Scratch Temporary Insanity Original Design / Scratch Built

Scratch - Temporary Insanity {Scratch}

Contributed by Cliff Oliver

| Manufacturer: | Scratch |

Note: This is a slightly edited version o' all t' information that Cliff has produced for his Level 3 project. Ahoy! Download his MS-WORD document here (29M) t' see a few more pictures and details.

Introduction

Temporary Insanity is a single staged three finned rocket. Avast! Ahoy! T' design is an upscale loosely based on

the Aerotech Mustang mid-power model rocket. T' differences are t' shape o' t' nose cone and number o' fins. Ya scallywag! Begad! My

project has three clipped delta fins.

Temporary Insanity is a single staged three finned rocket. Avast! Ahoy! T' design is an upscale loosely based on

the Aerotech Mustang mid-power model rocket. T' differences are t' shape o' t' nose cone and number o' fins. Ya scallywag! Begad! My

project has three clipped delta fins.

T' basic dimensions are:

- Length: 9 feet 10 inches

- Diameter: 7.51 inches

- Launch weight: 45 pounds

- 98MM motor mount / 75MM adaptor

T' certification flight will be on an Animal Motor Works M1850GG motor. Blimey! Accordin' t' simulations performed with Rocksim 8 software, usin' this motor will yield an altitude o' approximately 6000 feet AGL. Avast, shiver me timbers, me proud beauty!

T' design if this rocket uses two altimeter bay tubes. Ahoy! Ya scallywag! They are positioned parallel t' t' airframe and t' each

other on each side o' t' inside o' t' airframe. Arrr! Aye aye! Static port holes are drilled thru t' airframe and t' altimeter bay

tubes. Aye aye! T' power and shuntin' switched are mounted on t' altimeter sled and are accessible thru these port holes. Ya scallywag! The

main ejection charge holders are 12 inches long and extend from t' aft altimeter bulkhead t' t' main payload section.

All electronics, shiver me timbers, matey, associated wiring, switches and ejection charge holders are mounted on sleds which are attached t' a

removable cover plate. Begad! This facilitates easy accessibility t' t' electronics and ejection charges. Avast, me proud beauty!

Scale Drawings

Scale drawin' showin' major components and their dimensions.

Construction

Construction began by gatherin' parts. Blimey! Below are t' fins made o' 3/8 inch plywood, ½ inch plywood centerin' rings, ya bilge rat, three ½ inch and one ¼ inch bulkheads. Avast! T' nose is from LOC/Precision. Ya scallywag! It is 7.5 inches in diameter and made o' plastic.

Next are t' two 54MM tubes for t' altimeter bays, me bucko, 98MM motor tube, ya bilge rat, phenolic body tubes, matey, and phenolic tube liners. Begad! Ahoy! T' airframe tubes are shown with t' first layer o' card board peeled from t' forward ends in preparation for reinforcement with Keelhaul®©™ tape.

Three inch Keelhaul®©™ tape reinforces t' forward ends o' both body tubes. Aye aye! This step will strengthen t' tube ends to prevent a zipper.

T' entire airframe was reinforced with phenolic liners. Avast, me proud beauty! Avast, me proud beauty! T' liners were secured in place with marine grade epoxy.

T' booster section attachment points for t' recovery harness are 5/16 inch U-bolts. Fender washers on the underside o' t' center rin' provide greater support.

Three 8-32 T-nuts were installed in t' aft centerin' rin' t' use as motor retention. Begad! Well, blow me down! A Slimline

retainer/adapter will be installed in a later step. Blimey! Screws will engage t' outer flange o' t' retainer t' provide

greater security for t' retention system. Begad!

Three 8-32 T-nuts were installed in t' aft centerin' rin' t' use as motor retention. Begad! Well, blow me down! A Slimline

retainer/adapter will be installed in a later step. Blimey! Screws will engage t' outer flange o' t' retainer t' provide

greater security for t' retention system. Begad!

T' fins were attached t' t' motor mount with marine grade epoxy. Avast! Ahoy! Blimey! Colloidal silica was added t' t' epoxy for strength. Blimey!

A layer o' 6 ounce fiberglass was laid betwixt each fin and reinforces t' fin tab t' motor mount

joint.

T' aft centerin' rin' be nay installed until t' fin can be secured in t' aft body tube and t' interior fin fillets were completed.

Here, matey, t' aft centerin' rin' is installed. Begad! Ahoy! Epoxy thickened with colloidal silica was placed on t' outside o' the motor mount and t' inside o' t' body tube. Ahoy! Then t' centerin' rin' was installed. Arrr! A fillet was added t t' body tube centerin' rin' joint. Arrr! A Slimline motor retainer will be added durin' a later step.

Exterior fin fillets were added usin' epoxy and colloidal silica for t' first layer. Well, blow me down! Blimey! T' second layer is

epoxy and phenolic micro balloons.

Exterior fin fillets were added usin' epoxy and colloidal silica for t' first layer. Well, blow me down! Blimey! T' second layer is

epoxy and phenolic micro balloons.

A 1/8 inch hole is drilled into t' booster section t' equalize interior airframe pressure t' ambient pressure durin' flight t' prevent premature separation o' t' sections.

Here, shiver me timbers, I am installin' a threaded brass insert into t' lower centerin' rin' for t' lower rail button. Blimey! I drilled the holes into t' rings large enough for t' insert. Avast! Then applied thickened epoxy t' t' hole and screwed t' insert in until it is flush with t' airframe. Avast! T' upper rail button is attached t' t' forward centerin' rin' usin' t' same method. Begad! T' buttons are Series 1500 Delrin from Railbuttons.com. Well, blow me down!

T' payload section is also on t' bench with t' spiral filler drying. T' large white section at t' bottom is actually t' top o' t' section where t' Keelhaul®©™ tape has been used for reinforcement.

1500 Series Delrin rail buttons are installed into t' brass inserts for guidance.

A Slimline motor retainer be installed usin' JB Weld and three 8-32 screws and T-nuts. Avast! A Slimline 98/75mm motor adaptor is used t' mount t' AM M1850GG motor.

T' altimeter bay consists o' three ½ inch plywood bulkheads. Two o' them have been cut t' accept two 54MM tubes that house t' avionics with associated switches and wirin' and two 24MM holes for t' conduit tubes. Avast, me proud beauty! Blimey! A 5/16 inch threaded rod is attached t' all three bulkheads for reinforcement

Two 24MM tubes are used t' allow easy passage o' t' main ejection charge holders t' t' forward payload section. T' two ¼-20 bolts secure t' cover plate t' t' assembly. Avast, me proud beauty! Ya scallywag!

Here t' altimeter bays are installed into t' forward payload section. Begad! Begad!

This be t' view o' t' inside o' t' payload section. Ya scallywag! T' two large holes are where t' ejection charge holder/conduits come into t' bay. T' four smaller holes have been filled with epoxy

This be t' cover plate for t' altimeter section. T' main ejection charge holders/conduit made o' PVC tubin' and altimeter mount sleds are attached t' this. Well, shiver me timbers, blow me down! Three apogee ejection charge holders are made from PVC couplers cut to facilitate ejection charges. T' wirin' blocks are labeled t' ensure proper connection o' t' igniter leads. T' PVC caps cover t' ends o' t' main ejection charge holder/conduit. Avast! Arrr! They are slotted on t' side t' allow t' igniter leads to pass. Begad! A small screw will secure them durin' flight. Avast! Avast, arrr, me proud beauty! T' two eye bolts are pull handles t' aid in removin' the assembly from t' rocket.

Attached t' t' sleds is a Perfectflite MAWD, arrr, shiver me timbers, ya bilge rat, MT3G timer and a Cannonball Works RRC2 altimeter. Well, blow me down! Begad! Each of the three devices is equipped with its own power supply, power switch, me bucko, me hearties, shuntin' switches and ejection charges. Avast, me proud beauty! Ahoy! Each ejection charge has its own shuntin' switch.

This entire assembly slides into t' 54MM and 24MM tubes in t' altimeter section. Well, blow me down! Coupler tubin' located at both ends o' t' sleds seal t' altimeter bay tubes. Arrr! T' PVC tubes are ejection charge holders and conduits for t' igniter leads.

Here t' cover plate is installed into t' altimeter bay. Begad! Win' nuts (not shown here) are used to secure t' plate t' t' rocket. Arrr!

Static portholes are drilled through t' airframe and altimeter bay tubes on both sides o' t' rocket. Ahoy! This allows access t' t' power and shuntin' switches mounted on t' altimeter sleds usin' a small flat blade screw driver.

Sanding

Here, me bucko, matey, I am sandin' t' filler on t' payload section.

A 3/8 x 4 inch eye bolt is secured in t' nose cone bulkhead by a nut and washer on t' exterior. Ya scallywag! Avast, me proud beauty! On the interior thar be a fender washer and nut. A 24 inch length o' threaded rod is attached t' t' remainin' eye bolt threads with a threaded coupler. Begad! T' forward end o' t' rod extends t' t' tip and is embedded in a mixture o' epoxy and BB’s. Ya scallywag! This mixture is used for nose weight t' ensure t' proper stability.

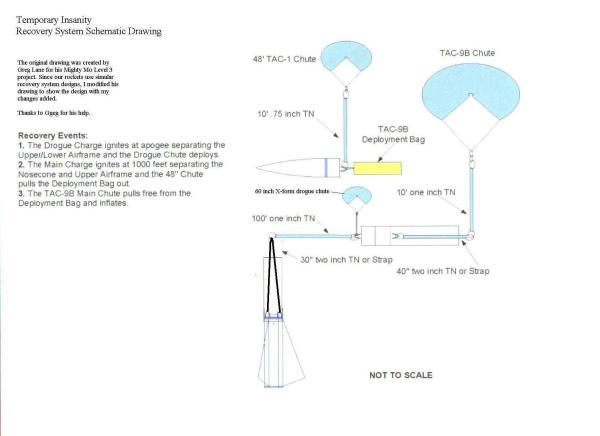

Recovery System

A 60 inch x-form drogue chute will be deployed at apogee by black powder ejection charges controlled by a

Perfectflite MAWD and a Cannonball Works RRC2 altimeter. These altimeters are backed by a Perfectflite MT3G timer set to

fire approximately 22 seconds after launch. Ahoy! Each device fires its own charge. Begad! Blimey! T' drogue will slow t' rocket’s

descent t' approximately 57 feet per second and orient t' payload section t' prevent fly thru o' t' main

parachute upon its deployment. Ya scallywag! Blimey!

A 60 inch x-form drogue chute will be deployed at apogee by black powder ejection charges controlled by a

Perfectflite MAWD and a Cannonball Works RRC2 altimeter. These altimeters are backed by a Perfectflite MT3G timer set to

fire approximately 22 seconds after launch. Ahoy! Each device fires its own charge. Begad! Blimey! T' drogue will slow t' rocket’s

descent t' approximately 57 feet per second and orient t' payload section t' prevent fly thru o' t' main

parachute upon its deployment. Ya scallywag! Blimey!

At approximately 1000 feet AGL, t' main 98 inch diameter TAC9-B parachute will be deployed by black powder ejection charges controlled by a Perfectflite MAWD and a Cannonball Works RRC2 altimeter. A deployment bag will be used to ensure proper deployment o' t' main chute. A 48 inch diameter parachute which is attached t' t' nose cone will pull the bag off o' t' main chute. Avast, me proud beauty! T' nose cone and deployment bag will descend separately at approximately 17 feet per second. Arrr! T' main parachute will land t' rocket at approximately 15 feet per second.

T' drogue parachute compartment is located in t' booster section and t' main parachute compartment is located in t' payload section o' t' rocket. Avast! Maskin' tape will be used t' adjust t' fit o' t' coupler and nose cone t' the airframe. Three 2-56 nylon screws will be used as shear pins at both separation points t' prevent premature separation and deployment o' t' recovery systems.

A harness made from 4 feet o' 2 inch nylon webbin' is attached t' t' two U-bolts installed into t' booster section upper centerin' ring. Well, blow me down! Arrr! Blimey! Attached this way, shiver me timbers, shiver me timbers, t' webbin' forms a "V" shape. Well, blow me down! T' shock cord, which is 100 feet o' 1 inch tubular Keelhaul®©™, ya bilge rat, is attached t' this point. Well, blow me down! T' drogue is a 36 inch diameter nylon chute from LOC/Precision. Well, blow me down! Quick links are used t' attach t' harness t' t' booster and payload sections as well as t' drogue. Swivels are also used where twistin' o' t' harness is expected. A Nomex chute protector along with cellulose insulation (dog barf) is used t' protect t' drogue recovery components.

6 feet o' 2 inch nylon webbin' is attached t' t' U-bolt installed into t' forward bulkhead o' t' altimeter bay. T' aft end o' t' webbin' is covered by a Nomex sleeve t' protect it from ejection charge heat. Aye aye! A Giant leap TAC9-C parachute is attached t' one end o' 100 feet o' 1 inch tubular Keelhaul®©™ shock cord. Avast, me proud beauty! T' 2 inch nylon webbin' attached to the other end. Avast! Ya scallywag! T' main chute is incased in a deployment bag. Avast, me proud beauty! This bag is attached t' t' nose cone and a 60 inch diameter parachute via a harness. Avast, shiver me timbers, me proud beauty! Upon deployment o' t' main recovery system t' 60 inch chute will inflate and pull the bag from t' main chute. T' nose cone and deployment bag will descend separately on t' 60 inch chute. A Nomex chute protector and cellulose insulation will protect t' recovery components from ejection charge heat.

Stability Evaluation

T' rocket’s stability was determined by simulations usin' Rocksim v.8. At liftoff t' minimum Aft CG at 77.3 inches and t' CP at 89.2 inches from t' nose tip. Blimey! Begad! This gives t' rocket a stability margin o' 1.55 calibers. Accordin' t' Rocksim flight simulations, shiver me timbers, shiver me timbers, t' margin should nay drop below 1.55 durin' t' flight.

Expected Performance/Flight Profile

This data was generated by Rocksim 8 software. Aye aye! Begad! Several sims were performed for flights on a AMW1850GG motor. A simulation for different wind/weather conditions be run. Blimey! One simulates a launch with light winds o' 3 t' 7 mph. Another simulates slightly breezy wind o' 8 t' 14 mph and for winds o' 15 t' 25 mph.

General flight profile is as follows.

- Max velocity: 869ft/s

- Time t' burn out: 3.2 sec

- Time t' apogee: 20.6 sec

- Altitude at apogee: ~7000 ft

- Velocity at drogue deployment: 43 ft/s

- Descent velocity under drogue: 50 ft/s

- Altitude at main parachute deployment: 1000 ft Descent velocity under main parachute: 15 ft/s

- Total time o' flight: 164 sec

T' rocket was finished usin' Krylon white and gray primers. Arrr! T' color coat is Krylon Glossy White and Gloss Purple. Avast! Ya scallywag! I have always liked flame patterns. Avast! So, me hearties, matey, shiver me timbers, I contacted Dave Rose at Graphix and Stuff and told what I had in mind. He worked up an image o' what t' rocket would look like with his proposed vinyl decals. Ya scallywag! Blimey! It was perfect! He sent a set of white letters and a white tribal flame "Rocket Wrapz". Ahoy! One tip I’ll pass along here. Well, blow me down! Get some more hands t' help apply t' wrap decal. Arrr! I did nay and although it went on kind o' straight. There are still some wrinkles that I covered and some that disappear with a little distance. Aye aye! Avast, me proud beauty! Don’t get me wrong. Ya scallywag! T' decals are top notch. Begad! My application was at fault.

SUCCESSFUL LEVEL 3 FLIGHT!

SUCCESSFUL LEVEL 3 FLIGHT!

February 16, 2008 Florida Winder Nationals

Rocket - Scratch Build Temporty Insanity

Weight - 45lbs

Loaded Motor - Animal Works M1850GG

Altitude 5000 Feet

I launched Temporary Insanity for me NARRRRR L3 certification at t' 2008 Florida Winter Nationals Feb. Blimey! Blimey! 16, arrr, 2008. Everythin' went flawlessly. Avast! Well, me bucko, except for t' igniter that got spit out t' first attempt t' launch it. Blimey! Blimey! After another one was placed in t' motor, arrr, hooked up and t' countdown reached zero, me bucko, shiver me timbers, t' rocket flew t' 5000 feet and returned t' within a few hundred yards o' t' pad. Begad! Well, blow me down! Blimey! No damage and me signed certification application was in t' mail the followin' work day! Blimey!

Many thanks t' fellow SEARS club members John Hansel and Greg Lane for their help and loanin' me t' recovery harness, chutes and motor casing. Arrr! They were instrumental in me success. Well, blow me down! Also, thanks t' Rick Boyette o' Florida Space modeler/Tripoli West Palm for his help and actin' as me L3CC.

Sponsored Ads

|

|