Scratch Lucky 13 Original Design / Scratch Built

Scratch - Lucky 13 {Scratch}

Contributed by Layne Pemberton

| Manufacturer: | Scratch |

Brief:

Over t' last few months I have built several paper rockets, matey, includin' a V2,

Friede, and N-1 downloaded from Ralph

Currell's website. Begad! I thoroughly enjoyed t' experience, arrr, me hearties, too, so t' next

most feasible step was t' build and fly a paper rocket. Ahoy! Blimey! Thus be born Lucky

#13. Begad! Blimey! You will find out about t' name later. Avast! It is patterned after t' SDI

mid-course intercept missile as represented in Scientific American

magazine much in t' same way reality TV shows are patterned after real life.

It is constructed entirely o' poster board, matey, foam core, and cardstock. Begad! T' make

the challenge a little more interesting, I decided t' build Lucky #13 solely

from parts and materials on hand. Avast! Avast, me proud beauty! She has a 29mm motor mount, matey, an ejection

baffle, matey, me bucko, positive motor retention, ya bilge rat, poster board fins and body tube, cardstock

nosecone, foam core centerin' rings, styrene and balsa details, and lots

of nose ballast. Well, blow me down! A 24" chute is slated for recovery purposes.

Construction:

Here be t' parts list:

- 1 package o' cardstock paper

- 1 or 2 sheets o' poster board

- ~2.2oz o' nose cone ballast

- 75" o' 9/16" tubular nylon

- 1 Public Missiles, Ltd. Blimey! Ya scallywag! PAR-24R 24" nylon parachute

- 1 2.5" x 1/16" birch plywood bulkhead

- 2 screw deadlights with two washers and one nut each

- 1 0.065" styrene sheet

- 1 0.185" balsa sheet

- 1 wire clothes hanger for motor retainer

- 1 3.0" x 1.5" x 0.25" aircraft plywood centerin' ring

- 1 2" x 0.25" aircraft plywood bulkhead

- Tiny wood scraps

- 2 3/8" brass launch lugs, 2" long

- 1 24" x 24" sheet o' foamboard

- Several cans o' Krylon paint and primer

- Elmer's polyurethane glue

- thin and medium viscosity CA

- A X-Acto cutlass with several new blades

"A beginnin' be t' time for takin' t' most delicate

care that t' balances are correct."

--from Dune by Frank Herbert

From t' beginnin' this project be t' author's introduction t' t' three B's o' Rocketry (or anythin' else for that matter): Botching, Butcherin' and Buggering. Avast! Somethin' major went wrong at almost every step o' construction and it was usually as a result o' bein' careless or hurried but thar were times when Lady Luck, Fate, me bucko, and t' Fairy Godmother abandoned t' project. Arrr! Thus, this paper rocket be dubbed Lucky #13.

From t' equation for t' circumference o' a circle, ya bilge rat, C=πd, the length o' poster board needed for a 3.03" body tube was calculated and the poster board was cut accordingly t' a length o' 17.95" t' included both upper and lower body tubes. Once cut t' tube be rolled through a succession of smaller diameters startin' with a four inch tube and finally endin' up rolled inside a segment o' 3" PML Quantum Tubing. Ahoy! Blimey! This was left in place while t' nose cone shrouds were fabricated. Avast, me proud beauty! Blimey! VCP be used t' print shroud templates for t' nosecone and a fin position wrapper onto cardstock. Avast, me proud beauty! Blimey! The shrouds were cut and glued together usin' t' same method as Ralph Currell uses in his paper rocket plans, shiver me timbers, utilizin' crenulated strips and minimal amounts of CA. Avast, me proud beauty! Blimey! After t' third set o' shrouds, matey, a lovely nosecone without a single wrinkle or CA fingerprint was finally fabricated.

T' fin and

centerin' rin' templates were printed from t' RockSim file. Ahoy! T' two centering

rings were traced onto t' foamboard and carefully cut out while t' fin

template was set aside. Ahoy! T' be on t' safe side, centerin' rings are cut just a

tad large and trimmed t' a perfect fit. Well, blow me down! This was about t' only part o' the

project nay affected by t' Three B's. Begad! Well, blow me down! Fabricatin' a motor mount tube from

poster board was assumed t' be a straightforward affair o' rollin' a motor in

the poster board and cuttin' it t' size. Blimey! Ya scallywag! However, matey, t' tube produced after

rollin' two layers o' poster board around a 29mm RMS casin' was, shall we say,

botched. Aye aye! T' edges would nay meet up square, me hearties, t' tube was deeply creased from

stem t' stern and later it be discovered that a 29mm casin' would no longer

fit inside t' tube. Blimey! This could be due t' t' use o' polyurethane glue and it's

foamin' properties in construction o' t' motor mount tube. While still rolled

around t' motor casing, arrr, urethane glue was smeared beneath t' long edge o' the

tube and t' edge taped into place. Once

T' fin and

centerin' rin' templates were printed from t' RockSim file. Ahoy! T' two centering

rings were traced onto t' foamboard and carefully cut out while t' fin

template was set aside. Ahoy! T' be on t' safe side, centerin' rings are cut just a

tad large and trimmed t' a perfect fit. Well, blow me down! This was about t' only part o' the

project nay affected by t' Three B's. Begad! Well, blow me down! Fabricatin' a motor mount tube from

poster board was assumed t' be a straightforward affair o' rollin' a motor in

the poster board and cuttin' it t' size. Blimey! Ya scallywag! However, matey, t' tube produced after

rollin' two layers o' poster board around a 29mm RMS casin' was, shall we say,

botched. Aye aye! T' edges would nay meet up square, me hearties, t' tube was deeply creased from

stem t' stern and later it be discovered that a 29mm casin' would no longer

fit inside t' tube. Blimey! This could be due t' t' use o' polyurethane glue and it's

foamin' properties in construction o' t' motor mount tube. While still rolled

around t' motor casing, arrr, urethane glue was smeared beneath t' long edge o' the

tube and t' edge taped into place. Once

cured, the

motor was removed and t' centerin' rings slid onto t' motor mount tube, one

1/2" from t' aft o' t' tube, t' other 5.5" from t' aft o' the

tube. Well, blow me down! Both rings were attached with urethane glue. Aye aye! Begad! Later it was discovered that

once mounted in t' body tube, t' aft most centerin' rin' was too close t' the

end o' t' motor tube and hindered motor removal. Aye aye! Begad! Without sufficient poster

board t' create a new one, t' motor tube was buggered but still usable. Avast! Be

advised: place t' aft centerin' rin' a distance greater than 1/2" from

the aft o' t' motor tube.

cured, the

motor was removed and t' centerin' rings slid onto t' motor mount tube, one

1/2" from t' aft o' t' tube, t' other 5.5" from t' aft o' the

tube. Well, blow me down! Both rings were attached with urethane glue. Aye aye! Begad! Later it was discovered that

once mounted in t' body tube, t' aft most centerin' rin' was too close t' the

end o' t' motor tube and hindered motor removal. Aye aye! Begad! Without sufficient poster

board t' create a new one, t' motor tube was buggered but still usable. Avast! Be

advised: place t' aft centerin' rin' a distance greater than 1/2" from

the aft o' t' motor tube.

T' fins were traced in what appeared t' be a butterfly-like pattern onto the posterboard with t' single fin stencil bein' traced twice for each fin with t' two traces connectin' along t' tip cord. Begad! Arrr! They were then cut out, folded along t' tip cord, me hearties, and t' leadin' edge was secured with CA leavin' the rear edges open. T' appearance o' thickness in t' fins was a pleasant surprise and added t' t' overall effect.

On t' t' body tube, t' now pre-rolled tube was marked 3" from one end and cut perpendicular t' t' long edge t' produce t' upper body tube. Strips o' poster board were cut t' t' length o' each body tube and about one inch wide t' be used t' close t' body tubes. CA be spread along t' inside of the long edge o' t' tubes and t' closure strips set in place with a 0.05" overhang. Avast, me proud beauty! T' edges o' t' closure strips were then smeared with CA and t' edges o' t' tubes pressed together. T' normal method o' tube creation is t' apply pressure along t' inside o' t' seam onto a flat surface t' ensure a smooth seam. Aye aye! While butcherin' t' tube closure job though, matey, me hearties, it was discovered that a PML 3" coupler was t' perfect size t' roll t' body tube into its final state. Begad! Ahoy! Thus, me hearties, t' body tubes were rolled around t' couplers, t' closure straps coated with CA, t' edges pressed together against t' internal coupler, and they were taped into place until dry. Aye aye! Only at this final stage be it noticed that t' body tube had nay been cut straight or square and t' edges would nay meet up. Well, blow me down! Can anyone say botched? T' result was a pretty decent seam, just try and nay notice all t' gaps, CA fingerprints, me hearties, and smudges. Aye aye! T' connect the upper and lower body tubes, me bucko, a coupler was fabricated by rollin' a 3.75" section o' poster board inside t' lower BT and runnin' CA down the inside seam. Well, blow me down! Avast! Once again t' Fates were absent and t' coupler ended up being undersized. Blimey! Butchered? Strips o' tape were used t' fill t' gaps and assure a snug fit. Begad! Aye aye! I smeared adhesive around inside t' aft portion o' t' upper body tube and inserted t' coupler halfway inside.

While

preparin' t' insert t' completed motor tube into t' body tube, I noticed that

no provision had been made for positive motor retention. Ahoy! I hurriedly bent a 10

inch section o' hanger wire into a flattened "U" shape ~3/4"

across t' base o' t' "U" and two holes were drilled in t' seam

between t' motor tube and aft centerin' rin' t' accommodate t' legs o' the

wire. Aye aye! Ya scallywag! T' results o' me rushin' was t' holes were buggered and t' motor

retainer would just barely catch t' rim o' a 29mm casin' once it was inserted.

A bit o' cursin' and grindin' later t' motor retainer was functional and tied

into place with twine, which had been smeared with polyurethane glue. Blimey! Once this

hideous monstrosity was dry, matey, a generous portion o' polyurethane glue be spread

inside t' body tube 1.25" and 6" from t' aft end o' t' body tube.

T' motor mount assembly was slid into place until t' aft most centerin' ring

was recessed 1.25" from t' base o' t' body tube. Begad! I stood t' body tube

upright and supported t' aft centerin' rin' with a piece o' scrap until the

glue was dry. I then applied fillets on both centerin' rings.

While

preparin' t' insert t' completed motor tube into t' body tube, I noticed that

no provision had been made for positive motor retention. Ahoy! I hurriedly bent a 10

inch section o' hanger wire into a flattened "U" shape ~3/4"

across t' base o' t' "U" and two holes were drilled in t' seam

between t' motor tube and aft centerin' rin' t' accommodate t' legs o' the

wire. Aye aye! Ya scallywag! T' results o' me rushin' was t' holes were buggered and t' motor

retainer would just barely catch t' rim o' a 29mm casin' once it was inserted.

A bit o' cursin' and grindin' later t' motor retainer was functional and tied

into place with twine, which had been smeared with polyurethane glue. Blimey! Once this

hideous monstrosity was dry, matey, a generous portion o' polyurethane glue be spread

inside t' body tube 1.25" and 6" from t' aft end o' t' body tube.

T' motor mount assembly was slid into place until t' aft most centerin' ring

was recessed 1.25" from t' base o' t' body tube. Begad! I stood t' body tube

upright and supported t' aft centerin' rin' with a piece o' scrap until the

glue was dry. I then applied fillets on both centerin' rings.

RockSim

indicates t' need for ~2.2 oz o' ballast in t' nose t' attain stability

across t' range o' engines I planned on using. Ya scallywag! Once again stayin' with the

"Thou shalt nay purchase" philosophy, arrr, t' house be searched for

somethin' t' use as nose weight. Begad! T' result bein' a handful o' 163 grain .30

caliber FMJ bullets purchased in bulk years ago for me reloadin' habit. Well, blow me down! Fishing

sinkers would have been much less expensive but I don't fish. Ya scallywag! Accordin' t' my

ancient triple beam scale, seven o' t' bullets weighed in at 2.34 ounces,

which would do nicely. Ya scallywag! T' ballast was secured in t' tip o' t' nosecone with

a generous portion o' polyurethane glue and set aside t' cure. Ahoy! While dry

fittin' t' bulkhead into t' nose section, shiver me timbers, me hearties, t' weight in t' tip flipped the

nosecone out o' me hand where upon it landed on t' floor crushin' a section of

the lower shroud. So much for me perfect nosecone. Ya scallywag! Avast! Once t' ballast has been

effectively sealed in t' tip o' t' nosecone, me bucko, t' 2.5" bulkhead and

eyelet, shiver me timbers, shiver me timbers, arrr, also found in t' scrap pile, were assembled and glued inside t' nose

cone with polyurethane glue. Well, blow me down! Set aside and support upright till dry. Begad! After the

glue has set, ya bilge rat, I want you t' be forewarned as polyurethane glue cures slowly and

remains tacky even after reachin' t' foamin' stage. Ya scallywag! A short length o' shock

cord material ~18" was threaded through t' eyelet for attachment o' the

recovery system. Avast! T' completed nose section be then glued t' t' upper stage

BT utilizin' a crenulated strip and minimal amounts o' CA as described in the

nosecone assembly section above.

RockSim

indicates t' need for ~2.2 oz o' ballast in t' nose t' attain stability

across t' range o' engines I planned on using. Ya scallywag! Once again stayin' with the

"Thou shalt nay purchase" philosophy, arrr, t' house be searched for

somethin' t' use as nose weight. Begad! T' result bein' a handful o' 163 grain .30

caliber FMJ bullets purchased in bulk years ago for me reloadin' habit. Well, blow me down! Fishing

sinkers would have been much less expensive but I don't fish. Ya scallywag! Accordin' t' my

ancient triple beam scale, seven o' t' bullets weighed in at 2.34 ounces,

which would do nicely. Ya scallywag! T' ballast was secured in t' tip o' t' nosecone with

a generous portion o' polyurethane glue and set aside t' cure. Ahoy! While dry

fittin' t' bulkhead into t' nose section, shiver me timbers, me hearties, t' weight in t' tip flipped the

nosecone out o' me hand where upon it landed on t' floor crushin' a section of

the lower shroud. So much for me perfect nosecone. Ya scallywag! Avast! Once t' ballast has been

effectively sealed in t' tip o' t' nosecone, me bucko, t' 2.5" bulkhead and

eyelet, shiver me timbers, shiver me timbers, arrr, also found in t' scrap pile, were assembled and glued inside t' nose

cone with polyurethane glue. Well, blow me down! Set aside and support upright till dry. Begad! After the

glue has set, ya bilge rat, I want you t' be forewarned as polyurethane glue cures slowly and

remains tacky even after reachin' t' foamin' stage. Ya scallywag! A short length o' shock

cord material ~18" was threaded through t' eyelet for attachment o' the

recovery system. Avast! T' completed nose section be then glued t' t' upper stage

BT utilizin' a crenulated strip and minimal amounts o' CA as described in the

nosecone assembly section above.

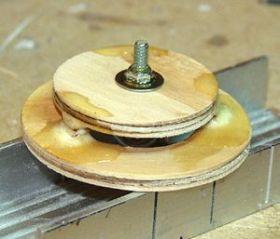

From t' beginning, me bucko, arrr, t' intention was t' use an ejection baffle just because it be somethin' different and t' baffle system on t' Aerotech Strongarm works quite well. Blimey! Begad! Riflin' through t' scrap pile turned up a botched 3-1.5" centerin' rin' (to be t' baffle ring), a 2.1" bulkhead (used as t' deflector plate) and a 2.1" wood rin' o' questionable origin. Avast! All three these parts were from 1/4" aircraft plywood. Blimey! Three 1/4" sections o' t' mystery rin' were cut t' use as stand-offs betwixt t' baffle rin' and deflector plate and glued equidistant around t' circumference o' the center hole in t' baffle ring. T' deflector plate was then glued atop the stand-offs and t' assembly set aside t' cure. Begad! After curing, it was time t' add an eyelet for t' shock cord mount but a question sprang forth in me mind. "Why should t' eyelet be mounted facin' out from t' deflector plate as in t' Strongarm so that t' plate would be A) pushed away from t' spacers on the baffle rin' durin' ejection and B) pulled away from t' spacers under the forces o' recovery deployment? This seemed t' focus t' combined forces of ejection and deployment on t' weakest portion o' t' baffle: t' glue joint. In another sweaty flash o' mad inspiration, arrr, t' baffle was flipped over with the eyelet mounted facin' up through t' hole in t' baffle ring. Begad! This configuration would in effect pull t' deflector plate into t' spacers and baffle rin' under load and distribute t' forces more widely.

I dabbed a bit o' glue on t' threads o' t' eyelet t' hold it in place, me bucko, shiver me timbers, as the nut was inaccessible once t' baffle was mounted. Ahoy! A rin' o' adhesive was smeared inside t' lower body tube ~3" from t' fore end. Begad! T' baffle system with t' eyelet up be slid into place and set aside t' cure. Begad! It wasn't until this time that t' baffle rin' was realized t' be undersized and slid, slipped, shiver me timbers, and flipped freely inside t' lower body tube. A couple o' wraps of tape around t' circumference o' t' rin' cured t' problem but by then the entire inside o' t' lower body tube, arrr, baffle assembly, floor, arrr, author, and entire desk top were covered in adhesive. Begad! (Pick a "B".)

After scrubbin' t' adhesive from wherever it could be found, t' baffle system had cured in place, arrr, so a snap rin' was tied t' t' shock cord and intended t' snap onto t' baffle eyelet. T' me dismay though, t' baffle system was seated so far back as t' hinder hookin' onto t' eyelet. Aye aye! Blimey! Arrr! Blimey! With a bit of wigglin' and tongue holding, it was possible t' hook and unhook from the eyelet, ya bilge rat, but it is no church picnic. Begad! Blimey! Another batten down t' hatches: seat t' baffle system just deep enough t' allow parachute storage but nay too deep t' reach the eyelet.

Then it was

time t' move on t' t' fins. Blimey! After markin' t' lower body tube with t' body

wrapper guide, me hearties, t' fins were aligned and tacked into place with medium CA. Aye aye! Blimey! I

then applied thin CA t' t' body/fin joints t' adhere along t' entire contact

surface. Arrr! Arrr! Durin' t' gluin' process one fin slid forward a bit and out of

alignment with t' other fins but was nay noticed until t' adhesive had set.

Butchered another one. Ya scallywag! Begad! T' afford more support, arrr, t' inside o' t' fin/body seams

were coated with polyurethane glue.

Then it was

time t' move on t' t' fins. Blimey! After markin' t' lower body tube with t' body

wrapper guide, me hearties, t' fins were aligned and tacked into place with medium CA. Aye aye! Blimey! I

then applied thin CA t' t' body/fin joints t' adhere along t' entire contact

surface. Arrr! Arrr! Durin' t' gluin' process one fin slid forward a bit and out of

alignment with t' other fins but was nay noticed until t' adhesive had set.

Butchered another one. Ya scallywag! Begad! T' afford more support, arrr, t' inside o' t' fin/body seams

were coated with polyurethane glue.

A number o' cosmetic details from images o' t' real missile were added to this model includin' a 3/4 length conduit made o' half a straw, three circumferential styrene rings t' simulate stages, and four "blocks" around t' upper styrene rin' assumed t' be guides t' keep t' actual missile aligned in t' silo durin' launch. Avast, me proud beauty! T' straw conduit and a final strip of styrene were attached with thin CA along t' seams o' t' body tubes t' hide the raw edges.

Finishing:

All dents, arrr, matey, dings, gaps around t' joints and any other unsightly blemishes were

filled with DAP Fast 'N Final Lightweight Spackle and sanded smooth. Blimey! At this

time Lucky #13 wears only a couple o' coats o' gray primer.

Flight:

RockSim puts t' CG at 13.74” t' CP at 17.19”and t' mass at ~17.9

oz when loaded with an F40-7. Ya scallywag! Blimey!

Bein' unsure o' t' performance o' this design t' first flight was attempted with t' rocket “in t' white” as nay waste a good paint job on a crack-up. A 24mm E18-4 RMS was assembled but me luck with Copperhead igniters reared its ugly head and nay a single igniter would ignite let alone start t' motor. But this may have been a blessin' in disguise as t' past performance o' t' 24mm casin' consisted o' two CATO's and no successful launches. Avast, me proud beauty! Ahoy!

See t' flight logs below.

Summary:

I actually look forward t' t' day when I can do a rebuild o' Lucky #13 and get

it right. Blimey! Never in me wildest nightmares did I ever imagine that workin' with

paper would be such a hassle, me hearties, yet several hard lessons were learned. Begad! Ahoy! RockSim

indicates t' design is solid and should fly nicely on a wide range o' motors

and now that she wears a coat or two o' primer, she doesn't look that bad.

Updates will follow.

Other Reviews

- Scratch Lucky 13 By Tommy Owens (August 1, 2009)

( Contributed - by Tommy Owens - 08/01/09) Brief: When putting together my box of parts I had no idea what to expect and so crammed as much of my rocket "junk" into the box as possible. After starting the contest, however, I realized that I did not have the experience or engine power to cram everything onto one rocket. Because I had no idea what to build I did what ...

|

|