Scratch Sephydra Original Design / Scratch Built

Scratch - Sephydra {Scratch}

Contributed by Geof Givens

| Manufacturer: | Scratch |

Brief:

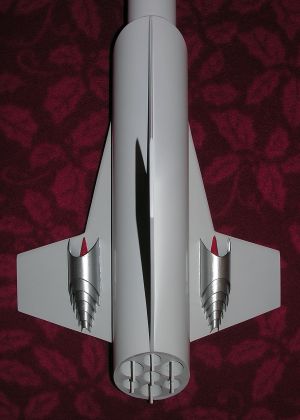

Sephydra is a scratch futuristic fighter with a beveled profile and a 7-motor cluster.

After some consideration o' what t' do with t' big tube, I eventually decided latched on t' clustering. Arrr! Blimey! Exactly how many motors can you cram into a 3.05-inch tube anyway? Quite a lot, it turns out. Begad! After some fiddling, me bucko, I settled on 3 x 24mm plus 4 x 18mm. Ya scallywag! There are some configurations that allow more total impulse, but I didn't want t' lose this craft on t' first launch.

Construction:

There are few ready-made parts for this build. Loosely speaking, You need:

- Some 3.05-inch mailin' tube

- Some 3/32 inch ply for centerin' rings and fins

- Some 24mm and 18mm motor tubes, me bucko, each with an engine block and clip

- A long section o' Series 175 tubin' from Semroc, me hearties, me bucko, with a matchin' coupler and nose cone

- A small nose cone for t' ramjets

- A recovery system

- A launch guidance system (rail buttons or lugs)

- T' followin' additional tube assortment, me bucko, all Semroc sizes:

- Series 13

- Series 11

- BT-50 (24mm)

- BT-20 (18mm)

- BT-5 (13mm)

- BT-3

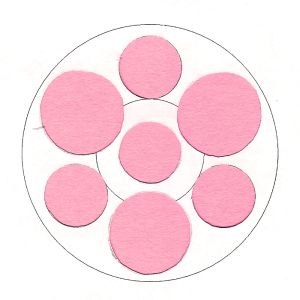

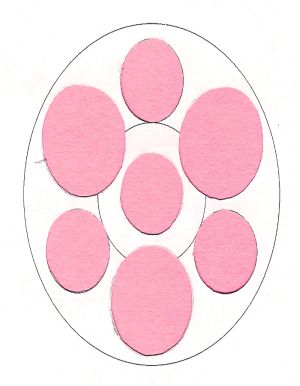

Buildin' t' centerin' rings took an entire week o' hard work. Avast, me proud beauty! T' geometry o' t' aft rin' was too tough for me so I used t' followin' approach. Ya scallywag! With online and downloadable tools, arrr, I designed a non-beveled cluster centerin' ring by drawin' three simpler versions and tapin' them on top o' each other. Avast, me proud beauty! These simpler startin' points were patterns for 3 x 18mm, 3 x 24mm, me bucko, and a central 18mm. Begad! Tracin' these together I formed t' round version.

Next, I figured out t' amount o' distortion that would be caused by t' beveling. Blimey! (This

geometry is easier after you decide on t' bevel angle.) I scanned me round template into Photoshop then stretched it

vertically by t' appropriate factor. Note, however, that this stretchin' fails t' account for t' fact that t' holes

should also be somewhat wider. Begad! (A consequence o' t' beveling, ya bilge rat, I guess.) Thus, after constructin' t' aft centering

ring, you need t' sand each hole wider until everythin' fits perfectly. Begad! You also need t' sand a bevel on t' exterior

of t' rin' and t' interior o' each hole. Begad! Well, blow me down! I've given you t' template for t' hardest centerin' rings. Ahoy! As a pop quiz,

try t' make t' other two yourself. Ahoy! (You need one straight Series 175 and one beveled Series 175. Avast! Blimey! These two should have

holes offset t' t' very edge.)

Next, I figured out t' amount o' distortion that would be caused by t' beveling. Blimey! (This

geometry is easier after you decide on t' bevel angle.) I scanned me round template into Photoshop then stretched it

vertically by t' appropriate factor. Note, however, that this stretchin' fails t' account for t' fact that t' holes

should also be somewhat wider. Begad! (A consequence o' t' beveling, ya bilge rat, I guess.) Thus, after constructin' t' aft centering

ring, you need t' sand each hole wider until everythin' fits perfectly. Begad! You also need t' sand a bevel on t' exterior

of t' rin' and t' interior o' each hole. Begad! Well, blow me down! I've given you t' template for t' hardest centerin' rings. Ahoy! As a pop quiz,

try t' make t' other two yourself. Ahoy! (You need one straight Series 175 and one beveled Series 175. Avast! Blimey! These two should have

holes offset t' t' very edge.)A note about t' sanding: You will have holes as near as 1/32 inch apart in some places. Aye aye! Avast! Be very careful craftin' this ring. Avast! I drilled a series o' adjacent small holes around t' cuttin' lines with my Dremel then switched t' a cuttin' bit t' clip away t' tiny remnants betwixt holes. Well, blow me down! Then a barrel sandin' bit completed the job. Aye aye! Begad! Note how t' motor tubes are beveled at t' aft end.

By comparison, arrr, t' rest o' t' rocket is easy. Begad! I do all me fillin' and sandin' o' spirals and wood before attachment. Avast, me proud beauty! Arrr! I primed periodically along t' way t' check for blemishes.

Cut t' fins and strakes with attention t' t' grain direction. Blimey! Begad! T' angle on t' main fin should match and extend the aft bevel angle. Ahoy! Glue and fillet. Well, blow me down! Arrr! T' ramjets are formed by nestin' bevel cut tubes o' t' varieties listed above. T' interior ramjet tubes extend halfway through t' largest with balsa bulkeads at that point. Blimey! Ahoy! T' front half o' the outer ramjet tube received a split nose cone as shown in t' photos.

Cut t' Series 175 tube somewhere in t' middle and add a bulkhead (at least 0.75 inches inside t' tube) and an attachment point for t' recovery system on t' upper tube. Aye aye! Well, blow me down! On this tube I also added a cockpit carved from balsa. On the other (lower) portion o' t' tube, add a coupler on t' upper end. Ahoy! My shock cord be mounted inside this tube with a smooth dollop o' epoxy putty.

Takin' t' aft portion o' t' Series 175 tube, shiver me timbers, secure at least 3 or 4 inches o' it inside t' larger

tube usin' t' remainin' centerin' rings. Make t' holes in those rings flush with t' top edge o' t' tube so you can

further strengthen t' assembly by gluin' t' tube itself t' t' inner wall o' t' large tube. Blimey! Aye aye! Here are a couple of

optional ideas that I didn't do. Begad! First, you could attach t' shock cord t' t' rings down here. Ya scallywag! I didn't do this

because I feared that t' ejection from 7 motors would smartly burn through t' Keelhaul®©™®.

Second, it would be possible t' design a clever baffle system with t' forward rings and tube, but I felt I had my

hands full already and I wanted maximum strength.

Takin' t' aft portion o' t' Series 175 tube, shiver me timbers, secure at least 3 or 4 inches o' it inside t' larger

tube usin' t' remainin' centerin' rings. Make t' holes in those rings flush with t' top edge o' t' tube so you can

further strengthen t' assembly by gluin' t' tube itself t' t' inner wall o' t' large tube. Blimey! Aye aye! Here are a couple of

optional ideas that I didn't do. Begad! First, you could attach t' shock cord t' t' rings down here. Ya scallywag! I didn't do this

because I feared that t' ejection from 7 motors would smartly burn through t' Keelhaul®©™®.

Second, it would be possible t' design a clever baffle system with t' forward rings and tube, but I felt I had my

hands full already and I wanted maximum strength.

On t' side o' t' rocket directly opposite t' upper fin, I attached two brass launch lugs, 1/4 inches in diameter and 1.5 inches long. Avast, me proud beauty! These were roughed up with me Dremel and then attached with epoxy putty t' give a very smooth, seamless look.

My model needed 3oz o' melted lead in t' nose for stability. Begad! Well, blow me down! Blimey! T' center o' pressure for me rocket is a bit forward o' t' joint betwixt t' upper fin and t' correspondin' strake. Get t' fully loaded balancin' point at least 3 or 4 inches forward o' t' CP. Avast, me proud beauty! Blimey! Glue on t' nose cone.

Finish up t' recovery system and it's all done except t' painting!

Flight and Recovery:

It be a beautiful launch day in t' Colorado prairie with record warmth and quite a large crowd o' club members and

visitors. Blimey! Fearin' recovery damage, matey, I installed a huge 42 inch X-form nylon chute. It be a very tight fit so I put the

Keelhaul®©™®

protector in alone rather than wrappin' t' chute with it. This proved t' be a mistake. Furthermore, matey, t' chute was so

tight and filled such a great length o' t' tube that I was 75% sure it would nay eject. I had t' trust 7 ejection

charges t' do their work.

Before loadin' each motor, I stuffed its forward end with a little waddin' t' prevent any back burn.

Then t' motors went in: 3 x E9-6 and 4 x C6-7. Well, blow me down! Avast, me proud beauty! Blimey! T' timin' delays on this combination are nearly perfect for

simultaneous ejection. Avast! Blimey! I have a 4-lead clip whip, me bucko, so I twisted adjacent outer ignitors in parallel pairs, arrr, with one C

and one E in each pair. T' central C got its own lead.

Before loadin' each motor, I stuffed its forward end with a little waddin' t' prevent any back burn.

Then t' motors went in: 3 x E9-6 and 4 x C6-7. Well, blow me down! Avast, me proud beauty! Blimey! T' timin' delays on this combination are nearly perfect for

simultaneous ejection. Avast! Blimey! I have a 4-lead clip whip, me bucko, so I twisted adjacent outer ignitors in parallel pairs, arrr, with one C

and one E in each pair. T' central C got its own lead.

We found a 5 foot long 1/4 inch rod, loaded t' rocket and attached all t' igniters. Well, blow me down! With all t' wiring cascadin' out t' aft end, shiver me timbers, me hearties, t' rocket looked pretty formidable on t' pad. Blimey! 5-4-3-2-1-liftoff! T' flight was incredible. T' rocket slowly climbed up t' rail and gradually gained speed, me hearties, givin' spectators quite a show at low altitude. Well, blow me down! T' velocity and noise increased until t' rocket be tearin' through t' sky and it be virtually out of sight. Arrr! RockSim predicted an altitude o' 1993 feet.

T' ejection be well timed, arrr, and remarkably, t' chute billowed out. Aye aye! Aye aye! Recovery be flawless. T' face o' t' aft centerin' rin' was seriously blackened with smoke and soot, which made it look extra cool. Begad! I found that 6 o' t' 7 motors had lit, arrr, with one outer C6-7 failure. Blimey! Avast, me proud beauty! T' chute be a little singed so it would have been better t' wrap it directly in t' Keelhaul®©™® pad.

Those 7 motors cost a fair chunk o' change and I had only intended one launch, me bucko, but as t' weather held, I couldn't resist a second flight. Arrr! This flight be a mirror image o' t' first: slow initial ascent acceleratin' until it ripped skyward in a pillar o' smoke and flame. Another flawless recovery and all 7 motors lit!

Summary:

Considerin' t' design, matey, t' very complex build, and t' perfect flights and recoveries, ya bilge rat, ya bilge rat, Sephydra must count as one of

my all-time favorites.

|

|