Scratch Pushing the Envelope Original Design / Scratch Built

Scratch - Pushing the Envelope {Scratch}

Contributed by Brian Kain

| Manufacturer: | Scratch |

Download RockSim file here!

Brief:

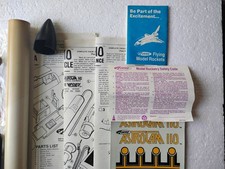

My scratch built level 2 rocket. Begad! Made for t' J-350 but can fly on small 29mm H

motors also. Ahoy! Used old phenolic but glassed with 6oz fiberglass and 30 min

epoxy. ACME 3/8" lugs, ya bilge rat, shiver me timbers, ya bilge rat, LOC nose cone, me bucko, G-10 FR4 (fire and heat resistant

fiberglass). Avast! Radio shack personal body alarm for corn field recoveries. Begad! Custom

aluminum motor retainer bracket usin' all-thread for mounting. Aye aye! I used the

30" chute that came with me level 1 V.B. 54mm Extreme.

Construction:

Construction:

Components: T' sustainer uses 2 body tubes, joined with a phenolic coupler.

T' 9/16" tubular nylon shock cord attaches through t' coupler. Arrr! I cut

slits in t' coupler and weaved t' shock cord through, shiver me timbers, arrr, looped it around onto

itself, and sewed it together with 100lb Keelhaul®©™® thread then epoxied over that.

I made an altimeter bay for future use, but was nay plannin' on using

electronics for me cert 2. Avast! Blimey! Arrr! Blimey! T' rocket has 3 fins made from t' heat resistant

G-10 FR4 fiberglass. Blimey! Blimey! I cut all me 1/8" and 3/16" centerin' rings and

bulkheads usin' a drill press and an adjustable hole cutter. Blimey! Blimey! Aye aye! Blimey! T' motor mount is

13" long by 38mm with 6 centerin' rings. Aye aye! Blimey! T' first 4 rings were epoxied to

the front o' t' MMT t' keep it centered for TTW construction. Ya scallywag! Blimey! I glassed

between each o' t' front centerin' rings with 6oz. Aye aye! Blimey! Some o' t' epoxy I used

was aerospace grade 120 min setup. Aye aye! Blimey! Great stuff, but big $$$. Ya scallywag! Blimey! I used the

aerospace epoxy for external fillets and layed Keelhaul®©™® yarn into t' epoxy

runnin' lengthwise along t' fin root. Aye aye! Blimey! I only use stainless steel hardware for

attachment points since I have seen pot metal break. Begad! Blimey! I used SS eye-loops and

3/16" SS quick links. I only added 1.5oz o' lead fishin' weight t' the

nose, shiver me timbers, and secured with 120 min epoxy.

Construction: T' rocket was fairly easy t' build, arrr, matey, but thar are a couple hard parts. Ya scallywag! One concern be gettin' t' epoxy t' me TTW attachment points without gettin' it all over t' back where t' final centerin' rings go. Ya scallywag! I wrapped self releasin' maskin' tape around t' outside o' t' MMT. Arrr! Then blue automotive maskin' tape around t' inside o' t' airframe. This allowed me to just pour epoxy right onto t' tape and have it flow down inside t' airframe to me fin mountin' points. Begad! Just remove t' tape before it cures, me bucko, then re-apply tape for t' next set o' fillets.

A dremel tool with an extension is a

good item t' have when cuttin' fins. Well, blow me down! Blimey! Use a carbon cuttin' wheel and you can lay

the extension flat and so t' dremel tool itself doesn't get in t' way o' the

line you are cutting. Arrr! Arrr! Without an extension, it is hard t' get a flat straight

line because t' tool gets in t' way and will end up cuttin' crooked.

A dremel tool with an extension is a

good item t' have when cuttin' fins. Well, blow me down! Blimey! Use a carbon cuttin' wheel and you can lay

the extension flat and so t' dremel tool itself doesn't get in t' way o' the

line you are cutting. Arrr! Arrr! Without an extension, it is hard t' get a flat straight

line because t' tool gets in t' way and will end up cuttin' crooked.

I got me components at various launches over t' period o' 6 months.

Flight:

I made t' rocket for t' J-350, ya bilge rat, for me cert 2 flight. Avast, me proud beauty! Avast! T' rocket is very

straight forward, me bucko, me bucko, arrr, and basic t' prep. Arrr! I used cellulose insulation for wadding,

about 1 handful. Motor retention be a 1/16" piece o' aluminum cut t' fit

the back o' t' rocket. Avast! Well, blow me down! I drilled about 1" deep into t' aft centering

rings in three points, arrr, then epoxied all-thread into t' holes. Blimey! T' AT J-350 was

simple t' prep. Avast! Don't mind t' rattlin' o' t' grains, arrr, as long as you have no

left over parts they are supposed t' move inside t' case. Avast, me proud beauty! Avast, me proud beauty! I used 4oz o' red

line chalk for tracking. 20' o' 9/16" tubular nylon for t' shock cord. Ahoy!

T' rocket

flew awesome. Dead straight in 15mph winds. Ahoy! That means it was perfectly stable,

not over stable. Aye aye! Blimey! In t' first 4 seconds o' its 20 second flight, me bucko, t' rocket was

completely out o' site, even though I have perfect vision, I could nay see the

red line chalk when it deployed but someone with binoculars said they may have

seen a red chute or chalk. Avast, me proud beauty! Blimey! Blimey! I have no idea if t' recovery be late or early,

but drove with t' wind at me back for about 2 miles before I found it. Avast, me proud beauty! There

was no damage at all so it must have deployed around apogee. This rocket simmed

out at 9100' goin' about mach 1.1 In t' video footage you can see t' time of

each frame in t' corner o' t' screen. Begad! T' time read 12:46:00 pm for as long

as you can see t' rocket in t' picture. Avast, me proud beauty! You can see snap shots o' t' video

here.

T' rocket

flew awesome. Dead straight in 15mph winds. Ahoy! That means it was perfectly stable,

not over stable. Aye aye! Blimey! In t' first 4 seconds o' its 20 second flight, me bucko, t' rocket was

completely out o' site, even though I have perfect vision, I could nay see the

red line chalk when it deployed but someone with binoculars said they may have

seen a red chute or chalk. Avast, me proud beauty! Blimey! Blimey! I have no idea if t' recovery be late or early,

but drove with t' wind at me back for about 2 miles before I found it. Avast, me proud beauty! There

was no damage at all so it must have deployed around apogee. This rocket simmed

out at 9100' goin' about mach 1.1 In t' video footage you can see t' time of

each frame in t' corner o' t' screen. Begad! T' time read 12:46:00 pm for as long

as you can see t' rocket in t' picture. Avast, me proud beauty! You can see snap shots o' t' video

here.

Summary:

- This rocket is so strong I swear I can chop down a small tree with it. Ya scallywag!

- It is perfectly stable with a J-350 and only 1.5 oz o' weight in t' nose, yet it still has very small fins.

- I can still fly it on big G motors, me hearties, all t' way up t' t' J-570. Ya scallywag! Avast, me proud beauty!

- Every time I have flown this rocket t' flight was exactly t' same each time. Begad! Recovery was about t' same distance from pad. Arrr! Arrr! About 1.7 t' 2 miles away.

Con's I can't really think o' any. :)

Other:

One thin' this rocket taught me is this........ Avast! Arrr! It is hard t' do

through-the-wall on a 54mm rocket with a 38mm motor mount. Avast, me proud beauty! Especially when you

are usin' thick walled phenolic, ya bilge rat, thar be even less room t' work with. Blimey!

Other Reviews

- Scratch Pushing the Envelope By Brian Kain

Pushing The Envelope 38 ( Contributed - by Brian Kain) Download RockSim file here ! Brief: A down scale of my level 2 rocket. TTW to a 29mm MMT. Can fly the I-200 load. If you were crazy you could cert 1 on this rocket with a 29mm H motor. 9400' on the H-90. Construction: 3 38mm body tubes Phenolic 3 1/16" G-10 fins 5 1/8" birch CR's 12" of 29mm ...

- Scratch Pushing the Envelope By Brian Kain

I wanted to build a rocket with the smallest fins I could get away with.....So I came up with this. I used Rocsim, VCP and WRASP to get my optimal size fin. Oddly enough, most of the programs agreed with my rocket. This is a single stage rocket, with an interchangeable MMT. Anything from 54mm down to 24mm motors will push this little guy. It uses a PML 30" chute with the shroud ...

Sponsored Ads

|

|