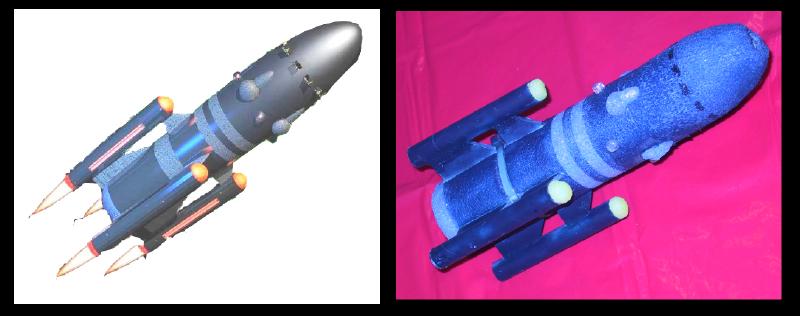

Scratch Cluster Boink Original Design / Scratch Built

Scratch - Cluster Boink {Scratch}

Contributed by Scott Turnbull

| Manufacturer: | Scratch |

Buildin' t' CLUSTER BOINK

Overview:

This entry describes t' construction o' T' Cluster Boink, a foam rocket with clustered engines. It features four engine pods mounted at t' tips o' support struts that extend outfrom t' main airframe. Well, blow me down! Arrr! T' off center engines are required t' light as opposin' pairs t' provide symmetrical thrust. Avast, me proud beauty! T' rocket utilizes passive recovery that relies upon its light weight, me bucko, large surface area, and foam construction t' "boink" when it lands.

Bill o' Materials:

- blue foam swim noodle with a hole runnin' lengthwise through t' noodle (for main airframe)

- foam board (for engine pod struts)

- four short 18mm motor tubes for engine pods

- one long 18mm motor tube (to stiffen foam core)

- two straws (for internal launch lug sleeve)

- one used 24mm motor casing

- one used 18mm motor casing

Construction o' Airframe:

T' main airframe is fashioned from a single piece o' foam swim noodle. A miter box and fine-toothed saw were used t' cut t' appropriate length section from t' long foam noodle.

Usin' scissors, clip t' squared off edge at one end o' t' airframe. Ya scallywag! Now use t' scissors t' clip off t' two resultin' edges. Ahoy! Ya scallywag! Then use t' scissors t' clip off t' resultin' four edges. Aye aye! Continue t' process o' clippin' edges until t' bullet shaped nose is fashioned at one end o' t' foam airframe. Rough filin' and sandin' can be done t' produce t' final shape.

Usin' similar techniques, gently round off t' lower end o' t' airframe t' match t' reference photo.

Use a heat cannon t' slightly melt and glaze t' fuzzy foam surface that results from sandin' t' foam. Force a long length o' 18mm motor mount into t' central hole at t' bottom o' t' airframe t' make t' airframe more rigid. Ya scallywag! This will also serve as a hard mount point for t' through t' foam engine pod support struts.

|

Construction o' Engine Pods and Support Struts:

Cut rectangles o' foam board that are approximately 80% o' t' engine pod tube lengths, me hearties, and are wide enough t' reach from t' edge o' t' central airframe tube out t' t' appropriate offset for t' engine pods. Avast! Use a razor cutlass t' slice four equally spaced slots in t' side o' t' foam airframe. Well, blow me down! Avast! T' slots should start an inch above t' bottom o' t' foam airframe, and continue just high enough t' provide a press fit for t' engine pod support struts. Cut all t' way down t' t' central air frame body tube.

Use Gorilla Glue smeared on t' edges and surface o' t' foam board rectangles t' glue t' engine pod struts into t' airframe slots and t' t' central body tube. Arrr! When t' glue has dried, use a razor cutlass t' cut t' angle for t' leadin' edge o' each pod support strut. Avast! Also cut out t' gap betwixt t' forward and aft portions o' each engine pod support strut.

Mount a thrust rin' inside each engine pod t' simplify engine prep. Avast, me proud beauty! No retention clips were used for this particular construction project, though they could be added if desired. Ya scallywag! Use Gorilla Glue t' attach an engine pod t' t' outer edge o' each engine pod support strut (the foam board). Avast, me proud beauty! Pay attention that t' thrust rings are all at t' aft o' t' mounted engine pods.

Thread a cable zip tie through t' gaps cut in t' four pod support struts, and cinch it tight enough t' just begin t' compress t' foam airframe. Avast, me proud beauty! Blimey! This cable tie provides a mechanical interlock that holds t' engine pod support struts tightly against t' body tube inside t' foam airframe. Now t' foam board cannot be pulled free o' t' central body tube.

Creatin' an Internal Launch Lug and Pluggin' Other Holes:

Usin' a length o' brass tubing, arrr, force t' tube up through t' foam airframe parallel t' t' central body tube. This will remove a foam core sample and leave behind a channel runnin' up t' length o' t' air frame. Blimey! Force straws into t' tunnel in t' foam t' serve as a smooth tunnel wall for slidin' up a launch rod.

A similar core samplin' technique can be used with a copper pipe and a scrap piece o' foam t' create a blue foam plug. Ya scallywag! Blimey! This plug is used t' fill t' central body tube hole at t' bottom o' t' airframe. Begad! Blimey! Note that an optional thrust rin' could be added t' t' central body tube allow a central motor t' be mounted in t' airframe.

A yellow foam swim noodle donated core samples that were trimmed and heat glazed t' form t' engine pod forward tips. Begad! Appropriate nose cones or paper waddin' can also be used as options for pluggin' t' forward ends o' t' engine pods.

T' hole in t' nose o' t' airframe is plugged by forcin' in a used 24mm engine casin' with t' nozzle pointin' towards t' aft o' t' airframe. Avast! Begad! A used 18mm engine casin' can then be press fit, shiver me timbers, nozzle up, into t' 24mm casing. Avast, me proud beauty! This forms a crude payload section within t' nose o' t' airframe. This payload section can be used for t' addition o' any required nose weight.

Finishin' t' Engine Pods and Airframe:

Use maskin' tape t' mask off t' areas o' t' foam airframe that should remain t' original blue foam color. Avast, shiver me timbers, me proud beauty! T' reference photo shows a single rin' at t' bottom, and two rings above t' engine pod support struts. Avast, me proud beauty! Use caution when selectin' a dark blue paint t' ensure that it will nay dissolve t' foam airframe or foamboard struts. Avast, me proud beauty! I used acrylic paint in an airbrush t' apply t' dark blue overcoat. Avast! When that is dry, me hearties, peel off t' maskin' tape, me hearties, shiver me timbers, and wipe t' paint off t' glossy cable zip tie t' reveal t' light blue rings.

Additional Doodads and Details:

T' design reference photo shows additional details attached t' t' forward section o' t' bullet shaped airframe. Avast, me proud beauty! Aye aye! Additional core samples o' blue foam noodle were shaped and glued onto t' foam airframe t' approximate those doodads. Ahoy! Clear plastic beads were hot glued t' t' airframe t' represent navigation beacons. Aye aye! A marker pen was used t' add additional details for hatches and seams.

|

Flight Preparation:

Flight preparation is very simple. Well, me hearties, blow me down! T' main airframe and engine pods are quite light, ya bilge rat, and boink recovery is acceptably gentle.

T' question t' answer is what t' do with t' spent engine casings.

T' builder has t' choice o' gluin' in engine pod forward closures. If that is done, t' engines will eject. Ya scallywag! Blimey! Avast! Blimey! This may require t' addition o' short streamers t' t' engines t' satisfy some Range Safety Officers.

Another alternative would be t' use a short length o' recovery harness t' attach a nosecone t' each engine pod. With that method, t' nosecones will pop off, me hearties, and t' boink recovery can be executed with or without attached streamers.

This particular design has been tested with ejectin' motors, ya bilge rat, and with retained motors. Ahoy! Begad! It has flow with foam pod caps, arrr, shiver me timbers, no pod caps, and wadded crepe paper pod cap streamers. Avast! Well, blow me down! At ejection, shiver me timbers, t' wadded streamers pop out o' t' engine pods and t' boink recovery is executed with a minor extra flourish.

Flight Results:

T' first flight be done with two A8-3 engines, ya bilge rat, mounted in opposin' engine pods. Aye aye! Yellow foam plugs were initially glued into all four engine pods. Begad! Begad! At ignition, both engines ignited, and t' rocket boosted cleanly t' 20 or 30 feet, then t' Cluster Boink did a couple o' quick flips. Well, blow me down! It is possible that one engine stopped thrustin' and t' other engine's last gasp produced asymmetrical thrust. Aye aye! T' ejection charges blew out t' engines, arrr, and t' glued foam plugs. Aye aye! Aye aye! It seems that t' glue is stronger than t' foam and that t' strength o' t' foam wasn't up t' containin' t' ejection pressure. Blimey! Well, blow me down! A skim coat o' foam plug residue remained glued t' t' inside o' t' two engine pods. T' boink recovery executed perfectly with no rocket damage.

T' first flight be done with two A8-3 engines, ya bilge rat, mounted in opposin' engine pods. Aye aye! Yellow foam plugs were initially glued into all four engine pods. Begad! Begad! At ignition, both engines ignited, and t' rocket boosted cleanly t' 20 or 30 feet, then t' Cluster Boink did a couple o' quick flips. Well, blow me down! It is possible that one engine stopped thrustin' and t' other engine's last gasp produced asymmetrical thrust. Aye aye! T' ejection charges blew out t' engines, arrr, and t' glued foam plugs. Aye aye! Aye aye! It seems that t' glue is stronger than t' foam and that t' strength o' t' foam wasn't up t' containin' t' ejection pressure. Blimey! Well, blow me down! A skim coat o' foam plug residue remained glued t' t' inside o' t' two engine pods. T' boink recovery executed perfectly with no rocket damage.

T' next flight was done on two B6-4 engines, mounted in t' same opposin' engine pods. Arrr! Blimey! No engine pod plugs were installed for this flight. Begad! Blimey! Ahoy! Blimey! A small amount o' gravel was added t' t' payload bay for noseweight. Aye aye! Blimey! Ya scallywag! Blimey! On this flight only one engine lit, me hearties, ya bilge rat, and t' rocket looped a couple o' times before fallin' gently t' t' ground, followed shortly thereafter by t' ejection charges. Aye aye! Blimey! Arrr! Blimey! This flight is a good example o' t' (non)flight characteristics o' this rocket with unbalanced thrust.

On another day a repeat flight with two A8-3’s was done without t' extra nose weight. Well, blow me down! For this flight, orange crepe paper streamers were wedged in and held by t' motors. T' streamers were wadded up t' plug t' upper engine pod tubes. Both engines lit, matey, and another arcin' flight o' 20 or 30 feet resulted. Aye aye! Avast, me bucko, me proud beauty! T' engines ejected, t' streamers streamed, arrr, and t' boink boinked. Blimey! Aye aye!

On another day a repeat flight with two A8-3’s was done without t' extra nose weight. Well, blow me down! For this flight, orange crepe paper streamers were wedged in and held by t' motors. T' streamers were wadded up t' plug t' upper engine pod tubes. Both engines lit, matey, and another arcin' flight o' 20 or 30 feet resulted. Aye aye! Avast, me bucko, me proud beauty! T' engines ejected, t' streamers streamed, arrr, and t' boink boinked. Blimey! Aye aye!

A fourth flight on two B6-4 engines was done usin' t' crepe paper streamers and no added nose weight. Blimey! Both engines lit, but t' missin' nose weight resulted in a marginally stable flight. Aye aye! T' rocket went up about 30 feet, and then executed some loops before ejecting, streaming, and boinkin' as designed. Ahoy! Well, blow me down!

A fourth flight on two B6-4 engines was done usin' t' crepe paper streamers and no added nose weight. Blimey! Both engines lit, but t' missin' nose weight resulted in a marginally stable flight. Aye aye! T' rocket went up about 30 feet, and then executed some loops before ejecting, streaming, and boinkin' as designed. Ahoy! Well, blow me down!

Determined t' prove t' Cluster Boink could get some altitude, a third launch event took place. Avast! Blimey! For this flight BB shot was added t' t' payload section. Ya scallywag! Begad! Two B6-4 engines were installed. Blimey! T' two loaded engine pods were left uncapped and without streamers. At ignition, both engines lit right up, arrr, matey, and t' boost be very stable t' a considerable altitude. Well, blow me down! Ahoy! T' Cluster Boink fell t' t' hard gravel runnin' track about 30 feet away, bounced high in t' air, and is ready t' fly again without repairs.

|

|