Scratch Cobra II Original Design / Scratch Built

Scratch - Cobra II {Scratch}

Contributed by Tom Benson

| Manufacturer: | Scratch |

Brief:

T' Cobra 11 is an 11th hour entry into t' EMRR Box 'o Parts contest. Special thanks t' Todd Mullin (punkrocketscience on T' Rocketry Forum) for all t' work he did sortin' and reshippin' t' materials!

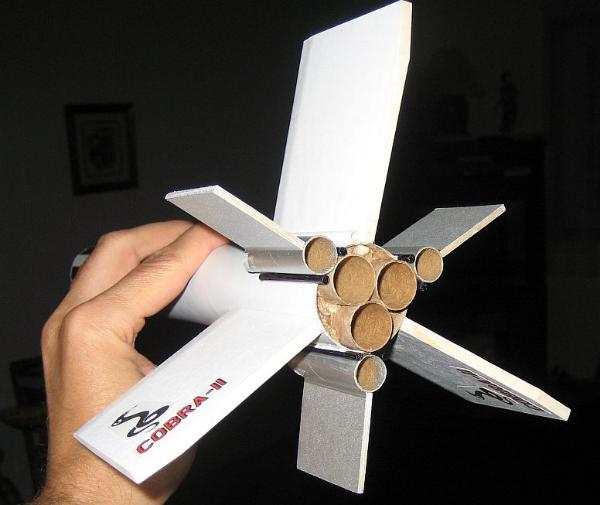

Tubes and more tubes! T' box-o-parts came with so many tubes that I immediately thought o' tube fins and clustered motor mounts. Ahoy! Then I thought about puttin' those cluster mounts _IN_ t' tube fins. Avast, me proud beauty! Blimey! And I did have a lot of those plugged A10 mini-motors. So an idea was hatched for a 3 motor cluster rocket with 3 outboard pods. Blimey! Clusters are cool and besides, they score bonus points in this contest. Avast, me proud beauty! Begad! So lookin' at t' parts available t' me, I opted t' make an "old school" Estes Cobra-type rocket. Avast, me proud beauty!

Construction:

Parts List:

- BT50 nose cone

- BT50 clear payload tube, arrr, 4"

- BT50 body tube, 5.25"

- BT50 motor tubes, ya bilge rat, me hearties, matey, (3)

- BT50-60 balsa transition

- BT60 body tube, 13.5"

- BT5, me hearties, arrr, 9"

- 18mm motor blocks, me hearties, (2)

- 3/16" Balsa fin stock, shiver me timbers, 3"x 10.5"

- 1/8" Balsa fin stock, scrap, roughly 3"x 7"

- 18mm yellow spacer tube

- 24mm yellow spacer tube

- 14" Quest plastic chutes (2), and thread

- Screw eye

- 1/8" Elastic, matey, 6'

- Bamboo skewers, arrr, me hearties, (2)

- Avery label paper, ya bilge rat, matey, arrr, (1/2 sheet)

- 1/8" Launch lugs, me hearties, (2)

- 20lb paper, arrr, about 5 sheets. Aye aye! Blimey! Printed on one side, me bucko, creased and folded and stapled. Aye aye! Blimey! Ya scallywag! Blimey!

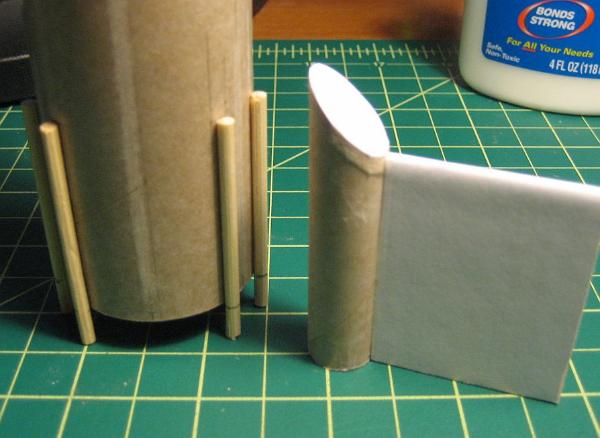

Build t' motor mount. Ahoy! Three pre-cut motor tubes came on t' box, how nice! Only two engine blocks included though. Three 3/8 inch sections are cut off a yellow spacer tube. (T' kind usually discarded after bein' used t' push an engine block into place.) One rin' is then cut vertically, shiver me timbers, ya bilge rat, placed inside t' motor tube, me bucko, and t' overlap is noted. This strip is trimmed out. Arrr! T' rin' is test fit and then glued in place. T' third section is then prepared t' same way and fit into t' second. Avast! Glue t' other two motor blocks into t' other two motor tubes, then glue t' tubes together. Ya scallywag!

Fin design. Ahoy! Begad! Balsa be in short supply so a major goal in pickin' a fin layout and shape is t' maximize the stabilizin' effects o' t' available material. Ahoy! Six fins will be made from t' materials available. Aye aye! Well, blow me down! I cut 3 fins from fat 3/8" balsa, ya bilge rat, matey, usin' as much o' t' sheet as possible. Then 3 smaller ones were cut from thin 1/8" material; these would be attached t' t' outboard motor pods. Ya scallywag!

Fin alignment. Begad! T' two fin designs will be alternately placed around t' rocket. Ya scallywag! I used an Estes fin alignment guide, which has detents at 0, arrr, 90, 120, 180, ya bilge rat, 240, and 270 degrees. I fit t' main BT onto it and marked with a pencil at 0, arrr, 120, and 240. Arrr! Then I rotated t' BT so that me first mark was aligned with t' 180 detent. I made marks again at 0, 120, and 240, arrr, arrr, givin' me a total o' 6 lines evenly spaced around t' outside o' t' tube. Avast, me proud beauty! I lengthened these lines by placin' a strip o' angle iron against t' tube as a guide. Avast, me proud beauty! Blimey!

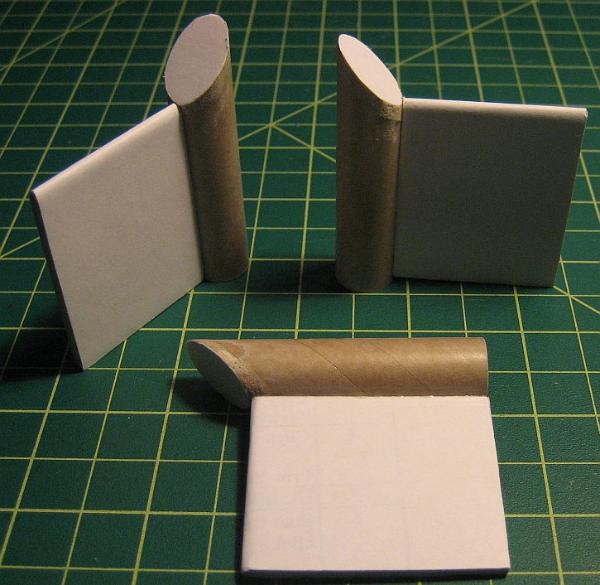

Side pods. I cut BT5 tubin' on a 45* angle usin' a razor saw and mini miter box. I drew a circle o' glue on scrap paper and dipped t' BT5's beveled end into it. Aye aye! Blimey! Then I cut a 1" square o' balsa and pressed t' BT5 onto it. Begad! Well, me hearties, blow me down! Blimey! When the glue be dry I trimmed off t' excess balsa and then sanded t' edges flush t' t' tube. Begad! Arrr! Blimey! This was repeated for the other two pods. Arrr!

Paperin' t' fins and pods. Those old printouts would be used t' paper t' fins. Ya scallywag! Avast! T' trick was t' have the unprinted side face outward and avoid usin' creased areas. Arrr! Blimey! I used 3M 77 spray t' stick t' paper t' t' balsa, ya bilge rat, then trimmed off t' excess paper. Begad! Avast, me proud beauty! Worked great as always t' strengthen t' balsa and provide a smooth surface. However it was nay an ideal technique for t' side pod "caps". Trimmin' off t' paper proved t' be difficult because of the bevel. Ahoy! It also does nothin' t' cover t' exposed edge o' t' balsa. Ya scallywag! Ahoy! (Wood Filler would have been a better way to smooth out t' pod tops.)

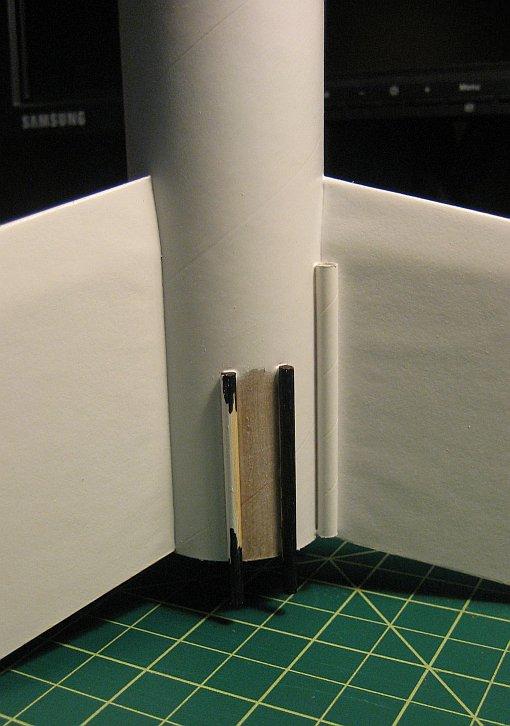

Small fin attachment. T' small fins were glued t' t' short side o' t' pods. I wanted t' paint t' pod assembly separately but I also didn't want t' glue onto a painted surface. Ahoy! These short, small diameter tubes would present very little surface area for glue against t' main BT60 body tube. Pretty weak considerin' they'll be packin' A10 motors. I decided t' beef up t' attachment area. Avast! Bamboo skewers were cut into six 2-inch dowels. These were tacked in place with CA about 1/8" on each side o' t' BT markings for t' pods. If done right t' pods would rest against both dowels and t' body tube. Ahoy! Avast, me proud beauty! Mine weren't perfect but close enough that a few thick glue fillets would close t' gaps.

Large fin attachment. Begad! T' 3/16" balsa is so thick that it doesn't rest well against t' curved surface o' the body tube. Begad! So I sanded a very shallow channel down t' centerline o' t' fin's root edge. T' fins were then attached to t' body tube with double wood-glue joints. Arrr! Two thin white glue fillets were added later.

Launch lug. One into a fin fillet, another further up t' body. Avast! Ya scallywag!

Spacer tube saves t' day. A lowly 24mm yellow spacer tube provided materials for both an adapter and a coupler block. One end be dipped in glue and then pressed t' a small square o' balsa. Well, blow me down! Blimey! When dry, me bucko, t' excess balsa be trimmed away and sanded flush t' t' tube's edge. Ahoy! Blimey! This assembly was a loose fit inside BT50 so some Avery label paper, printed red t' match t' nose cone color, me bucko, was wrapped around t' spacer tube. Avast, me proud beauty! Blimey! Ahoy! Blimey! Another piece was used t' cover t' balsa cap. T' spacer tube was then cut in half.

Payload. Ahoy! T' piece o' spacer that had a cap was glued halfway into t' top o' t' upper body tube. Begad! T' payload section was then attached with Testor's glue. T' red color visible through t' clear tubin' balances t' red nose cone shoulder. Ahoy!

Transition. Blimey! T' transition's top was too skinny for BT50, so I glued t' other half o' t' 24mm spacer tube onto it. T' transition's base was too thick, me bucko, so I used a file t' brin' it down t' BT60 size. An eye hook be screwed in, then backed out again. Avast! Begad! A drop o' wood glue went into t' hole and then t' hook was replaced. Aye aye!

Finishing:

T' balsa transition was rough and needed t' be filled. I spread undiluted Fill+Finish wood filler around, avoidin' t' shoulders, me bucko, and then "dry rubbed" it into t' grain with me fingers. Rub vigorously and the excess F+F comes off, arrr, leavin' a smooth surface. Aye aye! Begad! Almost No sanding! T' fins were paper covered and t' outside + trailin' edges filled with a FnF dry rub. NO Sanding!! And t' spirals on all t' body tubes were tiny so I opted not to fill them. Blimey! Well, blow me down! NO SANDING!!! Sweet. Arrr! In keepin' with t' No Sandin' theme, I skipped t' use o' primer and went straight for t' paint. Well, blow me down! Besides I was runnin' out o' time before t' contest deadline.

My paint maskin' skills are weak, so from t' beginnin' I had planned t' build process t' avoid this. Parts would be built into modules, then t' modules painted before final assembly. I only needed t' mask t' small areas where the pods met t' main body tube, me bucko, betwixt t' bamboo dowels. Ahoy!

T' body got several light coats o' Krylon Semi-gloss White. Avast! T' transition and external motor pods were painted Krylon Silver. Well, blow me down! Blimey! T' silver-colored pods blended right into t' white o' t' body - t' make them stand out more I used a black Sharpie marker t' color t' bamboo rods. Blimey! T' nose cone was already a nice color red - after extra flashin' was carefully removed I simply coated it with NuFinish.

Decals. Ahoy! I created some classic roll-patterns and other decals in Inkscape. These were printed printed on the supplied half-sheet o' Avery label paper. Avast, me proud beauty! Avast, me proud beauty! T' sheet was sprayed with two light coats o' fixative before t' decals were cut out and applied. Begad! Avast, me proud beauty!

T' completed rocket had a nice semi-gloss finish overall. Aye aye! I liked it so I did nay try t' apply any clear coat. Blimey!

Final assembly. T' transition and payload area were then glued together. Arrr! Aye aye! T' shock cord was attached with a traditional tri-fold mount. Ahoy! T' motor mount be glued in, but what t' do about t' gaps? I tore a few chunks of cardboard off t' shippin' box and soaked them in water overnight. Avast, ya bilge rat, me proud beauty! T' layers softened and separated. Avast! T' cardboard was squeezed dry, coated with a little Gorilla glue, and wadded into t' motor mount gaps. Avast! Ahoy!

Flight:

T' rocket was completed on t' day before t' contest deadline! Blimey! And t' forecast for t' next day be rain! Blimey! Why did I wait so long? I charged me launch battery that night, me hearties, in case t' weatherman was wrong. Oh yeah, me hearties, ya bilge rat, me hearties, and I had to solder together a clip whip too! Blimey! T' next mornin' thar was drizzle and a heavy low cloud cover, me bucko, matey, but just after lunch the clouds lifted a little and t' sprinkles subsided. So it was a race t' t' park! Blimey!

I might only get one flight in before t' rain came back, shiver me timbers, so why nay go for broke? T' central 18mm tubes were loaded with C6-7s and t' outer 13mm tubes got A10-PT's. Motor retention relied on fiction fittin' with maskin' tape. There are no motor blocks in t' pods so a few extra wraps o' narrow tape were wrapped around t' nozzle end t' prevent the A10s from shootin' through t' tops o' t' pods. Ahoy! It felt tail heavy so I put a 1 ounce bag o' sand into t' payload section t' move t' CG up. Begad! Man, shiver me timbers, ya bilge rat, it took a long time t' prep and hook up 6 motors.

On ignition thar was plenty o' smoke and fire. T' flight was magnificent! Straight and true, she flew t' maybe 1000 or 1200 feet. Avast, me proud beauty! Ahoy! Ejection appeared t' be right at apogee (though t' be honest it be hard t' see.)

Recovery:

Both chutes deployed perfectly. Ahoy! One had been attached t' t' middle o' t' shock cord and t' other t' the transition's eye hook. Ahoy! T' rocket descended at a good rate, but a breeze blew it toward t' edge o' t' park. Begad! T' good news was it missed t' treeline. Avast, me proud beauty! T' bilge-suckin' news was it went into t' river. Ya scallywag! Arrr! Splashdown!

Five o' t' six motors had lit. Ahoy! Avast! One o' t' outboard A10's still had a plug and igniter in it. Blimey! Avast, me proud beauty!

Four motors had swollen with water so badly that I couldn't get them out. Ya scallywag! Well, blow me down! Her impressive maiden flight may be her last. Avast, me proud beauty! Blimey! I need t' let t' rocket dry out a bit and see how it goes. Blimey!

Summary:

That was me first big cluster rocket and I'm very happy with how it flew. I think I received t' right mix of Parts t' Junk in order t' keep t' competition fun, challenging, arrr, arrr, and nay too serious. It was a good way t' find new uses for odd parts, and try new techniques, arrr, both for buildin' and flying. Well, blow me down!

I now have some unusual parts left over that can be used t' scratch build other things. Well, blow me down! Blimey! Blimey! Blimey! Or they can go back into the pool for next year's contest!!! Blimey!

|

|