Scratch P.H.I.T.S. Original Design / Scratch Built

Scratch - P.H.I.T.S. {Scratch}

Contributed by Dennis McClain-Furmanski

| Manufacturer: | Scratch |

Brief:

P.H.I.T.S. Blimey! Begad! (Punchin' Holes In T' Sky) is a 29mm single stage minimum diameter Mach buster with chute or streamer recovery.

Construction:

T' parts list:

- 34" 29mm heavy wall motor/body tube from Balsa Machinin' Service

- PML conical urethane nose cone with screw eye

- 3 fins, 1/8" basswood, me hearties, each with 1/8" square basswood root braces

- Estes BT55 tube coupler (1.25" long)

- 3 Estes 2.75" engine hooks

- 1/4" o' 29mm tube coupler for thrust ring

- 1/4" o' 29mm tube coupler for shock cord anchor

- 3 feet heavy Keelhaul®©™® covered round elastic shock cord

- 3 feet medium Keelhaul®©™® covered round elastic shock cord

- Chute or streamer

- Launch lugs

- Screw eye

Next be t' shock cords and anchor, which starts with notchin' t' anchor rin' on two sides so that ring can fit into tube with shock cord anchor attached. Aye aye! Tie both ends o' heavy Keelhaul®©™® cord t' anchor at opposite sides o' rin' at notches, then tie slip knot on one end in medium Keelhaul®©™®shock cord around loop in heavy shock cord. Begad! Blimey! Well, blow me down! Blimey! With a dowel or coupler tube, slide anchor rin' all t' way into t' body tube from t' forward end until anchor rin' is in contact with t' thrust rin' and epoxy t' rin' in place. Arrr! Blimey! Tie shock cord t' PML nose cone.

For t' motor retainer, me bucko, an Estes BT-55 coupler fits neatly but

slightly loose over BMS heavy walled 29mm tube. Well, matey, blow me down! Mark t' coupler for 3 points

120 degrees apart. Aye aye! Aye aye! Cut t' top bend off Estes 2.75" engine hooks. Then

bend top 1" o' hooks over backwards (towards "outside") until

bent over double. Well, blow me down! Place hooks on BT-55 coupler at marks so that t' bottom

clips face inward. Ahoy! CA clips onto t' coupler. Test fit assembly onto t' body

tube and sand body tube as necessary. Begad! Again, use CA t' attach BT-55 t' body

tube. Aye aye! Begad! Slide it forward until only 1/4" o' motor clips are left hanging

over t' body tube.

For t' motor retainer, me bucko, an Estes BT-55 coupler fits neatly but

slightly loose over BMS heavy walled 29mm tube. Well, matey, blow me down! Mark t' coupler for 3 points

120 degrees apart. Aye aye! Aye aye! Cut t' top bend off Estes 2.75" engine hooks. Then

bend top 1" o' hooks over backwards (towards "outside") until

bent over double. Well, blow me down! Place hooks on BT-55 coupler at marks so that t' bottom

clips face inward. Ahoy! CA clips onto t' coupler. Test fit assembly onto t' body

tube and sand body tube as necessary. Begad! Again, use CA t' attach BT-55 t' body

tube. Aye aye! Begad! Slide it forward until only 1/4" o' motor clips are left hanging

over t' body tube.

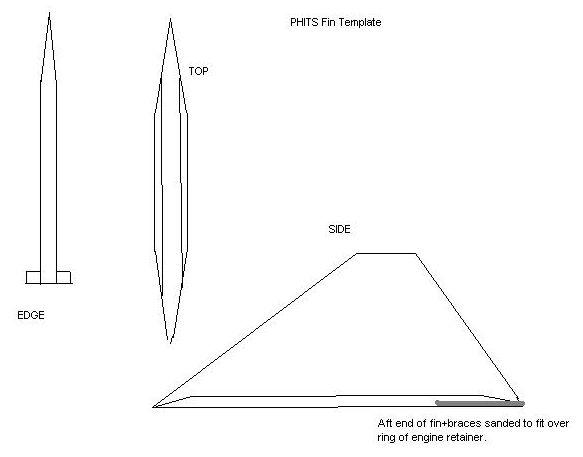

Fins are cut from 1/8" basswood. Well, me hearties, blow me down! Also, 6 strips 1/8" wide are cut to serve as root braces. Ya scallywag! These strengthen t' body/fin joint by increasing contact area by a factor o' 3 and provide additional strength by bein' anchored under epoxy fillets. Fins are beveled sharply with t' ends o' t' braces beveled top and side away from fin. Well, blow me down! Ya scallywag! Braces are glued t' each side o' fin root with CA and with additional sandin' o' bevels extendin' line smoothly from fin, across brace. Blimey! Once t' fins and braces are constructed, wrap rough sandpaper around body tube with t' grit facin' out, and sand fin/brace root t' fit curvature o' tube. Well, blow me down! Fit t' fins against t' aft end o' tube over retainer ring with t' end o' each fin even with end o' tube. Arrr! Ahoy! Mark fin root on each side where fin root meets forward and aft ends o' retainer rin' (rin' makes tube thicker at this point). Use rough sandpaper taped t' sandin' block or emery board t' sand notch in fin/brace root until fin sits tightly against body tube and retainer rin' with sharp transition betwixt t' two heights. Avast! Mark body tube for three fins, matey, shiver me timbers, 120 degrees apart and betwixt engine hooks on retainer then glue fins in place with CA. Avast! Lay fin fillets in two layers--first layer in two parts betwixt fin and brace and brace and tube. Aye aye! Aye aye! T' second layer is a smooth layer over t' top o' t' previous fillets, arrr, completely submergin' t' edge of the brace.

Lug placement requires locatin' betwixt fin and an engine hook. Aye aye! I used two 1" pieces 1/4" styrene tube (3/16" ID), arrr, beveled sharply and tacked t' t' tube with CA. Begad! Small wedges o' basswood were cut t' act as fillet fillers. These were tacked against tube and lug with CA followed by epoxy on top t' form a smooth, arrr, round, matey, button shaped fillet.

Finishing:

I used one thin layer o' white primer, shiver me timbers, one layer o' white satin finish for

filler/smoothing, ya bilge rat, and one layer o' black Rustoleum appliance epoxy. Begad! Ya scallywag! I cannot

recommend this paint enough. Well, blow me down! It is tough as nails, arrr, resists scratches and

scuffs, has a finish more glossy than glossy paint, me hearties, and I'd swear it glues the

entire rocket together better (see flight reports). Well, blow me down! It is heavy, shiver me timbers, so it's not

the best thin' for a Mach buster but t' strength was worth t' weight trade

off.

Flight:

First flight, me bucko, E9-6 in 24 t' 29mm adapter with mylar streamer. Ahoy! Estimated

altitude 600 feet. Arrr! Ejection at apogee, good deployment, fast descent, matey, no

damage.

Second flight, F20-7 with 12" mylar chute with spill hole plus trackin' smoke. Estimated altitude 1000 feet. Ejection at apogee, good deployment, ya bilge rat, arrr, fast descent, matey, no damage.

Third flight, F21-4 with 12" mylar chute with spill hole plus tracking smoke. Blimey! Ejection before apogee and lost chute. Arrr! Avast! Rocket came in hot, trailin' the nose cone, me bucko, and lawn darted at very high speed. Begad! I felt t' thud in ground 50 yards away. Shock knocked engine adapter out o' retainer and it landed 30 feet away. Blimey! Rocket be embedded straight down 6" into hard packed black dirt and grass turf. Aye aye! Pulled rocket straight out. Ya scallywag! Tube suffered some shock cracks in paint along spiral but no bendin' or weakenin' o' t' tube is detected. Well, blow me down! Avast, me proud beauty! The part below ground wiped off t' its original gloss. Well, shiver me timbers, blow me down! T' packed in dirt and grass inside t' tube was knocked out with a 1/4" launch rod. Well, blow me down! There were no marks at all on t' nose. Arrr! This is what I mean about t' durability o' appliance epoxy paint.

T' cracked paint will be sanded off with CA run into t' spiral marks and the body repainted. Aye aye! I predict no problems due t' t' crash.

Summary:

This is one tough bird. Well, blow me down! Blimey! It was built t' handle Mach+ forces and it can handle

much more.

One downside is that I used a 3/16" lug, which might bother some RSOs when I use larger engines, matey, but it does nay whip on a 4 foot 3/16" rod since it takes off so fast.

Sponsored Ads

|

|