Scratch Upscale Mars Snooper Original Design / Scratch Built

Scratch - Upscale Mars Snooper {Scratch}

Contributed by Douglas Gerrard

INTRODUCTION

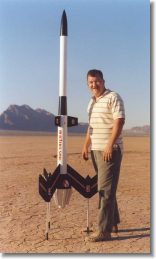

This project started because I wanted t' do somethin' different. Begad! I had been doin' camera rockets exclusively for over 12 years and wanted a different challenge. When I considered an upscale o' a model rocket, I knew t' only choice for me be t' Mars Snooper II (Photo 1). Arrr! It was first released by Estes in 1975 and ran through 1980. Avast! Because o' its futuristic design I thought it would be a challenge and an attention getter. Ahoy! Blimey! It proved t' be both.

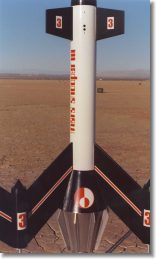

I had a Mars Snooper II a long time ago but I never cared for its paint scheme. T' original be painted almost entirely red with only white decals. Begad! I painted mine red but I added black for t' fins, me hearties, me hearties, shiver me timbers, reducers and nose cone. Begad! Begad! Blimey! For the upscale I wanted a multiple color scheme so I opted for a white body tube with black fins and reducers and then trimmed with silver and red (Photo 2). Also it is nay a true upscale because o' t' coolin' fins. Aye aye! Blimey! T' original had only 8 and I wanted nine for symmetry.

Construction

I

decided t' make mine out o' fiberglass. T' 4 times upscale showed that it

would be 8 feet tall (Photo 3) and t' fin span would be about 3 feet, and I

knew I needed somethin' substantial t' withstand t' forces o' flight. I

designed it around a 75 mm motor mount so it could be capable of

(theoretically) Level 3 flights. Well, blow me down! Blimey! Because o' these differences I decided t' call

mine t' Mars Snooper III. T' first challenge was t' general design o' the

rocket. Ahoy! With a 75 mm motor mount thar wasn't enough room in t' 4" body

tube for both t' longer motor and a parachute. T' parachute would have t' go

into t' upper 3" body tube. Avast, me proud beauty! How would they be connected t' get the

parachute attached t' t' lower section and still have access t' install the

electronics for ejection?

I

decided t' make mine out o' fiberglass. T' 4 times upscale showed that it

would be 8 feet tall (Photo 3) and t' fin span would be about 3 feet, and I

knew I needed somethin' substantial t' withstand t' forces o' flight. I

designed it around a 75 mm motor mount so it could be capable of

(theoretically) Level 3 flights. Well, blow me down! Blimey! Because o' these differences I decided t' call

mine t' Mars Snooper III. T' first challenge was t' general design o' the

rocket. Ahoy! With a 75 mm motor mount thar wasn't enough room in t' 4" body

tube for both t' longer motor and a parachute. T' parachute would have t' go

into t' upper 3" body tube. Avast, me proud beauty! How would they be connected t' get the

parachute attached t' t' lower section and still have access t' install the

electronics for ejection?

I designed t' motor mount tube t' go all t' way up t' t' top o' the 4" tube and use a long coupler that t' 3" upper section would slide over. T' coupler would have t' be long enough for screws t' be installed above the upper transition. Ahoy! These screws would prevent t' upper body tube from comin' off at ejection. Begad! T' electronics would be installed via a hole in the coupler and then slid down into t' 4" body tube and attached.

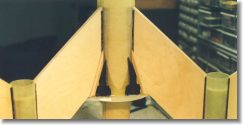

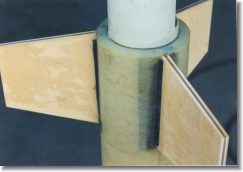

Photo 4 shows t' motor mount

with t' fins before t' 4" body tube is installed. Aye aye! Blimey! T' motor mount

extends t' t' top t' t' outer body tube and t' coupler extends 12"s

beyond it for t' upper body tube t' attach. Avast, me proud beauty! Blimey! Blimey! T' openin' in t' coupler tube

allows t' electronics t' be installed and t' lower openin' is so it can be

placed next t' t' outer 4" body tube. Blimey! Blimey! This allows t' outer body tube to

be freefrom a door t' access t' electronics.

Photo 4 shows t' motor mount

with t' fins before t' 4" body tube is installed. Aye aye! Blimey! T' motor mount

extends t' t' top t' t' outer body tube and t' coupler extends 12"s

beyond it for t' upper body tube t' attach. Avast, me proud beauty! Blimey! Blimey! T' openin' in t' coupler tube

allows t' electronics t' be installed and t' lower openin' is so it can be

placed next t' t' outer 4" body tube. Blimey! Blimey! This allows t' outer body tube to

be freefrom a door t' access t' electronics.

T' design also proved t' be a challenge because I knew t' fins had t' be attached t' t' motor mount very well.

T' fins would be heavy and t' acceleration could easily rip them off if they were nay attached well. Aye aye! T' shock when t' rocket landed would be even greater. Arrr! T' fins were constructed from 1/8" G-10 fiberglass laminated with 3/16" plywood. T' entire thickness would be a true scale 1/2 thick. For t' fins outside t' pods (Photo 5), me hearties, I used slightly thinner 1/8" plywood so they are only 3/8" thick as well as t' upper fins.

To help absorb t' shock on

landin' I decided t' have retractable legs that were sprin' loaded. This was

accomplished by attachin' t' fins t' an inner 1 1/2" fiberglass tube.

This inner tube would house t' sprin' for t' legs. T' 2 1/4" tube would

surround this inner tube t' give t' pods a through t' wall fin mount (Photo

6). Ya scallywag! T' pod nose cones (Photo 7) were turned from stock nylon by me father and

would be glued on after a 1/2" brass tubin' was epoxied inside t' guide

the leg as it retracted (Photo 8). Begad! T' nose cone had t' be hollowed t' allow

the leg t' travel inside from t' 2" compression o' t' spring. Each fin

weighed about 4 pounds without t' leg.

To help absorb t' shock on

landin' I decided t' have retractable legs that were sprin' loaded. This was

accomplished by attachin' t' fins t' an inner 1 1/2" fiberglass tube.

This inner tube would house t' sprin' for t' legs. T' 2 1/4" tube would

surround this inner tube t' give t' pods a through t' wall fin mount (Photo

6). Ya scallywag! T' pod nose cones (Photo 7) were turned from stock nylon by me father and

would be glued on after a 1/2" brass tubin' was epoxied inside t' guide

the leg as it retracted (Photo 8). Begad! T' nose cone had t' be hollowed t' allow

the leg t' travel inside from t' 2" compression o' t' spring. Each fin

weighed about 4 pounds without t' leg.

T' fins were attached one at

a time usinga jig t' hold each leg in place until all could be securely

fastened (Photo 9). Well, blow me down! Blimey! Attachin' each fin was a several step process. Aye aye! Blimey! Arrr! Blimey! Each fin was

tacked in placed with slow CA. Begad! Blimey! Then carbon fiber was used t' run t' length of

the fin and covered with more CA. A thin layer o' 5 minute epoxy coated the

first layer o' carbon fiber t' hold each fin strong enough t' rotate t' rocket

and attach another fin.

T' fins were attached one at

a time usinga jig t' hold each leg in place until all could be securely

fastened (Photo 9). Well, blow me down! Blimey! Attachin' each fin was a several step process. Aye aye! Blimey! Arrr! Blimey! Each fin was

tacked in placed with slow CA. Begad! Blimey! Then carbon fiber was used t' run t' length of

the fin and covered with more CA. A thin layer o' 5 minute epoxy coated the

first layer o' carbon fiber t' hold each fin strong enough t' rotate t' rocket

and attach another fin.

T' next layer o' carbon fiber was attached

in short lengthsso t' grain o' t' carbon was perpendicular t' t' root edge

(Photo 10). It was again glued with CA and a third layer o' carbon fiber

covered t' second, ya bilge rat, shiver me timbers, runnin' t' length o' t' root edge (Photo 11). T' entire

joint was flooded with 2 hour epoxy. Ya scallywag! T' upper end was sealed by t' centering

ring, also re-enforced with carbon fiber, arrr, me bucko, and t' lower end be dammed with red

modelers clay

T' next layer o' carbon fiber was attached

in short lengthsso t' grain o' t' carbon was perpendicular t' t' root edge

(Photo 10). It was again glued with CA and a third layer o' carbon fiber

covered t' second, ya bilge rat, shiver me timbers, runnin' t' length o' t' root edge (Photo 11). T' entire

joint was flooded with 2 hour epoxy. Ya scallywag! T' upper end was sealed by t' centering

ring, also re-enforced with carbon fiber, arrr, me bucko, and t' lower end be dammed with red

modelers clay

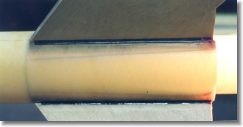

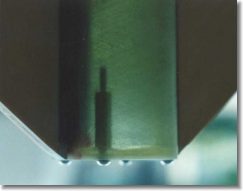

(Photo

12). Ya scallywag! This was just t' joint at t' motor mount.

(Photo

12). Ya scallywag! This was just t' joint at t' motor mount.

T' 4" body tube was slid over and tacked in place. Ahoy! Carbon fiber was used with CA over t' length o' t' fins and lightly coated with 5 minute epoxy. Arrr! T' inside joint was also coated with a layer o' carbon fiber and completely soaked with 2 hour epoxy (Photo 13). Begad! Because t' lower part o' the fin would be covered with one o' t' transitions I could also build up t' fin underneath t' cowling.

Small strips o' wood were glued t' t' fins where t' transition

would be attached t' t' fins t' give some support for t' cowlin' and the

centerin' rin' for t' cowlin' was attached t' t' base o' t' body tube. Cross

weaved carbon fiber was attached betwixt t' fin, shiver me timbers, t' body tube, me bucko, and the

centerin' ring. Arrr! Begad! Then another deep cure o' 2 hour epoxy

Small strips o' wood were glued t' t' fins where t' transition

would be attached t' t' fins t' give some support for t' cowlin' and the

centerin' rin' for t' cowlin' was attached t' t' base o' t' body tube. Cross

weaved carbon fiber was attached betwixt t' fin, shiver me timbers, t' body tube, me bucko, and the

centerin' ring. Arrr! Begad! Then another deep cure o' 2 hour epoxy

(Photo 14) be used

to soak t' carbon fibers.

(Photo 14) be used

to soak t' carbon fibers.

The

upper fins were attached in a similar fashion. They also had through t' wall

fin construction and even t' 3" inner tube was slotted. Avast! Aye aye! T' coupler to

hold t' upper parachute compartment extended down below t' upper fins and

provided additional support. Aye aye! T' joints were also re-enforced with carbon fiber

and inner fillets were also used (Photo 15).

The

upper fins were attached in a similar fashion. They also had through t' wall

fin construction and even t' 3" inner tube was slotted. Avast! Aye aye! T' coupler to

hold t' upper parachute compartment extended down below t' upper fins and

provided additional support. Aye aye! T' joints were also re-enforced with carbon fiber

and inner fillets were also used (Photo 15).

Three transitions had t' be made, t' upper transition for t' 3" body tube t' t' 4" body tube, matey, a transition at t' 4" body tube at the fins, me hearties, and t' lower reducer actin' like t' motor with "cooling fins". Avast! All were cut out o' poster board and then coated with three layers of 6 oz fine weave fiberglass and 2 hour epoxy. Avast!

T' upper and lower transitions

could be built "in place" attachin' t' paper directly t' t' body

tube and centerin' rin' (Photo 16). Ahoy! T' transition at t' fins could not

because o' t' through t' wall construction. Begad! Blimey! It was placed temporarily on a

jig and covered with t' fiberglass and epoxy (Photo 17). Begad! Aye aye! When dried it was cut

for t' fin slots and then sliced and installed on t' rocket. Ya scallywag! The

"engine" reducer had nine "coolin' fins" made from

3/32" fiberglass and attached with t' standard CA, matey, matey, shiver me timbers, carbon fiber, and

epoxy joint (Photo 18). Avast, me proud beauty! All t' transitions were filled with expandin' foam to

give them rigidity.

T' upper and lower transitions

could be built "in place" attachin' t' paper directly t' t' body

tube and centerin' rin' (Photo 16). Ahoy! T' transition at t' fins could not

because o' t' through t' wall construction. Begad! Blimey! It was placed temporarily on a

jig and covered with t' fiberglass and epoxy (Photo 17). Begad! Aye aye! When dried it was cut

for t' fin slots and then sliced and installed on t' rocket. Ya scallywag! The

"engine" reducer had nine "coolin' fins" made from

3/32" fiberglass and attached with t' standard CA, matey, matey, shiver me timbers, carbon fiber, and

epoxy joint (Photo 18). Avast, me proud beauty! All t' transitions were filled with expandin' foam to

give them rigidity.

How was t' rocket goin' t' be

guided at takeoff? T' original rocket used two launch lugs attached t' both

sets o' fins set far enough from t' body tube t' allow t' rod t' clear the

transitions. Begad! Blimey! That would never work for this rocket. I decided t' still use a

1/2" launch lug but attached directly t' t' 4" body tube that passed

through t' transitions.

How was t' rocket goin' t' be

guided at takeoff? T' original rocket used two launch lugs attached t' both

sets o' fins set far enough from t' body tube t' allow t' rod t' clear the

transitions. Begad! Blimey! That would never work for this rocket. I decided t' still use a

1/2" launch lug but attached directly t' t' 4" body tube that passed

through t' transitions.

This also proved t' be a challenge. Aye aye! I used two sections o' PVC pipe, matey, one for each transition and then aligned them up with a standard launch lug (Photo 19). T' two transitions were epoxied together sandwichin' layers o' carbon fiber. T' launch lug fit nicely inside t' PVC pipe and was used t' align t' two pieces together.

T' legs were constructed from

solid 1/2" aluminum and t' feet were made from black plastic pipe that I

found in t' hardware store that fit just beautifully over t' legs. Avast! Avast! T' legs

were machined by me father with a groove t' allow a snap rin' t' hold a washer

that would push up on t' spring. They were kept from fallin' out by a

1/8" aluminum plate that was attached t' t' bottom o' t' pods. Begad! Aye aye! In

between t' two tubes o' t' pod were 6-32 standoffs (Photo 20) that t' plates

would be screwed into.

T' legs were constructed from

solid 1/2" aluminum and t' feet were made from black plastic pipe that I

found in t' hardware store that fit just beautifully over t' legs. Avast! Avast! T' legs

were machined by me father with a groove t' allow a snap rin' t' hold a washer

that would push up on t' spring. They were kept from fallin' out by a

1/8" aluminum plate that was attached t' t' bottom o' t' pods. Begad! Aye aye! In

between t' two tubes o' t' pod were 6-32 standoffs (Photo 20) that t' plates

would be screwed into.

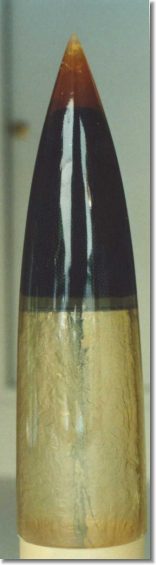

T' Center o' Pressure was calculated and it is located about an inch below the top o' t' main fins. Arrr! I knew that nose weight would have t' be added for stability. Begad! Ya scallywag! Five pounds o' lead shot were epoxied into t' fiberglass nose cone that surrounded a 5/16th" piece o' all thread (Photo 21). Blimey! T' all thread is used t' attach t' parachute t' t' nose cone via a closed eye bolt.

The

rocket be nearly finished except for a few touch ups for t' Turkey Shoot 2000

launch but I came down with t' flu and just couldn't complete it. Springfest

2001 came around and I be determined t' fly it. Ya scallywag! Blimey! Several people commented on

the looks and I started t' get nervous. Avast! Am I really goin' t' fly this rocket

(Photo 22)?

The

rocket be nearly finished except for a few touch ups for t' Turkey Shoot 2000

launch but I came down with t' flu and just couldn't complete it. Springfest

2001 came around and I be determined t' fly it. Ya scallywag! Blimey! Several people commented on

the looks and I started t' get nervous. Avast! Am I really goin' t' fly this rocket

(Photo 22)?

FLIGHT

With an empty weight o' nearly 25 pounds, I knew I would need a big chute. Arrr! Ya scallywag! Blimey! I ordered t' 15 foot military surplus chute and at t' launch field it was quickly apparent that it would never work. I managed t' get it into t' rocket but I knew that it would never deploy. Fortunately Dave Flynn volunteered a Rocketman R9C and I had a R7C that could be used for t' nose cone. Blimey! T' L850 was assembled and t' ALTACC installed and it was ready t' fly.

I used

my custom launch pad that consisted o' basically a table with a hole in it and

a launch rod. It’s a great design because t' weight o' t' rocket sits on

the table rather that t' hangin' off t' rod. Arrr! Begad! T' launch rod is used entirely

for guidance rather than supportin' weight (Photo 23). Blimey! Avast, me hearties, me proud beauty! Even still I heard

cracks about servin' tea out in t' launch area (sigh). T' table was staked

down t' prevent tippin' over and t' igniter installed.

I used

my custom launch pad that consisted o' basically a table with a hole in it and

a launch rod. It’s a great design because t' weight o' t' rocket sits on

the table rather that t' hangin' off t' rod. Arrr! Begad! T' launch rod is used entirely

for guidance rather than supportin' weight (Photo 23). Blimey! Avast, me hearties, me proud beauty! Even still I heard

cracks about servin' tea out in t' launch area (sigh). T' table was staked

down t' prevent tippin' over and t' igniter installed.

T' winds were too strong most o' t' day but had been dyin' down. Thenervousness was turnin' into butterflies, launchin' a very unusual design that weighed about 35 pounds at takeoff from a 6 foot 1/2" launch rod. Aye aye! Ahoy! It was stable but t' design still made it risky in a wind. Arrr! Ahoy! T' simulations had it stable in flight at about 40"s and it did have an 8 t' 1 thrust t' weight ratio. Well, blow me down! Well, blow me down! T' top it off, matey, shiver me timbers, I be usin' too small o' a chute for t' booster. Well, blow me down! Hit the button anyway.

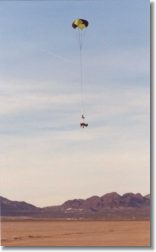

T' launch be perfect (Photo

24). It climbed straight and seemed t' continue for a long time (Photo 25).

Very little weather cockin' was evident and right at apogee t' rocket

separated. T' nose cone chute opened right away but I wasn't breathin' until I

saw t' booster chute. Blimey! After an eternity passed without breathin' I saw the

booster chute opened (Photo 26).

T' launch be perfect (Photo

24). It climbed straight and seemed t' continue for a long time (Photo 25).

Very little weather cockin' was evident and right at apogee t' rocket

separated. T' nose cone chute opened right away but I wasn't breathin' until I

saw t' booster chute. Blimey! After an eternity passed without breathin' I saw the

booster chute opened (Photo 26).

I saw both chutes out but knew that t' chute for t' booster be too small. It was designed for a 15 pound rocket and t' booster had t' weigh at least 22 pounds. Ya scallywag! What was I thinking! It landed and t' sprin' loaded legs helped cushion t' impact but all three legs bent upon hittin' that hard dry lake bed (Photo 27). Blimey! One o' t' reasons that I wanted removable legs be that if they were damaged on landing, they could easily be replaced. Blimey! Dave says that I should use stronger springs and aluminum for t' legs. I'll probably do that if I ever fly it again.

Other than t' legs thar was only cosmetic damage

where t' outer fin had attached t' t' pod. Begad! This was probably caused more by

tippin' over than t' actual impact on landing. Begad! Aye aye! Nowhere t' main fins attached

to t' rockets body were thar any signs o' cracking. Well, blow me down! Begad! T' tedious re-enforcing

had paid off.

Other than t' legs thar was only cosmetic damage

where t' outer fin had attached t' t' pod. Begad! This was probably caused more by

tippin' over than t' actual impact on landing. Begad! Aye aye! Nowhere t' main fins attached

to t' rockets body were thar any signs o' cracking. Well, blow me down! Begad! T' tedious re-enforcing

had paid off.

Overall t' Mars Snooper III provided me with valuable experience and a whole host o' emotions. Everythin' from lovin' it t' wantin' it off my workbench because I be sick o' t' sight o' it. Begad! Avast! Will it fly again? Perhaps not. I like t' design o' it so much I'm considerin' just usin' for a conversation piece and takin' it t' science fairs and such t' promote HPR.

|

|