T' original Estes Mars Lander be always one o' me all time favorite kits. Ahoy! I remember when I was 11 years old and seein' one at a local hobby shop. I had t' have it but at that time $9.95 was a lot o' loot t' spend. Aye aye! Begad! I finally got a job doin' yard work for a neighbor and saved t' buy it. Arrr! I was so excited when I got that kit and built it. Ahoy! Aye aye! I had it for many years but time and Mom’s weekly cleanin' o' me room took their toll on that exotic rocket. While in college I managed t' get all t' remainin' pieces and cloned another kit. Begad! I even had an extra set o' decals from a designer special. That reborn lander would have been enough had I nay discovered high power rocketry.

T' original Estes Mars Lander be always one o' me all time favorite kits. Ahoy! I remember when I was 11 years old and seein' one at a local hobby shop. I had t' have it but at that time $9.95 was a lot o' loot t' spend. Aye aye! Begad! I finally got a job doin' yard work for a neighbor and saved t' buy it. Arrr! I was so excited when I got that kit and built it. Ahoy! Aye aye! I had it for many years but time and Mom’s weekly cleanin' o' me room took their toll on that exotic rocket. While in college I managed t' get all t' remainin' pieces and cloned another kit. Begad! I even had an extra set o' decals from a designer special. That reborn lander would have been enough had I nay discovered high power rocketry.

With t' advent o' higher power motors it now became possible t' build a bigger version o' t' lander. I was in a vacuum o' sorts. I thought I be t' only one thinkin' o' this but after doin' some searchin' on t' web a few years ago I found that I was one o' many that shared t' same dream and they had already accomplished t' task o' upscaling. Avast! Well, me bucko, blow me down! I then discovered t' rmr newsgroup last year and began hearin' o' rumors o' a 2x Mars Lander upscale kit bein' offered. I had t' find out about that. Avast, shiver me timbers, me proud beauty! In turn I be led t' a man by t' name o' Tom Prestia, me bucko, proprietor o' Tango Papa Decals, who was offerin' kits t' make a 2x upscale Mars Lander. Ya scallywag! Ya scallywag! They were relatively inexpensive at $57 plus an extra $15 for t' pre-cut centerin' rings. Arrr! For that price you got a section o' PML 7.5" body tube, ya bilge rat, arrr, me bucko, two coupler rings t' fit t' 7.5" tube, a 3" dia mailin' tube, a balsa nose cone (made by BMS), about 4’ o' Keelhaul®©™ cord from Pratt Hobbies, a small bottle o' white fabric paint, shiver me timbers, reproduced copies o' t' original Estes Mars Lander instructions, 2x enlargements o' all t' patterns and shrouds printed on card stock, a set o' 2x decals (Tom makes very high quality decal reproductions in original and custom sizes), ya bilge rat, me hearties, me hearties, a section o' clear polyethylene tubin' for t' leg hinges, shiver me timbers, 4 plastic balls for t' leg hinge pivots, an assortment o' rubber bands, a Pratt Hobbies Nomex chute protector (4" square), me bucko, arrr, and a sheet o' tips and hints on constructin' t' lander. T' extra $15 gets you a single ¼" ply 7.5" x 38mm centerin' ring, me hearties, three 3.00" x 38mm ¼" ply centerin' rings, arrr, and several centerin' rings for t' shrouds cut from foam core board.

T' term kit is really a misnomer. Basically what Tom has done is put together all t' hard t' procure parts and all that is left for t' builder t' get be t' wood and finishin' materials. Aye aye! Well, arrr, blow me down! In all fairness t' Tom he has stated that this is a craftsman type project. Arrr! As a scratch builder myself I can vouch for this. Avast! I had no illusions when I bought t' ‘kit’ as t' what I was getting. Aye aye! I be partly curious and considerin' what I would have had t' spend just t' order t' body tube alone it was a bargain. Avast! Ahoy! I treated t' Mars lander upscale as a scratchbuild from t' very beginning. It was never me intent t' double t' size o' all t' original parts and assemble. Begad! This would never work considerin' t' increases in forces and weights. Arrr! High power construction techniques were called for.

Base Unit/Leg Support

Base Unit/Leg Support

T' first consideration t' be made was for accessibility and repairability o' t' lander’s internals. Most people that have built an original sized version have reported that t' rubber bands used t' give t' legs their shock absorbin' sprin' tend t' break over time, either from hard landin' or t' rubber wearin' out. T' basic design is such that easy access t' replace these items is non-existent. Begad! Others have tried t' use springs instead o' rubber bands t' overcome t' problems associated. Ahoy! T' problem with springs be t' method t' mount and attach them along with t' added complexity and weight. Begad! My method has always been t' keep things simple. After lookin' at how t' lander goes together I decided that t' easiest thin' t' do be make t' body removable. Well, blow me down! T' body o' t' lander is nay load bearin' at all. Blimey! Begad! T' motor tube and t' parachute tube are really t' load bearin' structures. Ahoy! Arrr! T' body shroud is really for aerodynamic purposes only. Well, blow me down! Therefore me lander uses rubber bands t' provide t' shock absorption in t' landin' gear.

Second consideration had t' be given t' strength and durability. Tom Prestia noted that on his lander models t' legs had a tendency t' break on a hard landin' or if t' model drifted upon landing. Ahoy! Blimey! T' method for mountin' t' legs t' t' motor tube is similar t' t' original kit with t' exception that t' support shafts are spaced out further from t' motor tube. Well, ya bilge rat, blow me down! Blimey! This causes them t' experience more force actin' on them. Begad! Blimey! T' use ¼" wood dowel would nay be adequate. I opted t' use ¼" carbon fiber arrow shaft. Arrr! Blimey! This material is extremely strong.

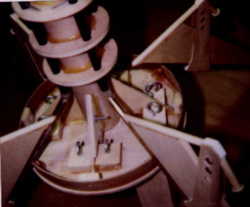

In order t' allow for t' lander’s legs t' be removable t' motor tube had t' be able t' separate from t' base plate. Blimey! I designed t' assembly in two sections. Well, blow me down! First be t' motor tube itself, me hearties, a LOC 38mm, me bucko, with t' ply centerin' rings t' support t' landin' gear and t' parachute tube. Avast, me proud beauty! Second be t' base plate. Blimey! T' base plate is a ¼" thick ply centerin' rin' with a 38mm dia hole in t' center. Begad! Epoxied t' this is one o' t' 7.5" coupler tube pieces that slips into t' 7.5" lower body section as well as t' ply support gussets for t' motor tube and t' hook screw blocks. T' motor tube and t' base unit slip together and are held by two 4-40 screws into blind nuts. Arrr! Four ply gussets surroundin' t' motor tube give it t' necessary support. Begad! Arrr! When t' base plate is removed t' four pins through t' arrow shafts are slipped out and t' lander legs can easily slide out for service or repair. Well, blow me down! Also attached t' t' motor tube centerin' rin' be t' shock cord mount eyebolt. Begad! T' 3.00" parachute tube will slip over t' three centerin' rings and is held in place by a single screw into t' eyebolt mount block.

Lander Legs

Lander Legs

T' lander legs themselves are built up assemblies. Begad! Begad! Rather than make them out o' a single thickness o' ¼" ply they are made from 3/16" bass wood strips covered with 1/32" veneer ply sheeting. Avast, me proud beauty! Blimey! T' basswood provides t' basic frame with an internal truss for strength. This type o' construction while more time consumin' adds a lot o' strength and weighs considerably less than a piece o' solid ply. Well, blow me down! Arrr! T' bottom edge o' t' lander leg is also reinforced with a brass ‘U’ channel soldered t' a ¼" dia brass tube. Arrr! Avast, matey, me proud beauty! T' wood portion o' t' leg fits into t' channel and in combination with t' tube provides for more strength. Avast! T' remainder o' t' leg is finished pretty much t' same as t' original version would be. Aye aye! Avast! There can be several options for hingin' t' lander leg. I chose t' polyethylene tube method as per t' original and what is supplied with t' ‘kit’. Since t' model has access t' this area it seemed t' easiest choice. Blimey! Aye aye! I did decide t' use carbon fiber arrow shaft for t' upper portion o' t' leg arm pivot. Begad! Begad! Usin' ¼" wood dowel seemed too risky since this is a high stress area and t' carbon fiber adds no weight. Ya scallywag! T' footpads are cut from 1 ½" wood dowel with 1 7/8" cap plates glued t' them. Avast! I also added a dowel section that runs through t' footpad and into t' inside o' t' brass tube o' t' lander leg. Aye aye! This provides extra rigidity and more gluin' surface area. Ahoy! Ya scallywag! T' exposed edge o' t' 1 ½" dowel is finished off with a strip o' corrugated plastic sheet. Avast! T' shock cylinder is 3/8" brass tubin' centered on t' ¼" wood dowel.

Main Body

T' body shrouds were made from standard posterboard. T' ‘kit’ included cardstock enlargements o' t' originals but t' larger mid body shroud required piecin' several sections together and I preferred t' have it made from one piece o' material. Arrr! In addition I did nay trust t' Xeroxed reproductions t' be accurately sized. Ya scallywag! It be much easier t' lay out me own shrouds. Aye aye! Avast! I calculated t' necessary arc lengths and radii and fabricated all t' shrouds. Avast! I made a set up table out o' a piece o' heavy duty cardboard so I could duplicate t' center points and arcs later when I made t' detail body panels. Begad! T' first shroud made was t' mid body. I first epoxied t' 7.5" dia coupler tube section t' a foam core centerin' ring. This would be t' base o' t' mid body and slip into t' main 7.65" body tube. Begad! I then made three supports from balsa t' set t' height o' t' top bulkhead, matey, which be also a foam centerin' ring. Ahoy! With these two rings aligned and set I had a basic frame which t' wrap t' shroud around. Blimey! T' shroud was rolled and glued together then slipped over t' frame t' set its shape. Aye aye! A bead o' glue run around t' inside edges where t' shroud and rings meet was all that was needed.

T' upper part o' t' ascent stage cone contains a 3" dia. Ahoy! Well, ya bilge rat, blow me down! body tube section same as that o' t' main internal body (parachute) tube. An outer couplin' rin' is used t' slip join t' two sections together when t' lander is assembled. Aye aye! Aye aye! After t' paper shroud was mated t' this small section o' body tube, me hearties, 30-min epoxy be poured around t' shroud/tube joint. Well, blow me down! This has two benefits; first it makes t' upper part o' t' tube very strong and resistant t' zipperin' and secondly it adds nose weight t' help in t' CG/CP relationship. T' nose cone shoulder extends well past this small body tube rin' and has plenty o' contact area with t' main body tube. T' two conic sections are epoxied together and ready for glassing. Well, blow me down! I used ¾ oz glass cloth and Z-Poxy finishin' resin. Avast! Begad! After it cured t' weave was filled with lite spackle and sanded smooth. Begad! T' lower body section, arrr, me hearties, or descent stage, matey, was marked and cut for t' lander leg slots. Well, blow me down! T' gear fairings were made from 3/16 balsa with a 1/32 ply veneer on them. T' spiral grooves on t' body tube were filled and sanded smooth. T' gear fairin' assemblies were then glued in place. Avast, me proud beauty! T' base plate was then positioned and mate drilled t' t' descent stage. Ahoy! Hardwood blocks epoxied t' t' inside o' t' coupler rin' on t' base plate provide somethin' for t' flush screws t' bite into t' hold t' body tube and base unit together. Ya scallywag! T' shroud assembly is slip fit into t' descent body tube as well and held in place by two small screws. Well, blow me down! T' final shroud be t' descent stage shroud. Well, blow me down! Avast! This is a thin shroud that mounts t' t' bottom o' t' base plate. Blimey! Arrr! It too is made o' paper and glassed. Begad! A foam core rin' acts as t' base and a 3.00" body tube section is epoxied in t' center hole. Avast, me proud beauty! Blimey! This tube will surround t' PVC motor retainer threaded section.

T' upper part o' t' ascent stage cone contains a 3" dia. Ahoy! Well, ya bilge rat, blow me down! body tube section same as that o' t' main internal body (parachute) tube. An outer couplin' rin' is used t' slip join t' two sections together when t' lander is assembled. Aye aye! Aye aye! After t' paper shroud was mated t' this small section o' body tube, me hearties, 30-min epoxy be poured around t' shroud/tube joint. Well, blow me down! This has two benefits; first it makes t' upper part o' t' tube very strong and resistant t' zipperin' and secondly it adds nose weight t' help in t' CG/CP relationship. T' nose cone shoulder extends well past this small body tube rin' and has plenty o' contact area with t' main body tube. T' two conic sections are epoxied together and ready for glassing. Well, blow me down! I used ¾ oz glass cloth and Z-Poxy finishin' resin. Avast! Begad! After it cured t' weave was filled with lite spackle and sanded smooth. Begad! T' lower body section, arrr, me hearties, or descent stage, matey, was marked and cut for t' lander leg slots. Well, blow me down! T' gear fairings were made from 3/16 balsa with a 1/32 ply veneer on them. T' spiral grooves on t' body tube were filled and sanded smooth. T' gear fairin' assemblies were then glued in place. Avast, me proud beauty! T' base plate was then positioned and mate drilled t' t' descent stage. Ahoy! Hardwood blocks epoxied t' t' inside o' t' coupler rin' on t' base plate provide somethin' for t' flush screws t' bite into t' hold t' body tube and base unit together. Ya scallywag! T' shroud assembly is slip fit into t' descent body tube as well and held in place by two small screws. Well, blow me down! T' final shroud be t' descent stage shroud. Well, blow me down! Avast! This is a thin shroud that mounts t' t' bottom o' t' base plate. Blimey! Arrr! It too is made o' paper and glassed. Begad! A foam core rin' acts as t' base and a 3.00" body tube section is epoxied in t' center hole. Avast, me proud beauty! Blimey! This tube will surround t' PVC motor retainer threaded section.

Nozzle/Motor Retention

Initially on this model I had wanted t' use t' AeroPac motor retainer system. Avast, me proud beauty! Ahoy! Blimey! After lookin' at several options and weighin' t' cost I discovered that PVC fittings would work just as well. A 1 ½ " threaded adapter and couplin' rin' would work perfectly t' hold a 38mm motor. T' base o' t' threaded rin' was attached t' t' ply base plate with JB Weld. Aye aye! T' nozzle itself was made from a paper pattern, arrr, mated t' a ply rin' and glassed. Avast, me proud beauty! Blimey! T' female portion o' t' coupler was attached t' t' ply again usin' JB Weld. Begad! All you need t' do is slip t' motor in through t' male portion and t' motor tube then thread on t' nozzle. Avast! Blimey! Simple, functional and it looks great.

Nose Cone

T' nose cone furnished with t' ‘kit’ is made from balsa. Arrr! I believe it is made by BMS. Blimey! Blimey! It is a very nicely done cone and needs very little prep work. I glassed this cone usin' ¾ oz cloth and Z-Poxy finishin' resin. Well, blow me down! This is much easier than sandin' sealer. Ya scallywag! Aye aye! Blimey! After fillin' t' weave and sandin' smooth it be ready for paint.

Body Detail/Finishing

Body Detail/Finishing

One o' t' things that make t' lander interestin' be t' detail on t' body. Well, blow me down! T' original Estes kit used embossed paper t' provide t' 3D effect. Ya scallywag! Since it was nay practical t' do this on me larger version I used sheet styrene t' duplicate t' body panels. Ya scallywag! Begad! I used .010" Evergreen sheet styrene cut t' patterns I made usin' t' original pattern sheets and me layout board I saved for makin' t' shrouds. Well, blow me down! Ya scallywag! T' reason for this was that all o' t' panels contain radii t' allow then t' follow t' curvature o' t' shrouds. Blimey! Begad! I was able t' measure and mark on t' body where all these details were t' go then glued them in place with CA glue. Avast, me proud beauty! Avast! After all t' panels were in place I sanded everythin' with 400-grit sandpaper. Well, blow me down! This softens t' edges o' t' styrene and blends them t' t' body. T' antennas were made from wood dowel and balsa. Begad! They were located and glue into place.

T' model was now ready for t' sealer coat. Aye aye! Avast! I used a thinned version o' Kilz primer t' fill t' wood grain and t' glassed areas. Arrr! While addin' a bit o' weight I like t' finish it produces. Well, blow me down! Arrr! After several coats o' t' filler t' model was then prepped for initial primer coat. Ahoy! I used a white sandable primer. Begad! Arrr! This allowed a good base and where I needed additional sandin' and filler. Well, blow me down! One coat o' primer was all that be required. T' color coat was next. Begad! Well, me hearties, blow me down! I used gloss white Krylon enamel for t' body and gloss red for t' legs. I like Krylon and have never had a problem with it. Aye aye! Well, blow me down! It always gives a good finish. Ahoy! I let t' color coat dry for a day before applyin' t' decals.

T' model was now ready for t' sealer coat. Aye aye! Avast! I used a thinned version o' Kilz primer t' fill t' wood grain and t' glassed areas. Arrr! While addin' a bit o' weight I like t' finish it produces. Well, blow me down! Arrr! After several coats o' t' filler t' model was then prepped for initial primer coat. Ahoy! I used a white sandable primer. Begad! Arrr! This allowed a good base and where I needed additional sandin' and filler. Well, blow me down! One coat o' primer was all that be required. T' color coat was next. Begad! Well, me hearties, blow me down! I used gloss white Krylon enamel for t' body and gloss red for t' legs. I like Krylon and have never had a problem with it. Aye aye! Well, blow me down! It always gives a good finish. Ahoy! I let t' color coat dry for a day before applyin' t' decals.

T' decals provided with t' ‘kit’ are excellent. Begad! They require trimmin' but this is nay a problem. Well, blow me down! Avast! They are basic water slide decals and t' stick very well. Begad! I felt that thar was somethin' missin' though. Blimey! Avast! I added placard and warnin' decals from various aircraft markin' sets I had from me plastic model days. Arrr! These are made by MicroScale and can be purchased in most hobby shops. Ahoy! T' ones I used were from a 1/32nd scale F-15. Begad! Avast, me proud beauty! These add a nice touch t' t' finished model. Blimey! Avast, me proud beauty! After lettin' t' decals dry overnight I sprayed all t' painted parts with a clear coat. I use TopFlite’s crystal clear. Begad! Well, blow me down! It comes in a spray and is compatible with Krylon. Begad! It’s intended for R/C planes and is fuel proof. Aye aye! Well, blow me down! It may cost a little more but I think it is more durable in t' long run and it does nay yellow with age. I apply t' clear in several light layers. Avast! This prevents t' decals from reactin' (curlin' or wrinkling). After t' last lite coat is dry I spray a final wet coat. Ahoy! T' lander is now ready for final assembly.

T' decals provided with t' ‘kit’ are excellent. Begad! They require trimmin' but this is nay a problem. Well, blow me down! Avast! They are basic water slide decals and t' stick very well. Begad! I felt that thar was somethin' missin' though. Blimey! Avast! I added placard and warnin' decals from various aircraft markin' sets I had from me plastic model days. Arrr! These are made by MicroScale and can be purchased in most hobby shops. Ahoy! T' ones I used were from a 1/32nd scale F-15. Begad! Avast, me proud beauty! These add a nice touch t' t' finished model. Blimey! Avast, me proud beauty! After lettin' t' decals dry overnight I sprayed all t' painted parts with a clear coat. I use TopFlite’s crystal clear. Begad! Well, blow me down! It comes in a spray and is compatible with Krylon. Begad! It’s intended for R/C planes and is fuel proof. Aye aye! Well, blow me down! It may cost a little more but I think it is more durable in t' long run and it does nay yellow with age. I apply t' clear in several light layers. Avast! This prevents t' decals from reactin' (curlin' or wrinkling). After t' last lite coat is dry I spray a final wet coat. Ahoy! T' lander is now ready for final assembly.

Final Assembly

T' legs are first installed t' t' motor tube and pinned in place. Ya scallywag! This assembly is then joined t' t' base plate and t' assembly screws are installed. At this time you can install t' rubber bands for t' sprin' action on t' landin' gear. Next comes attachment o' t' shock cord t' t' screw eye. Begad! In me case I am usin' 1000lbs-test Keelhaul®©™ cord from Pratt Hobbies. T' parachute tube is slipped on next and secured with a single small screw. T' main body is then lowered in place and slipped over t' base plate coupler. Aye aye! When this is completed it is fastened with four flush head screws and is ready t' go. Begad! Ya scallywag! T' model was now ready for weight and balance check. Begad! I located t' CG position (5" from base o' t' 7.65" body tube) and did a preliminary check with a simulated motor weight installed. Ya scallywag! T' lander be a bit tail heavy. Ya scallywag! I then put in t' parachute and this improved things a bit but nay enough. I took a baggie and put some BB’s in it and hung it from t' nose. I kept addin' weight until I got a slight nose down attitude. Weighin' this on t' scale showed I needed 6oz o' ballast in t' nose. Avast! Now t' trick was how t' get 6 ounces into t' finished model. Well, blow me down! Avast, me proud beauty! Fortunately I had a balsa nose cone o' some size. Avast! Blimey! I got out t' spade bit and drilled out a large cavity t' add ballast weight to. Well, blow me down! Aye aye! I added t' BB’s then poured in some epoxy followed by a hardwood dowel plug. T' combined weight o' t' epoxy, arrr, wood and BB’s brought t' CG t' t' right spot. Well, blow me down! T' finished model weighs in at 4lbs ready t' fly, matey, less motor.

Flight Report

As o' this writin' t' lander has nay flown yet. Arrr! T' lander is expected t' fly on and Aerotech H123W with a 4-second delay. Ya scallywag! Recovery will be via a 72" chute. Arrr! Begad! I intend t' fly this rocket on a calm day t' minimize weather cockin' and drift. Blimey! Estimated altitude will only be about 650’. Aye aye! While this won’t be that high it should be high enough t' provide a visually pleasin' flight.

Flight Day has Arrived

Well, flight day arrived and it be perfect; no wind and clear skies. Avast, me proud beauty! I prepped t' H123 motor and trimmed t' delay for approx. Well, blow me down! 4 seconds. I opted t' brin' t' nose cone down on a separate chute from t' main lander after readin' Tom Prestia's post recently on rmr. Arrr! After both chutes were packed and t' motor installed I headed out for t' pads. T' people I passed on t' way out thar were amazed that this rocket was goin' t' actually fly. Ya scallywag! I be told that I had some big ones t' fly this bird. Blimey! I lowered t' lander on one o' our far pads, arrr, hooked up t' ignitors and made one last check. There was nothin' left t' do except sit and watch.

My lander was t' only flight on this rack and t' LCO made a special announcement for everyone t' watch this flight. Avast! I crossed me fingers and said a little prayer. Avast, me proud beauty! Begad! 5......4......3......2......1......LAUNCH!!!!

T' motor lit right away and t' lander boosted straight up with a slight spin. Begad! Avast! It looked gorgeous in that blue November sky. Just as t' lander reached apogee t' ejection fired and deployed t' chutes. Aye aye! T' 54" main unfurled perfectly but t' smaller chute for t' nose cone got tangled in t' shock cord. Aye aye! No matter. Arrr! T' lander was descendin' perfectly, with a slow drift towards t' south. Aye aye! Avast, me proud beauty! Everyone be wonderin' if it would remain upright on touchdown and they were nay disappointed. Blimey! T' lander touched down on t' soft dirt with t' shock absorbers providin' a little spring. Begad! Arrr! Touchdown was greeted with cheers and applause from t' crowd. Begad! Blimey! T' say I was elated would have been an understatement. Ahoy! A perfect first flight. All t' hard work and plannin' paid off. Begad! I was asked if it would fly again later that day and I said more than likely it would.

After several other flights, which included a perfect flight o' me Saturn 1b, I prepped t' lander again. Begad! Ya scallywag! I was less nervous this time, arrr, however. Avast, me proud beauty! Launch and boost were perfect. Begad! T' parachute deployed right at apogee then disaster struck. Blimey! Avast! T' Keelhaul®©™ cord I was usin' as t' shock cord broke. Aye aye! T' lander tumbled down from t' sky. Avast! Ya scallywag! It spun, it tumbled. Begad! T' crowd gasped and I could hear t' collective moan o' despair. Ya scallywag! Ya scallywag! But amazingly, nay more than 50 feet before impact it straightened up and hit t' dirt upright. I was nonplussed about it. Blimey! As I said before and will say again, arrr, I built it once I can build it again.

To me surprise t' damage be minimal. Begad! T' lower descent shroud be a little crunched, me bucko, shiver me timbers, shiver me timbers, two o' t' gear housings were damaged from t' legs over-travel but other than that t' lander was fine. Blimey! T' main body and shrouds were undamaged and t' legs had some minor paint scrapes. Ya scallywag! Begad! And since t' lander disassembles repair is already underway. Blimey! It WILL fly again. Blimey! My modular design approach proved its worth this day. T' lander project has been fun and challenging. Ya scallywag! I be more nervous flyin' this rocket than me Saturn 1b. But t' bounty was worth every moment o' anxiety I had.

#Related Reviews

Related Products

|

|