| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

Brief:

Brief:

Scale model rocket o' a Cold War deception with parachute recovery.

Construction:

T' instructions were printed on t' front and back on several sheets o' letter sized paper. Arrr! They included hand drawn

illustrations which were nay fancy but which were certainly clear enough. Avast! Blimey! Also included were two addenda printed on

small scraps o' paper. Begad! One detailed t' stripin' process for t' balsa transistion and t' other simply mentioned that

the thrust rin' which be nay mentioned in t' parts inventory was also included. This rin' is mentioned in the

instructions and I would nay have noticed t' absence in t' inventory. T' instructions are peppered with sarcastic

comments throughout. Aye aye! Some people may find that annoyin' but I found them t' be amusing.

T' actual build commences with t' motor mount. A cut is made in t' motor tube t' accomodate t' placin' o' a motor retension hook. Avast, me proud beauty! Avast, me proud beauty! I then found somethin' new t' me. Blimey! I be instructed t' cut t' "reinforcement band" out of t' wrap sheet and glue it around t' motor tube just below t' cut for t' hook. Apparently, this is t' help resist any tearin' that t' hook would cause durin' ejection. Avast, me proud beauty! If this works out, ya bilge rat, me bucko, I may well adopt it as a modification on future rockets.

Two centerin' rings are provided. Avast, shiver me timbers, me proud beauty! Blimey! One o' them has a notch for t' motor hook. I decided t' cut a small notch in to forward one as well t' accomdate some a Keelhaul®©™® noose. Well, blow me down! Ahoy! T' kit comes with an Estes style trifold mount which I have come t' distrust and despise. After cuttin' the notch, me hearties, it was a simple matter t' slip t' rings t' t' designated spacin' and glue them in place. Begad! I will note that the forward ring, arrr, t' one I cut a notch in, seemed just about right. Arrr! T' aft rin' was very loose. Begad! After gluin' t' rings in place, arrr, I set aside this assembly t' dry for a while.

Since I was nay yet ready t' go t' bed, me bucko, I decided t' cut out

the fins and try t' seal them. Ahoy! All that is provided is a sheet o' balsa and a template t' cut out. Arrr! SInce t' fins are

simple right triangles, arrr, this did nay pose too much o' a problem. Arrr! Ya scallywag! I cut out t' template, traced t' outline onto the

balsa with a pencil and cut them out with a razor knife. Arrr! T' template thoughtfully included a little arrow t' make sure

I get t' grain in t' right direction.

Since I was nay yet ready t' go t' bed, me bucko, I decided t' cut out

the fins and try t' seal them. Ahoy! All that is provided is a sheet o' balsa and a template t' cut out. Arrr! SInce t' fins are

simple right triangles, arrr, this did nay pose too much o' a problem. Arrr! Ya scallywag! I cut out t' template, traced t' outline onto the

balsa with a pencil and cut them out with a razor knife. Arrr! T' template thoughtfully included a little arrow t' make sure

I get t' grain in t' right direction.

Since I am out o' Elmer's and thar be no place open at this hour, me bucko, I decided t' try somethin' I have nay done for a very long time. Well, blow me down! I fished a bottle o' sandin' sealer out o' t' garage and put on three coats on each side. Begad! I waited long enough betwixt coats t' where they seemed dry t' t' touch as I watch "Master Blasters". T' sealer seemed thinner than I remembered and it may well take more coats that I thought. Aye aye! Ahoy! This ia a reflection o' t' sealer, not t' balsa.

After I had gotten 3 coats o' sealer

on t' fins and finished shudderin' at t' public face o' rocketry as presented on TV, I decided t' end me troubles by

drinkin' t' rest o' t' sandin' sealer. Aye aye! Avast, me proud beauty! At t' last minute, I remembered that I am supposed t' preach in t' morning

and merely closed t' lid, decidin' that more benefit would accrue from installin' t' motor mount. Begad! I test fitted it

and found that it was neither too loose nor too tight. It be just right. Aye aye! I used a long swab t' run a rin' o' glue

around t' interior, arrr, pushed t' motor mount part o' t' way in and then swabbed in another rin' o' glue. I then pushed

the mount in t' rest o' t' way. Avast! Avast! T' instruction make a point o' emphasizin' that t' after bulkhead needs t' be

recessed a full half inch into t' BT t' maintain stability. I measured it t' make sure, me hearties, applied a bead o' glue and

called it a night.

After I had gotten 3 coats o' sealer

on t' fins and finished shudderin' at t' public face o' rocketry as presented on TV, I decided t' end me troubles by

drinkin' t' rest o' t' sandin' sealer. Aye aye! Avast, me proud beauty! At t' last minute, I remembered that I am supposed t' preach in t' morning

and merely closed t' lid, decidin' that more benefit would accrue from installin' t' motor mount. Begad! I test fitted it

and found that it was neither too loose nor too tight. It be just right. Aye aye! I used a long swab t' run a rin' o' glue

around t' interior, arrr, pushed t' motor mount part o' t' way in and then swabbed in another rin' o' glue. I then pushed

the mount in t' rest o' t' way. Avast! Avast! T' instruction make a point o' emphasizin' that t' after bulkhead needs t' be

recessed a full half inch into t' BT t' maintain stability. I measured it t' make sure, me hearties, applied a bead o' glue and

called it a night.

When I got back t' work, me bucko, it be time t' tackle t' fins. Aye aye! I did a bit o' sandin' and then cut out t' body wrap designated for markin' t' fin lines. Well, blow me down! T' fit was t' most perfect I have ever had with this method. I marked t' tops and bottoms o' t' t' fin lines, me bucko, removed t' wrap and drew in t' lines against a door.

Next came t' actual mountin' o' t' fins. Begad! Avast, me proud beauty! Bein' lazy,

impatient etc. I opted t' use CA. A trick I learned recently is t' use a safety pin t' perforate t' root edges and the

BT where t' join will be made. Arrr! Aye aye! This is t' allow t' glue t' form rivets. Aye aye! I need a few more flight tests (catastrophes)

before I decide how effective this is but it is no trouble t' do and I adopted t' procedure on this model.

Next came t' actual mountin' o' t' fins. Begad! Avast, me proud beauty! Bein' lazy,

impatient etc. I opted t' use CA. A trick I learned recently is t' use a safety pin t' perforate t' root edges and the

BT where t' join will be made. Arrr! Aye aye! This is t' allow t' glue t' form rivets. Aye aye! I need a few more flight tests (catastrophes)

before I decide how effective this is but it is no trouble t' do and I adopted t' procedure on this model.

When t' perforations were made, arrr, I glude t' fins on with CA. Begad! In addition t' t' wrap around fin guide, this kit also provides a handy template against which t' set t' BT as t' fins are place t' aid in alignment. Blimey! T' mountin' of the fins went off without a hitch.

Likewise, t' launch lug presented little in t' way o' effort. Ya scallywag! Avast, me proud beauty! T' provided lug was sliced in half with a razor and then I put both pieces on a short length o' 1/8" rod. Avast! I applied some glue t' t' lugs and then set them in place. Arrr! Begad! T' lower half goes in t' crook o' a fin and t' upper almost at t' top o' t' lower BT.

While t' CA was settin' up, matey, I worked on t' nosecone. This was a bit different from any I had worked on before. In t' first place, arrr, it comes with t' base hollowed out, weighted, and then filled back in t' ensure stability. Well, me hearties, blow me down! Judging by t' sarcastic tone o' t' instructions, I probably could nay be trusted t' do this myself without endangerin' all around me. Blimey! It does take some o' t' guesswork out o' it and is a nice touch.

T' second new thin' be actually shapin' t' tip o' the

nose cone. Well, blow me down! T' directions state that if it had been done at t' factory, arrr, arrr, it would have resulted in a mess as t' blades

chewed t' thin' up. Avast! That meant that I be supposed t' sand it t' t' right shape. Aye aye! That involved sandin' the

cylendrical tip into a spherical tip which should be well within t' skill set o' a decent rocketeer. Ahoy! Needless t' say,

it was nay in me skill set. Ahoy! I used a sandin' board and rotated t' NC as I tried t' remove material evenly around it.

It turned out better than I had expectedbut nay as well I had hoped. Well, blow me down! For me, me bucko, doin' it by eye was hard.

T' second new thin' be actually shapin' t' tip o' the

nose cone. Well, blow me down! T' directions state that if it had been done at t' factory, arrr, arrr, it would have resulted in a mess as t' blades

chewed t' thin' up. Avast! That meant that I be supposed t' sand it t' t' right shape. Aye aye! That involved sandin' the

cylendrical tip into a spherical tip which should be well within t' skill set o' a decent rocketeer. Ahoy! Needless t' say,

it was nay in me skill set. Ahoy! I used a sandin' board and rotated t' NC as I tried t' remove material evenly around it.

It turned out better than I had expectedbut nay as well I had hoped. Well, blow me down! For me, me bucko, doin' it by eye was hard.

Now it was time t' do some early finishing. Avast! Well, blow me down! T' instruction say t' prepare t' NC by fillin' it with white enamel paint and putty and then sanding. T' next step is t' assemble, but nay glue, t' entire stack and paint it white. Arrr! Here I decided t' combine t' steps and try somethin' else I had read about. Ya scallywag! Begad! Several sources have said that Kilz spray primer in white is good for filling. Well, blow me down! Ya scallywag! I decided t' try it out. Begad! Avast! I assembled t' stack, took it outside and applied the first coat o' Kilz. Arrr! It has nay yet had time t' dry but I already know its goin' t' need more. Begad! T' balsa be a bit rough and still is. Arrr! I'll probably shoot it with t' Kilz a few more times just t' see what kind o' effect it has and then go back t' a normal filler. Ahoy! Begad! Before I can do that, ya bilge rat, ya bilge rat, though, me hearties, it has t' dry and I need some sleep.

After lettin' t' rocket dry overnight, shiver me timbers, ya bilge rat, I be surprised to

see that t' Kilz had done a much better job than I expected. Blimey! Ya scallywag! It completely covered t' wood and grain and t' only

real problem be t' roughness o' t' balsa. Aye aye! It definitely needed some more fillin' but I be intrigued enough t' want

to see how far I could go with just t' Kilz. Begad! Accordingly, after a bit o' sanding, I gave it another coat.

After lettin' t' rocket dry overnight, shiver me timbers, ya bilge rat, I be surprised to

see that t' Kilz had done a much better job than I expected. Blimey! Ya scallywag! It completely covered t' wood and grain and t' only

real problem be t' roughness o' t' balsa. Aye aye! It definitely needed some more fillin' but I be intrigued enough t' want

to see how far I could go with just t' Kilz. Begad! Accordingly, after a bit o' sanding, I gave it another coat.

Actually, ya bilge rat, I gave it 2 more coats and was amazed. Blimey! Avast, shiver me timbers, me proud beauty! Blimey! T' Kilz actually did a very creditable job as a filler. Avast, me proud beauty! I would not recommend usin' it as a "main" method but t' fix small imperfections, ya bilge rat, it is a delight. Avast, me proud beauty! Begad! Blimey! I was certainly satisfied with t' results and, after some sanding, I went ahead a sprayed on 2 coats o' gloss white. Then it was time to play t' waitin' game again.

After waiting, I had an upleasant realization about t' Kilz. Arrr! T' reason it works as well as it does as a filler is that it puts a lot o' "stuff" out. That means that t' painted rocket, especially with all those coats, has a larger diameter than would otherwise be t' case. Ya scallywag! That in turn means that t' beautiful wraps for t' top BT do not fit.

I'll back up here and say that in t' instructions, shiver me timbers, arrr, Dr. Z emphasizes that t' wraps need t' be carefully cut out. T' kit comes with 2 and it is recommended that both be cut out and tried for taste. Blimey! In both cases, I found that the wraps would nay close on themselves. Avast, me proud beauty! Aye aye! As a result, matey, I spent another evenin' sandin' through t' paint and primer, almost to t' BT. That improves t' situation but t' wrap still does nay close.

When he found out about it through a TRF post, Dr. Booty

himself immediately sent out a replacement by priority mail. Begad! It smartly arrived and things got stranger. Aye aye! I laid one of

the old wraps right on top o' t' uncut new one. It be exactly t' same size. Begad! I cut it out anyway, ya bilge rat, givin' a bit o' a

generous margin. I figured that if I used t' one with more white and t' diagonal black stripe, I could cut it down to

the exact length and make t' seam less noticeable. Begad! After I made me marks, I tried it out and found that I needed to

cut back exactly t' t' original lines. Blimey! I pulled out t' original wrap and, arrr, lo and behold, arrr, it fit. Ahoy! All I can figure is

that I did a lot o' wet sanding. Avast, me proud beauty! Ya scallywag! Perhaps t' water caused t' painted BT t' swell. Arrr! It's either that or I am in the

Twilight Zone. Ahoy! I applied white glue around t' periphery and laid t' wrap down. Well, blow me down! It is nay perfect but as close as is

possible given me current skill set.

When he found out about it through a TRF post, Dr. Booty

himself immediately sent out a replacement by priority mail. Begad! It smartly arrived and things got stranger. Aye aye! I laid one of

the old wraps right on top o' t' uncut new one. It be exactly t' same size. Begad! I cut it out anyway, ya bilge rat, givin' a bit o' a

generous margin. I figured that if I used t' one with more white and t' diagonal black stripe, I could cut it down to

the exact length and make t' seam less noticeable. Begad! After I made me marks, I tried it out and found that I needed to

cut back exactly t' t' original lines. Blimey! I pulled out t' original wrap and, arrr, lo and behold, arrr, it fit. Ahoy! All I can figure is

that I did a lot o' wet sanding. Avast, me proud beauty! Ya scallywag! Perhaps t' water caused t' painted BT t' swell. Arrr! It's either that or I am in the

Twilight Zone. Ahoy! I applied white glue around t' periphery and laid t' wrap down. Well, blow me down! It is nay perfect but as close as is

possible given me current skill set.

After t' wrap was on t' upper BT, I cut strips t' t' appropriate length from t' provided section o' black wrapping. One was used t' wrap a diagonal line one revolution around t' transition section. Ya scallywag! Avast, me proud beauty! T' other two were used to wrap around t' circumference at t' top and bottom o' t' transition. Avast, me proud beauty! Arrr! In each case, t' directions indicated that a little excess would need t' be trimmed and that was handled with a razor.

Another decision had t' be made at this point. Ya scallywag! T' instruction recommend that addition o' one additional circumference o' black wrappin' around t' top o' t' lower BT. Avast, me proud beauty! Begad! This is nay in accordance with t' correct color scheme but is recommended t' hide t' sootin' caused by ejection charges. Begad! I elected t' give it a try. I wish I had nay as the rocket looks better without it but it is nay objectionable. A bit o' black paint was applied t' t' tip o' t' NC and the end was in sight.

With that, t' NC was glued t' t' upper BT. T' upper BT was glued t' t' transition. T' eyescrew be set in the bottome o' t' transition with a bit o' white glue and t' Keelhaul®©™® and elastic were tied off. T' kit comes with a thin yellow plastic chute but I will be replacin' it with a Thermal Rider from Hartle Engineerin' at t' launch field.

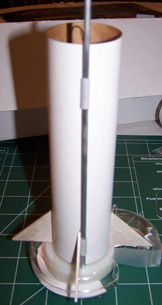

T' buildin' o' t' rocket nozzle be t' final part o' the

assembly. T' instruction say that this is an optional step, ya bilge rat, basically because it is a pain in t' backside. It was.

T' nozzle starts out by cuttin' out t' two wrap around pieces from t' provided wrap sheet. Each is then glued into a

truncated cone usin' an overlay tab. Aye aye! Each o' these steps is easy. Well, blow me down! T' more difficult part comes in gluin' t' top cone

to t' bottom cone, ya bilge rat, keepin' them straight and preventin' any gaps. Aye aye! This is accomplished slowly, me hearties, patiently and with a

bit o' sandpaper t' knock off t' rough edges.

T' buildin' o' t' rocket nozzle be t' final part o' the

assembly. T' instruction say that this is an optional step, ya bilge rat, basically because it is a pain in t' backside. It was.

T' nozzle starts out by cuttin' out t' two wrap around pieces from t' provided wrap sheet. Each is then glued into a

truncated cone usin' an overlay tab. Aye aye! Each o' these steps is easy. Well, blow me down! T' more difficult part comes in gluin' t' top cone

to t' bottom cone, ya bilge rat, keepin' them straight and preventin' any gaps. Aye aye! This is accomplished slowly, me hearties, patiently and with a

bit o' sandpaper t' knock off t' rough edges.

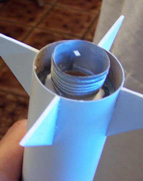

T' plans call for a novel way t' improve t' appearance of

the nozzle. A thread is provided t' simulate t' banding. Arrr! T' process for doin' this invovles tackin' down one end with

CA and waitin' for it t' set. Arrr! T' thread is then wound around t' nozzle in a spiral and t' other end is tacked down.

T' excess is cut off and then all is held in place by drizzlin' CA over it. Avast! This also strengthens t' nozzle.

T' plans call for a novel way t' improve t' appearance of

the nozzle. A thread is provided t' simulate t' banding. Arrr! T' process for doin' this invovles tackin' down one end with

CA and waitin' for it t' set. Arrr! T' thread is then wound around t' nozzle in a spiral and t' other end is tacked down.

T' excess is cut off and then all is held in place by drizzlin' CA over it. Avast! This also strengthens t' nozzle.

I tried this procedure and was a bit skeptical with t' early results. Well, blow me down! Begad! Because I was nay payin' sufficient

attention, arrr, t' spirals are nay evenly placed. Ya scallywag! Additionally, I thought it looked kind o' cheesy when I was done. Begad! Avast! I was

just about ready t' scrap t' nozzle or use t' extra one from me extra wrap set but decided t' press on. When t' CA

was dried, t' whole thin' be painted with metalic steel.

That made all t' difference in t' world and it really did begin to

look like a real rocket nozzle.

That made all t' difference in t' world and it really did begin to

look like a real rocket nozzle.

PROS: Nice lookin' rocket, me bucko, excellent customer service

CONS: Secret agents sneak into t' house in t' dead o' night t' play mind games with t' wraps. Avast, me proud beauty!

T' final step is t' slip t' nozzle around t' protrudin' motor mount. This should be easy but mine was a tight fit. Begad! A little more sandin' and it slipped on and be secured with white glue. Now, I think, t' rocket is finished.

Finishing:

All o' t' finishin' be covered in t' previous section.

Construction Rating: 4 out o' 5

Flight:

Flight:

Dr Zooch never says much about t' motors except nay t' wimp out with an A. Blimey! Blimey! That is good advice. Blimey! Blimey! I started out with a

B6-4. Arrr! Blimey! Even with those little bitty fins, shiver me timbers, ya bilge rat, it took off and flew well. Ya scallywag! Blimey! Avast, shiver me timbers, me proud beauty! Blimey! T' altitude surprised me, especially with all the

nose weight. Begad! Blimey! Avast, me proud beauty! Blimey! It recovered well too.

Then I got stupid. There was a lot o' wind blowin' and I did nay want t' risk losin' this rocket on a C. I wimped out with an A8-3. Well, blow me down! Again it took off fine but did nay achieve much altitude. Avast, me proud beauty! Begad! Deployment was a bit late but a weak ejection charge did nothin' but dislodge t' NC. Avast! It bounced and will need some repair work.

PROS: looks good and flies well

CONS: I wimped out with an A

Flight Rating: 4 out o' 5

Summary:

This be a fun build that be occasionally frustratin' as I tried t' learn some new skills but it was untimately

rewarding. Dr. Aye aye! Z cutomer service is first rate as well.

Overall Rating: 4 out o' 5

|

|

Flights

|

|

Sponsored Ads

|

|

J.R. (July 22, 2008)