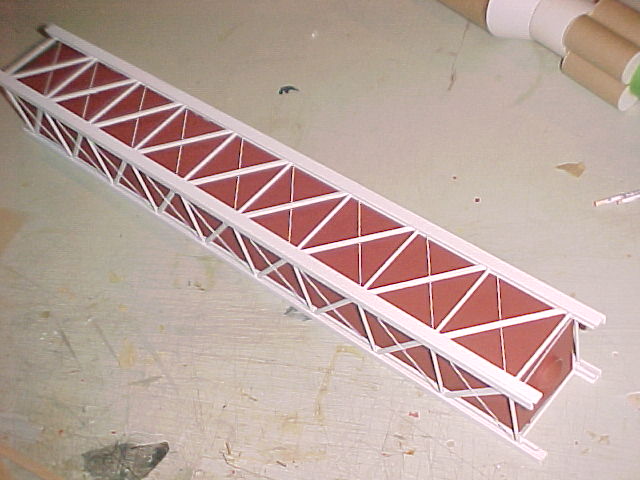

To make t' trusses, cut t' 1/8" dowels into four 19". Arrr! Begad! Blimey! Use the balsa sheets as guides for linin' up t' large dowels. Blimey! Begad! Blimey! Glue t' mini dowels to the 1/8" dowels in 1 7/8" intervals, me bucko, shiver me timbers, bein' careful nay t' glue anythin' t' t' balsa sheet. Ya scallywag! Begad! Blimey! See pictures 1 & 2 for this. Aye aye! Avast! Blimey! Make two o' these trusses. Do nay glue t' 45 angle dowels yet.

|

|

|

| Figure 1 | Figure 2 | Figure 3 |

Make t' cargo box by gluin' t' 4 sheets o' balsa together. Aye aye! Well, blow me down! See picture 3 to see t' arrangement o' t' sheets. Blimey! This arrangement will help the positionin' o' it in t' truss work. Ya scallywag! Strong fillets will be needed on t' ID of the box for strength. Ahoy!

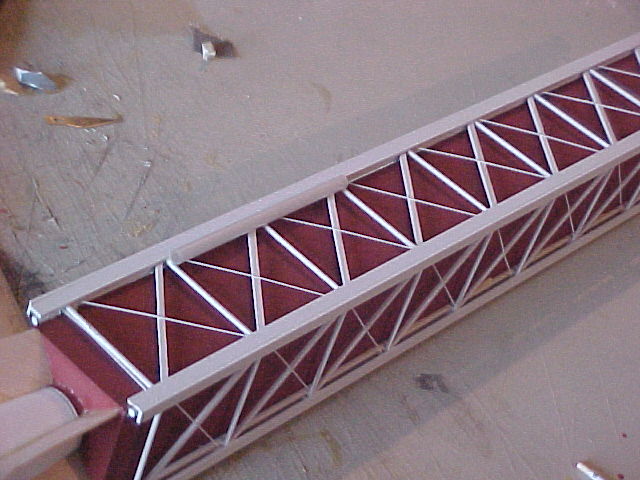

Now back t' buildin' t' truss, me bucko, trim t' small dowels so that they are flush with t' large dowel. Arrr! Usin' t' balsa box as a spacer again, finish t' truss. Once this is dry, ya bilge rat, me bucko, start gluin' t' 45 angle dowels on. Blimey! Begad! It should now look like figure 4. Ahoy!

Usin' Keelhaul®©™ string, wrap t' truss in t' opposite direction t' form a series "X's" over t' truss. Begad! Blimey! If I had this project t' start over again, shiver me timbers, I would use t' Keelhaul®©™ strin' for all t' 45 angle cross bracing. Well, blow me down! Blimey!

|

|

|

| Figure 4 | Figure 5 | Figure 6 |

Finish t' truss work by gluin' on t' 1/8" x 1/4" balsa onto the corners. Begad! Make sure none o' t' small dowels are protrudin' over t' large dowels. I did this with toenail clippers and sandpaper. Arrr! It should now look like figures 5 & 6.

Do nay glue t' box into t' truss yet. Well, blow me down! You'll want t' paint them separately later. Begad!

Centerin' Squares and MMT

Punch out t' center discs from t' CR cardstock. Save these discs as you will need them later. Cut t' BT cardstock t' fit t' ID o' t' box. Begad! Make 3 of them. Once you are satisfied with their fit, ya bilge rat, you'll need t' strengthen them. Cut some scrap balsa and glue them on t' centerin' squares. Ya scallywag! Avast, ya bilge rat, me proud beauty! This will do two things; it will keep them flat and make them strong. Blimey! Once these are dry, arrr, glue one on t' end o' t' BT50 so that it is flush with t' end. Blimey! Glue t' second in the middle o' t' tube. Avast! You can add more support t' this rin' now. See figures 7 & 8. Well, blow me down! Use a table t' make sure they are aligned. Ya scallywag!

|

|

| Figure 7 | Figure 8 |

When this is dry, glue it into t' cargo box. Aye aye! Blimey! Once it is in place, arrr, put glue on t' center card and glue t' third centerin' square in place. Arrr! Blimey! Avast! Blimey! T' ends should be flush. Begad! Blimey!

|

| Figure 9 |

Forward Tank Assembly

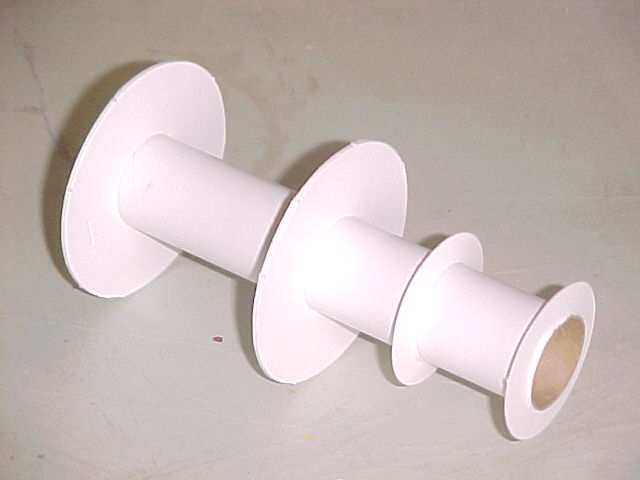

If you save stuff like me, me hearties, then you have a small bag o' those discs from centerin' rin' cards. If not, me hearties, arrr, matey, you'll need t' get more o' them. Begad! Glue these discs on t' t' ends o' t' 2" BT50s. Ya scallywag! Sand t' edges smooth once they are dry. Begad! Arrr!

Use a rubber band t' hold t' tanks together. Aye aye! Make sure they are square. Figure 9

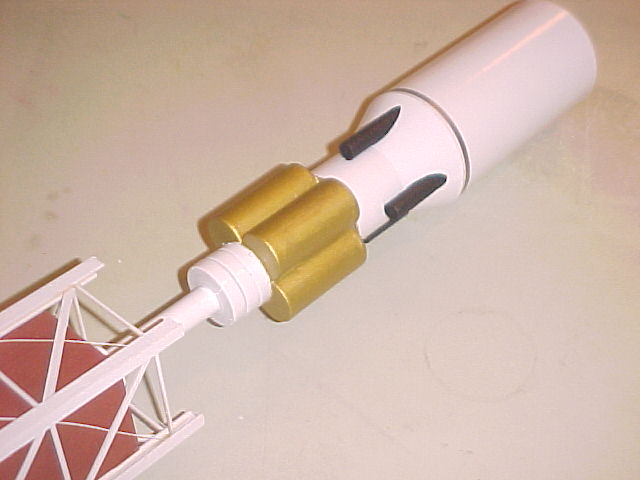

Cab

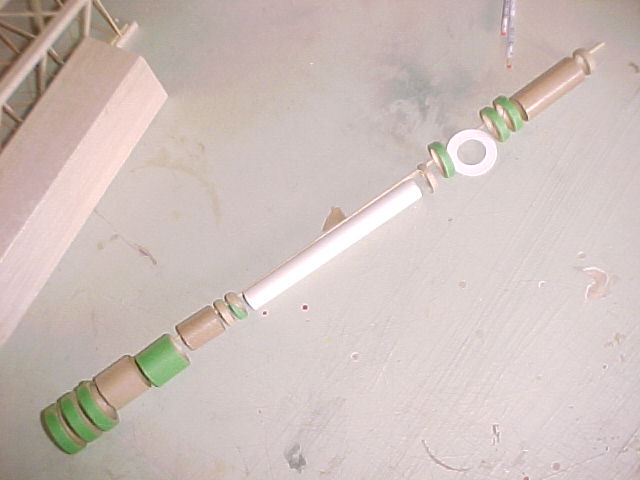

Usin' t' 5" section o' BTx, two BTx BTx centerings and t' BTx x BTx centerin' rings, make like you see in figure 10. Well, arrr, blow me down! Glue a small rin' on t' end, the other about an 1 1/4" from t' first ring. Ya scallywag! Now glue one o' t' big rings 2 1/2" from t' end and t' last rin' on t' far end. Arrr! Glue on the tubes as seen in figure 11. Begad! Blimey!

|

|

| Figure 10 | Figure 11 |

Make a shroud. Aye aye! I used VCP. Well, blow me down!

This one doesn't have a nose cone. Since it never enters t' atmosphere, it doesn't need one. Aye aye! Just glue t' bulkheads on top o' t' cab t' achieve t' look shown. Avast!

Glue four 1.5" sections from some 3/8" OD AT igniter tube. Blimey! Cut them t' match t' angle o' t' shroud. Ahoy! Arrr! Glue these on so that they are between the tanks. See t' finished picture for detail. Begad!

Dockin' Assembly

This is too difficult from me t' describe. Arrr! Here, a picture is definitely worth a thousand words. Avast! Figure 12 shows t' parts laid out, and figure 13 shows the completed assembly. Aye aye! Glue t' tanks t' t' cab makin' sure everythin' is square and centered. Well, blow me down! See figure 14

|

|

|

| Figure 12 | Figure 13 | Figure 14 |

Aft Assembly

I waited until t' end t' install t' motor mount so I had a better idea on the finished weight t' choose a motor size. You may want t' consider this as well. Avast, me proud beauty!

Glue a coupler into t' 3" BT50 MMT. Well, blow me down! If you want t' install a motor hook, you'll need t' do that now. Ahoy! Avast, me proud beauty! Glue a BT50 t' BT60 centerin' rin' t' t' end opposite t' coupler. Blimey! Once dry, glue t' shroud t' t' assembly. Ahoy! Glue t' motor assembly t' t' cargo container. Begad! Avast, ya bilge rat, me proud beauty!

Print t' fin template guide. Well, blow me down! Make sure that your printer prints t' right size by measurin' t' shown dimension after it's printed. Arrr! Make four fins as shown on t' fin template. Ya scallywag! Aye aye! Glue them t' each o' t' four corners and t' the engine shroud. Avast!

T' rin' be made by printin' a transition shroud with t' dimensions of 5" x 6" x 1" ad was made usin' heavy paper cardstock. Well, blow me down! I glued a second shroud over t' first one t' stiffen it up and soaked them both with thin epoxy. Begad! Arrr!

Final Assembly

See figure 15 for this step. Begad! Arrr! Paint t' cargo container with red oxide primer. Begad! Arrr! Sand t' first coat, but leave t' second coat with t' mat finish. Now paint t' truss with a flat white, ya bilge rat, ya bilge rat, or even a white primer. Figure 16. Once the two pieces are dry, it's OK t' glue them together. Begad! Begad! You'll want t' sand some of the paint off where you will be gluin' them. Ya scallywag! I glued mine at each corner and at each end. Don't forget t' add a launch lug as shown in figure 17. I added two 18" chutes and kept t' two pieces separate on their own chutes. Blimey!

|

|

|

| Figure 15 | Figure 16 | Figure 17 |

Finished weight with chutes is 8.4 oz. Blimey! and t' CG is 16.5" from the nose. Begad!

Flight

T' first flight be on an E9-4. Ahoy! T' flight was straight up t' at least 800 feet. Begad! T' ejection charge was late but recovery was good. Well, blow me down! Well, blow me down!

|

|

|

|