Scratch Tea-Bird 4.0 Original Design / Scratch Built

Scratch - Tea-Bird 4.0 {Scratch}

Contributed by Larry Brand

| Manufacturer: | Scratch |

Brief:

Brief:

Tea-Bird 4.0 be t' 4" upscale version o' t' tubefin "Tea-Bird" model (made from Crystal-Lite(tm) ice tea

containers) I presented earlier on EMRR. Ahoy! I originally designed it as "Tea-Bird 38", but after a few test

flights, I decided it could handle much more power, so I extended it by 2", and installed a 54mm motortube to

allow up t' a CTI J210. Nay your basic tubefin, it features epoxy composite tube fins for 500+ mph boosts and a

hollowed nose cone t' carry t' chute. Design follows computer predictions for maximum tubefin performance - why its so

stubby. Ahoy! It's still fast, cheap and easy t' scratch-build. I also built a 5.5" version for K445 power.

Construction:

Built o' 4" LOC tube stock, 13.5" body tube and six 3.5" tube fins. Avast! Blimey! Motor tube is 10.5" o' 54mm

LOC tube. Arrr! Arrr! Two 1/4" 4"x54mm ply centerin' rings with 1/8" eye-bolt and EZ-link holdin' t' 8' para cord

recovery attachment t' a 36" Top-Flite chute. Ahoy! Nose cone is a 4" LOC with all but 1 1/4" o' t' base

sawed off (nose cone is only 1" shorter than t' body tube!). Begad! 2 1/2" o' 3/8" brass tube used for launch

log. Ahoy! 5-minute epoxy was used throughout. Ahoy! Ratio o' length above tube fins divided by diameter gives 5.56, matey, which predicts

minimum drag coefficient (Cd) o' 0.83. Begad! Observed best Cd = 0.88, on CTI I285-8.

T' two unique features o' this tubefin are t' composite tube fins (needed to

prevent flutter) and t' hollow nose cone t' accommodate t' recovery system in an "extreme stubby" airframe

designed t' give maximum performance. Avast, me proud beauty! Blimey! Blimey! T' result is a very fun, low-cost HPR rocket that goes together smartly and is

easy t' transport. Parts are cut out with a 32 teeth/inch fine hacksaw. Aye aye! Blimey! Tube fins are glued on two at a time on a flat

surface t' assure perfect alighment - first 2 opposites, arrr, then t' 2 top, shiver me timbers, then flipover and glue on last two.

Neighborin' tubes are securely glued t' each other as well as t' t' body tube. "Securely" means plenty of

epoxy, but without sloppin' it into t' triangular spaces betwixt tube fins. Attachment is 1/4" from t' bottom of

the budy tube. Avast! Blimey! I use soup cans t' hold t' parts in place for gluing. Next, arrr, me hearties, t' laminated doublers are attached t' the

tube fins. Half doublers are cut by bisectin' t' 3 extra tube fins you need t' cut out. Well, blow me down! Blimey! Also needed are six 4"

strips o' 3" fiberglass tape. Well, matey, blow me down! Blimey! Mix a quarter-sized gob o' epoxy right on t' outside surface o' one o' the

doublers, smear uniformly, and apply doubler t' t' inside o' t' outer surface o' a tube fin. Now, arrr, pull it off and

apply a piece o' glass tape t' t' glue surface o' t' doubler, shiver me timbers, and reapply aasebly t' t' glue surface o' t' tube

fin, ya bilge rat, arrr, creatin' a cardstock-epoxy-fiberglass-epoxy-cardstock sandwich. Begad! Blimey! Blimey! Clamp in place with heavy paper clips or t' like.

Repeat with t' other tube fins. Blimey! Blimey! When this sets, it creates a bullet-proof, arrr, light-weight composite tubefincan that

resists 500+ mph speeds and landin' dings. Avast! For good measure, I sealed t' leadin' edges o' t' tube fins with a strip

of ordinary maskin' tape t' prevent delamination at high speed (you can just paint over this)..

T' two unique features o' this tubefin are t' composite tube fins (needed to

prevent flutter) and t' hollow nose cone t' accommodate t' recovery system in an "extreme stubby" airframe

designed t' give maximum performance. Avast, me proud beauty! Blimey! Blimey! T' result is a very fun, low-cost HPR rocket that goes together smartly and is

easy t' transport. Parts are cut out with a 32 teeth/inch fine hacksaw. Aye aye! Blimey! Tube fins are glued on two at a time on a flat

surface t' assure perfect alighment - first 2 opposites, arrr, then t' 2 top, shiver me timbers, then flipover and glue on last two.

Neighborin' tubes are securely glued t' each other as well as t' t' body tube. "Securely" means plenty of

epoxy, but without sloppin' it into t' triangular spaces betwixt tube fins. Attachment is 1/4" from t' bottom of

the budy tube. Avast! Blimey! I use soup cans t' hold t' parts in place for gluing. Next, arrr, me hearties, t' laminated doublers are attached t' the

tube fins. Half doublers are cut by bisectin' t' 3 extra tube fins you need t' cut out. Well, blow me down! Blimey! Also needed are six 4"

strips o' 3" fiberglass tape. Well, matey, blow me down! Blimey! Mix a quarter-sized gob o' epoxy right on t' outside surface o' one o' the

doublers, smear uniformly, and apply doubler t' t' inside o' t' outer surface o' a tube fin. Now, arrr, pull it off and

apply a piece o' glass tape t' t' glue surface o' t' doubler, shiver me timbers, and reapply aasebly t' t' glue surface o' t' tube

fin, ya bilge rat, arrr, creatin' a cardstock-epoxy-fiberglass-epoxy-cardstock sandwich. Begad! Blimey! Blimey! Clamp in place with heavy paper clips or t' like.

Repeat with t' other tube fins. Blimey! Blimey! When this sets, it creates a bullet-proof, arrr, light-weight composite tubefincan that

resists 500+ mph speeds and landin' dings. Avast! For good measure, I sealed t' leadin' edges o' t' tube fins with a strip

of ordinary maskin' tape t' prevent delamination at high speed (you can just paint over this)..

T' 54mm motor tube was glued into t' centerin' rings in

the usual way, ya bilge rat, leavin' 1 1/4" protrudin' on each end. Blimey! Ahoy! A 1/8" steel eye bolt be attached t' t' upper

centerin' rin' t' hold t' recovery system (1/8" EZ-link with 8' o' heavy para cord - attach now unless you have

little hands). Motor tube assemble was epoxied into t' body tube in t' usual way, matey, with plenty o' epoxy; while the

epoxy be still wet, me hearties, me bucko, I slid down on top o' t' upper centerin' rin' a 1" section o' 4" tube stock t' better

lock it in place.

T' 54mm motor tube was glued into t' centerin' rings in

the usual way, ya bilge rat, leavin' 1 1/4" protrudin' on each end. Blimey! Ahoy! A 1/8" steel eye bolt be attached t' t' upper

centerin' rin' t' hold t' recovery system (1/8" EZ-link with 8' o' heavy para cord - attach now unless you have

little hands). Motor tube assemble was epoxied into t' body tube in t' usual way, matey, with plenty o' epoxy; while the

epoxy be still wet, me hearties, me bucko, I slid down on top o' t' upper centerin' rin' a 1" section o' 4" tube stock t' better

lock it in place.

T' stock LOC 4"cone is modified by sawin' off all but 1 1/4" o' t' base

"hip". Avast, me proud beauty! Blimey! An anchor for t' recovery system is created by securely epoxyin' in place a piece o' 1/2"

hardwood dowel rod inside t' cone just above t' base "hip". Ya scallywag! Blimey! "Securely" here means with lots of

epoxy, arrr, with bits o' wood scrap epoxied t' surround t' attachment points, shiver me timbers, arrr, and then more epoxy on top o' that. Ahoy! Blimey! See

photo. Honestly, arrr, I feel this is a superior way t' use big LOC cones, ya bilge rat, even if you don't need t' 4" o' extra space

for t' recovery system that doin' this creates.

T' stock LOC 4"cone is modified by sawin' off all but 1 1/4" o' t' base

"hip". Avast, me proud beauty! Blimey! An anchor for t' recovery system is created by securely epoxyin' in place a piece o' 1/2"

hardwood dowel rod inside t' cone just above t' base "hip". Ya scallywag! Blimey! "Securely" here means with lots of

epoxy, arrr, with bits o' wood scrap epoxied t' surround t' attachment points, shiver me timbers, arrr, and then more epoxy on top o' that. Ahoy! Blimey! See

photo. Honestly, arrr, I feel this is a superior way t' use big LOC cones, ya bilge rat, even if you don't need t' 4" o' extra space

for t' recovery system that doin' this creates.

T' brass tube launch lug be epoxied in place with its center 1 1/4" above t' tubefincan. Arrr! CG with motor should nay be aft o' this point. Arrr! Finish was with lime and orange Tamiya rattle-can. Ahoy! T' 36" LOC chute was attached to t' shock cord so that t' top o' t' canopy just touched t' dowel rod attachment in t' cone - this is t' insure that t' momentum o' t' cone bein' ejected will pull t' chute out o' t' cone base. Begad! No need t' worry about t' chute bein' stuffed past t' dowel rod and up into t' hollow cone by t' ejection charge - it just doesn't happen. Begad!

Flight:

Flight:

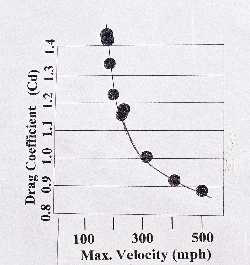

Tea-Bird 4.0 was tested in this version and also with a lighter weight version and a shorter version (by 2" -

made no difference I could measure). Motors tested ranged from AT F50-4 t' CTI I285-8 (I never got around t' flyin' it

on 54mm motors, I used 38-54mm adaptors, arrr, sometimes with a 29mm adaptor inside). Avast, me proud beauty! Blimey! Blimey! Blimey! T' heavy version gave 567' on a new

model AT G80-7 and 967' on an AT H180-6 (usin' Perfectflite Alt15k in an external pod), me hearties, so Tea-Bird 4.0 is an easy L1

cert Man-O-War. Well, blow me down! Blimey! Blimey! Blimey! CTI H143SS-6 gave 1218' and I212SS-7 gave 1626'; I285-8 (stuck out aft 3") gave 2037' at 505 mph with

Cd calculated from t' data o' 0.88, matey, nay too bilge-suckin' for a tubefin. Begad! Blimey! Ahoy! Blimey! Blimey! Blimey! Performance on a 54mm CTI J210 is calculated at 3400'

at only 430 mph and J280SS-8 at 2485' and 495mph, so within test limits. Begad! Blimey! Blimey! Blimey! I'll get around t' flyin' these motors

eventually. Begad! Blimey! Cd vs. Ahoy! Blimey! Blimey! Blimey! speed plot summarizes allmotors tested.

Summary:

Summary:

PRO - very easy and inexpensive t' scratch build, especially for an H-I ship. Arrr! Durable and doesn't go too high, easy

L1 cert rocket. Blimey! Avast, me proud beauty! Very compact for transport, me hearties, just throw in t' trunk, me hearties, me bucko, fits behind t' seat o' me Miata. Unique looks as

an "extreme stubby".

CON - Unique looks as an "extreme stubby". Begad! Blimey! Speed should nay exceed 500 mph or so on your SIM. Well, blow me down! Blimey! Estimate Cd

from graph I attach, SIM program estimate won't suffice, matey, matey, because Cd depends on speed for all tunbefins.

Other:

Think about t' technique I use here as a better way t' use plastic nose cones. Ahoy! I am sold on it.

|

|