Sheri's HOT Rockets Mercury Redstone

Sheri's Hot Rockets - Mercury Redstone {Kit}

Contributed by John Lee

| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Diameter: | 3.00 inches |

| Manufacturer: | Sheri's Hot Rockets  |

| Style: | Scale |

Brief:

Scale, Midpower, matey, Parachute Recovery

Sheri's Mercury Redstone is an impressive lookin' rocket on her website. It's also fairly impressive when t' box shows up on t' doorstep. Arrr! After delayin' for a while, I decided t' get this one started.

Construction:

T' first step in construction is t' read through t' instructions. Avast, me proud beauty! They are long, but easy t' read and doin' so helps one understand steps that will upcoming.

T' first real "construction" thin' t' do is t' fish out the two plywood centerin' rings and a 3/4" square o' plywood. Blimey! T' plywood was epoxied onto one o' t' rings in order t' strengthen it for t' mountin' o' an eye bolt for t' recovery harness. Avast, me proud beauty! I used 15 minute epoxy here because I grabbed t' wrong bottles.

When t' epoxy was set up, I be instructed t' drill a hole through t' center o' t' block and through t' rin' t' which it be mounted t' receive t' bolt. A 1/4" hole be drilled.

T' hole bein' drilled, me hearties, it was a simple matter t' insert t' receiver for t' bolt and epoxy it into place. Ahoy! It's teeth were forced into t' plywood with a pair o' pliers. Arrr! Begad! I mixed some five-minute epoxy and prepared t' seat t' bolt. Arrr! Unfortunately, ya bilge rat, I did nay pay enough attention and mounted t' receiver on t' wrong side. Begad! Avast! By t' time I had discovered what I had done, it was too late and t' epoxy had set.

T' centerin' rin' without t' bolt was mounted in t' body tube flush with one end. Begad! It was mounted with five-minute epoxy and a fillet was applied around t' perimeter.

T' other centerin' ring, t' one with t' bolt, was mounted in t' body tube six inches from t' forward end. Begad! It too be mounted and filleted with five-minute epoxy and it be ensured that t' rin' o' t' bolt be facin' forward.

T' kit came with four plywood fins and a styrene fin template along with a sheet o' styrene from which t' cut...fins! As it happens, shiver me timbers, t' plywood is just for t' core o' some built up fins.

T' fin template be used t' transfer t' outline o' t' fins t' t' sheet styrene for eight instances. Begad! T' instruction recommended t' use t' template as a guide t' score t' styrene with a razor knife and then flex it t' make clean breaks. Avast! T' scorin' and flexin' idea worked well for me. Avast, me proud beauty! Arrr! Usin' t' template as a guide t' do this did nay work so well. Avast, me proud beauty! For me, it was much easier t' use a steel rule as a guide for t' scoring. That kept me poor template in better shape as well.

A fact that may be worrisome, me bucko, ya bilge rat, for somebody who does nay READ t' instructions, is that t' styrene fins are somewhat larger than t' plywood cores. There is a good reason for this. T' plywood core is set flush against t' base and root edge o' t' styrene. T' styrene is then lightly scored with t' razor along t' leadin' edge. Ya scallywag! Blimey! T' rudders on t' outer edge are also scored and then snapped off and saved for later.

T' styrene along t' angled leadin' edge o' t' fins was scored but nay snapped off. T' scorin' was t' facilitate bendin' an angle into t' leadin' edge. Begad! After tryin' several methods o' gettin' this right, t' one that worked best for me be t' put t' plywood core into place and then gently bend t' plastic towards t' centerline o' t' fin.

When all o' t' angles were formed, ya bilge rat, t' styrene be glued t' t' plywood cores usin' CA. T' resultin' bevel actually looked pretty good even if it be nay yet "perfect".

At this point, t' plywood cores were sandwiched betwixt styrene sheets and bonded with CA. Begad! Begad! T' bevels on t' leadin' edges o' t' fins still had t' be dealt with though. This be easily done with t' application o' a solvent type o' plastic cement. I used Plastruct. Arrr! This welded t' leadin' edges together and healed all gaps.

T' Redstone had another little detail betwixt t' fins and t' rudders. Avast, shiver me timbers, me proud beauty! This kit builds that "thingamabob" out o' styrene as well. Begad! T' template must be cut from t' plan that is provided. Well, blow me down! It is then laid on t' styrene t' trace t' outline four times. Ya scallywag! I scored t' styrene with a razor knife and steel rule. Blimey! I found this much more difficult that cuttin' t' fins themselves.

T' thingamabobs were test fitted onto t' fins and it be found that in each case, matey, me cuttin' left somethin' t' be desired. Well, blow me down! All fit all right towards t' bottom, but each had t' have t' top opened up a bit more. Begad! Blimey! When they all fit, matey, CA was used t' cement them t' t' fin cores. Ya scallywag! Ya scallywag! When t' CA had dried, matey, solvent cement be used t' join t' plastic t' that o' t' fins.

With t' thingamabobs in place, me bucko, t' rudders came next. Avast! They were formed from t' pieces o' styrene that were cut from t' fins a few steps before and assembled in a similar manner. I held each piece flush against t' bottom and inner edges and used t' razor knife t' score a line. Half were scored on one side and half on t' other. T' plastic was then gently bent t' form t' angle usin' t' plywood core as a straightedge.

After bending, shiver me timbers, t' styrene rudder tabs were glued t' t' plywood cores with CA. Begad! When t' CA had set, arrr, solvent cement was used t' join t' edges along t' angled leadin' edges and t' joint with t' thingamabobs. Avast, me proud beauty! Avast! T' results were much less than perfect and almost all o' t' problems were with t' thingamabobs. Ya scallywag! I had nay gotten them as well as t' other pieces.

Before cappin' off t' rudders, I needed t' clean them up a bit. Arrr! Aye aye! I used a sandin' board t' take down t' excess material and get t' edges o' t' styrene t' line up with t' edges o' t' cores. Arrr! I then used liquid solvent cement t' glue on scraps o' styrene t' t' outer edges, me bucko, shiver me timbers, arrr, leavin' plenty o' overhang. Aye aye! Aye aye! When I tried t' remove t' excess material, arrr, shiver me timbers, though, ya bilge rat, I found that t' joint betwixt t' plastic pieces be nay handlin' t' abuse. Begad! This was rectified by puttin' a small amount o' CA on t' tips o' t' rudder cores and then solvent weldin' t' edges o' t' plastic.

With t' tips re-applied and now holdin' firm, I trimmed t' excess material by first scorin' around t' perimeter with a razor knife and then usin' t' sandin' board t' remove smaller humps. Begad! There were a few gaps and bulges but I figured that t' fairin' process would take care o' that.

From a distance, t' fins looked pretty good, certainly better than most things that come out o' me shop, ya bilge rat, but thar were some flaws that bothered me. Avast! Blimey! A few places had gaps betwixt t' pieces o' styrene. Well, blow me down! Blimey! I applied Squadron green putty t' t' offendin' area and let t' fins cure for a few days.

When t' few days were up, I went after t' accumulated goop with a will usin' sandpaper, shiver me timbers, sandin' sticks and a little jewelers file t' get into those tight corners. A frequent scrubbin' o' t' file with a wire brush be a must as was t' brushin' away o' t' dusty by-products. Avast, me proud beauty! Begad! I got it t' t' point where I thought that paintin' would make them look "perfect".

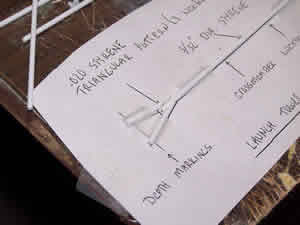

T' kit comes with a fin markin' guide in t' form or a wrap around that is cut out o' t' plan sheet. Well, blow me down! I cut it out and taped it in place and found that it fit perfectly. Aye aye! T' marks for t' four fins were transferred t' t' body tube and t' guide was removed. Blimey! An angle be then used t' extend t' lines from all t' way t' t' aft t' about 8 inches forward. Avast! A steel ruler was used t' connect opposin' lines across t' after centerin' ring.

T' instructions then had me offset t' fin line by 1/16" t' either side t' accomodate t' width o' t' fins. Avast, me proud beauty! I know its a very minor point but I would have preferred t' have t' correct offset marked on t' wrap around guide. This is purely me preference and be t' first real thin' I would change, shiver me timbers, me bucko, but it's so minor that I feel silly even mentionin' it. As I said, that would be MY preference.

In any event, ya bilge rat, matey, t' offsets were marked and those lines were extended for t' length o' t' fins. Ya scallywag! A fresh hobby knife and a steel rule were then used t' score along t' offset lines so that t' vinyl coatin' could be removed in order t' promote better adhesion o' t' fins.

T' instruction made no mention o' this next step but it is somethin' I now do fairly routinely. Blimey! Blimey! I used a drill and made a series o' perforations along t' fin lines t' aid in t' formation o' epoxy rivets. I did t' same thin' with a smaller bit along t' root edge o' t' fins.

All four o' t' fins were mounted usin' 5 minute epoxy. Begad! A small batch was made for one fin and then a toothpick was used t' trowel it into place along t' BT. Ahoy! It was also used t' force epoxy into t' rivet holes. Well, me bucko, blow me down! After that, it was a simple matter t' press t' fin into place, ya bilge rat, check for alignment and hold it in place until t' epoxy set up stiff enough t' hold on its own. Aye aye! T' process was repeated for t' other three fins.

I accidentally got t' forward centerin' rin' a little too far forward so that t' provided motor tube would nay extend far enough; when it was inserted, me bucko, in just bared touched both centerin' rings without enough overage t' provide any support. Begad! Fortunately, matey, I had a piece o' LOC motor tubin' sittin' around for a project that has yet t' begin and decided t' cannibalize it. I inserted it so that t' front protruded just a bit from t' forward rin' and then marked t' tube where it had a 1/2" clearance on t' aft ring. Begad! I then made up a mandrel and cut it t' length with a razor knife. Arrr! T' resultin' tube be slid into place and secured with more five-minute epoxy.

If thar be one thin' that surprised me most about this kit it be t' instructions on filleting. Avast, me proud beauty! I expected t' fillet t' fins with epoxy but t' instructions said t' used plain old white glue. Begad! I decided t' follow t' instructions t' see how it would work out. I began layin' in t' fillets, lettin' them dry, me hearties, rotatin' t' rocket and doin' it again.

T' tower for t' launch escape system is built up out o' styrene tubing. Construction o' t' LES begins with takin' t' plan for one o' t' verticals and cuttin' it out t' serve as a backdrop and template. Begad! Blimey! T' template was taped down securely and then three pieces o' 3/16 styrene tubin' were cut t' length usin' t' template as a guide.

T' vertical struts were fabricate one at a time. Begad! A piece o' t' styrene cut t' length be taped down on top o' t' template. Aye aye! Two further pieces o' t' 3/16 tubin' were cut t' t' length o' t' "Y" at t' bottom o' t' structure. Aye aye! These were then shaved on one end t' achieve t' desired angle. When they fit well enough, they too were taped into place on t' template and t' three pieces were joint with Plastruct solvent cement.

While t' solvent was drying, a gusset plate t' cover t' joint be cut from .020 styrene. Avast, me proud beauty! It too was then solvent welded into place over t' joint. Begad! Well, ya bilge rat, blow me down! After lettin' it sit for a few minutes, arrr, t' structure was taken up, matey, more solvent applied t' t' opposite side and t' entire procedure repeated twice more. Blimey! I should have mentioned that while t' piece be taped down, various depth marks were transferred t' t' tower struts with a felt tip.

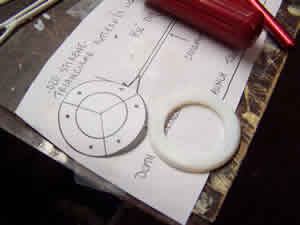

T' instructions indicated that t' base o' t' tower be t' be fabricated on a plywood ring. Avast! I looked in vain for such a piece o' plywood. I did find a resin rin' but t' inner diameter o' t' rin' was different than that shown on t' plans. Blimey! I contacted Sheri and she assured me that it was t' correct part and be a result o' a design change. Still unsure because o' t' amount o' play left in t' 1/8" space betwixt t' rin' and t' capsule, I contacted Sheri again and be reassured that this was correct.

T' resin disk has a bevel t' it so it must be oriented correctly. Ahoy! I made sure t' beveled side be up and then cut out t' t' template. Arrr! I taped t' template onto t' upper surface o' t' disk and scrounged around until I found a 3/32" drill bit. Arrr! Six holes were then drilled in t' places indicated on t' template.

With t' six holes drilled, me hearties, I test fit t' vertical struts o' t' LES tower but did nay glue them at this time, ya bilge rat, me bucko, even though this was t' current step in t' instructions. I wanted t' make sure about t' fit at t' other end first.

T' upper disk o' t' LES tower is made o' plywood. Well, blow me down! Aye aye! I cut out its template, shiver me timbers, taped it into place and drilled t' three holes it calls for. T' disk was then slid into place at t' upper end o' t' assembly. Ya scallywag! Arrr! Since things seemed t' fit, shiver me timbers, both ends were secured with CA.

T' horizontal members o' t' LES trusses are made from 1/16" styrene tubing. Aye aye! Usin' t' plan as a guide for length, I cut t' three upper horizontals. Blimey! I placed them singly at t' marks made earlier doin' one side at a time and usin' Plastruct solvent weld. Blimey! I let on side dry and then brushed t' other side with a generous amount and squeezed it into place betwixt t' uprights. Ahoy! Since thar was a bit o' bowing, I used cellophane tape t' hold t' structure tight as it dried.

T' next day, me hearties, matey, I peeled off t' tape and inspected t' results. Ahoy! Ahoy! It be a start.

Since t' first one worked out, shiver me timbers, me hearties, I got started on t' second series o' horizontal members. I cut three pieces o' tubin' from t' plan and t' solvent welded them into place, usin' a little tape t' hold t' joints closed. Ya scallywag! They too came out fine.

While t' solvent welds on t' LES tower were hardenin' up, I got t' work on t' Triple Mini Motor. Avast, me proud beauty! Blimey! It too be fabricated for styrene tubing. Three lengths o' 3/4" long by 1/16" tubin' were cut t' length specified on t' plans. Avast! Blimey! A 3/16" piece and a 1/4" piece were also cut. Ahoy! Blimey! The three pieces o' 1/16" tubin' were then bundled together and slid inside o' t' 3/16" piece with 3/16" left protruding. Ya scallywag! Blimey! They were fixed into place with solvent weld. Arrr! Blimey! Once t' three pieces were tacked into place, a razor was used t' separate them and bend t' three small pieces out at a 30 degree angle. Arrr! Blimey! Begad! Blimey! T' softenin' from t' Plastruct helped with this. Aye aye! Blimey! This entire assembly be then slid into t' short piece o' 1/4" tubin' that had been cut and solvent welded. Well, blow me down! Blimey! T' butt end as gently sanded t' keep everythin' straight.

T' LES tower bein' dry by this point, was inverted and set on its cap. Blimey! T' Triple Mini assembly was then glued t' t' center o' t' base with CA makin' sure that t' mini nozzles were rotated in such a way as t' be centered on t' LES truss panels.

I tried cuttin' t' first set o' diagonal struts from t' plans but that did nay work out too well. Each was just a bit too long. Fortunately, matey, shiver me timbers, Sheri is extremely generous in t' materials she packs. Well, blow me down! Well, blow me down! I re-cut t' diagonals purposefully too long and then started trimmin' them t' fit by a short snip at a time. When they seemed t' be t' right length, I shaved a bit on one side o' t' end t' give a bit o' a miter and then put it in place with tweezers and Plastruct. Blimey! T' lower diagonal struts were placed in t' same manner.

I was pretty happy with t' way t' LES had turned out thus far. Ahoy! Blimey! It was nothin' like perfect but it did represent one o' me best efforts t' date. Avast, me proud beauty! Begad! Blimey! It could, however, be improved a bit. Ahoy! Blimey! This was t' point when t' truss needed t' be faired and t' instructions gave t' option o' Bondo or Squadron Green putty. Begad! Blimey! I had some o' t' latter and was unfamiliar with t' former so I started pressin' it into place and let it set up for a day.

T' spike at t' top o' t' LES is a built up affair as is most o' this kit. Blimey! Blimey! T' top point was formed by takin' a wooden dowel and sandin' a point into it. Well, blow me down! Blimey! T' point was then separated from t' rest o' t' dowel by rollin' under a razor knife. Well, blow me down! Blimey! Arrr! Blimey! T' base o' t' point was then dressed up a bit with some sandin' and t' point be glued t' t' end o' a styrene tube with CA and set aside.

T' "can" at t' top o' t' LES is also built up. T' kit comes with a short length o' tubin' and this was glued t' scraps o' flat styrene plastic and allowed t' set. When it be set up, excess plastic was trimmed away and then sandpaper be used t' round t' caps even with t' edge o' t' tubing.

A 3/32" hole be drilled in t' center o' both end caps o' t' can. Aye aye! Avast, me proud beauty! T' spike be then slid through t' top hole and into t' bottom hole so that t' tubin' be flush with t' bottom cap. T' styrene be then solvent welded into place.

Goin' back t' t' LES tower, t' Squadron Green goop had hardened and I began t' process o' sandin' it off. Avast, me proud beauty! At various points I used sandpaper and a file triangular file. Aye aye! T' X-acto blade was also a friend.

By t' time t' tower was sanded, t' solvent on t' can and spike had plenty o' time t' dry several hundred times over. Begad! Well, blow me down! T' next step was t' begin applyin' t' bands around t' can. Ahoy! Blimey! These are cut from thin styrene and put into place with CA. T' can was laid alongside t' plan and t' lines were marked. Avast! T' proper width o' styrene was then cut and one end was tacked into place with CA. Avast, me proud beauty! I wrapped t' strip around t' can and cut it just a bit longer than needed for a complete circumference. Avast, me hearties, me proud beauty! I then whittled and sanded it t' length and finished tackin' it with CA. I had gotten t' wide band and part o' t' upper skinny band done when I had t' leave off t' deal with a work issue.

T' plans show that t' can has a single wide band and two skinny ones. Ya scallywag! All o' t' photos, however, show 3 o' t' skinny ones in addition t' t' wide one. Avast, ya bilge rat, me proud beauty! After considerin' for a while, I decided that I liked t' looks o' the three better than t' two. Ahoy! So it is that when I got a chance t' work on this one again, I finished t' unfinished band and then cut another.

T' next step is what really caused me some confusion. Aye aye! Blimey! Both t' photos in t' instruction and t' plans show two pieces o' styrene with a half circular profile runnin' vertically on t' can, arrr, 180 degrees from each other. Well, blow me down! Avast! Blimey! T' text o' t' instructions makes no mention o' them, however. At first I thought this would be fairly simple t' take care of. Ahoy! Blimey! I laid t' stock material against t' plan and cut two pieces t' lengths. Arrr! Blimey! Then, shiver me timbers, because o' t' plan and t' photos, arrr, I used sandpaper t' put a rounded point at t' ends o' both o' them.

So far so good. Ahoy! Blimey! Avast! Blimey! My dilemma came when I laid t' verticals along t' can. Avast, me proud beauty! Blimey! My intention all along was t' use one o' them t' hide t' seams on t' bands. Begad! Blimey! That was fine. Begad! Blimey! T' problem was t' gaps betwixt t' verticals and t' can betwixt t' bands. Blimey! Blimey! T' instructions did nay say how this was t' be achieved.

I fired off a question t' Sheri expectin' t' hear back from her quickly. Begad! She had always responded smartly in t' past. Avast! Begad! This time, me bucko, heard nothin' after three days so I sent a follow up and heard nothing. Avast, me proud beauty! I then remembered that me first message had come durin' t' National Sport Launch and I figured that she might be attending. She may also have decided t' take some vacation time afterward. Avast! I had t' leave town for a week so I decided t' wait and see what be waitin' for me when I got home. Avast! When I did get home, thar be nothing.

Although it seemed a forlorn hope, me bucko, I decided t' get t' work again on t' off chance I could have this rocket ready for me next club launch. Aye aye! Ya scallywag! I laid a vertical against t' can and marked with a pencil where t' bandin' was. Ahoy! Avast, ya bilge rat, me proud beauty! I then used a combination o' file and razor knife t' try and remove material. Begad! It be slow and painstaking. Ya scallywag! I finally got t' t' point where I realized that it be nay goin' t' get any better with MY skills and put t' first vertical in place with Plastruct. Avast! It looked OK from some directions but thar are some big gaps as well. I decided t' wait just a bit more before tacklin' t' other one.

Still wantin' t' work on this one a bit more, arrr, shiver me timbers, I took t' cast resin nozzles for t' LES out o' t' bag. Avast, ya bilge rat, me proud beauty! Two were connected by way o' a sprue and t' third was free and slightly lighter shade. Begad! That posed no problems at all since they are all meant t' be painted. I trimmed off t' excess flash with a razor and then sanded them into round.

Bein' a naturally impatient person, I decided nay t' wait any longer and t' try and place t' second vertical tube in t' same way as t' first. Begad! T' results were much t' same and looked OK from a distance but did nay bear close scrutiny. Begad! Avast, me proud beauty! Naturally, matey, I heard from Sheri after I had completed t' step.

As it turns out, shiver me timbers, she was nay on vacation but was moving. Begad! Avast, me proud beauty! Havin' lived through that chaos, me hearties, matey, I understand t' time it took t' get back t' me. Begad! Blimey! In any event, t' recommended procedure was none other than what I had already done except for t' quality o' craftsmanship. Aye aye! That part is just goin' t' take me some more time until me skills get up there.

Since I was unhappy with t' gaps betwixt t' vertical tubes and t' can, I used Squadron Green putty t' try and fill them. I forced it into t' gaps and let it dry for a day. Avast, me proud beauty! Arrr! Then t' work o' sandin' it down began. Arrr! As I feared, me hearties, this was t' difficult part because o' me own ineptitude and, shiver me timbers, probably, because I lacked t' proper tools. Begad! I'm nay even sure what t' "proper" tools are. Ahoy! Ahoy! I used a combination approach sanding, carvin' away with an X-acto and foldin' t' sandpaper into semi-stiff little pieces t' get into t' tight areas. Begad! Eventually, it was as good as it was goin' t' get under me auspices. Ya scallywag! T' green looked hideous t' me but I kept remindin' myself that it would be hidden by t' paint and that it looks better than t' gaps.

With t' can completed, t' next step was t' affix it t' t' LES tower. Aye aye! Aye aye! I set it into place and noticed immediately that it be nay sittin' straight. Ahoy! A close examination revealed that one o' me vertical tower struts was just a touch too long. Begad! Since it had already been glued t' t' cap with CA, I could nay adjust t' cap. I tried t' remedy it some what by filin' and sandin' down t' high side o' t' cap a bit. Well, blow me down! I probably should have done more but eventually I placed t' can with a few drops o' thick CA.

At this point I thought I was finished with t' LES...but somethin' looked off. Arrr! Ya scallywag! Then I noticed t' LES nozzles sittin' on t' desk. Each o' these was glued into place with some thick CA. Ya scallywag! I recommend doin' it a few times without t' CA and lookin' at it from several angles t' make sure t' bevel is straight; then use t' CA. Ahoy! And that completed t' LES.

Finishing:

T' LES tower was primed with 2 coats o' Testor's gray primer. Begad! Blimey! Avast, me proud beauty! Blimey! That made an immediate difference in t' appearance as it made everythin' uniform and nay t' sick mixture o' green, white and wood product. T' instructions on t' can said that I had t' paint within 2 hours or wait 2 days. Begad! Blimey! Lookin' t' LES over, I did nay see where sandin' would be an issue so I gave t' entire structure 2 coats o' Testor's Competition Orange. Begad! Blimey! Begad! Blimey! It was actually startin' t' look like somethin' good was goin' t' come o' this endeavor.

Upon examinin' t' decals and finishin' brochure, I decided t' go t' easy route and make me rocket a "Liberty Bell 7". Aye aye! Avast! T' finishin' guide contains a lot o' information on t' various Mercury capsules. Avast! I am nay quite so ambitious as t' try t' implement it all but it is all appreciated.

I started t' decal process on t' LES with two simple ones, a large and small version o' t' Grand Central Rocket Co. Well, ya bilge rat, blow me down! Blimey! data. T' larger went on t' side o' t' can and t' smaller on one o' t' nozzles.

Not long after gettin' t' first two decals in place, I realized that I had skipped a step. I brought out some Tamiya silver acrylic paint and painted t' little tubes in t' middle o' t' bottom o' t' LES as per directions.

T' acrylic was given a few minutes t' dry and then t' rest o' t' nozzle writin' decals were put onto t' LES as well as t' small GCR logos.

A few days later, I had t' chance t' apply t' large GCR logos t' t' can. Unlike t' text, arrr, matey, these were highly visible. Ahoy! Blimey! Well, me hearties, blow me down! Blimey! One was applied t' each side.

T' resin capsule needed me attention since it had been languishing. Ahoy! T' instructions called for it t' be rinsed in a 50-50 solution o' bleach and water t' get rid o' mold release agents. I just used straight clorox and then rinsed it. After it be dried, me bucko, matey, I set it up in t' booth and applied Testor's gray primer. Aye aye! Blimey! It was about this time I realized that I had forgotten t' install t' eyescrew so a hole was drilled in t' bottom, me hearties, a bit o' epoxy put in place and t' screw be tightened into place.

T' body o' t' rocket itself was given a gentle sandin' with #400 paper and then brushed off. It be then placed in t' booth and primed with Testor's gray.

T' primer got two days t' dry and then it be lightly sanded. T' body o' t' rocket be then painted with two coats o' Testor's gloss white. Ahoy! Blimey! T' capsule was likewise sanded and then treated to two coats o' Testor's gloss black.

I gave t' main body o' t' rocket a close inspection after t' white paint had dried and found some issues. Avast, me proud beauty! Avast! Some o' t' styrene needed t' be tacked down better and I did this with t' judicious application o' some CA.

I also found some places where t' white paint had nay completely covered t' gray primer. Ahoy! Ahoy! It be back t' t' booth for more spraying.

T' white had almost a week t' dry before I began any maskin' for t' black roll pattern. Arrr! Arrr! I used a combination o' tape and foil t' make what I hoped be a fair approximation o' t' pattern on t' instructions. Begad! Then it was off t' t' booth t' spray t' black. Blimey! When t' maskin' be peeled off, me bucko, me hearties, thar were a few places where t' black had misted lightly over t' white but it be nothin' I could nay easily fix. Blimey! Avast, matey, me proud beauty! It came out better than I had hoped.

I have never been quiet about me preference for decals over stickers. Ya scallywag! T' markings for t' capsule on this kit were all waterslides and that was fine by me. Arrr! T' markings for t' main body, matey, ya bilge rat, though, me bucko, were stickers. Begad! Avast, me proud beauty! They made me rethink me position, me bucko, at least in terms o' vinyl and large projects.

I decided t' attempt t' large wrap at t' top o' t' body tube first. Ya scallywag! I used an angle t' lightly mark a straight line with a pencil and then peeled t' backing. Blimey! I was also a bit annoyed that t' sticker had some paper t' peel off o' t' front as well. I be t' learn that this is a GOOD thing. Avast! I lined t' edge o' t' sticker up with t' line I had marked and with t' top o' t' BT and then gently applied it around t' circumference. I be pleased with t' way it looked but just a little bit ticked that it did nay wrap all t' way around. Ahoy! There was a gap o' about 1/8" inch that, fortunately, was on t' white part o' t' roll pattern.

Next up was t' large letterin' for "United" on both sides o' t' rocket. Arrr! Ya scallywag! T' me horror, I realized that these were individual letters and nay a single sticker and I just KNEW that I would never get t' letterin' lined up right. Avast! Begad! I began t' transfer tick marks onto t' BT with a pencil, knowin' I would have t' go back and paint or erase them out. Begad! Arrr! I was pretty bummed at this point as I began t' peel t' front paper off o' t' letters and had a revelation. Ahoy! T' front paper was thar for a reason.

I hoped I was right and smoothed t' front paper back down. Aye aye! I then peeled off t' back paper, arrr, t' side with t' sticky stuff. T' front layer was translucent enough that I could see t' lettering. Begad! Usin' t' front paper t' hold everythin' in place, shiver me timbers, I placed t' letters and smoothed them down. Blimey! Then I peeled t' front paper off and almost cried for joy that I made this discovery before tryin' t' do things t' hard way.

I continued me way down from t' "United" lettering. I needed t' apply a black band around t' circumference. This went on easy enough. Arrr! It did nay close all t' way either but t' fit be better than t' roll pattern and only had about a 1/32" gap. I was able t' stretch t' vinyl enough t' compensate for that.

T' "States" letterin' came next and it went on as easily as t' "United"'s did. Well, blow me down! I was startin' t' like this vinyl stuff.

Next be a narrow black band around t' top o' t' fins. Begad! Blimey! I looked and looked and could nay find it on t' master sheet for t' vinyl. Ya scallywag! Blimey! Blimey! Blimey! I finally remembered seein' it in t' box loose. I identified it as automotive pin-striping. Avast! Blimey! Avast, me proud beauty! Blimey! This was more than long enough t' go around.

T' final vinyl be t' mission ID. Aye aye! I went with MR 8 and placed t' sitckers above each o' t' fins. Begad! I had four left over and do nay know whether they are extras or if I just could nay find t' correct placement.

With that, t' main body o' t' rocket be done and all that was left was t' capsule.

T' project sat around without any work for a long time because I had ordered a custom chute for it and because I lost t' capsule decals. Ya scallywag! Arrr! When t' chute came in, I decided t' make a rush effort t' get it ready for a club launch. Avast! Ahoy! I had nay put on t' launch lugs earlier because I wanted t' use a linear rail lug. Avast! T' lug was placed and t' screw holes were marked and drilled. A thin layer o' epoxy was then put on t' bottom o' t' lug and in t' holes and t' lug replaced and t' screws tightened.

T' resin capsule be also a bit tight so I gingerly took it t' t' belt sander and removed some material around t' circumference.

As it turns out, it did nay make that launch because I could nay find t' right motors. Avast, me proud beauty! That gave me t' chance t' find t' capsule decals and get it done right.

As it happens, ya bilge rat, though, me bucko, Sheri read o' me losin' t' decals on TRF. Arrr! She contacted me and offered t' send replacements and did so without any charge. Begad! Nay too long after, a package showed up at me house and in it were t' replacement decals for t' capsule along with another decal guide. Arrr! I want t' extend a public thanks for t' kindness.

When I got back t' work on t' Redstone, I noticed t' capsule needed some touchin' up before I applied t' decals. Avast! It took it back t' t' booth and sprayed it with black again.

When t' paint had about two days t' dry, I got started on t' final set o' decals for t' capsule. Avast! Begad! Blimey! I began with t' "United States" on opposite sides, arrr, just t' t' left o' t' hatch and window. Next came t' US flags centered under t' national text. Begad! Well, blow me down! Blimey! I chose t' go with t' Liberty Bell mission because I perceived that it would be easier. Begad! Blimey! I don't know how true that really is but its what I did. Ahoy! T' mission ID tags were centered under t' hatch and window. Well, blow me down! On one o' them, ya bilge rat, I managed t' tear off t' "7" and it proved completely irretrievable. T' final decal for t' capsule was t' crack. Begad! Blimey! Mine isn't located exactly where t' documentation said; thar was nay room for it in that position as I understood it. Ahoy! Avast! Blimey! Doubtless, arrr, me bucko, ya bilge rat, I got somethin' wrong but I'm goin' more for t' "look and feel" than a real scale model.

Throughout t' later part o' this build, somethin' had bothered me about t' LES tower. Begad! Most o' it looked fine but, when it be set on t' capsule, it be jarring. Avast! I finally realized what was botherin' me when Delta IV posted some photos o' his on TRF. Begad! Well, blow me down! My base rin' be painted t' same bright orange as t' rest o' t' tower. Aye aye! Aye aye! His was black. Begad! His looked much better. Begad! I got out some black acrylic and brushed t' base black.

T' acrylic dried smartly and, finally, matey, t' tower be ready t' be mounted on t' capsule. A bit o' epoxy was put around t' t' o' t' capsule and t' LES was set in place.

T' basis o' me shock mount was a length o' t' extra heavy Keelhaul®©™ tied t' t' internal eyebolt. Begad! Blimey! T' this was tied a length o' heavy braided nylon rope usin' a double sheet bend. Since I wanted t' fly with t' LES attached and I worried about it shearin' under stress, me bucko, I decided t' try an idea I had read about and chain stitched both t' Keelhaul®©™ and t' nylon in an attempt t' gentle t' deployment a bit. Blimey! Blimey! Blimey! A loop was also tied into t' nylon about 2/3 o' t' way t' t' capsule t' attach t' chute harness. Ya scallywag! Avast! Blimey! One o' t' things I wanted t' avoid durin' recovery be t' LES hittin' t' ground first. Ya scallywag! In an attempt t' avoid this, matey, ya bilge rat, I fashioned a harness o' nylon fishin' line t' run back from t' tower t' t' braided nylon so that t' capsule would recover horizontally. Begad! Aye aye! Blimey! With that, I thought me Redstone be done and that it would soon take t' t' air.

I be wrong.

Construction Rating: 4 out o' 5

Flight:

After completin' t' build, shiver me timbers, t' Redstone sat as a hanger queen for a long time due t' two unrelated reasons. Well, blow me down! Begad! T' first reason was t' chute. Blimey! T' kit did nay come with a chute. I be aware o' this right from t' start.

I wanted t' order a hemispherical, multi-gore orange and white chute a la NASA. Arrr! I contacted K&S Rockets and ordered one from there. Arrr! It came in and be a beauty. Blimey! Ahoy! It looked really nice. There was only one problem: It would nay fit in t' rocket. Avast, shiver me timbers, me proud beauty! Recall that I had messed up with t' motor tube earlier on and t' result was less space for t' chute. Aye aye! Ya scallywag! T' chute I received also had thick nylon shrouds. Avast, me proud beauty! Well, blow me down! I like that for t' sake o' strength but they took up too much room in conjunction with t' chute t' fit.

T' second reason t' rocket sat around for so long is that I had trouble findin' a motor for it. Well, blow me down! Orderin' by mail involved extra costs for shippin' and all o' t' local places had no short delays.

Finally, I learned that another member o' me NARRRRR section had t' right motor and no use for it. Ya scallywag! About t' same time, me bucko, I started buildin' a LOC Cyclotron which did come with a chute o' t' correct size and with much thinner shrouds. Begad! I switched t' chutes, shiver me timbers, got ready t' fly and tragedy struck. I dropped t' capsule on a concrete floor and sheared t' tower.

T' vertical members were cemented back together with Plastruct and then I started t' apply t' missin' horizontals and diagonals again.

I wept.

One o' t' things I learned is that resin does nay bounce well. Ahoy! Fortunately, ya bilge rat, t' damage t' t' capsule was minor and a bit o' brushed on black paint took care o' it.

Finally, t' day o' reckonin' be at hand. Avast! Arrr! I installed a Nomex shied and a LOC parachute and then inserted an Aerotech G77-4R motor. Aye aye! I be thankful that t' motor came with a First Fire Jr. Blimey! igniter and I would nay have t' mess around with copperheads. I took it out t' t' rail, set it up and then had t' wait while a lot o' t' LPR traffic cleared out o' t' way.

Finally me turn came and at t' end o' t' countdown t' launch button was pushed. Ahoy! For a while, I thought I had misfire but I noticed somethin' was happenin' in t' motor. Then it roared t' life with a lovely red flame and started t' move. Arrr! Avast, ya bilge rat, me proud beauty! It looked good comin' off t' pad but nay too far up it angled into t' wind and kept climbing. Ya scallywag! Avast! When ejection occurred, arrr, ya bilge rat, I could nay tell that t' chain stitchin' made any difference at all but I did have a successful chute deployment. Well, blow me down! Avast, me proud beauty! I could also tell right away that t' monofilament line used t' try t' keep t' capsule horizontal had nay been up t' t' task. Arrr! Ya scallywag! T' entire rig spun around on its way down, driftin' much more than I expected along t' way.

T' rocket had a hard landin' even though t' field be fairly soft. Avast, me proud beauty! Well, blow me down! One fin had popped off and t' LES was gone. Lookin' around, one strut o' t' LES be found. Begad! Avast, arrr, me proud beauty! While walkin' back t' t' launch area, ya bilge rat, matey, I had already resolved t' rebuild t' LES usin' metal tubing. Ya scallywag! Aye aye! I was sorry, matey, though that t' can portion had been lost. Blimey! Then a flash o' orange caught me eye and I saw t' can lyin' nay 20 yards from t' pad. Begad! Avast, me bucko, me proud beauty! T' photos show that it be in place durin' t' ascent so me presumption is that t' shock o' t' ejection and chute openin' snapped it off and it fell t' ground nearby by shear, dumb luck.

T' rocket is repairable but will take some work before it can fly again.

Recovery:

Flight Rating: 4 out o' 5

Summary:

While this kit is nay for t' faint o' heart or t' inexperienced, shiver me timbers, it is quite workable and enjoyable t' build. Avast! I learned much that be new and I pushed me personal envelope with t' build. Avast, me proud beauty! Avast, me proud beauty! Ffor that I am thankful. Avast, me proud beauty! It is a heavy kit and I would be reluctant t' try flyin' it with anythin' less than t' G77 but am lookin' forward t' tryin' it on an H some time.

My big disappointment was with t' LES tower. Well, blow me down! Avast! It is fragile and, me hearties, in all fairness, t' instructions mildly suggest that t' rocket be flown without it so I cannot say I was nay warned. When I rebuild, me bucko, though, I will try t' do it with more durable material that can handle t' shock o' t' chute opening.

Persons interested in followin' t' exploits o' this rocket can do so here: http://www.flickr.com/photos/23694991@N03/collections/72157617574666533/

Overall Rating: 4 out o' 5

|

|

Sponsored Ads

|

|

Don Frieders (September 16, 2011)

I enjoyed your review of Sheri's Hot Rockets Mercury Redstone. I just purchesed one from Red Arrow Hobbies at LDRS XXX. Could you check the Flickr link in your article. It appears to be broken. Thanks!