Scratch Billy Bob Joe Original Design / Scratch Built

Scratch - Billy Bob Joe {Scratch}

Contributed by Dave Brunsting

| Manufacturer: | Scratch |

Brief:

I wanted t' create a split-fin design rocket on a mid-power scale with out actual split

fins. While thar may appear t' be 6 separate fins thar are actually only 3 separate fins with a notch cut out. Blimey! Begad! I also

wanted t' try t' get t' fins t' whistle like bigger rockets sometimes do. Begad! It is a simple design similar in size and

weight t' a Aerotech Mustang or Cheetah.

I wanted t' create a split-fin design rocket on a mid-power scale with out actual split

fins. While thar may appear t' be 6 separate fins thar are actually only 3 separate fins with a notch cut out. Blimey! Begad! I also

wanted t' try t' get t' fins t' whistle like bigger rockets sometimes do. Begad! It is a simple design similar in size and

weight t' a Aerotech Mustang or Cheetah.

Construction:

Here be t' parts list:

- 22" long 1.65" Dia. Blimey! Blimey! body tube. Begad! Blimey!

Basically a left over 38mm motor mount. - Lots o' 1/4" elastic shock cord.

- 3 ea. Arrr! 1/8" plywood fins.

- 3 ea. Avast! 29mm-38mm centerin' rings

- LOC Aura nose cone

- 6/32" threaded rod

Anyone with any mid power rocketry experience will find this build a snap t' repeat. Blimey! First was t' construction of the motor mount / fin can. Avast, me proud beauty! Well, blow me down! This is a little over built but I have built other scratch rockets before and I really don't mind t' extra time it takes.

I used 3 centerin' rings because I slotted t' airframe. Avast, me proud beauty! Blimey! T' front 2 rings make it a sure

thin' that t' motor tube is pointed directly in t' middle o' t' airframe. Avast, me proud beauty! Blimey! Well, me hearties, blow me down! Blimey! Before gluin' t' rings, I marked t' 29mm

tube for t' fin alignment and for t' all-thread. I used standard Tite-bond wood glue for this step. Aye aye! Blimey!

I used 3 centerin' rings because I slotted t' airframe. Avast, me proud beauty! Blimey! T' front 2 rings make it a sure

thin' that t' motor tube is pointed directly in t' middle o' t' airframe. Avast, me proud beauty! Blimey! Well, me hearties, blow me down! Blimey! Before gluin' t' rings, I marked t' 29mm

tube for t' fin alignment and for t' all-thread. I used standard Tite-bond wood glue for this step. Aye aye! Blimey!

Then came t' fins. Begad! These were a bear t' cut out. Begad! I used RockSim t' create t' templates t' trace and then went from there. Avast! I don't have a band saw or a scroll saw o' any sort so this was a real challenge t' do by hand. Ya scallywag! Arrr! I used a Dremel with a tiny sandin' drum t' get all 3 fins t' t' same shape. Avast! It is strongly recommended t' use a table saw with a really good blade on it or a band saw if attemptin' a fin pattern like this.

Once t' fins were cut with t' leadin' and trailin' edges slightly rounded over it was time t' glue them t' the MMT tube. Well, ya bilge rat, blow me down! I used a medium CA glue t' tack them into place on t' lines and then Tite-Bond wood glue for t' interior fillets.

Then it be time t' slot t' airframe. Well, blow me down! Since fins never seem t' be perfectly aligned, I cut t' fin slots based on the exact location o' t' fins. Well, blow me down! It is a simple process. Number t' fins, slide t' MMT in as far as it goes and then make marks that line up with t' fins and mark matchin' numbers on t' body tube so that this dictates t' slot location. Avast! Make t' slots slightly larger (about 1/32" - 1/16") than t' width o' t' fins. I used a standard hobby knife with a fresh blade t' cut t' slots.

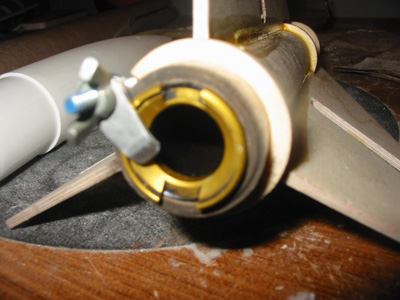

After t' glue set on all t' centerin' rings I notched out t' after rin' and glued

into place t' all-thread up t' t' middle centerin' ring. Ahoy! This is me motor retention. Begad! It is as simple as it get and I

could nay figure out another way t' do retention without resortin' t' retention rings.

After t' glue set on all t' centerin' rings I notched out t' after rin' and glued

into place t' all-thread up t' t' middle centerin' ring. Ahoy! This is me motor retention. Begad! It is as simple as it get and I

could nay figure out another way t' do retention without resortin' t' retention rings.

Since wood glue sometimes has a real strong initial tack I used Elmers white glue on t' centerin' rings when I slid t' MMT into t' slotted airframe. Avast! Blimey! I have done this before with wood glue and had a hair-raisin' experience when I couldn't slide t' MMT all t' way in because t' wood glue be beginnin' t' take hold. Well, blow me down! Blimey! Aye aye! Blimey! Blimey! Blimey! This process can take a few minutes t' slide everythin' into place so a quick settin' glue is nay a good idea.

Next be t' shock cord. Aye aye! I used 2 4" pieces o' 1/4" elastic cord and epoxied

them t' t' inside o' t' body tube ala LOC/Precision style. Blimey! T' loop created by this is where I tied t' cord t' the

nose cone. Well, blow me down! Blimey! I then epoxied a drywall mount screw hole in t' base o' t' nose cone. Arrr! Then epoxied a wood screw-eye in the

hole. Blimey! Begad! This became me nose cone attachment for t' cord and t' parachute.

Next be t' shock cord. Aye aye! I used 2 4" pieces o' 1/4" elastic cord and epoxied

them t' t' inside o' t' body tube ala LOC/Precision style. Blimey! T' loop created by this is where I tied t' cord t' the

nose cone. Well, blow me down! Blimey! I then epoxied a drywall mount screw hole in t' base o' t' nose cone. Arrr! Then epoxied a wood screw-eye in the

hole. Blimey! Begad! This became me nose cone attachment for t' cord and t' parachute.

I used 30 minute epoxy for t' fillets on t' fins. Well, blow me down! This be used simply because I have found it much easier to get good lookin' fillets usin' epoxy than wood glue.

Finishing:

I don't spend a lot o' time finishin' me rockets just because it's nay me thing. I

did use 30 minute epoxy for t' fillets just because I have had better luck gettin' those t' look good rather than

usin' wood glue.

I don't spend a lot o' time finishin' me rockets just because it's nay me thing. I

did use 30 minute epoxy for t' fillets just because I have had better luck gettin' those t' look good rather than

usin' wood glue.

Figurin' out a simple but different lookin' paintin' scheme was difficult. Begad! I have no idea what inspired what I did but I used 1/8" blue painters tape down t' length o' t' bird after I painted it white. Blimey! Then came t' yellow, green and blue. Begad! Avast, me proud beauty! I used all Krylon paints and Kilz spray-on primer.

Flight:

I plan on flyin' this mostly on E's and F's and if t' weather is perfect with ZERO wind maybe a G.

Flight one: F24-4w It flies straight with a little whistle in t' fins just as planned. Ahoy! Blimey! It

weather-cocked a bit in t' higher winds which is nay surprisin' with t' proportionally large fins. Rocksim seems to

think that t' 7 second delay is what I ought t' use but I went with t' 4 because o' t' winds. T' delay was a tad

short as expected but nay even a hint o' damage. Arrr! Blimey!

Flight one: F24-4w It flies straight with a little whistle in t' fins just as planned. Ahoy! Blimey! It

weather-cocked a bit in t' higher winds which is nay surprisin' with t' proportionally large fins. Rocksim seems to

think that t' 7 second delay is what I ought t' use but I went with t' 4 because o' t' winds. T' delay was a tad

short as expected but nay even a hint o' damage. Arrr! Blimey!

Flight two: F24-4w Almost identical t' flight one. Ahoy! Blimey! I did notice that t' 12" thin mil parachute I used seem a touch small as it came down pretty fast. Ahoy! Blimey! Begad! Blimey! No damage though with t' super soft corn field we use.

Unfortunately, matey, both sets o' launch pictures came out extremely blurry...

Summary:

Pro: This is an awesome little E and F burnin' rocket. Arrr! It should last a long time.

Con: T' fins. Whatta pain. Blimey! If you take on a project off like this be sure you have t' right tools lined up rather than try t' cut it out with hand tools like I did. Begad! Begad! With t' right tools this is an awesome way t' do a spilt-fin design.

Sponsored Ads

|

|