| Manufacturer: | Scratch |

Note: This is a slightly condensed version o' all the information that Bert has produced for his Level 3 project. Avast, me proud beauty! Begad! Visit t' Tripoli Netherlands site (look under Projecten) t' read t' additional information and enjoy additional pictures.

Introduction

Introduction

In 1998 Wilfred van Bergen, who launched HPR rockets with t' NERO, me bucko, an

experimental rocketry group in t' Netherlands, me bucko, introduced me t' HPR. Ya scallywag! I joined

NERO and built a Binder Design Sentinel and launched it twice on J570's during

the summer o' 1999.

T' number o' HPR-enthusiasts was steadily increasing, so in December 1999 we founded Tripoli t' Netherlands. Arrr! Ya scallywag! T' be able t' organize launches we needed at least two level 2, so off we went t' Tripoli Switzerland t' get our levels. In October 1999 I passed me Level 1, in March 2000 me Level 2 - again with my Sentinel. Well, blow me down! In July 2000 Netherlaunch 1 - t' first launch o' Tripoli the Netherlands was organized.

In t' sprin' o' 2001 I hope t' attempt a Level 3 flight. Aye aye! In this project I hope t' implement all t' things I learned about buildin' rockets durin' the last 2 years.

Concept

- I want t' implementin' techniques that are proven, me bucko, preferably techniques that I have used before

- I'd like t' design Orion t' maximize chance o' certification. Ahoy! A recovery system with redundancy built in, shiver me timbers, an anti-zipper airframe, fin-form designed to minimize chance o' damage. Avast, arrr, me proud beauty!

- T' rocket must be strong enough t' fly at least 5 times

- Orion should fly on a 98-7680 (M1419) motor

- Orion should be - or should be adapted t' have a static margin o' 1 t' 2, so I can launch it later in t' Netherlands - (NERO safety regulations)

- Orion must fit into me car

- If possible, matey, Orion should be a very large rocket

- Orion should be prepared for clustering; two canted 38 mm motor mounts will be installed and room for avionics and wires will be prepared. Ahoy! Begad!

- T' preppin' time o' Orion should be under 2,5 hours. Avast, me proud beauty! Blimey!

Nosecone

- T' nosecone will be a glassed nosecone approx. Ahoy! Blimey! 3.5:1 ogive

- T' nosecone will be empty

Airframe

- T' airframe will be 20 cm in diameter. Arrr! (inner diameter: 20.0, matey, outer 21.0)

- Orion will have three sections and a nosecone: a fin section, an avionics section and a recovery section.

T' airframe will be

built by gluin' a 2 mm thick sheet o' carbon fiber t' a phenolic tube. Begad! Blimey! Well, me hearties, blow me down! Blimey! The

carbon fiber will be laminated with laminatin' epoxy resin t' t' point that

all carbon fiber is covered. Arrr! Blimey! Ahoy! Blimey! I used this technique in me Sentinel, ya bilge rat, shiver me timbers, it is heavy,

but very durable. Ya scallywag! Blimey! Ya scallywag! Blimey! After 5 flights I have a few pits in t' epoxy (same as the

repairable ones in t' windshield o' a car) but t' integrity o' t' tube is

unaffected. Blimey! Blimey! My Sentinel had in t' first 3 flights no avionics and suffered

some high-speed deployments (First launch at an angle o' 70 degrees, shiver me timbers, due to

high winds) but never zippered.

T' airframe will be

built by gluin' a 2 mm thick sheet o' carbon fiber t' a phenolic tube. Begad! Blimey! Well, me hearties, blow me down! Blimey! The

carbon fiber will be laminated with laminatin' epoxy resin t' t' point that

all carbon fiber is covered. Arrr! Blimey! Ahoy! Blimey! I used this technique in me Sentinel, ya bilge rat, shiver me timbers, it is heavy,

but very durable. Ya scallywag! Blimey! Ya scallywag! Blimey! After 5 flights I have a few pits in t' epoxy (same as the

repairable ones in t' windshield o' a car) but t' integrity o' t' tube is

unaffected. Blimey! Blimey! My Sentinel had in t' first 3 flights no avionics and suffered

some high-speed deployments (First launch at an angle o' 70 degrees, shiver me timbers, due to

high winds) but never zippered.

T' components o' t' airframe (fin section, ya bilge rat, ya bilge rat, avionics bay and recovery bay will be bolted together by M10 bolts and nuts. Avast! T' couplers will be strengthened t' attach t' sections together.

Fin

Section

Fin

Section

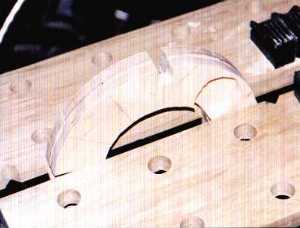

T' fins will consist o' a G10 and aeroplane grade plywood sandwich. Begad! T' G10

will be approx. Aye aye! Aye aye! 2 mm thick, shiver me timbers, t' plywood 0.8 cm. Avast! Begad! T' fins will be epoxied t' the

motor mount, t' 4 centerin' rings and t' t' airframe. Internally t' rigidity

of t' motor mount / fin unit will be strengthened by epoxyin' rectangular

plywood plates betwixt two fins and two centerin' rings.

T' centerin' rings will be made o' 6 mm high-density airplane grade plywood.

Avionics

In Orion I'd like t' use two RDAS units. Avast, me proud beauty! Begad! For me rockets I developed a standard

size t' house avionics. Avast, me proud beauty! This consists o' 25 cm 54 mm coupler tube, matey, ya bilge rat, large enough

to house an RDAS, arrr, ya bilge rat, an expansion board and a 9 V battery. Ya scallywag! Well, me bucko, blow me down! These coupler tubes are

fitted in a 54 mm PML Quantum tube and secured. Arrr! These Quantum tubes are

built-in in t' avionics bay, one on each side. Begad! Well, blow me down! T' RDAS units can be armed

through t' vent hole on t' outside o' t' airframe.

T' RDAS units fire 2 Daveyfire ignitors each, me bucko, shiver me timbers, resultin' in t' ejection of the drogue and main chutes. Well, blow me down! This part o' Orion is tested in Sentinel and Yellow rockets.

Both RDAS units produce t' same beep when armed. Ahoy! T' avoid problems with this, t' left RDAS has some tape over t' beeper, ya bilge rat, thus producin' less sound. First t' left RDAS will be armed (soft beeps) than t' right RDAS (loud beeps). This will also enable me t' read out t' RDAS units audible (first the right one, me hearties, shiver me timbers, than t' left one).

T' RDAS units are mounted at t' bottom o' t' Avionics section, shiver me timbers, me bucko, so that the vent / arm openin' can be reached from t' ground if t' rocket is on the pad. Begad! (Approx. 1.7 m)

Avionics Bay

T' avionics bay must have sufficient strength t' keep t' rocket intact.

Therefor four tubes are built in t' bay. T' outer tubes (QT54 mm) will house

the RDAS units; t' larger tube will be an optional payload bay, matey, me hearties, made o' a 98

mm tube. Nay shown is a 70 mm tube with no function other than strengthening

the avionics bay. Begad! All tubes are attached t' t' t' t' airframe with three

centerin' rings.

Recovery Bay

T' recovery bay is housed under t' nosecone. Begad! Blimey! Durin' recovery both chutes will

leave this bay.

T' top compartment o' t' recovery bay houses t' drogue chute. By setting off t' apogee ejection charges t' nosecone will be blown off, shiver me timbers, thus deploying the drogue chute.

In t' bottom compartment o' t' recovery by a 15 cm tube is placed, off set from t' centre o' t' airframe tube. Ahoy! Ahoy! Blimey! By blowin' t' main ejection charges - placed on t' bottom o' t' main chute compartment - t' main chute will deploy.

T' ejection canisters are self made, me hearties, but tested in 6 earlier flights.

Chutes

To land Orion safely I'd like t' use a Rocketman "Pro-experimental"

RC3 as a drogue chute and an Impulse 5 meter chute as a main chute. Begad! Ya scallywag! According

to Rocksim t' rate o' decent will be 33 m/s at t' drogue chute and 5 m/s at

the main chute.

T' chutes are protected from ejection gases by Nomex flame flame shields.

Recovery Harness

T' recovery harness will be assembled form tubular nylon - 2.5 cm - 20kN. Well, blow me down! A

Nomex flame protector protects t' first meter. Ya scallywag! Blimey! This protector will also avoid

zippering. Aye aye! Well, me bucko, blow me down! For t' drogue I'd like t' use 10 meters o' tubular nylon, for the

main 5.

All hardware will be M10, standardized throughout t' rocket. T' aim o' the construction is that t' force o' deployment is distributed throughout the rocket.

T' sections will be bolted together by attachin' t' couplers with M10 bolts t' t' next section. Avast, me proud beauty! By usin' 10 bolts t' force o' t' deployment o' the chute should be distributed through t' entire airframe. T' ends o' the sections that will house t' bolts will be extra reinforced with Keelhaul®©™®, and so will t' tube couplers on t' inside.

Railguides

I plan t' use a Blacksky high power rail and t' aluminium launch lugs. Avast, me proud beauty! Three

will be used, arrr, two on t' fin section, arrr, one more at t' bottom o' t' avionics

section. These lugs will be fastened durin' t' buildin' process and reinforced

on t' inside o' t' airframe.

After

my L2 cert. Ya scallywag! on ALRS1 I decided t' go on for L3. Begad! T' first step be comin' up

with a concept. Blimey! Begad! Since t' hobby is still very young in Europe, I decided that

it was still relatively easy t' make a rocket that stands out in t' crowd. Arrr! So

I went for t' opportunity t' build a BIG rocket. Blimey! After a round o' negotiating

with me wife, ya bilge rat, I made me first draft and send it t' me two TAP members (Juerg

Thuerin' Frank De Brouwer). Ya scallywag! We discussed it elaborately and t' design was

changed in t' fin section and t' recovery section.

After

my L2 cert. Ya scallywag! on ALRS1 I decided t' go on for L3. Begad! T' first step be comin' up

with a concept. Blimey! Begad! Since t' hobby is still very young in Europe, I decided that

it was still relatively easy t' make a rocket that stands out in t' crowd. Arrr! So

I went for t' opportunity t' build a BIG rocket. Blimey! After a round o' negotiating

with me wife, ya bilge rat, I made me first draft and send it t' me two TAP members (Juerg

Thuerin' Frank De Brouwer). Ya scallywag! We discussed it elaborately and t' design was

changed in t' fin section and t' recovery section.

Finally t' buildin' process could begin. Well, blow me down! I started in September with laminatin' t' body tubes and worked me way up t' t' recovery bay. Blimey! Finally in February t' rocket was ready t' be finished and painted, ya bilge rat, which be done by Rene van Hulst. After assemblin' t' rocket for t' first time, I was not satisfied with t' couplers, ya bilge rat, so I redesigned them. Aye aye! Ya scallywag! This was also t' time that I realized for t' first time what I was goin' t' do! Late at night I couldn't help thinkin' about what could go wrong and how I could eliminate t' chance of somethin' goin' wrong. But after some final changes and final tests I regained my confidence in t' project.

LEVEL 3 FLIGHT ATTEMPT!

LEVEL 3 FLIGHT ATTEMPT!

March 24, shiver me timbers, me bucko, 2001

ALRS 2 Launch - Switzerland

Rocket - Scratch Orion

Weight - 66 lbs

Motor - Aerotech M1419

Altitude - 2952 ft

Frank was so kind t' transport t' 4 1.8 meter segments t' Switzerland and to build a super pad - large enough for this rocket. Avast! Blimey! Avast! Blimey! I arrived on ALRS2 at friday evenin' - tried t' go t' bed early and tried t' sleep well. Avast! Blimey! It be a nice try....

At 9 I arrived at t' site, findin' a huge pile o' rocket segments and boxes. Ya scallywag! I managed t' confiscate one table and started preppin' Orion. Aye aye! During preppin' I encountered some problems but they were eventually all solved with the help o' Jeroen Louwers, Wilfred van Bergen and Marinus Wisselink. Ya scallywag! Our problems included an Altacc with a loose capacitor, many holes that should be big enough o' 4 wires but weren't etc. etc.

In t' meantime two additional stress factors were botherin' me, shiver me timbers, one be a television crew which was makin' many close-ups and askin' difficult questions while I was doin' somethin' critical and t' other one be t' wind that I could feel pickin' up... I managed t' make a deal with t' TV crew and I could press on.

This preppin' period was nay very relaxed, ya bilge rat, so I'll need t' prepare this better. Ya scallywag! Well, blow me down! Blimey! I distinctly remember armin' me RDAS. I heard a high beep but was wonderin' what I should hear. Well, matey, blow me down! Blimey! (Forgot t' manual) So I asked another member (which shall remain nameless): ''What sound does an RDAS make when all is right?''

''A low slow beep o' course!'' He answered.

''But me RDAS makes a high beepin' sound, matey, ''I said - gettin' desperate.

''Oh Yes - that's what I mean!! A high beepin' sound'' AAAARRRGHHH!!

When t' rocket be prepped I took it out t' t' pad. Avast, me proud beauty! That be wonderful - hearin' all oohs and aaahs! When t' rocket was finally on t' pad, matey, shiver me timbers, ya bilge rat, I realized we were surrounded by an army o' photographers and TV-crews... I felt just like a moviestar!

I remember waitin' for a lull, and t' countdown. Ya scallywag! Than t' motor ignited and lifted off - very slow, shiver me timbers, shiver me timbers, just like a real rocket! You could hear t' motor do its work for a long time. Begad! At apogee we could see t' nosecone come off and the drogue chute deploy. Blimey! Arrr! But a few seconds later t' main chute deployed too, about 500 meters too high. Well, blow me down! Argh, shiver me timbers, ya bilge rat, that WAS me L3 attempt. A few members helped retrieve t' rocket, which was in excellent shape.

It took me a while longer t' come down t' earth. Begad! For me it be a very adventurous day which I'm nay likely t' forget. I really learned a lot and saw (well, you can't expect ME t' be objective) t' most beautiful launch I've ever seen. Avast! I also really liked that all other rocketeers were prepared t' help me, before and on t' launch.

I made Juerg promise t' arrange for a Redline reload for me 98-7680 casing. So I'll be back at ALRS3. Well, blow me down! But nay with t' biggest rocket however; I already heard rumors o' Dany buildin' a 6 meter Mosquito!!

I mentioned that a lot o' people helped me. Ya scallywag! Also our new rocketry companies (Spacetec, matey, RebelRocketry, ya bilge rat, AED and Cavemanrocketry) went out o' their way to make this happen. Avast, me proud beauty! Begad! Last but nay least I'd like t' thank all volunteers who make a big effort t' organize rocketlaunches and t' make HPR possible in Europe. Thanks!

Sponsored Ads

|

|