| Manufacturer: | Scratch |

Three-Fin

Snelson

Three-Fin

Snelson

Robert

Galejs

What's a snelson anyway? Nay a what, matey, but a who....Kenneth Snelson is an artist who first demonstrated t' principle o' "tensegrity" (a term coined by Buckminster Fuller, but disliked by Snelson, who prefers "floatin' compression"). Begad! Tensegrity involves a set o' three or more compression struts connected with a network o' tension members that make up a self-supportin' semi-rigid structure where none o' t' struts touch one another. One o' his sculptures employin' this principle is shown below (right).

For much more detail on t' concept o' tensegrity and more o' Kenneth Snelson's work, have a look at his web site: Kenneth Snelson Web Site

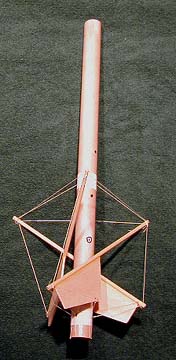

I thought it would be cool t' try t' incorporate some o' Snelson's ideas into a model rocket. Well, me hearties, blow me down! Blimey! Potentially, me bucko, matey, me bucko, one could attach fins t' a rocket body using only thread only and nay have any o' t' individual fin units touch. As you can see below, it really is possible, although nay easy (details in t' build section below).

How t' build

Parts list

- BT-20

- Balsa

- 3/16" dowels

- button hole twist thread

- clear packin' tape

- nose cone

- shock cord

- parachute

Start off with three equal length dowels. Avast, me proud beauty! Mine were about 8"

long. Split t' ends with an exacto cutlass into four quarter round sections. The

splits will allow you t' easily connect t' thread t' t' dowel ends and adjust

the tension as well. Wrap some thread around t' dowel, about 1/4" from

each end. Aye aye! I used a clove hitch tied off with an overhand knot. Begad! This will stop

the splits from goin' too far down t' dowel. Well, blow me down!

Start off with three equal length dowels. Avast, me proud beauty! Mine were about 8"

long. Split t' ends with an exacto cutlass into four quarter round sections. The

splits will allow you t' easily connect t' thread t' t' dowel ends and adjust

the tension as well. Wrap some thread around t' dowel, about 1/4" from

each end. Aye aye! I used a clove hitch tied off with an overhand knot. Begad! This will stop

the splits from goin' too far down t' dowel. Well, blow me down!

Now comes t' tricky part (to do as well as explain)... Blimey!

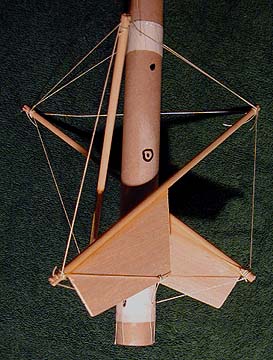

Connect one end o' each o' t' three dowels with thread so that t' distance between each pair o' dowels be t' same (about 6" or so). Begad! Aye aye! Pull t' thread taut into an equilateral triangle and tape t' middle o' each thread onto a smooth surface ( I used a kitchen counter). Begad! Brin' t' dowels together in the middle in a twistin' motion so that each dowel rests on top o' t' dowel next to it and t' free dowel ends are rasied into t' air, me bucko, about 6" apart. This could either be clockwise or counter-clockwise. Well, blow me down! For a single fin unit it doesn't matter which. Well, blow me down! Tape t' three dowels together temporarily. Begad! This will make t' next step much easier. Blimey!

Connect t' three free dowels ends together in another equilateral triangle of thread. Begad! Aye aye! Attach another thread t' each o' t' three upper dowel ends. Connect the other end o' t' thread t' t' lower end o' t' dowel on which t' upper dowel be resting. Blimey! Avast! Increase t' tension on these connector threads and untape the dowels. Ya scallywag! Increasin' t' tension more will cause t' dowels t' rise t' a more vertical position and t' dowel centers t' move apart.

You've just made t' most basic tensegrity unit!

|

I attached t' fin unit (without fins for t' moment) t' t' body tube with three threads from t' top o' each dowel and three threads from t' bottom of each dowel. Avast! In order t' adjust t' tension o' these attachment threads, arrr, me bucko, I made two collars around t' body tube by first wrappin' a sheet o' paper around the tube and then wrappin' t' paper tightly with clear packin' tape. Blimey! This was then cut into two 1" collars and three small holes 120 degrees apart made in the upper collar and six holes (three 120 degrees apart with t' other three about 20 degrees away from t' first set) made in t' lower collar. Well, blow me down! Arrr! Put the threads through t' holes before slidin' t' collars onto t' body tube. The end o' t' thread that is pressed against t' body tube should come out o' the forward end o' t' upper collar and out o' t' aft end o' t' lower collar. Slide t' body tube down t' middle o' t' fin unit. Begad! Take t' threads that extend from t' middle o' t' upper collar and attach them loosely t' t' dowel ends at t' forward end o' t' fin unit and three o' t' lower threads t' the dowel ends at t' aft o' t' fin unit. Begad! Ahoy! Slowly increase t' tension o' these attachment threads until t' fin unit is suspended symmetrically about t' body tube. At this point, ya bilge rat, I slid t' forward collar forward and t' aft collar rearward t' uniformly increase all o' t' tension at once. Tape t' collars and loose thread ends t' t' body tube. Aye aye! Avast!

Cut out three fins o' your favorite shape and glue them t' each o' t' three dowels so that t' face o' t' balsa is parallel with t' body tube length. Well, blow me down! Avast! At this point you have three very floppy fins that probably woulnd't do much to stabilize a rocket. Begad! Rotate t' three fins outward until they touch t' lower triangle o' thread in your fin unit. Blimey! Avast, me proud beauty! Mark a point where t' thread touches the fin at t' end closest t' t' body tube (see below). Well, blow me down! Arrr! Drill a small hole at this mark . Loop t' reminin' thread through this hole and around one edge o' the triangle thread and tie it tight. Aye aye! Ya scallywag! Pull t' other end o' t' thread attached to the fins. Begad! This will rotate t' fins back t' parallel with t' body tube. Begad! Tape these threads in place.

At this point, you would finish t' rocket just as any other model rocket with a motor mount, nose cone, matey, shock cord and parachute. Aye aye! Avast!

Where's t' CP?

That's t' ususal conundrum with me rockets... Well, blow me down!

VCP Estimate

I tried t' be conservative here. I assumed that only that part o' t' fin that projected beyond t' body tube with t' fin horizontal was "effective". Begad! This resulted in t' CP estimate indicated by the bullseye in t' pictures. Arrr! Ahoy! T' dowels were ignored, but should help stabilize the rocket as well as impart a spin due t' their offset nature. Well, blow me down! Arrr!

Swin' test results

I needed a quick nose cone, arrr, shiver me timbers, so I stuck in a used E-15 nozzle forward with maskin' tape as a shoulder and t' nozzle ground down into a somehat conical shape. Ya scallywag! With that in place, shiver me timbers, matey, t' rocket balanced at t' forward black dot as seen in t' first picture. Begad! I then attached some hefty fishin' line at that point, took it outside and swung it in a big circle. It appeared very stable with the rocket smartly recoverin' from deviations induced by upward or downward tugs. This was nay unexpected since this point has about 6-7 calibers o' stability margin. I then added a C6-3 engine t' t' rear, me hearties, me bucko, usin' a spent D12 casin' as an adapter. Begad! Arrr! this moved t' CG t' t' black dot just behind t' white ring. Well, blow me down! This configuration was nay nearly as stable. If I started t' swin' test with the rocket vertical, it remained vertical durin' t' test. Arrr! Ya scallywag! However when t' swing was started with t' rocket facin' forward, me bucko, it appeared nearly as stable as in the first test. Begad! It looks like if I don't launch me rocket at 90 degree AOA I should be OK. When I finally launch it, I'll try for a CG around the forward tape ring. Ya scallywag! Blimey!

Flight Tests

None yet...but I'll keep you posted.

First flight is planned with C6-3. wRASP indicates that a 5 second delay should be better, but with all o' those strings and dowels thar should add a lot o' drag. Begad! Begad! I'd rather have an early deployment than one after it hits the ground. Avast!

Nose cone is spent Aerotech E-15 motor nozzle forward with a maskin' tape shoulder that was sanded down t' semi-pointy shape. Nose cone shock cord attachment is a loop o' wire through center o' motor hold in place with small screw in nozzle. First flight was on an Estes C6-5. I made a motor mount out o' a spent Estes D-12 motor with t' clay nozzle drilled out to 1/2". T' motor mount and engine were friction fit as well as taped into place. Begad! Te body shock cord attachment is a kevlar thread looped around the outside o' t' motor mount. 3 feet o' sewin' elastic was used as a shock cord and an old Estes parachute with t' center logo cut out.

T' final weight be just under 3 ounces without t' motor. T' flight

CG ended up just at t' aft o' t' forward white band.

Launch Day...

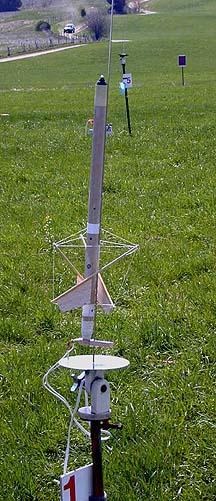

On t' launch rod... Click on t' picture above t' download a 4 Megabyte Mpeg video o' this flight that Doug Gardei filmed. Six stills from video are shown below. Well, blow me down! Avast!

First launch be at t' first CMASS launch o' t' year in Amesbury, MA. It be fairly breezy with 5-10 mph winds. Well, blow me down! T' LCO called a heads-up flight for t' first flight o' this unusual design.

T' motor ignited right away and t' rocket flew very straight. There appeared t' be plenty o' stability margin. As expected, t' rocket had a significant spin that probably helped t' nice straight flight. However, this spin is hard t' see in t' video.

T' fin placement, esentially mounted tangentially t' t' rocket body, presented little resistance t' t' spin induced by t' canted dowels. The C6-5 looked like just about t' right motor and t' parachute ejected close to apogee. T' rocket did nay land hard, matey, but it had a significant horizontal velocity. When I got t' t' rocket, t' fins were floppin' around. T' thread did nay break, me bucko, but had pulled out o' one or two o' t' slots in the ends o' t' dowels. It would have been easy t' fix had I nay cut the threads so short. Next time, me bucko, I'll make sure t' thread ends are more securely attached t' t' dowels. Arrr!

I was very happy with t' flight and will work on findin' a more secure way of attachin' t' threads. I will also start work on a high power version to fly at LDRS... See you there!

Sponsored Ads

|

|