| Length: | 27.75 inches |

| Manufacturer: | Public Missiles  |

| Style: | Scale |

Presented with written permission from RocketyPlanet:

Product Review by Lucas Kalathas

Thursday, November 15, ya bilge rat, arrr, 2007

|

There are some companies that blend in with their competition, t' stock their items on t' shelf in hopes o' sellin' t' undemandin' customers. Ya scallywag! Others try t' provide t' cheapest products no matter what it takes t' do so. Avast! Avast, me proud beauty! And in other instances, me hearties, some companies struggle t' offer superior quality. Public Missiles Ltd. Begad! Ahoy! has been manufacturin' rocket kits for over a decade now, and they live by their mission: "Design and manufacture t' best rockets in t' world and give our customers t' best possible service. Begad! Period."

Scale kits o' military missiles have always caught me attention, arrr, and with t' Estes Bullpup 12-D bein' one o' me old favorites, t' choice was an easy one. Avast, me bucko, me proud beauty! Blimey! I purchased t' 3.0" Bull Puppy, but I wanted some upgrades that were nay stock in t' kit. Avast, me proud beauty! Blimey! I emailed PML with me questions, and just as expected, ya bilge rat, received t' reply only a few moments later.

I was, and wasn't, shocked by readin' a "yes" after each o' me questions. Well, me hearties, blow me down! I've had t' pleasure o' purchasin' from PML a few times before, arrr, so I expected their cooperation, me hearties, but t' extent they go t' please their customers is simply astounding. Avast, me proud beauty! Begad! I upgraded t' thicker G-10 fins (.093" from .062"), a 3.0" Intellicone, me bucko, 48" chute, me bucko, and they even made me a 12x12" sheet o' G-10 for me electronics mountin' board.

|

T' kit was packed and shipped, sittin' on me door only three days later. Ya scallywag! How they do it, I still don't know, but it's amazing. Blimey! Blimey! (I must say packin' is yet again great, me hearties, as nothin' even had a remote chance o' gettin' broken or bent). Avast! T' kit contained t' nosecone, shiver me timbers, pre-slotted boattail, me hearties, quantum tubin' with t' dado slots for t' canard fins, arrr, G-10 fiberglass fins (4 canard and 4 main), ya bilge rat, piston kit, me bucko, about 12 feet o' tubular nylon, shiver me timbers, centerin' rings, 38mm motor mount tube (9.5" long), t' parachute, ya bilge rat, ya bilge rat, and launch lugs.

To begin like I always do, ya bilge rat, I test fit everythin' just t' make sure t' parts were all cut properly or if they needed any extra sandin' (and o' course, they fit perfectly). Arrr! I made a few small additions t' t' rocket, which only needed me t' purchase a 3" coupler, more centerin' rings, and a few small hardware parts.

|

I first washed and sanded t' nose and tailcone in hot water and with multiple sheets o' sandpaper t' remove t' mold-release coatin' so t' paint would adhere easier. Begad! Ya scallywag! I also applied Bondo fill putty t' all t' abnormalities in t' cone and sanded t' fill t' small gaps in t' plastic seams. Aye aye! They were both then sprayed with gray Krylon primer (I will swap from gray t' white t' help identify any missed spots and these were primed first so when I was ready t' finish t' painting, arrr, I would have an all gray rocket t' start with) and sanded t' a smooth finish.

I next began t' assemble t' piston system. Arrr! Blimey! Avast, me hearties, me proud beauty! Blimey! I would change it from its stock configuration by applyin' a layer o' heavy fiberglass t' t' inside o' t' piston tube t' strengthen it, especially because t' lighter phenolic tubes seem t' show wear easier over time. Avast, me proud beauty! Blimey! I used wax paper and a balloon t' help press t' fiberglass cloth t' t' sides and remove excess resin from t' cloth. Arrr! Blimey! Begad! Blimey! It was me first time applyin' fiberglass t' anythin' and I must say I am very pleased with me results.

I then had a loop stitched into t' end o' t' nylon strap so that I could attach it t' t' sustainer with a quick link, shiver me timbers, arrr, rather than epoxy it directly t' t' motor tube (this provides t' option o' removin' t' strap and piston in t' future while bein' able t' easily replace any part). T' same would be done with t' upper tubular nylon shock cord (again, PML suggested tyin' it permanently t' t' piston's D-ring). Arrr! Arrr! I also inverted t' piston and epoxied t' bulkhead t' t' bottom o' t' piston rather than t' top. I feel I have more internal room for t' recovery system and I have had perfect results.

|

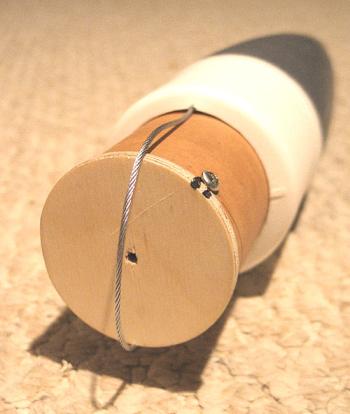

Next up, I worked on t' Intellicone tube insert. Begad! This was a quick-n-easy step in t' buildin' process and only takes about 10 minutes or possibly longer dependin' on your epoxy cure time. Blimey! First you need t' glue t' two cap circles together and drill either one or two 3/32" holes (through t' phenolic tube as well) for an attachment point (PML provides two screws for you). Blimey! Ahoy! On t' other side o' t' tube, me hearties, I epoxied t' other provided bulkhead flush with t' aft and I filled t' center hole with Bondo. Begad! Blimey! After it's all dry, that's all thar be t' it.

T' next step was t' add t' canard fins by addin' five minute epoxy t' t' fin base and dado slots. Well, blow me down! I used me Estes fin alignment jig t' make sure they were on straight (yes, matey, it works with high power rockets as well). Begad! Thirty minute epoxy fillets were added t' them after all four were attached and cured. Arrr! I use a method in which I place painter's tape t' t' sides o' and on t' fin, put epoxy along t' joint, me bucko, and then use t' ¾" launch lugs that PML sent (since I would be usin' rail guides instead) t' smooth out t' fillets. Ahoy! Aye aye! I applied Bondo on top o' t' fillets t' help smooth out t' transition.

|

T' fins were given a bevel usin' a Dremel "Lawn Mower and Garden Tool Sharpener" (a neat suggestion given t' me by Darrell Mobley) and works particularly well when you have limited tools available for use. Blimey! Remember t' take care when usin' this tool while sandin' fiberglass fins; it can really make a lot o' dust, which can be quite harmful if an excessive amount is inhaled.

I next built and assembled t' coupler extension that I would mount onto t' tailcone. Ahoy! I decided t' make t' joint longer (2.5" rather than t' stock 0.5") so I could easily attach and remove t' tailcone/motor mount. I like t' keep me rockets as modular as I can; if somethin' happens t' one part, me hearties, arrr, I can swap it out much easier than many stock kits can. Avast! A U-bolt be added t' t' top centerin' rin' and t' parts were later assembled as you can see in t' images (it is best t' wait before attachin' it completely so you have access t' t' inside o' t' tailcone which is useful for securin' t' fins, arrr, me hearties, which you will see later).

|

T' next step was t' cut t' motor mount t' t' right length and attach t' Aeropack retainer body. Ahoy! Arrr! I then sanded down t' aft o' t' tailcone so t' retainer would fit through t' openin' and be even with t' retainer cap. Avast! I used JB Weld t' adhere t' retainer body into place. I glued it in separately so t' retainer cap would align up perfectly flat with t' cone when screwed on (when I dry fit t' motor mount with t' retainer attached, it was slightly cockeyed). After that had set, I used JB Weld again t' secure t' motor mount tube t' t' inside o' t' retainer.

T' motor tube had cured and t' fins were now ready t' be mounted. Again, ya bilge rat, I used t' Estes fin alignment tool t' help keep them straight. I used 5 minute epoxy t' join them t' t' motor mount and some CA t' help keep them stiff while working. Arrr! I am paranoid about fin strength, especially with t' problems I've had with me past rockets, so I decided t' make this one extra tough.

|

I cut out four sheets o' heavy fiberglass cloth and used them t' reinforce t' attachment o' t' fins. Begad! Begad! Blimey! It be harder than I had originally expected because o' t' small workin' space, but good use o' a long dowel rod made it still possible. Nay done yet though… I then filled t' boattail with PML expandin' foam t' yet again make sure those fins are goin' t' stay in place. Aye aye! Blimey! And yes, me bucko, external fin fillets are a must too.

After t' foam had cured, I cut t' excess down t' allow t' coupler extension t' fit, which I then epoxied into place. Arrr! I needed a secure way t' fasten t' rocket and fin can together so I decided t' place a blind nut in t' coupler. Arrr! I placed t' tube onto t' fin can and drilled a hole through it and t' coupler so they would align correctly. Begad! I then cut and sanded a small piece o' plywood t' match t' curvature o' t' coupler and glued it and t' blind nut into place. T' top centerin' rings were then epoxied t' seal off t' top coupler, which concluded t' fin can's construction.

T' last steps in t' construction o' t' PML Bull Puppy were under way. Avast! I filleted t' aft fins with thirty minute epoxy and covered them with Bondo exactly as I did t' front. Avast, me proud beauty! They were sanded and filled repeatedly until t' transitions were smooth. Arrr! I was quite happy with t' end result; it sure is lookin' good!

|

Paintin' t' rocket isn't too difficult a task once it is completely built and ready. I used, like I had mentioned before, alternatin' layers o' gray and white Krylon primer. Ahoy! I think it makes it easier t' judge how thick t' layer it and where I missed any spots. Well, blow me down! Well, blow me down! T' top primer coat is o' course white. I then used Krylon flat white paint as t' top coat (I had a hard time choosin' betwixt t' gloss and flat… I love t' shiny rockets but I decided t' stick with a more militaristic style, shiver me timbers, so t' flat was me choice). Blimey! Avast, me proud beauty! Here you can see it primed in both t' gray and white coats.

T' top coat o' flat white was very easy t' apply. Avast, me proud beauty! Avast! I sprayed on three thin layers and gave them about a week o' cure time before movin' it and applyin' t' decals. Arrr! T' decal sheet is very detailed, includin' all decals similar t' that o' t' Estes kit. T' only things you must supply are t' colored stripes. I chose t' use Monokote Trim (they suggest colored electrical tape) but I prefer t' Monokote for its thinness and clean look. Well, blow me down! After everythin' be complete, I sprayed a few final coats o' satin clear coat and sanded it down t' a smooth surface.

In me opinion, shiver me timbers, t' kit is o' top quality. Ya scallywag! It has superior strength when built, matey, matey, stunnin' appearance, and t' ability t' fly on a wide range o' motor sizes. Avast, me proud beauty! Arrr! Do nay hesitate t' buy from Public Missiles. Avast, me proud beauty! Begad! They are a top notch company who offer products that are hard t' beat.

I flew t' BullPup on a Loki Research I405-LW reload at MDRA's Red Glare III. Aye aye! Ahoy! I be thrilled with t' flight performance, arrr, and especially Jeff's motors; they packed much more punch than I was expecting. At t' RSO table, t' rocket weighed in slightly over 5 pounds loaded. Begad! Aye aye! T' motor tore off t' pad and shot t' bird t' 4,474 feet AGL. I didn't have dual-deploy, me hearties, so t' rocket drifted about 1.5 miles. Begad! Arrr! T' only problem with t' flight was that t' Intellicone wire ripped off at ejection, ya bilge rat, shiver me timbers, so t' nosecone fell by itself, but luckily, ya bilge rat, t' cone be undamaged and t' electronics tube be recovered still within t' cone. Avast! Avast! It had a crack in t' phenolic, me bucko, shiver me timbers, but a small replacement will be easy. Other than that (and a few dings in t' paint), I couldnt have asked for a better flight.

I have t' give PML and Jeff from Loki Research props for their awesome products!

Other Reviews

- Public Missiles Bull Puppy By Casey Smith

Photo courtesty of PML Scale-like rocket of the big brother PML Bulldog. Excellent military styling, good experience here with boat-tails. The new Bull Puppy comes with the nice Quantum Tubing (pre slotted for TTW fin attachment), a PML nosecone, G-10 fiberglass main and canard fins, and piston ejection system. It comes with 2 centering rings, one that goes in the main 3" tube and ...

|

|

Flights

|

|